Dr Fellenius Presentation

Transcript of Dr Fellenius Presentation

-

7/29/2019 Dr Fellenius Presentation

1/27

Drag Load and

DowndragWhat We Know and How

to Design for It

2

3

& DECOU RT 235

4

Interpretation of a series of tests

performed at different times

0 10 20 30 40 50 60 700

10

20

30

40

50

60

70

Movement (m m)ChangeofHorizontalStress(KPa)

5 Da ys

1 Day

8 Da ys

4 Months

22 M onths

Cell D1

Results thought dueto set-upexplained as Increase inHorizontal Effective Stress

Felle nius 200 2

Results plottedAccording toMovement Path

0 50 100 150 200 250

0

10

20

30

40

50

60

70

Movement ( mm)

5 D ays

1 Day

8 D ays

4 Months

22 M onths

5

A. Distribu tion o f residual load in Piles DA

and BC beforestart of the loading test

Sand

Tests on instrumented 280 mm square precastconcrete piles in Drammen, Norway

0

2

4

6

8

10

12

14

16

18

0 50 100 150 200 250 300

LOAD (KN)

DEPTH

(m

Pi le DA

Pile BC,Tapered

0

2

4

6

8

10

12

14

16

18

0 100 200 300 400 500 600

LOAD (KN)

DEPTH

(m) True

Residual

T rue minusResidual

B. Load and resistance in Pile DA

fo r th e ultimate load ap plied in the test

Data from Gregersen et al., 1973

6

Result on a test on a 2.5 m diameter, 85.5 m long pile at

My Thuan Bridge, Vietnam

0 50 1 00 150 200 250

0

10

20

30

Movement (mm)

Load

(MN)

LEVE L A Do wnward, STAGES1 and 5

Test Data

FE analys is

Does unloading/reloading add anything of value to a test?

-

7/29/2019 Dr Fellenius Presentation

2/27

7

True 50 years ago and true today: when something newis proposed, people try to incorporate it into the old.

Especially for loading tests on instrumented piles,

occasional unloading/reloading will add nothing ofvalue, but might severely impair the evaluation of the

test results. As will holding the load levels for differentlengths of time. Each lo ad should be kept on the pile anequal length of time!

The unloading/reloading cycle is an atavist, a remnantof a distant past!

Engineers of today are unaware of that the concept offactor-of-safety applied to an ultimate resistanc e

(capacity) was once a novel approach.

Before that approach was brought into practice, testingwas by measuring load-movement and the net

movements after unloading (several cycles) wasthought to show the pile toe load-movement response.

8

9

Distribut ion of soil stress, excess pore pressure, soil s ettlement, and

pile shorte ning. Hery a site. (Data from Bjerr um et al., 1969).

0

5

10

15

20

25

30

35

0 10 0 20 0 300 4 00

EFFECTIVE STRESSAND PORE PRESSURE (KPa)

DEPTH

(m

)

'z

afterfull

dissipationof

excess porepressure

'zu

Marine

Clay

FILL

Start o f

BedrockGrav el

0

5

10

15

20

25

30

35

0 30 0 60 0 900 1 ,2 00 1, 500

PILELOAD ( KN)

DEPTH

(m)

Bitumen

coated

uncoated

Distribution

calculatedfrom

=0.3times 'z for

actual excess u

Measureddistributio n

Notice the dis tinct ForceEquilibr ium, the Neutra l Plane

0

5

10

15

20

25

30

35

0 5 10 15

PILE SHORTENING (mm )

DEPTH

(m)

Bitumen

coated uncoated

10

Compilation of Norw egian results

0

cm cm

Dragload

11

Profile of test site and piles

Closed-toe, Open-toe, Inclined, and short pile

Study in Japan (Endo et al., 1969)

12

Soil profile and pore pressure distribution

Data from En do et al. 1969

0

10

20

30

40

50

0 20 40 60 80 100

CONSISTENCY LIMIT S (%)

DEPTH

(m)

Sandy

Silt

C lay

S ilt

Fil l

Sand

S ilt

0

10

20

30

40

50

0 50 100 150 200

PORE PRESSU RE (KPa)

DEPTH

(m)

Ju ne

1964

April

1966

Hydros tatic

D istribution

-

7/29/2019 Dr Fellenius Presentation

3/27

13

Loads from shortening of closed-toe pile

June 1964 through March 1967(Data from Endo et al., 1969)

0

500

1,000

1,500

2,000

2,500

3,000

3,500

0 200 400 600 800 1,000

DAYSA FTER START

LOAD

(KN)

#2

#3

#4

#5

#6

#7

#

#3

#4

#5

#6

#7

0

5

10

15

20

25

30

35

40

45

50

0 5 0 0 1,0 00 1 ,50 0 2,0 00 2 ,50 0 3,0 00 3 ,50 0

LOAD (KN)

DEPTH

(m)

29DAYS

124DAYS

275DAYS

400DAYS

672DAYS

#2

#3

#4

#5

#6

#7

14

Combining the Pil e cE43 distributions of load and of settlement

measured June 1964 through March 1967

N.P.

Soil

Pile

Load Distribution Settlement Distribution

(Endo e t al., 1969)

Notice the

increasing

mobiliz ation of toe

resistance

Notice the

increasing

movement of th e

pile to e

15

0

5

10

15

20

25

30

35

40

45

50

0 5 00 1,00 0 1,500 2,000 2,500 3,000 3,500

LOAD (KN)

DEOTH

(m)

Close d-toe

P iles

Open-toe

Pile

Sandy

Silt

C

l

a

y

S

a

n

d

S

il

t

0

5

10

15

20

25

30

35

40

45

50

0 50 100 15 0 2 00

SETTLEMENT (mm)

Soil

P ile

Closed -toe PileToePenetration

Neutral plane

Load distribution in the t hree long piles t ogetherandsettlement of soil an d pilesmeasured March 1967 672 days after s tart. (Da ta from Endo et al., 1969).

16

0

5

10

15

20

25

30

35

40

45

50

0 2,000 4,000 6,000 8,000

LOAD ( KN)

DEPTH

(m)

Measured

load

Calculate d

Curve

= 0.40

= 0.35

= 0.30

= 0.25

Measured load distribution and distribution matched to measured

valu es in effective stress analys is. (Data from Endo et al., 1969).

17

Study of two instrumented, precast concrete piles driven throughmarine clayand into sand at Bckebol, Gteborg, Sweden (Fellenius 1972)

18Measured loads in piles versus time after driving

0

200

400

600

800

1000

1200

1400

1600

1800

0 500 1,000 1,500 2,000 2,500 3,000 3,500

DAYS AFTER END OF DRIVING

FORCEATGAGE

(KN

Firstload plac ed

on piles

Secondload

placed onpiles

2m thickfi ll

placed over siteM1 & M5

M2 & M

M3 & M7

M4

M4

M1 & M5

M2 & M6

M3 & M7

-

7/29/2019 Dr Fellenius Presentation

4/27

19

0

10

20

30

40

50

60

0 500 1000 1500 2000

FORCEAT GAG E (KN)

2,650

19881923

Distribution of load in Piles I and II

Note, the

dragload was

eliminated by

the live lo ad

= L IVE LOADS

Neutral

Plane

That th e toe

resist ance is s mall is

due t o t hat t he

move ments are not

large enough t o

mobiliz e any la rger t oe

resistance

Placing the fill

20

Distribution of measur ed and calculated consolidation settlement

The settl ement

measured at d ept h

amount ed to o nly

a few millim eters,

but t his was

enou gh to fully

mobilize th e

nega tive s kin

friction

0

5

10

15

20

25

30

35

40

0 5 0 1 00 150 200 2 50

STRESS (KPa)

DEPTH

(m)

( 'Z) f

('Z)iPRECONSOLI DATION

STRESS, 'c

0

5

10

15

20

25

30

35

40

0 100 200 300 400 500

S ETTLEME NT (mm)

DEPTH

(m)

MEASURED

CALCULATED

FINAL (after80

year s)

Force gage locations

21

Leung, C.F, Radhakrish nan, R., and Siew-Ann Tan (1991) presented a c ase history on

instrumented 28 0 mm s quare precast c oncrete piles driven in marine clay in Singapo re

Neutr al Plane

Note, the distribution of nega tive

sk in friction is linear (down to the

beginning of the trans ition zone)

indica ting the proportionality to

the effective o verburden stress

CASE #7

22

Data from Leung, Ra dhakr ishnan, and Tan (1991)

0

5

10

15

20

25

30

0 200 400 600

LOAD (KN)

DEPTH

(m

)

OldS ilt

&

Clay

Fill

MarineClay

Weak

Shale

Bedrock

and

Residual

Soil

Clay

= 0.5

Two

months

after start

( 57days )

Two years

later

(745 days)

Variable load

Inoue, Y., Tamaoki, K., Ogai, T.,1977. Settlement of building due to

pile downdrag. Proc. 9th I CS MFE,

Tokyo, Vol.1, pp. 561 564.

