DIRECT VENT SPECTRA SERIES - Inglenook Energy installation manual will help you obtain a safe,...

Transcript of DIRECT VENT SPECTRA SERIES - Inglenook Energy installation manual will help you obtain a safe,...

1NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

INSTALLATIONINSTRUCTIONS

VENTED GAS FIREPLACE HEATERS - DIRECT VENT MODELSP/N 850,016M REV. H 08/2007

FOR YOUR SAFETY: Do not store or use gasolineor other flammable vapors or liquids in the vicin-ity of this or any other appliance.

FOR YOUR SAFETY: What to do if you smell gas:

• DO NOT light any appliance.• DO NOT touch any electrical switches.• DO NOT use any phone in your building.• Immediately call your gas supplier from a

neighbor’s phone. Follow your gas suppliersinstructions.

• If your gas supplier cannot be reached, call thefire department.

Installation and service must be performed by aqualified installer, service agency or the gassupplier.

MODELS

POUR VOTRE SÉCURITÉ: Ne pas entreposer ni utiliserd'essence ni d'autre vapeurs ou liquides inflammablesdans le voisinage de cet appareil ou de tout autreappareil.

POUR VOTRE SÉCURITÉ: Que faire si vous sentez uneodeur de gaz:

• Ne pas tenter d'allumer d'appareil.• Ne touchez à aucun interrupteur. Ne pas vous servir

des téléphones se trouvant dans le batiment oùvous vous trouvez.

• Evacuez la piéce, le bâtiment ou la zone.• Appelez immédiatement votre fournisseur de gaz

depuis un voisin. Suivez les instructions dufournisseur.

• Si vous ne pouvez rejoindre le fournisseur de gaz,appelez le service dos incendies.

L'installation et service doit être exécuté par un qualifiéinstalleur, agence de service ou le fournisseur de gaz.

DIRECT VENTSPECTRA SERIES

This appliance may be installed in an aftermar-ket permanently located, manufactured home(USA only) or mobile home, where not prohib-ited by local codes. This appliance is only foruse with the type of gas indicated on the ratingplate. This appliance is not convertible for usewith other gases, unless a certified kit is used.

LENNOX HEARTH PRODUCTS

OTL Report No. 116-F-02-05

LSS-35CN LSS-40CNLSS-35CP LSS-40CP

WARNING: IF THE INFORMATION IN THIS MANUALIS NOT FOLLOWED EXACTLY, A FIRE OR EXPLO-SION MAY RESULT CAUSING PROPERTY DAM-AGE, PERSONAL INJURY OR LOSS OF LIFE.

AVERTISSEMENT: ASSUREZ-VOUS DE BIEN SUIVRELES INSTRUCTIONS DONNÉ DANS CETTE NOTICE POURRÉDUIRE AU MINIMUM LE RISQUE D'INCENDIE OUPOUR ÉVITER TOUT DOMMAGE MATÉRIEL, TOUTEBLESSURE OU LA MORT.

A French manual is available upon request. Order Form Number850,016CF.

Ce manuel d’installation est disponible en francais, simplement enfaire la demande. Numéro de la pièce 850,016CF.

INSTALLER: Leave this manual with the appliance.CONSUMER: Retain this manual for future reference.

2 NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

TABLE OF CONTENTS

Packaging ........................................ page 2

Introduction ..................................... page 2

General Information ......................... page 2

Location .......................................... page 3

Appliance and Vent Clearances ....... page 4

Framing Specifications .................... page 5

Facing Requirements ....................... page 6

Hearth Requirements ....................... page 7

Fireplace Specifications ................... page 8

Vent Termination Clearances ........... page 9

Typical Installation Sequence .......... page 9

Detailed Installation Steps ............... page 9

Step 1. Framing ............................. page 9

Step 2. Routing Gas Line ............... page 11

Step 3. Install the Venting System . page 11

Vertical Termination Systems .......... page 11

Vent Section Length Chart ............... page 12

Vertical Vent Tables and Figures ...... page 15

Horizontal Termination System ........ page 16

Horizontal Vent Tables and Figures . page 18

Venting Using Flexible Vent Pipe ..... page 20

Step 4. Field Wiring ....................... page 21

Step 5. Connecting Gas Line .......... page 21

Comfort Control Valve ..................... page 22

Step 6. Installing Ceramic Panels

And Logs ..................................... page 24

Step 7. Checking Unit Operation ..... page 24

Step 8. Installing Glass Door ......... page 24

Step 9. Burner Adjustments ........... page 25

Finishing Requirements ................... page 26

Cold Climate Insulation .................... page 26

Installation Accessories ................... page 27

Gas Conversion Kits .................. page 28

DO NOT ATTEMPT TO ALTER OR MODIFYTHE CONSTRUCTION OF THE APPLIANCE ORITS COMPONENTS. ANY MODIFICATION ORALTERATION MAY VOID THE WARRANTY,CERTIFICATION AND LISTINGS OF THIS UNIT.

