DP 800 Series-Rev.8/2/01 Scotch-Weld Structural …...regardless of the legal theory asserted,...

Transcript of DP 800 Series-Rev.8/2/01 Scotch-Weld Structural …...regardless of the legal theory asserted,...

3Scotch-Weld™

Structural Strength Acrylic Adhesives Bond plastics, oily metal, and more with your choiceof adhesive worklife, low odor, viscosity, color, and strength

Acrylic adhesives are recognizedthroughout industry for bonding thewidest range of substrates, including plastics and oily metals. Now, with theexpanded line of 3M™ Scotch-Weld™

Acrylic Adhesives, you have more choices than ever for performance andhandling characteristics to meet yourspecific requirements.

If you want low odor and fast handlingstrength, you can select Scotch-WeldDP-810 in different formulations thatinclude new black and non-sag versions.

From the entire line, you can choose a

5, 10, or 20-minute worklife – whateverworks best for your production speed.

You save time with minimal surfacepreparation even on oily metals. Andthese 2-part, 1:1, room-temperature curingadhesives are easy to apply with preciseautomatic metering and mixing to help

improve productivity.

For end use reliability, selectfrom a variety ofhigh shear andpeel strength

combinations and know that you’ve gotthe strength to replace mechanical andfusion fastening in many applications.

Application ideas

• Plastic or metal housings

• Sheet metal assemblies

• Plastic or metal components in doors,windows, and awnings

• Signs, P.O.P., and trade show displays

• Rubber fabrication

• Electronic components

• Truck, bus, and camper bodies

• Commercial floor cleaning equipment

Adhesive

Adhesive

Molded-in threaded inserts

Metal-to-metal for awning hinge

Plastic-to-plastic for equipment housing

Clean surface ofequipment exterior

3M™ Scotch-Weld™ Structural Strength Acrylic Adhesives

Production versatility

To meet a wide range of production requirements, you can select 50, 200,and 400ml Duo-Pak cartridges for usewith hand-held 3M™ EPX™ manual orpneumatic applicators. Bulk pails are alsoavailable for higher volume production.

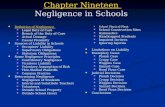

Typical Characteristics AdhesiveDP-805 DP-810 DP-810 DP-810 NS DP-820

Black (non-sag)

Overlap Shear (psi) 73°F (23°C)Aluminum - etched 3500 4200 4200 4200 3200Aluminum - (120 grit abraded) 3200 3900 3750 3850 3100Aluminum - (solvent cleaned) 900 3800 3850 4100 300Cold Rolled Steel CRS (oily) 2700 3450 3450 3500 2400Galvanized Steel 1300 3400 3500 3400 1200FR-4 Glass Epoxy 2500 3800 3000 1900 2000ABS 1000 600 700 650 1000PVC 1750 1000 1000 1000 1750Polycarbonate 950 850 500 500 1150Acrylic 1200 1100 550 800 1250

180° T-Peel Adhesion (piw) 73°F (23°C)

Etched AI/Etched AI 35 30 20 23 22

Worklife at 73°F (23°C) 3-5 min. 10 min. 10 min. 10 min. 15-20 min.

Time to Handling Strength 50 psi shear at 73°F (23°C) 7-10 min. 10 min. 10 min. 10 min. 35-45 min.

Viscosity at 73°F (23°C) cpsBase 75,000 20,000 20,000 92,500 70,000Accelerator 150,000 20,000 19,000 97,500 45,000

ColorBase Off-white Green Black Blue-green Off-whiteAccelerator Yellow White White White Yellow

Note: This technical information and data should be considered representative or typical only and should not be used for specification purposes.

Engineered Adhesives Division

3M Center Bldg. 220-8E-05St. Paul, MN 55144-1000www.3m.com/adhesives

Printed in U.S.A.

© 3M 2001 78-6900-9993-8 (08-01)

Recycled paper40% pre-consumer10% post-consumer

E

IMPORTANT NOTICE: 3M MAKES NO WARRANTIES, EXPRESS ORIMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTYOF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.User is responsible for determining whether the 3M product is fit for a particularpurpose and suitable for user's method of application. Please remember thatmany factors can affect the use and performance of a 3M product in a particular application. The materials to be bonded with the product, the surfacepreparation of those materials, the product selected for use, the conditions inwhich the product is used, and the time and environmental conditions in whichthe product is expected to perform are among the many factors that can affectthe use and performance of a 3M product. Given the variety of factors thatcan affect the use and performance of a 3M product, some of which are

uniquely within the user’s knowledge and control, it is essential that the userevaluate the 3M product to determine whether it is fit for a particular purposeand suitable for the user’s method of application.

LIMITATION OF REMEDIES AND LIABILITY: If the 3M product is proved tobe defective, THE EXCLUSIVE REMEDY, AT 3M'S OPTION, SHALL BE TOREFUND THE PURCHASE PRICE OF OR TO REPAIR OR REPLACE THEDEFECTIVE 3M PRODUCT. 3M shall not otherwise be liable for any loss or damages, whether direct, indirect, special, incidental, or consequential,regardless of the legal theory asserted, including but not limited to contract,negligence, warranty, or strict liability.

3

When to use acrylic adhesives

Scotch-Weld 2-part acrylic, epoxy and urethane adhesives are available to help you meet different applicationrequirements. Consider Acrylic for thewidest range of substrates, includingplastics and oily metals.

Epoxy provides higher strength and elevated temperature resistance. Urethanes are lower cost and highlyelastic for applications requiring flexibility between dissimilar materials.