A three-storey building with a foot print of 15 m by 100 m founded on500 mm diameter open-toe pipe piles driven through sandand silty clayto bearing in a sand layer at about 35 m depth. The piles had morethan adequate capacity to carry the building. Two years afterconstruction, the building was noticed to have settled some 150 mm.Measurements during the following two years showed about 200 mmadditional sett lement. The building was demolished at that t ime.

CASE #10

A Downdrag Case

FINE SAND

S ILTY CLAY: w= wL

= 40% - 60%; u

= 40

SILTYCLAY: w = wL = 40% - 60%; u = 80

FINE SAND

SANDFILL

FINE SAND

SILT &

SAND

Pile Toe Depth Inoue 1977

-

7/29/2019 Dr Fellenius Presentation

5/27

Sett lement between piles in Row6 and Row10from Sep. 1967 throughMay 1969 = 150mm.

Slope 1 : 100(Sep 67 Apr 71)

FINE SAND

SILTYC LAY: w= wL= 40%- 60%; u = 40

SILTYCLAY: w = w L = 40% - 60%; u = 80

FINE SAND

SANDFILL

FINE SAND

SILT &

SAND

Inoue 1977

-5

0

5

10

15

20

25

30

35

40

45

0 200 400 600 800

Stress and Pressure (KPa)

Depth(m)

SAND

S AND

SAND

CLAY

CLAY

SAND

silt

SettlingLaye r

"Curr ent"Ef fecti ve

Stress

FinalEf fecti ve

Stress

PoreP ressu re

LOAD SETTLEMENT

Depth(m)

S oilset tlement

Load in Pile

Building

Speculative distribution

Data f rom Inoue 1977

27

Two case historieson

Damaging Drag Loadand

Damaging Downdrag

28One Bridge Two foundations

30 mlo ng

piles driven

to bedrock50 mlong

pilesdrivento

sh aft bea rring

Provinc e A Prov ince B

?

Marineclay onbedrock

XXXXNEUTRALPLA NE

Highly loaded(max allowedby code)

Lightly loaded

29Limestone bedroc k providing good bearing

A CAS E HISTOR Y OF A STRIP-MALL FOUNDE D ON PILE S

GROUND

SURFACE

The so ils invest igation revealed 54 ft (16 m)

of no-s trength "muck".

Design called for 54 ft long piles. Desig ner

discounted all s haft r esistance contribution.

54 ft( 16 m)

30

54 ft (16m)

of "muck'

Limestone bedrock providing good bearing

GRO UNDSURF ACE

Strip-Mall as designed

-

7/29/2019 Dr Fellenius Presentation

6/27

31

A real DOWNDRAG case

X x X x X x X x X x X x X x X

54 ft (1 6m)of "muck"

Limestone bedrock providing good bearing

ORIGINAL

GROUND

SURFACE

5 ft (1.5m) of

fill adde d

before thepiles were

drive n

5 ft (1.5m ) of "muc k"

32

The distribution of load at the pile cap is governed b y the

load-transfer beh avior of the piles. The design pile can

be said to be the ave rage pile. However, t he loads can

differ considerably between the piles depending on toe

resistance, length of piles.

The location of the neutral plane is Natures compromise

in finding the equili brium. If the end result by design

or by mis ta ke is that the neutral plane li es in or above

a compressibl e soil layer, the pile group will settle even

if the total factor of safety appears to be acceptable.

33

The princip les of the mechanism are ill ustrated

in the following three diagrams

The mo bilized toe resista nce, Rt, is a f uncti on of the

Net Pil e Toe Movem ent

34

Pile toe response for where the settlement issmall (1) and where it is large (2)

0

0 1,50 0

LOAD an d RESISTANCE

DEPTH

0

0

SETTL EMENT

21

1 2

NEUTRAL PLANE 1

NEUTRA LP LANE 2

Utimate

Resistance

Toe Penet rations

Note, t he magnitu de of settlement affects not only the magnitudeof toe resistance but also the length of the Tran sition Zone

= Movement into the soil

35

Pile toe res ponse for where the settlement is small (1)and where i t is large (2), showi ng toe pene tration

Note, the magnitude of settlement affects not only the m agnitude oftoe resistance but a lso the lengt h of the Transition Zone:

0

-50 0 1, 000

LOAD and RESISTANCE

DEPTH

0

0 200

SETTLEMENT

2

1

1 2

NEUTRAL PLAN E 1

NEUTRAL PLANE 2

U timate

Resistance

ToePen etrations

0

0

TOE PENETRATION

TO

ERESISTANCE

C

a b

a b

1

2

ToeResistances

A B

3

3

c

c

36

Load-movement relationsPile shaft by t-z relationPile toe by q-z relat ion

0 2 0 40 60 8 0 100

0

2 0

4 0

6 0

8 0

10 0

Movement (%)

Resistance

(%)

Exp. =0.75

Exp. =0.05

R = MVM NT Exp

Exp . = 0.50

Exp.= 0.33

Exp. = 0.20

Exp. =0.10

TOE

SHAFT

exp

2

1

2

1)(

=

R

R

-

7/29/2019 Dr Fellenius Presentation

7/27

37

Alternative

expression

b = Constant =about 0.04 0.15

w = Penetration, 0

100

200

300

400

500

600

0 5 1 0 1 5

MOVEMENT (mm)

LOA

D

(KN)

exp

2

1

2

1)(

=

R

R

bw

eR

R

= 12

1

38

A quote from a textbook *) assigned to 4th Year students at

several North American Universities

Piles located in settling soil layers are subjected to negative skinfriction called downdrag. Thesettlement of the soil layer causesth e

friction forces to act in the samedirection as the loading on the pile.Rather than providing resistance, the negative skin friction i mposesadditional loads on the pile. The net effect is that the pile load

capacity is reduced and pile settlement increases. The allowableload capacity is given as:

neg

S

ultallow Q

F

QQ =

If you thi nk this ghas tly recommenda tion is c orrect, you

have not been pa ying attention!

*) Compassionperhaps misdirectedcompels me not to identify the author

39

0

5

10

15

20

0 500 1,000 1,500 2,000 2,500

LOAD(KN)

DEPTH

(m)

ALLOWABLE

LOAD- (Fs = 2.5 )

CAPACITY

DRAG LOA D

0

5

10

15

20

0 500 1,000 1,500 2,000 2,500

LOAD (KN)

DEPTH

(m)

ALLOWABLE LOADminus

DRAG LOAD*1.0

CAPACITY

DRAG LOA D

Do not include the dragload when determining the allowable load!

Drag load not sub trac ted fr om t he allowa ble l oad Drag l oad su btr acte d!

40

Similarly for the LRFD:

Do not include the dragload when determining thefactored resistance!

Drag load not subtracted from the factored resistance Drag load factored and subtracted!

0

5

10

15

20

0 500 1,000 1,500 2,000 2,500

L OAD (KN)

DEPTH

(m

)

FACT OREDRESISTANCECAPACIT Y

DRAG LOAD

0

5

10

15

20

0 500 1,000 1,500 2,000 2,500

LOAD(KN)

DEPTH

(m)

FACTORED RESISTANCE

minus FACTOREDDRAGL OAD

Factors =0.6and 1.5, respectively

FACTORED RESISTANCE

CAP ACI TY

DRAGLOAD

The locationof the neutral plane (i.e., thelocation of theforce equilibriumand the settlement equilibrium) cannot be determined using factoredloads and resistances! Mother Nature does not do factoring.