INTRODUCTION

These fireplaces are designed, tested and listedfor operation and installation with, and only with,Secure Vent™ Direct Vent System Components,Secure Flex™ Flexible Vent Components manu-factured by Security Chimneys International andZ-Flex™ Model GA Venting Systems, listed toUL1777 and ULCS635 manufactured by Flex-master Canada Limited. These approved ventsystem components are labeled for identifica-tion. DO NOT use any other manufacturer's ventcomponents with these appliances.

These appliances comply with National SafetyStandards and are tested and listed by Omni-Test Laboratories (Report No. 116-F-02-5) toANSI Z21.88 (in Canada, CSA-2.33), and CAN/CGA-2.17-M91 in both USA and Canada, asvented gas fireplace heaters.

PACKAGING

The assembled Spectra direct vent gas fire-place heater is packaged with:

1 - one log set located in firebox area.2 - one envelope containing the literature

package which consists of the homeowner'smanual, installation instructions, log setsupplement and warranty; envelope is lo-cated in the control area.

3 - one bag of glowing embers located in thecontrol area.

4 - one ceramic panel set, located on top ofunit.

5 - one hand held remote control, located inthe control area.

6 - an additional one of the following itemsrequired:1: Cast Iron Face (Classic Arch) and Grillwork (Black, Gold or Nickel) or2: Arched Face (Black, Gold or Nickel) or3: Rectangular Face (Black, Gold or Brushed Stainless)

Each kit comes with an individual set ofinstallation instructions.

Note: Installation and repair should be per-formed by a qualified service person. The appli-ance should be inspected annually by a quali-fied professional service technician. More fre-quent inspections and cleanings may be re-quired due to excessive lint from carpeting,bedding material, etc. It is imperative that thecontrol compartment, burners and circulatingair passage ways of the appliance be kept clean.

S'assurer que le brùleur et le compartimentdes commandes sont propres. Voir les in-structions d'installation et d'utilisation quiaccompagnent l'appareil.

Provide adequate clearances around air open-ings and adequate accessibility clearance forservice and proper operation. Never obstructthe front openings of the appliance.

Please read and understand theseinstructions before beginning your

installation.

GENERAL INFORMATION

Note: For combustible material refer toFigure 48 on page 26.

These appliances are designed to operate onnatural or propane gas only.

This installation manual will help you obtain asafe, efficient, dependable installation for yourappliance and vent system.

The Installation must conform to local codesor, in the absence of local codes, with theNational Fuel Gas Code, ANSI Z223.1/NFPA54, or the Natural Gas and Propane Installa-tion Code, CSA B149.1. The appliance, wheninstalled, must be electrically grounded inaccordance with local codes or, in the ab-sence of local codes, with the National Elec-trical Code, ANSI/NFPA 70, or the CanadianElectrical Code, CSA C22.1.

These appliances are listed by Omni-TestLaboratories for installation in bedrooms andmobile homes.

WARNING: 1) FIRE HAZARD: DO NOTPLACE ANY COMBUSTIBLE MATERIALOVER THE FIREPLACE OPENING. 2) DOORFRONT ACCESSIBILITY: ANY NON-COM-BUSTIBLE FINISHING MATERIAL AREASTHAT PROTRUDE MORE THAN 1" FROMTHE FACING SHOULD MAINTAIN A 9"CLEARANCE TO THE FIREPLACE OPEN-ING. SEE FIGURE 7, PAGE 6 FOR DETAILS.

3NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Test gage connections are provided on thefront of the gas control valve (identified INfor the inlet and OUT for the manifold side).

Do not use these appliances if any part hasbeen under water. Immediately call a quali-fied, professional service technician to inspectthe appliance and to replace any parts of thecontrol system and any gas control whichhave been under water.

Ne pas se servir de cet appareil s'il a été plongédans l'eau, complètement ou en partie. Appelerun technicien qualifié pour inspecter l'appareil etremplacer toute partie du système de contrôle ettoute commande qui ont été plongés dans l'eau.

