Dissemination workshop Madrid Review of DEMO 3 · also during thermal unit ramp ... programmable...

Transcript of Dissemination workshop Madrid Review of DEMO 3 · also during thermal unit ramp ... programmable...

1st Steering Committee / 29th October 2014 / Rome

Technological innovation by Toshiba’s VSC system

2

WP 5 (DEMO 3 R&D)

• Task 5.7: HVDC

converter

technology

WP 10 (DEMO 3 - demonstration)

• Task 10.4: Manufacturing, installation and testing the converter demonstrator

• Task 10.5: Experimentation and assessment of the overall solution

1st Steering Committee / 29th October 2014 / Rome

Technological innovation by Toshiba’s VSC system

• Focus on the “SACOI”

rehabilitation by VSC

• Identification of new

converters & controls

technologies / solutions

complying with “SACOI"

operating requirements

• Analyses and studies on

system integration of

the enhanced SACOI by

Toshiba’s VSC (ready for

WP10 demonstration)

3

Task 5.7 (HVDC converter technology) –WP 5: D5.7 “Innovative HVDC converter technology” – July 28, 2017

1st Steering Committee / 29th October 2014 / Rome

Technological innovation by Toshiba’s VSC system

• Focus on VSC & controls

technical specification

• Factory Acceptance Tests

• Demonstration Tests

4

Task 10.4 (Manufacturing, installation and testing the converter demonstrator) –WP 10: D10.9 “Construction of the HVDC converter”

1st Steering Committee / 29th October 2014 / Rome

Technological innovation by Toshiba’s VSC system

Demo Work-scope

Summary

Design, Supply, Erection & Commissioning of buffer-reactor free, Half-B VSC

• Full current (1200 A) - Pro-rated voltage (10 kV) - Asymmetric monopole

• Real scale MMC modules and controls

Operational Testing

5

1st Steering Committee / 29th October 2014 / Rome

Technological innovation by Toshiba’s VSC system

6

VSC Demo configuration:

• DC back-to-back connection

• DC asymmetrical configuration

• Point of common AC coupling

VSC Demo operation:

• Active power recirculating

• Reactive power management

1st Steering Committee / 29th October 2014 / Rome

Technological innovation by Toshiba’s VSC system

7

VSC Demo Layout

1st Steering Committee / 29th October 2014 / Rome

Technological innovation by Toshiba’s VSC system

8

VSC-MMC valves

&

shielding

enclosure

1st Steering Committee / 29th October 2014 / Rome

Technological innovation by Toshiba’s VSC system

9

VSC-MMC

Charging

Resistors

1st Steering Committee / 29th October 2014 / Rome

Technological innovation by Toshiba’s VSC system

10

VSC-MMC Converter Transformer

1st Steering Committee / 29th October 2014 / Rome

Technological innovation by Toshiba’s VSC system

11

VSC-MMC Converter Transformer

1st Steering Committee / 29th October 2014 / Rome

Technological innovation by Toshiba’s VSC system

12

VSC-MMC DC side disconnectors & grounding

1st Steering Committee / 29th October 2014 / Rome

Technological innovation by Toshiba’s VSC system

13

VSC Control Cabinets

1st Steering Committee / 29th October 2014 / Rome

Technological innovation by Toshiba’s VSC system

14

Demo Activities Planning

Status of Demo-related Activities (on November 2017)

• Installation Site Selection………………………………….…..Completed

• AC network connection…………………………………….……. Completed

Converter Transformers:

• Specification………………………..………….….Completed• Procurement………………………….............Completed• Delivery on site………………………... Completed

• IEGT Valves and Converter Control:

• Design…………………………………………………Completed• Delivery on site…………………………Completed

• Erection Works………………………………………………………November 2017 (E)

• Site Tests………………………………………………………………December 2017

• Grid Connection Tests…………………………………………….February 2018

• Demonstration Tests……………………………………………...April 2018

1st Steering Committee / 29th October 2014 / Rome

Context• SACOI HVDC connects 2 / 3 AC islands: Sardinia, Corsica, mainland

• Large RES penetration and conventional generation displacementin Sardinia stability issues