41

If afactor of safety of 2.0 is applied alsoto the dragload and the drag load

is subtracted from theallowable load . . . , then?

Imagine that same pile designed for uplift: Logically, if onesubtracts the

drag load for the push case, should one not add it for the pull case ??!!??

The allowable load becomes zero!

Imagine a shaft-bearing pile (no toe resistance) with acertain capacity and

an allowable load for a factor of safety of 2.0.

Do you think that t here is a dif ference in bearing capacity between an

ordinary precast and a prestressed pile? The stress in the pile has

nothing to dowith the bearing capacity.

42

Negative-skin-friction/drag-load does not diminish capacity.

Drag load (and dead load) is a matter for the pile structural

strength, and the main question is if there is settlement that

can cause downdrag. The approach is expressed in The

Unified Design Method.

-

7/29/2019 Dr Fellenius Presentation

8/27

43

The Unified Design Method is a

three-step approach

1. The deadplus live load must be smaller thanthe pile capacitydivided by an appropriate factor of safety. The dragload is not included

when designing against t hebearing capacity.

2. The deadload plus the drag load must be smaller than thestructural strength divided with a appropriate factor of safety. Thelive load is not included because live load and drag load cannotcoexist.

3. The settlement of the pile (pile group) must besmaller than a limitingvalue. The live loadand drag load are not included in this analysis.

44

Construing the Neutral Pla ne and

Determining the Allowa ble Load

45

Settlement analysis by theEquivalent Footing Method

Thec ompressibili tyinthis

zonemustbe of soil and pilecombined

Equivalent Footing

placedat the Location

of the NeutralPlane

2:1 distri bution2:1 dis tribution

G.W.

FILLS ,etc.

Settlement of thep iledfoundation isc aused

by the compres sion of the soil due to i ncreaseof effective stress below the neutralplane

frome xternallo ad applied tothep iles and , for

example, fromf ills, embankments,loadson

ad jacent foundations, andlo wering ofgro undwater table.

soilpile

soilsoilpilepile

combinedAA

EAEAE

+

+=

46Sandpoint, Idaho

Exampleof wherepile length is governed by settlement as opposed to capacity

0

10

20

30

40

50

0 1,000 2,000 3,000 4,000

Axia l Load (KN)

Depth(m)

0

10

20

30

40

50

0 100 200 300

Settlement (mm)

With outwick drains

Primary and

Seco ndary

After wick

drain effect

Axialdesign forseismiccondition

48

Liquefaction (Adapazari, Turkey)

Photo courtesy of Noel J. Gardner, Ottawa

-

7/29/2019 Dr Fellenius Presentation

9/27

49

Photo courtesy of Noel J . Gardner, Ottawa

Liquefaction (Adapazari, Turkey)

0

5

10

15

20

25

30

35

0 1,000 2,000 3,000 4,000

LO AD and RESI STANCE (KN)

DEPTH

(m)

Liqu efiable zone

The Unified Method Applied toSeismic (Liquefaction) Design

0

5

10

15

20

25

30

35

0 1,000 2,000 3,000 4,000

L OAD and RESISTANCE (KN)

DEPTH

(m)

Liquefie d!

Liquefacti on in q li mited thickness zo ne

occurring above the neutral pl ane i s of

no practical c onsequence fo r the piles.

0

5

10

15

20

25

30

35

0 1,000 2,000 3,000 4,000

LOADa nd RESISTANCE (KN)

DEPTH(m)

L iquefied!

What about liquefaction occurring below the neutral plane?

0

5

10

15

20

25

30

35

0 1,000 2,000 3,000 4,000

LOAD and RESISTANCE (KN)

DEPTH

(m)

Liquefied!

Increase in toe

penetrat ion

Pile toe load-movement curv e

0

5

10

15

20

25

30

35

0 1,000 2,000 3, 000 4,000

LOAD and RES ISTANCE (KN)

DEPTH

(m)

Liquefied!

Increase in toe

penetration

Pile toe load-

movement curv e

0

5

10

15

20

25

30

35

SETTLEMENT

DEPTH(m)

Sudden increased

settlement

CASE HISTORY EXAMPLES

The New Internati onal Airport,Bangkok T hai land

Data fro m

Fox, I., Du, M. and Butt ling,S. (2004) and

Buttling, S. (200 6)

54

THAILAND

-

7/29/2019 Dr Fellenius Presentation

10/27

Cur rent and Future ( long-term)

Pore Pressure Distribution

0

5

10

15

20

25

30

35

40

45

50

0 100 200 30 0 400 500

Pore Pres sure (KPa )

Depth

(m)

Long-Term

Shor t- Term

( Current)

0

10

20

30

40

50

60

70

1 975 1 98 0 1 98 5 1 99 0 19 95 20 00 20 05 2 01 0

YEAR

Depth

toGraounwaterTabl

e

(m)

Design

Phase

Co nstruction

Phase

Nearby Observations of Groundwater Tab le

Pumping (mining) of groundwater has reduced the pore pressures. In 1996during the beginning of the design process, pumping in thearea was stopped.Pore pressure measurements indicate that thedesired eff ect is being reached;the porepressures arerising.

The clay is soft and normally consolidated with amodulus number smaller t han10.

All foundations thet rellis roof, terminal buildings, concourse, walkways, etc. are placed on piles. The stress-bulbs from the various foundations will overlap eachothers areas resulting ina complicated sett lement analysis.

Several static loading tests on instrumented piles were

performed to establis h the load-transfer conditions at the

site at the time of the testing, i.e., short-term conditions.

Effective stress analysis of the test results for the current

pore pressures established the coefficients applicable to

the long-term conditions after water tables had stabil ized.

A total of25,000+ piles were installed.

The design employed the unified pile design met hod.

The extensive test ingand theconservative assumption on future porepressures allowed anF

sof 2.0. The structural strength of thepile is more than

adequate f or the loadat the neutral plane: Qd+ Q

n 1,500 KN1,800KN

The design (resis tance distri bution) for 600 mm diameter

bored pile i nstalle d to a 30 m embedment de pth.

0

10

20

30

LOAD (KN)

DEPTH(m

)

Qn =

770 KN

Qd = 1,040 KN RULT= 2,870 KNFs = 2.0

Short-Term

Fs = 2.0on long-

term capac ity

0

10

20

30

LOAD (KN)

DEPTH(m)

Long-Term

Qn =

500 KN

Qd = 1,040KN RULT = 2,160 KNFs =2.0

Clay

Sand

Settlementoccurringbelowthisdepthisthekeyto thedesign

Data fro m Fox, I., Du, M. and But tling,S. (2 004)

The settlements for the piled foundations were calculated to:

Construction Long-term Total

Trellis Roof Pylons 20 mm 90 mm 110 mm

Terminal Building 30 15 45

Concourse 35 20 55

* * *

60

0

5

10

15

20

25

30

0 500 1,000 1,500 2,000

LOAD (KN)

DEPTH

(m)

Neutral plane

CAPACITYDEAD

LOAD

DRAG

LOAD

LIVE

LOAD

TOE

RESISTANCE

C

L

A

Y

S

A

N

D

FIL L

A B

Examplefrom an actual p roject somewhere in Europe

A 30 0 mm diameter pile installed to a depth of 25 m through a surficial 2 m thick f illplaced on a 20 m thick layer of soft clay deposited on a thick sa nd layer.

A static loading test has been performed and the

eva luation of the test data has established thatthe pile capacity is 1,400 KN. Applying a factor

of safety of2 .0 results in an allowable load

of700 KN (dead load 600 KN and live load

100 KN). The drag load is 300 KN.

The designer insis ted on subtrac ting the d rag load

from the ca pacity ( considered available only from

below the neutral plane) before determining the

factored resistance (then = 900 KN). The ac tion

load was considered to be the su m of dead load,

live loa d, and drag load, whic h sum already before

multiplication by the load factor w as la rger than the

factored resistance! The tes t results w ere s tated to

show that the 1,400 KN c apacity pile piles was

inadequate to sup port the 700 KN load . The

des igner required longer piles and a considerably

incr eased number o f piles.