These appliances feature a comfort controlvalve which allows remote control of tem-perature, fan and flame appearance. Theseappliances also use a spark ignitor (piezo)that allows the appliance's pilot gas to be litwithout the use of matches. This systemprovides continued service in the event of apower outage.

These appliances must not be connected to achimney or flue serving a separate solid fuelburning appliance.

Carbon Monoxide Poisoning: Early signs ofcarbon monoxide poisoning are similar tothe flu with headaches, dizziness and/ornausea. If you have these signs, obtainfresh air immediately. Turn off the gas sup-ply to the appliance and have it serviced bya qualified professional, as it may not beoperating correctly.

LOCATION

In selecting the location, the aesthetic and func-tional use of the appliance are primary concerns.However, vent system routing to the exterior andaccess to the fuel supply are also important.Consideration should be given to traffic ways,furniture, draperies, etc., due to elevated surfacetemperatures (see Figure 2 ).

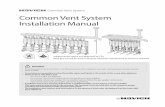

Figure 1

TYPICAL INSTALLATION

Table 1

Installations at Altitudes of 0 to 4500 ft.-Units are tested and approved for elevationsof 0 to 4500 feet (0 to 1372 meters).

Installations at Altitudes above 4500 ft.-For elevations above 4500 feet (1372meters), install the unit according to theregulations of the local authorities havingjurisdiction and, in the USA, the latestedition of the National Fuel Gas Code (ANSIZ223.1) or, in Canada, the latest edition ofthe CAN1-B149.1 and .2 codes.

Gas Inlet And Manifold Pressures

Gas Specifications

Table 1 shows the units' gas orifice size forthe elevations indicated.

ledoM leuF raeRrenruB

tnorFrenruB

NC53-SSL saG.taN 44# 05#

PC53-SSL saGPL 55# 16#

NC04-SSL saG.taN 24# 54#

PC04-SSL saGPL "450.0 65#

These appliances must be isolated from the gassupply piping system (by closing their individualmanual shut-off valve) during any pressure test-ing of the gas supply piping system at test pres-sures equal to or less than 1/2 psig (3.5 kPa).

These appliances and their individual shut-offvalves must be disconnected from the gassupply piping system during any pressuretesting of that system at pressures in excess of1/2 psig (3.5 kPa).

ledoM leuFmumixaM

tupnI)H/UTB(

muminiMtupnI

)H/UTB(

NC53-SSL saG.taN 000,33 005,32

PC53-SSL saGPL 000,13 005,32

NC04-SSL saG.taN 005,14 004,82

PC04-SSL saGPL 000,93 007,03

larutaN )enaporP(PLmuminiM

erusserPtelnI .c.w"0.5 .c.w"0.11

mumixaMerusserPtelnI .c.w"0.41 .c.w"0.41

dlofinaMerusserP .c.w"5.3 .c.w"0.01

The external electrical power (120V) is re-quired to operate the provided circulatingblower.

Drywall

Mantel

Non-Combustible

Top OfFireplace Opening

WARNING: FAILURE TO COMPLY WITHTHE INSTALLATION AND OPERATING IN-STRUCTIONS PROVIDED IN THIS DOCU-MENT WILL RESULT IN AN IMPROP-ERLY INSTALLED AND OPERATING AP-PLIANCE, VOIDING ITS WARRANTY. ANYCHANGE TO THIS APPLIANCE AND/ORITS OPERATING CONTROLS IS DANGER-OUS. IMPROPER INSTALLATION OR USEOF THIS APPLIANCE CAN CAUSE SERI-OUS INJURY OR DEATH FROM FIRE,BURNS, EXPLOSION OR CARBON MON-OXIDE POISONING.

WARNING: CHILDREN AND ADULTSSHOULD BE ALERTED TO THE HAZARDSOF HIGH SURFACE TEMPERATURES. USECAUTION AROUND THE APPLIANCE TOAVOID BURNS OR CLOTHING IGNITION.YOUNG CHILDREN SHOULD BE CARE-FULLY SUPERVISED WHEN THEY ARE INTHE SAME ROOM AS THE APPLIANCE.

WARNING: DO NOT PLACE CLOTHINGOR OTHER FLAMMABLE MATERIALSON OR NEAR THIS APPLIANCE.

AVERTISSEMENT: SURVEILLER LESENFANTS. GARDER LES VÊTEMENTS,LES MEUBLES, L'ESSENCE OU AUTRESLIQUIDES À VAPEUR INFLAMMABLESÀ COTE DE L'APPAREIL.