• Another HVDC (LCC) from Sardinia to mainland Italy operational complexity

• 3 market zones involved

Objectives

• Stable operation

• Restoration

• Evaluation of admissible

RES increase

• Cost-Benefit Analyses (CBA) Sardinia (IT)

Corsica (F)

Mainland IT

1st Steering Committee / 29th October 2014 / Rome

Stable operation with SACOI VSC

16

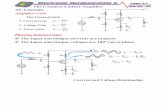

Impact of power reversal Impact of fast Frequency response

Under-frequency in Sardinia due to 280 MW generation loss Scenario V1, modified with less traditional generation

1st Steering Committee / 29th October 2014 / Rome

Restoration: SACOI VSC used as…

17

•1. Black start unit

• Fast and reliableload reconnection

• Load connection possible also during thermal unit ramp

2. STATCOM

0 10 20 30 40 50 600.999

1

1.001

time, min

p.u.

Rotor speed (blue) and mechanical power (green curve) of G3 at F. Santo PP

0 10 20 30 40 50 600

0.2

0.4

rotor speed, p.u.

mechanical power, p.u.

≈ Constant1 p.u. speed

Unperturbedpower ramp

Black start power plant

Thermalpower plant

1st Steering Committee / 29th October 2014 / Rome

Analysis of Sardinian operational security with respect to frequency stability limits

18

18

Market simulator - 2030 scenario

Hourly conventional generation unit commitment & dispatchHourly values of load, wind and PV

Assessment of available reserve

Hourly reserve margin supplied by: thermal p.p, programmable hydro p.p., pumped storage p.p., battery storage, HVDC links , RES (only downward

reserve)

Assessment of reserve requirements

Hourly needed FCR reserve (maximum unbalance), FRR reserve (ENTSO-E formula), RR reserve (probabilistic combination of maximum generation loss and load,

wind, PV uncertainties)

Assessment of control actions in order to assure RESERVEREQ ≤ RESERVEAVAILABLE , or Assessment of maximum increment of SA.CO.I. and SA.PE.I. flow (e.g. due to RES)

Number of critical hours and hourly quantities of insufficient upward or downward reserve in Sardinia requiring preventive and/or corrective actions

1st Steering Committee / 29th October 2014 / Rome

Analysis of Sardinian operational security with respect to frequency stability

Missing upward reserve – PRATED_SA.CO.I.= 2 x 300 MW

2030 Vision 1 “slow progress” 2030 Vision 3 “green transition”

Number of critical hoursScenario Power reversal

No Yes

V1 82 (0.9% of annual total) 0

V3 324 (3.7% of total annual) 0

Downward reserve always sufficient Big margin available from RES

Without power reversalWithout power reversal

With power reversal With power reversal

1st Steering Committee / 29th October 2014 / Rome

Cost-Benefit Analyses (CBA) of the upgraded SACOI 3 three-terminal link

20

The methodology focuses on several aspects contemplated by ENTSO-E CBA 1.0 methodology, namely:Reliability (B1), Socio-Economic Welfare (B2), RES integration (B3), grid losses (B4), CO2 emissions (B5)

Based on ENTSOE TYNDP 2016 Vision 1 and Vision 3 scenarios for 2030, zonal and nodal models.

Two OPF (Optimal Power Flow) simulation tools based, for zonal and nodal analyses respectively, were applied to deal with the three-terminal SACOI 3 study case.

The simulations so far conducted have identified the key techno-economic benefits provided by a three-terminal HVDC system such as the SACOI 3 both in the European context and in the Italy+Corsica grids.