Fellenius 2006

!! $$$ !!

-

7/29/2019 Dr Fellenius Presentation

11/27

61

0

5

10

15

20

25

30

0 500 1,000 1,500 2,000

LOAD (KN)

DEPTH

(m)

Neutral p lane

Force

equilibrium

0

5

10

15

20

25

30

0 50 100 150 200

S ETTLEMENT ( KN)

DEPTH

(m)

Pile toe penetrations

Neutral planeEqual settlement

Pile-head

settle ments

Groundsurface

settlement

GraphicIllustration of the Case

62

0

5

10

15

20

25

30

35

40

45

0 500 1,000 1,50 0 2,000 2,50 0 3,000

LOAD and RESISTANCE ( KN)

DEPTH

(m)

0

5

10

15

20

25

30

35

40

45

0 1 0 20 30 4 0 50 60 70 8 0

SETTLEMENT (mm)

DEPTH

(m)

NEUTRAL PLANE

TOE MOVEM ENT THAT

MOBILIZES THE TOERESISTANCE

SETTLEMENT OF

PILE HEAD

TOERESISTANCE

PILE

"CAPACITY"

DEAD LOAD

DRAGLOAD

*)Portiono fthe toe

res istance will ha ve

developedf romthe driving

*)

TheUnified Method (repeated Illustration)

63

Factors of safet y and LRFD

FOR YOUR SAFETY, PLEASE

HOLD ON TO THE HAND RAILS

I KNOW, I KNOW, . . .

BUT HAVE Y OU EVER

T RIED TO EXPLAIN

T HE REAL WORLD

T O THE CODE

WRITERS?

64

Piled foundations in current codes

The Canadian Building Code and Highway Design Code ( 1992), as well as the Ho ng KongCode (Geo Guide 2006) app ly the Unified Design method. That is, the drag load is only of

concern for the struc tural s trength of the pile. Indeed, the Ca nadian H ighway Code even

states that for piles shorter than aspect ra tio (b/L) than 80, the des ign does not have to

check for drag load. However, the des ign must alwayscheck for downdrag.

The Manual of US Corps of Engineers indicate a similar approach (but less explicit), s tating

that the dr ag load constitutes a settlement problem.

The ASCE Prac tice for the Design and Installation on Pile Foundations (2007) in cludes thefollowing d efinitions and statements:

DOWNDRAG:The s ettlement due to the pile bein g dragged down by the settling ofsurrounding soil;

DRAG LOAD:Load imposed on the pile by the surrounding soil as it tends to movedownward relative to the pile sha ft, due to s oil consolidation, surcharges, or other c auses.

And: In some cas es, the allowable load, as well as the pile e mbedment depth, is governedby concerns for settlement and d owndrag, and by c oncern for structural s trength for de ad

load plus drag lo ad, rather than by capacity.

65

The FHWA has produced one of the most extensi ve r ecent g uidelines docum ent. The f ull refe rence is:

Report N o. FHWA-NHI-0 5-042, Design and Construction of D riven Pile Foundations - V olume I and II.

National Highway Institute, Federal Highway Ad ministration, U.S. Department of Transport ation,

Washingto n, D.C. , April 2006. 1,450 pages.

The issue of dr ag lo ad and dow ndrag, is cover ed i n a bout 20 of the tot al numb er of p ages. I n all

essential parts, th e FHWA docu ment ad heres to t he princi ples of the Unified Design Met hod.

The FHWA doc ume nt i ndicates t he followi ng c riteria f or i dentifying a drag lo ad and /or dow ndrag

pro blem. If any one of th ese c riteria is met, drag load and downdr ag s hall be considered in the design.

The crit eria are:

1. The settl ement of t he gro und sur face (afte r the piles are i nstalled) will be larger th an 1 0 mm (0. 4 in ).

2. The piles will be l onger than 25 m (82 ft).

3. The compr essible soil laye r is thicke r th an 10 m ( 33 f t).

4. The water table will be lowered more than 4 m (13 ft) .

5. The height of the emb ankment to be plac ed o n t he gro und sur face exceeds 2 m (6.5 ft).

Note however, that negative skin f riction is usua lly f ully mobilized a t amovement between the p ile an d the soil of about 1 mm, not 10 mm.

Where settlement is smal ler than 10 mm, downdrag is not the problem.However, for piles longer than 30+ m (100+ ft), the drag load p lus dead loadmight be of concern for the structural strength o f the pile.

66

The most recent AASHTO LRFD Specifications has applied the requirement ofthe Eurocode 7 in that the drag load (factored) is added to the factored serviceload (dead plus live) and the condition is applied that the resistance is the pilecapacity minus the drag load (factored):

)( negultrnegnfq QRfQfQf +

?!?

-

7/29/2019 Dr Fellenius Presentation

12/27

67

5.0 m

SOFT CLAY

SILTY CLAY

11.5 m

FILL

Ave rage unit shaft r esistance, rs =20 KPa

Rs =9 4.2 KN; Rs =Q n

Average rs =5 0 KPa

Rs = 543 KN

"The sett lement due to the fill is sufficie nt to develop maximum negative skin fri ct ion in the soft clay ".

fq*300 + fn*94 543/fr

1.35*300 + 1.35*94 543/1.0

532 543

(Alternative: If fr= 1.1, the lengthin the silty clay becomes 12.4 m)

Q (unfactored) =3 00 KN

Eurocode Guide , E xample 7.4 (Bored 0. 3 m diameter pi le)

Rt =0 KN ?!

CALCULATIONS

The Gui de states that the neutral plane lies at the i nterface o f the two clay layers,

which based on the infor mati on given in the example, cannot be correct. Bu t there is a

good deal mor e wr ong with this desi gn ex ample.

The Gui de st ates that the tw o rs-values are from effective stress c alcul ation. The

values correl ate to s oil unit weights of 18 KN/m3 an d 19.6 KN/ m3, -coefficients of 0.4

in both layer s with groundwater tabl e at ground surface, and a fill str ess of 30 KPa.

68

If the settlement is acceptable, there is room for shortening the pile or increasingthe load. That would raise thelocation of the neutral plane. Would then the pilesett lement still be acceptable?

Analysis using the same numerical values for the pile shaf t,

but including the benef it of a small toe resistance

0

5

10

15

20

0 200 400 600 800 1,000

LOAD (KN)

DEPTH

(m

)

Maximum

Load = 500 KN

Q = 200 KN not 94KN

Rf

=760/1.35 KN >1. 35*300 KN

Rf= 560 KN >405KN

Rt125 KN

= Factored resistance

Fs

=2.50

5

10

15

20

SETTLEMENT (m m)

DEPTH

(m)

Toe

Movem ent

Neutr alPlane

THE KEY QUESTION:

is the settle ment accept able?

?

69

Conventional piled foundati ons with f loor suppor te d on the piles or as a gr ound slab

Piled Raft and Piled Pa d Foundations

70

Piled raft foundation with loads supported by contact stre ss and piles

Remaining load on raft evenly distributed as con tact stress

Evenly distributed load on the r aft supported by evenly distr ibuted piles (Fs = 1.0)

Uneven load on raft

supported by the piles

(Fs = 1.0)

71

Piled pad foundation with loads supported by co ntact stress and piles

Enginee red Backfi ll

Conventional raf t or mat Geotextile

-

7/29/2019 Dr Fellenius Presentation

13/27

Jorj Osterberg2001

The Bi-D irectional

Static Loading Test

The O-cell Test

2

Schematics of the Osterberg O-Cell Test(Meyer and Schade 1995)

Upward L oad

Downward Load

THE O-CELL

Telltales

and

Grout Pipe

Pile Head

3

Three O-Cells inside the reinforcing cage(My Thuan Bridge, Vietnam)

4

5

The O-cell can also be installed in a driven p ile. Here in

a 600 mm cylinder pile with a 400 mm central v oid

6

-

7/29/2019 Dr Fellenius Presentation

14/27

7

Results of an O-cell test on a 2.8 m by 0.8 m,24 m deep barrette in Manila, The Philippines