4 NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

.oNledoM)mm(sehcnithgieHflehS

woblEeergeD09enOhtiw-tneVpoT

tneVeruceS xelFeruceS53-SSL 2/175 )1641( 4/195 )5051(04-SSL )9941(95 )3451(4/306

Shelf Height(see table)

Do not insulate thespace between theappliance and the

area above it.

Shelf Above Fireplace With Top Venting

12 ¹⁄₄”(311mm)

*Note: For Secure Vent A SV4.5L6 6” Section (Cat. No. 77L70) Is Required.

*See Note

Figure 2

Figure 3

HORIZONTAL VENT VERTICAL VENT

TOP VENT APPLICATIONS

*Note: 3 in. (75 mm) above any horizontal/inclined vent component.

Note: The nailing flange and the cabinetsurfaces directly adjacent to the framingmember attached to the nailing flange, areexempt from the 1/2" clearance to combus-tibles defined for the rest of the cabinetsides and back.

Table 2

KCAB )mm31(.ni2/1srecaps)mm0(.ni0

SEDIS )mm31(.ni2/1srecaps)mm0(.ni0

SRECAPSPOT )mm0(.ni0

ROOLF )mm0(.ni0

fomottoBmorFgnilieCottinU )mm6261(.ni46

TNEV *)mm4.52(.ni1

SECNARAELCECIVRES

TNORF )sretem9.0(.teeF3

Typical Locations

The location should also be free of electrical,plumbing or other heating/air conditioning duct-ing. These direct vent appliances are uniquelysuited for installations requiring a utility shelfpositioned directly above the fireplace. Utilityshelves like these are commonly used for locat-ing television sets and decorative plants.

Do not insulate the space between the appli-ance and the area above it. See Figure 3. Theminimum height from the base of the applianceto the underside of combustible materials usedto construct a utility shelf in this fashion is shownin the table in Figure 3.

The appliance should be mounted on a fullysupported base extending the full width anddepth of the unit. The appliance may be locatedon or near conventional construction materi-als. However, if installed on combustible ma-terials, such as carpeting, vinyl tile, etc., ametal or wood barrier covering the entire bot-tom surface must be used.

APPLIANCE AND VENT CLEARANCES

These appliances are approved with zero clear-ance from spacers to combustible materials onall sides (as detailed in Table 2 ), with thefollowing exception: When the unit is installedwith one side flush with a perpendictular sidewall, the wall perpendicular to the opposite sideof the appliance front face must not extendmore than five inches beyond the front edge ofthe unit. In addition, when the unit is recessed,the side walls surrounding the unit must notextend more than five inches beyond the frontedge of the unit. Refer to Figure 2.

5NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Figure 4

Figure 5 Corner Framing with Square Termination (SV4.5HT)

Framing Dimensions

FIREPLACE FRAMING SPECIFICATIONS

A

B

7(178)

(308)

(267)

C

VENT FRAMING -TOP VENT WITH ONE

6” SECTION ANDONE 90° ELBOW

Framing should be constructedof 2x4 or larger lumber.

Inches (mm)

(130)

**FRAMING WITH SQUARE HORIZONTAL TERMINATIONS (SV4.5HT)

** See the horizontal venting Figures 29 and 30 on page 17 forrestrictions on the use of the square termination (SV4.5HT).

NOTE: For Secure Vent A 6” SectionSV4.5L6 (Cat. No. 77L70) Is RequiredBefore Installing The 90 Degree Elbow.

5-1/8

12-1/8

10-1/2

20-13/161/2 A

ledoM.oN A B C D E

53-SSL.ni 53 8/1 61/526 8/193 8/163 61/1151mm 298 3851 499 819 004

04-SSL .ni 8/104 61/576 8/574 8/583 61/771mm 2201 0171 0121 189 344

C

Back wall of chase/enclosure(including any finishing materials)

Note-Venting requirements for corner installations -

D

A

B

E

ledoM.oN A B C

53-SSL.ni 53 8/1 8/524 8/115mm 298 3801 9921

04-SSL .ni 8/104 8/144 8/525mm 2201 1211 7331

6 NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

FACING REQUIREMENTS

Figure 6

Figure 7 Non-Combustible Requirements

Unit Nailing Flange (On Both Sides)

Fireplace

TOP VIEW

1/2” Drywall

Faceplate

3/8” Tile

1/2” Concrete Board

2” x 4”

9”Min.