Source: ENTSO-E CBA methodology

1st Steering Committee / 29th October 2014 / Rome21

CBA Key provisional results

Benefits introduced by SACOI3, with respect to the case «without SACOI3»

V1400 MW

V3400 MW

Zon

alap

pro

ach

B1 – Expected Energy Not Supplied EENS

(MWh/year)

0 0

B2 – Socio-economic welfare SEW (M€/year) + 66.5 + 65.6

B3 – Expected Energy Not Produced EENP

(MWh/year)

0 - 111 500

B4 – Joule Losses (GWh/year) n/a n/a

B5 – CO2 emissions (kton/year) + 358 - 47

No

dal

app

roac

h

B1 – EENS (MWh/year) 0 0

B2 – SEW (M€/year) + 37.9 + 12.7

B3 – EENP (MWh/year) + 3 - 70 336

B4 – Joule Losses (GWh/year) - 59 - 9

B5 – CO2 emissions (kton/year) + 180 - 78

Variations on «with – without» SACOI 3:• Zonal approach results: pan-European system• Nodal approach results: Italian grid system + network of Corsica

(EENS: Expected Energy Not Supplied; EENP: Expected Energy Not Produced; SEW: Socio-Economic Welfare)

1st Steering Committee / 29th October 2014 / Rome22

HVDC Submarine Pre-qualification Test in Calais

• The Pre-qualification test on the unarmoured cable is ongoing in the new R&D HV Lab in Halden

• Test will be carried out according to CIGRÈ TB496 utilizing the dedicated HVDC DC Current Generator

• Test will terminate in January 2018

1st Steering Committee / 29th October 2014 / Rome23

HVDC Land Pre-qualification Test in Calais

• The Pre-qualification test on the fully armoured cable has been interrupted after a breakdown in the cable.

• A new production run is planned for 3Q 2017 to eneble testing of Land System

• Test Voltage has been selected at 500kV

• New Test will initiate in 1Q 2018

1st Steering Committee / 29th October 2014 / Rome

HVDC Extruded Submarine

400 kV cable

• Not a small cable (43 kg/m)

• As compact as possible

• Very strong (can resist without damage to

50 tons of pull

• Completely impervious to water ingress

• Fondamentally the same as your pc cable

Just slightly bigger

24

1st Steering Committee / 29th October 2014 / Rome25

HVDC Submarine Pre-qualification Test in Halden

• The Pre-qualification test on the fully armoured cable is ongoing in the new R&D HV Lab in Halden

• Test will be carried out according to CIGRÈ TB496 utilizing the dedicated HVDC DC Current Generator

• Test will terminate in August 2018

1st Steering Committee / 29th October 2014 / Rome

HVDC Submarine 400 kV Type Test in Halden

• Assembly of the Type Test object will be finalised in the second Half of October

• Test is planned in the new R&D HV Lab in HALDEN

• Test will be carried out according to CIGRÈ TB496

• Test object is shown hereby

26

1st Steering Committee / 29th October 2014 / Rome

ACFR Conductor

Kevlar® Fibres Core

Aramid fibre core

1st Steering Committee / 29th October 2014 / Rome

ACFR Kevlar ConductorRECAP:

•Characterizations test @RSE lab

• Stress Strain

• Tensile strength

• Sag and coefficient of thermal expansion determination

• Thermal cycling

• Fittings Stability

• Self Damping

1st Steering Committee / 29th October 2014 / Rome

Aluminium Alloy wires

Carbon core multistrand

Extruded tube

Tape

Carbon Multistrand

1st Steering Committee / 29th October 2014 / Rome

Carbon Multistrand•Characterizations test lab

• Stress Strain

• Tensile strength

• Sag and coefficient of thermal expansion determination

• Thermal cycling

• Fittings Stability

• Self Damping

• Pulley Test

• Test on the Fittings

1st Steering Committee / 29th October 2014 / Rome31

Next Steps

• Continue of the characterization test @RSE lab

• Installation test beginning 2018

• Installation pilot line

Carbon Fiber Conductor:

• Continue of the characterizations test @RSE lab

• Installation test

• Installation pilot line

ACFR Conductor:

1st Steering Committee / 29th October 2014 / Rome32

Task5.4: “Requirements and specifications for optimal sizing of insulation”

Task 5.4• Long duration multi-stress

ageing test on RTV, fullyand partially, coveredinsulator chains: aftermore than 1000h (the testduration is 2000h) the firstphenomena of erosionsare taking place on someof the chains under test.The measured leakagecurrents are on the order,at max, of 20-30 mA(relatively low values).