- 60

- 50

- 40- 30

- 20

- 10

0

1 0

2 0

3 0

4 0

5 0

6 0

7 0

0 5,000 1 0,000 15,0 00 20,00

M

ovement(mm)

Load (KN)

Upward

Downward

Upward

Approximate

extension of

the toemovement to

the zero

conditions

EXAMPLE 1

8

O-Cell test on a1,250 mm

diameter, 40 m

long, bored pileat US82 Bridge

in Washington,Mississippi

installed into

dense sand-80

-60

-40

-20

0

20

40

60

80

100

120

0 2,0 00 4 ,00 0 6,0 00 8 ,00 0 1 0, 00 0

LOAD (KN)

MOVEMENT

(mm)

UPPER PLATE

UPWARD MVMNT

LOWE RPLATE

DOWNW ARD MVMNTWeight

of

Shaft

Residual

Load

Shaft

Toe

EXAMPLE 2

9

Resistance Distribution

0

5

10

15

20

25

30

35

40

0 2, 00 0 4 ,0 00 6 ,00 0 8 ,0 00 1 0, 00 0

LOAD (KN)

DEPTH

(m)

Stra in -Gag e

L eve l#4

Strain-Ga ge

Le vel # 3

Strain-Gag e

Lev el # 2

Strain-Ga ge

Le vel # 1

O-Cell Level

PileT oe

ClaySilt

SandySilt

Dens eSand

withGravel

The unit she ar resis tance a t shaft

failureco rresponds to a beta

coe fficient of abou t 1.0.

0

5

10

15

20

25

30

35

40

0 100 200 300 400

AVERAGE UNIT SHAFT RESISTANCE ( KPa)

DEPTH

(m)

G.W.

10

Load-Movement Curves

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

0 2 0 40 6 0 8 0 1 00 12 0

MO VEMENT (mm)

LOAD

(KN)

Strain-Gage

Level #4

Stra in -Gag e

Level #2

Strain-Gage

Level #1

O- Cell

11

Searching for the Residual Load

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

0.0 0.5 1.0 1.5 2.0

P ILE C OMPRESSION (mm)

LOAD

(KN

INDICATED RESI DUALLO AD

0

1,0 00

2,0 00

3,0 00

4,0 00

5,0 00

6,0 00

7,0 00

8,0 00

9,0 00

0 . 0 2 5. 0 50 . 0 7 5 . 0 1 0 0. 0 1 25 . 0 15 0 .0

PLATESEPARATION (OPENING) (mm)

LOAD

(KN) O-Ce ll Load

O-Ce ll Load

12

From the O-Cell results, one can produce the load-movement curvethat one would have obtained in a routi ne Head-Down Test

Head down

-

7/29/2019 Dr Fellenius Presentation

15/27

13

14

O-Cell Results Shown Two Ways

-80

-60

-40

-20

0

20

40

60

80

100

120

0 2 ,0 00 4, 00 0 6 ,0 00 8, 00 0 1 0,000

LOAD (KN)

MOVEMENT

(mm)

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

0 2 0 4 0 60 80 1 00 1 20

M OVEM ENT (mm)

LOAD

(KN)

Sha ft

Mo veme nt

Toe

Move ment

Weight ofShaft

Re sidua lLo ad

15

Finding a Soft Pile Toe

0 2 4 6 8 1 0 1 2 14 16

- 80

- 70

- 60

- 50

- 40

- 30

- 20

- 10

0

10

20

APPLIED L OAD (MN)

MOVEMENT

(mm

)

REBOUND

WHEN

UNL

OADING

COMPRESSION OF

SOFT SOILAT T O E

Toe load-movement for a pile witha soft toeat Albuquerque, NewMexico(Data from Osterbergand Hayes, 1999)

EXAMPLE 3

16

Kahuku Bridge acr ossKamehameha Highway, Hawaii

Test on 600 mm, 17 m long, bor ed pile

0

10

20

30

40

50

60

70

80

0 100 200 300 400 500 6 00 700 800

LOAD (kips)

DEPTH

(ft)

DATA FRO MO-CEL L TEST

O-cell

Shaftandtoeresist ances

arenot fully mobilizedb elowt he O -cell

0

10

20

30

40

50

60

70

80

0 100 200 3 00 400 5 00 600 700 800

LOAD (k ips)

DEPTH

(ft)

CONVERT ED TO

HEAD- DOW N"TEST"

APPROXIMATED

SPECUL AT IVE

FULLY

MOBILI ZED

O-cell

EXAMPLE 4

17

EXAMPLE 5

Test at Bangkok Airport

18

Stage 1Lower Cell activated

Upper cell closed

Stage 2Lower Cell openUpper Cell activated

Stage 2Lower Cell closedUpper Cell activated

Data fromFox, I., Du, M. an d Buttling,S. (2004)

Buttling, S . (2006)

-

7/29/2019 Dr Fellenius Presentation

16/27

19

Downward movements during test phases 1, 2, and 3

Concern was expressed (Buttling 2006)t hat the toe resistance (Phase 1) was3,000KN and

the shaf t resi stance for the lower segment was 5,000 KN (Phase 2), while in Phase 3 the

combined shaft and toe resistances were only 6,000 KN. Should not the Phase 3 resistancebe 8,000 KN rather than 6, 000 KN (i.e., the sum of the values5,000 KNand 3,000)?

0

25

50

75

100

125

150

175

0 2,000 4,000 6,000 8,000 10,000

LOAD (KN)

MOVEMENT(m

m)

Active CellInactive, Open Cell

Inactive, ClosedCel

P1 P2P 3

1 2 3

20

Downward toe mov ements

0

2 5

5 0

7 5

100

125

150

175

0 2 ,000 4,000 6,000 8,000 10,0 00

LOAD (KN)

MOVEMENT(mm)

Active Cell

Inactive, Open CellInactive, Closed Cell

P1 P2P3

1 2 30

25

50

75

1 00

1 25

1 50

1 75

0 2,00 0 4,000 6,0 00 8,000 10 ,000

LOAD (KN)

DOWNWARDMOVEMENT(mm)

Active Cell

Inacti ve, Open CellInacti ve, Closed Cell

P2

P1 and P2

datacombined

P3

1 2 3

are best plott ed per sequenc e of testing

21

0

5

10

15

20

25

30

35

40

45

0 2,00 0 4,0 00 6 ,000

Load (KN)

Depth(m)

Stage 1

101 mm toe

0

5

10

15

20

25

30

35

40

45

0 2,000 4 ,000 6,000

Load (KN)

Depth(m)

Sta ge 2

62 mmDow nw ard

Movement

0

5

10

15

20

25

30

35

40

45

0 2,000 4 ,000 6,000

Load (KN)

Depth(m)

Sta ge 2

Stage 3

Load Distri butions for the Bangkok Airport Test

22

0

5

10

15

20

25

30

35

40

45

0 2 ,000 4,0 00 6,00 0

Load (KN)

Depth(m)

Stage 3

48 mm

DownwardMovement

0

5

10

15

20

25

30

35

40

45

0 2, 000 4,0 00 6 ,00 0 8, 00 0 1 0,0 00 1 2,0 00

Load (KN)

Depth(m)

St age 2 St ag e 3Stage 1

?

?