Requires A Concrete Board(Or Other Non-Combustible

Material) Extending FromThe Top Of The Fireplace To

The Floor And To TheFraming Members On Both

Sides. Do Not UseSheetrock, Plywood Or Other

Combustible Material

4 1/2” Min.(Both Sides)

Top Of Fireplace Non-Combustible Material

Warning: 1) Fire Hazard: Do NotPlace Any Combustible MaterialOver The Fireplace Opening. 2) DoorFront Accessibility: Any Non-Combustible Finishing MaterialAreas That Protrude More Than 1”From The Facing Must Maintain A 9”Clearance To The Fireplace Opening. For Combustible Material, Refer ToFigure 48 On Page 26.

Top Of Fireplace Opening

10”

7NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

HEARTH REQUIREMENTS

Figure 8

Cement Board

Tile, Marble, Brick, Carpet,Or Other Non-CombustibleOr Combustible Material

FireplaceStand

1”Min.

Figure 9 RAISED FIREPLACE

Fireplace

Floor Plywood Platform

Face

Thickness Of the Floor Covering(Carpet, Flooring, Etc.)

1” Min.

8 NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Figure 10

FIREPLACE SPECIFICATIONS

H

ELECTRICALINLET

Diminsions In Inches (mm)

* Includes The 1/2” Spacers

1 (25.4)

3 (76)

11 ¹⁄₄(286)

G

1/2” Spacers

8 ¹¹⁄₃₂(211)

A E

D

F

B

C

1(25.4)

3 (76)

GAS INLET(BOTH SIDES)

*21 ³⁄₈(543)

6(152)

8 ¹³⁄₁₆(225)

2 ⁹⁄₁₆(65)

3(76)

FRAMING SPACERS

CONCENTRIC FLUECombustion Air - 7 ¹⁄₂ (190)Flue - 4 ¹⁄₂ (114)

3 (76)

Vent RestrictorAdjustment Rod

ledoM.oN A B C D E F G H

53-SSL.ni 8/383 61/153 2/192 91 61/361 8/313 2/112 4/301mm 579 198 947 384 114 797 645 372

04-SSL .ni 8/793 61/104 2/143 2/102 61/312 8/723 2/162 4/131mm 3101 8101 678 125 835 538 376 733

9NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

hctiPfooR )teef(H21/6ottalF 0.1

21/7ot21/6revO 52.121/8ot21/7revO 5.121/9ot21/8revO 0.221/01ot21/9revO 5.221/11ot21/01revO 52.3

ot21/11revO21/21 0.4

12X

Roof Pitch is X/12

2 FTMIN.2 FT MIN.Lowest

DischargeOpening

H*

*H = MINIMUM HEIGHT FROM ROOF TOLOWEST DISCHARGE OPENING OF VENT

TERMINATION HEIGHTS FOR VENTS ABOVEFLAT OR SLOPED ROOFS

Horizontal Overhang

VerticalWall

VentTermination

Storm Collar

ConcentricVent Pipe

Flashing

1 inch (25.4 mm) MinimumClearance to Combustibles

Figure 11

Figure 12 - Side Elevation View

3"(76 mm)

12"(305 mm)

Termination Kit

Combustible Projectiongreater than inches in length

Combustible Projection2-1/2 inches or less in length

18"(457 mm)

VentilatedSoffit Unventilated

Soffit

Horizontal Vent Termination Clearances

2-1/2

Termination Kit

All horizontal terminationsmay be located as close

as 6” (152mm) to any(non-combustible andcombustible) exterior

sidewall. This distancemay be decreased to

2” (51mm) for non-combustible exteriorsidewalls only, if the

SV4.5HT-2 terminationis used.

Horizontal Vent Termination ClearancesThe horizontal vent termination must have aminimum of 3" (76 mm) clearance to anyoverhead combustible projection of 2-1/2" (64mm) or less. See Figure 5. For projectionsexceeding 2-1/2" (64 mm), see Figure 5. Allhorizontal terminations may be located asclose as 6" (152mm) to any (non-combustibleand combustible) exterior sidewall. This dis-tance may be decreased to 2" (51mm) for non-combustible exterior sidewalls only, if theSV4.5HT-2 termination is used. For projec-tions exceeding 2 ¹⁄₂" (64 mm), see Figure 12.

Terminate multiple vent terminations accord-ing to the installation codes listed at the top ofthis page.