23

0

50

100

150

200

0 500 1,000 1,500 2,000 2,500 3,000 3,5 00

LOAD FOR LOWEST STRAIN-GAGE (KN)

MOVEMENT(mm) Stage 1

Stage 2( Stage 3)

Stage 3

The lowest strain-gagevalues are very suspect

24

O-Cell tests for Hacienda ElenaDevelopment, Guay nabo, Puerto Rico

EXAMPLE 6

-

7/29/2019 Dr Fellenius Presentation

17/27

25

Clayey Silt

Sapro lite

HardClay

Weathered

Bedrock

O-cell Test Results

- 80

- 70

- 60

- 50

- 40

- 30

- 20

- 10

0

10

20

0 1,0 0 0 2 ,00 0 3 ,0 00 4, 000 5 ,00 0

LOAD ( KN)

MOVEMENT(m

m)

26

Measured load-movements can besimulated (fitting) to t-z and q-z relations

Pile shaft by t-z relation; Pile to e by q-z relat ion

0 2 0 40 60 8 0 100

0

2 0

4 0

6 0

8 0

10 0

Movement (%)

Resistance(%)

Exp. =0.75

Exp. =0.05

R = MVM NT Exp

Exp . = 0.50

Exp.= 0.33

Exp. = 0.20

Exp. =0.10

TOE

SHAFT

exp

2

1

2

1)(

=

R

R

27

O-c ell Test Resultswith UniPile Simulation

0

5,000

10,000

15,000

0 10 20 30 40 50 60 70

MO VEMENT (mm)

LOAD

(KN)

Toe

Shaft

Exp.= 0. 20

Exp.= 0.55

O-c ell Test Resultswith UniPile Simulation

0

5,000

10,000

15,000

0 10 20 30 40 50 60 70

MO VEMENT (mm)

LOAD

(KN) Head

Toe

Shaft

Extrapolation of

O-cell dataExp.= 0. 20

Exp.= 0.55

Fitting Result s

O-c ell Test Resultswith UniPile Simulation

0

5,000

10,000

15,000

0 10 20 30 40 50 60 70

MO VEMENT (mm)

LOAD

(KN) Head

Toe

Shaft

Extrapolation of

O-cell dataExp.= 0. 20

Exp.= 0.55

Combining the

t-zand q-z

curves

Pensacola, Florida

410 mm diameter, 22mlong, precast concretepile driven into silty sand

EXAMPLE 7

Pensacola, Florida, USA

-10

0

10

20

30

40

50

60

0 500 1, 000 1,500 2,000 2, 500

LOAD (KN)

MOVEMENT

(mm)

Pensacola, Florida, USA

-4

-3

-2

-1

0

0 500 1, 000 1,500 2,000 2, 500

LOAD (KN)

MOVEMENT(mm)

-

7/29/2019 Dr Fellenius Presentation

18/27

Pensacola, Florida, USA

0

1,000

2,000

3,000

4,000

0 2 4 6 8 10

DOWNWARD TO E MOVEMENT (mm )

LOAD

(KN)

0

1,000

2,000

3,000

4,000

0 2 4 6 8 10

DOWNWARD TOE MOVEMENT (mm)

LOAD

(KN)

Exp. = 0.45

CURVE FIT

TEST

Pensacola, Florida, USA

0

1,000

2,000

3,000

4,000

5,000

0 10 20 30 40 50 60

UPWARD SHAFT MOVEMENT (mm)

LOAD

(KN)

E xp. = 0.15

CURVE FIT

TEST

33

Bridge ove r Panama Canal, Paraiso Reach, Republic of Panama

O-cell test on a 2.0 m (80 inches) diameter, 30 m (100 ft) deep s haftdril led into the Pedro Miguel and Cuc aracha formations, February 2003.

EXAMPLE 8

34

O-cel l

Strain-Gage

Locations

-50

-40

-30

-20

-10

0

10

20

30

40

50

0 5,000 10,000 15,000 20,000

LOAD (KN)

MOVEMENT(m

m)

Downw ardMovement

Upward

M ovemen t

Load-Movements . Measured and Fitted to UniPile Calcula tion.

35

Test Results Processed for Design Analysis

0

5

10

15

20

25

30

0 5 ,000 1 0, 00 0 1 5, 00 0 20 ,00 0 25 ,000 30, 0 00

LOAD (KN)

DEPTH

(m)

0

5

10

15

20

25

30

0 5,000 10,000 15,000 20,000 25,000 30,000

LOAD (KN)

DEPTH(m)

0

5,000

10,000

15,000

20,000

25,000

30,000

35,000

0 1 0 20 30 4 0 50 6 0 70

MOVEMENT (mm

LOAD(KN))

Measured and Calculated

Load-Movement Curves

plus Simulated Pile HeadLoad-Movement

TOE

SHAFT

HEAD

Off set

Limit

0.30

0.45

0.30

___

1.20

Torre Chapultepec, Mexico City, Mexico

O-cell Tes t on a 700 mm diameter 34 m deep bored pi le

0 m - 26 m desiccated clayey silt

5 m 34+ m dense sandand silt

EXAMPLE 9

-

7/29/2019 Dr Fellenius Presentation

19/27

Torre Chapultepec, Mexico City, Mexico

- 400

-350

-300

-250

-200

-150

-100

-50

0

0 500 1 ,000 1, 500 2,000 2,500

LOAD (KN)

DOWNWARDMOVE

MENT(mm) Toe-Up O-cell Test

Torre Chapultepec, Mexico City, Mexico

0

2,000

4,000

6,000

8,000

10,000

0 20 40 60 80 100 120 140

MOVEMENT (mm)

LOAD

(KN)

Head-Down Test

0

2,000

4,000

6,000

8,000

10, 000

0 20 40 60 80 100 120 140

MOVEMENT (mm)

LOAD

(KN)

Head-Down Test

Torre Chapultepec, Mexico City, Mexico

-400

-350

-300

-250

-200

-150

-100

-50

0

0 500 1,000 1, 500 2,000 2,500

LOAD (KN)

DOWNWARDMOVEMENT(mm) Toe-Up O -ce ll Test

- 400

-350

-300

-250

-200

-150

-100

-50

0

0 500 1 ,000 1, 500 2, 000 2,500

LOAD ( KN)

DOWNWARDMOVEMENT(mm) Toe-Up O-cell Test

40

O-cel l Tests on an 11 mlong, 460 mm square

precast concrete piledriven in silica sand in

North-East Florida

(Data from McVay et al. 1999)

A study of Toe and

Shaft Resista nce

Response to

Loading

41

CPT sounding next to an 11 m long, 460 mm square precastconcrete pil e driv en in s ilic a sand in North-East Florida

Data fromBullock et al. 2005, 1999

0

2

4

6

8

10

12

14

0 1 0 2 0 3 0 40

Cone Stress, qt (MPa)

DEPTH

(m)

0

2

4

6

8

10

12

14

0 1 00 2 00 30 0

Sleeve Friction (K Pa)

DEPTH(m)

0

2

4

6

8

10

12

14

0.0 0.2 0 .4 0 .6 0.8 1.0

Friction Ratio (%)

DEPTH(m)

PRES

2b

42

Load-mo vement curves for the pil e toe.The t wofirst cycles and beginning of the third cycleThe t wofirst cycles and beginning of the third cycle

0

200

400

600

800

1,000

1,200

1,400

1,600

-3 -2 -1 0 1 2 3 4 5 6 7 8

T OE MOVEM ENT (mm)

CELLLOAD

(KN

1

2

3

Toe Re sistance

Response

Data from

Bullock et al. 2005, 1999

-

7/29/2019 Dr Fellenius Presentation

20/27

43

Load-mo vement cur ves

for the pile toe during all four load cycles

0

200

400

600

800

1,000

1,200

1,400

1,600

-5 5 15 25 35 45 55 65 75

T OE MOVEMENT (mm)

CELLLOAD(KN

Data fromBullock et al. 2005, 1999

44

0

2

4

6

8

10

12

14

0 10 2 0 3 0 40

Cone St ress, qt (MPa)

DEPTH

(m)

PRES

2b

Data fromBullock et al. 2005, 1999

45

0

200

400

600

800

1,000

1,200

1,400

1,600

0 5 10 15 20 25 30 35 40 45 50

CELLEXT ENSION (mm)

LOAD

(KN)

8 hours 4days

16days

SHAFT LOAD-MOVEM ENT DIAGRAM FROM O-CELL TEST S

PDA

CA PWAP

1 8 min.BOR

1 hBOR

EOD

Shaft

Resista nce

Response

UPWARD MOVEMENT (mm)

Data fromBullock et al. 2005, 1999

46

0

2

4

6

8

1012

14

16

18

20

0 500 1 ,000 1,50 0 2 ,000 2,50 0 3 ,000

Shaft Res istance, Rs (KN)

DEP

TH

(m)