Vertical Vent Termination Clearances

VENT TERMINATION CLEARANCES

These instructions should be used as a guide-line and do not supersede local codes in anyway. Install vent according to local codes,these instructions, the current National FuelGas Code (ANSI-Z223.1) in the USA or thecurrent standards of CAN/CGA-B149.1 and -B149.2 in Canada.

Terminate single vent caps relative to buildingcomponents according to Figure 11.

TYPICAL INSTALLATION SEQUENCE

The typical sequence of installation follows,however, each installation is unique resulting invariations to those described.

See the page numbers references in the follow-ing steps for detailed procedures.

Step 1. (page 9) Construct the appliance fram-ing. Position the appliance within the framingand secure with nailing brackets.Step 2. (page 11) Route gas supply line toappliance location.Step 3. (page 11) Install the vent system andexterior termination.Step 4. (page 21) Field WiringInstall the operating control switch (not factoryprovided) and bring in electrical service line forforced air circulating blower.Step 5. (page 21) Make connection to gas supply.Step 6. (page 24) Install the ceramic panel, logs,and glowing embers.Step 7. (page 24) Checkout appliance operation.Step 8. (page 25) Install glass door frame assembly.Step 9. (page 25) Adjust burner to ensureproper flame appearance.

DETAILED INSTALLATION STEPS

The appliance is shipped with all gas controlsand components installed and pre-wired. Re-move the shipping carton, exposing the frontglass door. Remove ceramic panel kit from thetop of the fireplace and set it aside with care.Remove the cardboard from underneath thepressure relief plates. Open the two latches(located under the firebox floor) securing theglass door. Remove the door by tilting it out-ward at the bottom and lifting it up. Set the dooraside protecting it from inadvertent damage.See Figure 46 on page 25.

Step 1. FRAMING

Frame these appliances as illustrated inFigure 4 on page 5, unless the appliance isto be installed in a corner. See Figure 5 onpage 5 for corner framing installations. Allframing details must allow for a minimumclearance to combustible framing mem-bers as shown in Table 2 on page 4. SeeFigure 6 on page 6 for the facing detail.

See Figure 7 on page 6 for the Non-Combus-tible requirements. See Figures 8 and 9 onpage 7 for Hearth Requirements.

10 NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Figure 14

EXTERIOR HORIZONTAL VENT TERMINATION CLEARANCE REQUIREMENTS

V

VV

V

V

F

C

FixedClosed

Window

OperableWindow

B

B

A

B

H

M

I

= Vent Terminal = Area where Terminal is not Permitted= Air Supply InletX V

D

V

3 ft.

3 ft.

A A

A = 9” in U.S.= 12” in Canada

VL

B

J

X E

V

A

G

InsideCorner Detail

*18”

Ventilated Soffit

HorizontalTermination

Detail D

Exterior Wall Center Lineof Termination

18”

Inside Corner

BC

C

C

* See Item D in the Text Below.

*noitallatsnInaidanaC **noitallatsnISU,hcrop,adnarev,edargevobaecnaraelC=A

.ynoclabro,kced*)mc03(sehcni21 **)mc03(sehcni21

ebyamtahtroodrowodniwotecnaraelC=B.denepo

secnailpparof)mc51(ni6)mc03(ni21,)Wk3(hutB000,01<

dna)Wk3(hutB000,01>secnailpparof)mc19(sehcni63,)Wk03(hutB000,001<

*)Wk03(hutB000,001>secnailpparof

secnailpparof)mc51(ni6)mc32(ni9,)Wk3(hutB000,01<

dna)Wk3(hutB000,01>secnailpparof)mc03(sehcni21,)Wk51(hutB000,05<

**)Wk51(hutB000,05>secnailpparofwodniwdesolcyltnenamrepotecnaraelC=C tneverpotdednemmocer)mm503("21

noitasnednocwodniwtneverpotdednemmocer)mm922("9

noitasnednocwodniw

tiffosdetalitnevotecnaraelclacitreV=Dlatnozirohanihtiwlanimretehtevobadetacolretnecehtmorf)mm854(sehcni81foecnatsid

lanimretehtfoenil

)mm854("81 )mm854("81

tiffosdetalitnevnuotecnaraelC=E )mm503("21 )mm503("21renrocedistuootecnaraelC=F muminim)mc7.21("5 muminim)mc7.21("5

renrocedisniotecnaraelC=G •2-TH5.4VS-muminim)mc80.5("2SSTH5.4VS-muminim)mc2.51("6

•2-TH5.4VS-muminim)mc80.5("2SSTH5.4VS-muminim)mc2.51("6

enilretnecfoedisnihcaeotecnaraelC=Hylbmessarotaluger/retemevobadednetxe

teef51fothgiehanihtiw)mc19(teef3*ylbmessarotaluger/retemehtevoba

teef51fothgiehanihtiw)mc19(teef3**ylbmessarotaluger/retemehtevoba

teltuotnevrotalugerecivresotecnaraelC=I *)mc19(teef3 **)mc19(teef3telniylppusrialacinahcemnonotecnaraelC=J

ynaottelnirianoitsubmocehtrognidliubotecnailpparehto

secnailpparof)mc51(ni6)mc03(ni21,)Wk3(hutB000,01<

dna)Wk3(hutB000,01>secnailpparof)mc19(sehcni63,)Wk03(hutB000,001<

*)Wk03(hutB000,001>secnailpparof

secnailpparof)mc51(ni6)mc32(ni9,)Wk3(hutB000,01<

dna)Wk3(hutB000,01>secnailpparof)mc03(sehcni21,)Wk51(hutB000,05<

**)Wk51(hutB000,05>secnailpparoftelniylppusrialacinahcemaotecnaraelC=K *)m38.1(teef6 )m3(teef01nihtiwfievoba)mc19(teef3

**yllatnozirohdevaproklawedisdevapevobaecnaraelC=L

ytreporpcilbupnodetacolyawevid‡)m31.2(teef7 ‡)m31.2(teef7

rokced,hcrop,adnarevrednuecnaraelC=Mynoclab

‡*)mc03(sehcni21 ‡)mc03(sehcni21

.edoCnoitallatsnIenaporPdnAsaGlanoitaN1.941B-ASCtnerrucehthtiwecnadroccanI*.sedoCsaGleuFlanoitaN45APFN/1.322ZSISNAtnerucehthtiwecnadroccanI**

sevresdnasgnillewdylimafelgnisowtneewtebdetacolsihcihwyawevirddevaproklawedisaevobayltceridetanimrettonllahstnevA‡.sgnillewdhtob

:roolfehthtaenebsedis2muminimanonepoyllufsiynoclabrokced,hcrop,adnarevfidettimrepylnO‡*.ylnO2-TH5.4VSrofselbitsubmoC-noNotecnaraelC"2•

11NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Right SideFront Corner of

Fireplace Framing

6"(152 mm)

3"(76 mm)

Figure 13

Step 3. INSTALL THE VENT SYSTEM

General Information

These instructions should be used as a guide-line and do not supersede local codes in anyway. Install vent according to local codes,these instructions, the current National FuelGas Code (ANSI-Z223.1) in the USA or thecurrent standards of CAN/CGA-B149.1 and -B149.2 in Canada.

These fireplaces are designed, testedand listed for operation and installationwith, and only with, Secure Vent™ DirectVent System Components, Secure Flex™Flexible Vent Components manufacturedby Security Chimneys International andZ-FLEX™ Model GA Venting Systems listedto UL1777 and ULCS635 manufactured byFlexmaster Canada Limited.

These approved vent system componentsare labeled for identification. DO NOTuse any other manufacturer's ventcomponents with these appliances.

Some local jurisdictions may require the gapbetween the outer wall of the vent systemand the firestop penetration opening to besealed. This is not a requirement of thelisting of this product, however this gap maybe sealed using aluminized tape or similarnon-combustible material.

The vent system may not service multiple appli-ances, and must never be connected to a flueserving a solid fuel burning appliance. The ventpipe is tested to be run inside an enclosing wall(such as a chase). There is no requirement forinspection openings in the enclosing wall at anyof the joints in the vent pipe.

Select Venting System - Horizontal or Vertical

With the appliance secured in framing, deter-mine vent routing and identify the exteriortermination location. The following sectionsdescribe vertical (roof) and horizontal (exte-rior wall) vent applications. Refer to the sec-tion relating to your installation. A list ofapproved venting components is shown inthe two tables on page 27.

VERTICAL TERMINATION SYSTEMS (ROOF)

Figure 15, and Figures 25 through 27 onpages 12 and 15 and their associatedVertical Vent Tables illustrate the various verti-cal venting configurations that are possible foruse with these appliances. Secure Vent pipeapplications are shown in these figures; SecureFlex pipe may also be used. A Vertical VentTable summarizes each system’s minimumand maximum vertical and horizontal lengthvalues that can be used to design and install thevent components in a variety of applications.