E-F

LCPC

Schm ertmann

Dutch

Meyerhof

Beta

Tests

Distributions of unit and total shaft resistances

0

2

4

6

8

1012

14

16

18

20

0 50 100 1 50 200

Unit Sh aft Resistance, rs (KPa)

DEPTH

(m)

E-F LCPC

=1.60

=1.00

= 0.20

=0.80

Data fromBullock et al. 2005, 1999

-

7/29/2019 Dr Fellenius Presentation

21/27

ShinHo and MyeongJi Housing Project,ShinHo and MyeongJi Housing Project,in the estuary of the Nakdong River, Pusan, Koreain the estuary of the Nakdong River, Pusan, Korea

Project Managers: Drs. Song Gyo Chung andProject Managers: Drs. Song Gyo Chung and

SSung Ryul Kim, Dongung Ryul Kim, Dong--A University, BusanA University, Busan

2

3

4

5

AIR VIEW

(Shinho Site)

SITE PLAN (SH Site)

6

Silty cl ay

-

7/29/2019 Dr Fellenius Presentation

22/27

7

0

1 0

2 0

3 0

4 0

5 0

6 0

0 10 20 30

ConeStress, qt

(MPa)

DEPTH

(m)

0

1 0

2 0

3 0

4 0

5 0

6 0

0 25 5 0 75 100

Sleeve Friction,fs (KPa)

DEPTH(

m)

0

10

20

30

40

50

60

0 500 1, 000 1, 500

PoreP ressure (KPa)

DEPTH

(m)

0

10

20

30

40

50

60

0 1 2 3 4 5

Fricti onRatio,fR

(%)

DEPTH

(m)

SILT&CLA Y

VerydenseS AND

Profile

FILL

SiltyCLAY

(marine)

SAND

805-08-08 Myeongji Site C -block

0

10

20

30

40

50

0 10 20 3 0

Cone Stress, qt

(MPa)

DEPTH

(m)

0

1 0

2 0

3 0

4 0

5 0

0 2 00 400

Sleeve Friction (KPa)

DEPTH

(m

)

0

10

20

30

40

50

0 25 0 500 7 50 1,000

Pore Pressure (KPa)

DEPTH

(m

)

0

10

20

30

40

50

0 1 2 3 4 5

Friction Ratio (%)

DEPTH

(m)

Profile

Mixed

CLAY

SAN

Reduced porepressure (dilation)

SAND

9

0

5

10

15

20

25

30

35

40

45

0 500 1,000 1,50 0 2,000 2,50 0 3,000

LOAD and RESISTANCE ( KN)

DEPTH

(m)

0

5

10

15

20

25

30

35

40

45

0 1 0 20 30 4 0 50 60 70 8 0

SETTLEMENT (mm)

DEPTH

(m)

NEUTRAL PLANE

TOE MOVEM ENT THAT

MOBI LIZES THE TOE

RESISTANCE

SETTLEM ENTOF

PILE HEAD

TOE

RESISTANCE

PILE

"CAPACITY"

DEAD LOAD

DRAGLOA D

*)Portiono f the toe

res istance will ha ve

developed f rom the driving

*)

TheUnified Method for Design of Piled Foundations(typical only ; the numbers arenot applicable to this site)

10

The ques tions to resolve in the de sign

1. What is the capacity in the different layers?

2. What is the depth to the force equilibrium/settlementequilibrium, i.e. , the neutral plane

3. What will be themaximum load int he pile? Is thestructuralstrength adequate?

4. What is the sett lement of thepile as a function of thelocation ofthe neutral plane.

11

The shaft resistance: 10,000 KN

The toe resistance: 5,000 KN KN

Pile structural strength 12,000 KN

(when grouted) 16,000 KN

12

01A, 01B

12A, 1 2B,12C,1 2D

0

5

10

15

20

25

30

35

40

45

50

55

60

0 50 1 00 1 50 2 00 2 50 3 00

PRES (Bl/200m m)

DEPTH

(m)

0

10

20

30

40

50

60

0 10 20 30

Cone Stress,qt

(MPa)

DEPTH

(m)

PRES HEIGHT of

FALL

(cm)10

20

40

10

20

First Shinho O-cell test pile

-

7/29/2019 Dr Fellenius Presentation

23/27

13

14

0

10

20

30

40

50

60

70

0 2 4 48 72 96 12 0 144 168 19 2 216 240

HOURS AFTER GROUTING

TEMPERATURE

(C)

Temperature a t various

depths in the gr out of a 0.4 m

center hole in a 56 m long,

0.6 m diameter, cylinder pile.

Temperature Records

15

-20 0

-15 0

-10 0

-50

0

5 0

10 0

15 0

20 0

25 0

30 0

0 24 48 72 96 120 144 168 192 2 16 24 0

HOURSAF TER GROUTING

STRAIN

()

Strain Records

16

0

5

10

15

20

25

30

35

40

45

50

55

60

- 300 -200 -100 0 100 200 300 400

STRAIN ()

DEPTH

(m)

9d

15d

23d

30d

39d

49d

59d

82d

99d

122d

218dDay of

TestAtan E- modulusof 30 GPa,this strai nchange corres ponds

to a load c hange of 3,200 KN

Strain measuredduring the 218-daywait-period betweendriving (grouting)and testing.

17

-90

-60

-30

0

30

0 1, 000 2,000 3,000 4,000 5,000 6,000

LOAD T OE-UP TEST (KN)

MOVEMENT(mm)

Breaking outthe O-cellbottom plate

Upper O-cell plate continuedupward during the unloading, butpile head did not move ?!?

The O-cell Toe-up Test

Plunging ?!?

18

0

5

10

15

20

25

30

0 1,00 0 2,00 0 3 ,000 4 ,000 5 ,000 6 ,000 7,0 00

LOAD TOE-UP TEST (KN)

UPWARDMOVEMENT(mm)

The pile head

did not move.

A 16 mm pile

shaft

compression is

not pos sible.

Pile must be

crushed above

(and below? )

O-cell plat e.

-

7/29/2019 Dr Fellenius Presentation

24/27

19

0

10

20

30

40

50

60

- 5,000 0 5, 000

LOAD 2nd TOE-UP (KN)

DEPTH

(m)

0

10

20

30

40

50

60

-5,000 0 5, 000

LOAD 1st TOE-UP ( KN)

DEPTH

(m)

20

-1,000

-500

0

500

1,000

1,500

0 1,000 2,000 3,000 4,000 5,0 00 6,000

O-c ell Load 2nd Toe-up (KN)

Strain-GageLoad(KN)

SG-1

SG-2

3.0 mm mvmnt up

21

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

10,000

0 10 20 30 40 50 60 70 80 90

MOVEMENT (mm)

LOADHEAD-DOWNTESTS(KN)

Now The Head-down Test

22

We have got the strain.

How to we get the load?

Load is stress times area

Stress is Modulus (E) times strain

The modulus is the key

E=

23

For a concrete pile or a concre te-filled bored pile, the

modulus to use is the combined modulus of concrete,

reinforcement , and steel casing

cs

ccss

comb

AA

AEAEE

+

+=

Ecomb

= combined modulusE

s= modulus f or st eel

As

= area of steelE

c= modulus for concrete

Ac

= area of concrete

24

For a concrete pile or a concre te-filled bored pile, the

modulus to use is the combined modulus of concrete,

reinforcement , and steel casing

cs

ccss

comb

AA

AEAEE

+

+=

Ecomb

= combined modulusE

s= modulus f or st eel

As

= area of steelE

c= modulus for concrete

Ac

= area of concrete

-

7/29/2019 Dr Fellenius Presentation

25/27

25

Themodulus of steel is 200GPa (207GPa for those weak at heart)

Themodulus of concrete is. . . . ?

Hard to answer. There is a sort of relation to the cylinder strengthand themodulus usually appears as avalue around 30GPa, or perhaps 20GPaor so, perhaps more.

This is not good enough answer and being vague is not necessary.

Themodulus can be determined from thestrain measurements.

Calculate first the

Values are known

=

tE

26

0 200 4 00 6 00 80 0

0

10

20

30

40

50

60

70

80

90

100

MICROSTRAIN

TANGENTMODULUS

(GPa)

Level 1

Level 2

Level 3

Level 4

Level 5

Best Fit Line

Example of Tangent Modulus P lot

27

First Head-down Test

0

10

20

30

40

50

60

0 500 1,000 1,500

STRAIN ()

CHANGEOFSTRESS/CHANGEOFSTRAIN,Mt

(GPa)

SG-12 CD

SG-12 AB

SG 11

SG-10

SG-9

SG-8

Q =A(-0.0035()2

+ 29 )

The Shinho te st pile head-down test

28

The Shinho te st pile head-down test

0

10

20

30

40

50

60

0 2,000 4,000 6,000 8,000 10,000

LOAD , 2nd HEAD-DOWN (KN)

DEPTH

(m)

ZEROLINE IS ATS TARTOF

2NDHEAD-DOWNTEST

Afte r

Unloading

0

10

20

30

40

50

60

0 2,000 4,000 6,000 8,000 10,000

LOAD, 2ndHEAD-DOWN (KN)

DEPTH(m)

ZERO LINEI SA TSTARTOF

2NDHEAD-DOWN TEST

= 1.0

= 0.4

(0.2

= 0.1

(0.1)

= 0.7

(0.2)

= 0. 3

(0.1

TRUERESISTANCE(fo r

max imum residual load)

RESIDUAL

(maximum)

Afte rUnloading

PRESUMED RESIDUALL OADATSTART OFO-CELL TEST

29

0

10

20

30

40

50

60

0 2,000 4,000 6,000 8,000 10,000

L OAD, 2nd HEAD-DOWN (KN)

DEPTH

(m)

ZEROLINE IS A TSTART OF

2ND HEAD -DOWNTEST

= 1. 0

= 0.4

(0.25

= 0.1

(0.1 )

= 0.7

(0.2 )

= 0.3

(0.1

TRUERESISTANCE(for

maxim um residual load)

RESIDUAL

(maxim um)

AfterUnloa ding

PRE UMED REI DUALL OAD ATSTARTOFO-CELL TEST

30

0

10

20

30

40

50

60

0 2,000 4,000 6,000 8,000 10,000

LOAD, 2nd HE AD-DOWN ( KN)

DEPTH

(m)

ZERO LINE IS AT STARTOF

2ND HEAD-DOWN TEST

= 1.0

= 0.4

(0.2

= 0.1

(0.1)

= 0.7

(0.2)

= 0.3

(0.1)

TRUE RESISTANCE(for

maximum residual load)

RESIDUAL

(maximum)

After

Unloading

Theshadedforcearea corresponds

to a shortenin g of just abo ut 3 mm

PRESUMED RESIDUAL LOADATSTARTOF O-CELL TEST

EstimatingResidual LoadDistributionat Start ofthe O-cellTest

-

7/29/2019 Dr Fellenius Presentation

26/27

31

FHWA tests on 0.9 m diameter bored piles

One in sand and one in clay(Baker et al., 1990and Briaud et al., 2000)

0

2

4

6

8

10

12

0 10 20 30 4 0

Cone Str ess a nd SPT N-Index(MPa andbl/0 .3 m)

DEPTH

(m

)

Silty

Sand

Sand

Pile 4

0

2

4

6

8

10

12

0 1 0 2 0 3 0 40

Cone Stres s (MPa)

DEPTH

(m

)

Pile 7

N

qc

Clay

SiltySand Clay

32

RESULTS: True Load-transfer curves

0.0

2.0

4.0

6.0

8.0

1 0.0

1 2.0

0 1, 0 00 2 ,0 00 3 , 000 4, 00 0 5, 0 00

LOAD (KN)

DEPTH

(m)

PILE 4

SAND

Measu re d

Di stribu ti on

0.0

2.0

4.0

6.0

8.0

1 0.0

1 2.0

0 1, 0 00 2 ,0 00 3 , 000 4, 00 0 5, 0 00

LOAD (KN)

DEPTH

(m)

PILE 4

SAND

True

Dis t r ib utio n

Re sidua

Loa d

Measu re d

Di stribu ti on

0.0

2.0

4.0

6.0

8.0

10.0

12.0

0 1 ,000 2 ,000 3,00 0 4,00 0 5, 00 0

LOAD (KN)

DEPTH

(m

)

PILE 7

CLAY

Me asured

Distribution

0.0

2.0

4.0

6.0

8.0

10.0

12.0

0 1 ,000 2 ,000 3,00 0 4, 00 0 5,00 0

LOAD (KN)

DEPTH

(m)

PILE 7

CLAY

TrueDistribution

Res idualL oad

33

Results of analysis of a Monotube pile in sand(Fellenius et al., 2000)

0

5

10

15

20

25

0 1, 000 2 ,000 3,0 00

LOAD (KN )

DEPTH

(m

True

Resistance

Measured

Resistance

Residual

Load

(Fellenius et al., 2000)

34

Note, just bec aus e a strain- gage has registered some strain

values dur ing a test does not g uarantee that the data are

useful. Unavoidable errors and natural variati ons amount to

about 50 microstra in to 100 microstra in. Therefor e, the test

must be des igned to achieve strain values at least of about 600

microstrain, preferably 1, 000 microstrain and beyond. If the

imposed strain are small er, the relativ e errors and imprecision

wil l be too large, a nd int erpretat ion of the test data becom es

uncertain, causing the inv estment in instrumentation to be less

than meaningful. The test should engage the pile material up

to at least half the strength. Preferably, aim for reac hing close

to t he material strength (structural strength).

35

Residual Load is the same as Drag Load . The

distinction made is that by residual loadwe mean the

locked-in load present in the pil e immediately before westart a static loading test. By drag loadwe mean the load

present in the pile i n the long-term

Residual load

Residual load as well as drag load can develop in

coarse-grained soil just as it does in clay soil

Both residual load and dragload develop at ve ry small

movements betw een the pile and the soil

36

0

200

400

600

800

1,000

1,200

0 5 10 15 20 25

MOVEMENT (mm)

LOAD

(KN)

HEAD

TOE

TOE TELLTALEA

Does not this shape of

measured toe movementsuggest that there is a

distinct toe capacity?

Toe Resistance

-

7/29/2019 Dr Fellenius Presentation

27/27

37

0

200

400

600

800

1,000

1,200

0 5 10 15 20 25

MOVEMENT (mm)

LOAD

(KN)

HEAD

TOE

TOE TELLTALEA

0

200

400

600

800

1,000

,

0 5 10 15 20 25

MOVEMENT (mm)

LO

AD

(KN)

HEAD

"Virgin" Toe Curve

TOE

B

No, it onl y appears that way when we forget to consider the residualtoe load (also called the initial, or virgin toe movement)

38

Of course,

we must consider also other aspects:

39

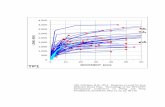

Interpretation of a series of tests

performed at different times

0 10 20 30 40 50 60 70

0

10

20

30

40

50

60

70

Movement (m m)Changeo

fHorizon

talStress

(KPa

)

5 D ays

1 Day

8 D ays

4 Months

22 Mon ths

Cell D1

Results thought dueto set-upexplained as Increase inHorizontal Effective Stress

Fellenius 2002

Results plottedAccording toMovement Path

0 50 100 150 200 250

0

10

20

30

40

50

60

70

Movement ( mm)

5 D ays

1 Day

8 D ays

4 Months

22 Mon ths

40

Also the best field work can get messed up if the analysis and

conclusion effort loses sight of the his tory of the data

0

1,000

2,000

3,000

4,000

5,000

6,000

0 25 50 75 100 125 150 175 200

MOVEME NT (mm)

LOAD(

KN)

STATNAMICCAPWAP

STATIC

0

1,000

2,000

3,000

4,000

5,000

6,000

0 25 50 75 100 125 150 175 200

MOVE MENT (mm)

LO

AD

(KN)

STATIC

STATNAMIC

CAPWAP

41

The O-Cell test with a couple of straingages, judiciously placed, will provide:

1. Separate values of shaft and toe resistances

2. Estimate of residual load

3. Load-transfer for the pile

4. Pile-toe load-movement curves (q-z function)

5. Results that can be extrapolated to other piles

6. Data necessary for settlement analysis