Both these vertical vent systems terminatethrough the roof. The minimum vent heightabove the roof and/or adjacent walls is speci-fied in ANSI Z223.1-(latest edition) (In Canada,the current CAN-1 B149 installation code) bymajor building codes. Always consult yourlocal codes for specific requirements. A gen-eral guide to follow is the Gas Vent Rule (referto Figure 11 on page 9).

Massachusetts And New York City, NYRequirements

These appliances are approved for installationin the following USA locations listed in thefollowing:

Massachusetts:Installation of these fireplaces are approvedfor installation in the US state of Massachu-setts if the following additional requirementsare met-

• Installation and repair must be done by aplumber or gas fitter licensed in the Common-wealth of Massachusetts.• The flexible gas line connector used shall notexceed 36 inches (92 centimeters) in length.• The individual manual shut-off must be a T-handle type valve.

New York City, NY:Installation of these fireplaces are approvedfor installation in New Your City in the US stateof New York.

Massachusetts Horizontal Vent Requirements

In the Commonwealth of Massachusetts, hori-zontal terminations installed less than seven(7) feet above the finished grade must complywith the following additional requirements:

• A hard wired carbon monoxide detector withan alarm and battery back-up must be installedon the floor level where the gas fireplace isinstalled. The carbon monoxide detector mustcomply with NFPA 720, be ANSI/UL 2034listed and be ISA certified.

• A metal or plastic identification plate must bepermanently mounted to the exterior of thebuilding at a minimum height of eight (8) feetabove grade and be directly in line with thehorizontal termination. The sign must read, inprint size no less than one-half (1/2) inch insize, GAS VENT DIRECTLY BELOW. KEEPCLEAR OF ALL OBSTRUCTIONS.

These fireplaces must be vented directlyto the outside.

Step 2. ROUTING GAS LINE

Route a 1/2" (13 mm) gas line along the insideof the right side framing as shown in Figure 13.Gas lines must be routed, constructed andmade of materials that are in strict accordancewith local codes and regulations.

All appliances are factory-equipped with a flex-ible gas line connector and 1/2" inch shutoffvalve. (See step 5 on page 21).

12 NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Figure 15

Vertical (Offset) Installation

Analyze the vent routing and determine thequantities of vent sections and number ofelbows required. Refer to Vertical Vent Fig-ures and Tables on page 15 to select the typeof vertical installation desired. Vent sectionsare available in net lengths of 4-1/2" (114 mm),10-1/2" (267 mm), 22-1/2" (572 mm), 34-1/2"(876 mm) and 46-1/2" (1181 mm). Refer to theVent Section Length Chart on this page for anaid in selecting length combinations. Elbowsare available in 90° and 45° configurations.Refer to Figure 20 for the SV4.5E45 andSV4.5E90 elbow dimensional specifications.

TRAHCHTGNELNOITCESTNEVnoitceSlanimoN)sehcni(htgneL 6 21 42 63 84 T

OTAL

QTY

noitceSteN)sehcni(htgneL 2/1-4 2/1-01 2/1-22 2/1-43 2/1-64

tneVfothgieH snoitceStneVforebmuN

sehcni tf

441 21 1 0 0 0 3 4

051 5.21 0 1 0 0 3 4

5.451 578.21 1 1 0 0 3 5

5.061 573.31 0 2 0 0 3 5

5.271 573.41 0 0 0 5 0 5

771 57.41 1 0 0 5 0 6

381 52.51 0 1 0 5 0 6

681 5.51 0 0 0 0 4 4

5.091 578.51 1 0 0 0 4 5

5.691 573.61 0 1 0 0 4 5

5.502 521.71 0 1 1 5 0 7

702 52.71 0 0 0 6 0 6

5.112 526.71 1 0 0 6 0 7

5.712 521.81 0 1 0 6 0 7

5.922 521.91 0 0 1 6 0 7

5.232 573.91 0 0 0 0 5 5

732 57.91 1 0 0 0 5 6

5.142 521.02 0 0 0 7 0 7

642 5.02 1 0 0 7 0 8

252 12 0 1 0 7 0 8

462 22 0 0 1 7 0 8

672 32 0 0 0 8 0 8

972 52.32 0 0 0 0 6 6

5.082 573.32 1 0 0 8 0 9

5.382 526.32 1 0 0 0 6 7

5.982 521.42 0 1 0 0 6 7

5.103 521.52 0 0 1 0 6 7

5.013 578.52 0 0 0 9 0 9

513 5.62 1 0 0 9 0 01

5.523 521.72 0 0 0 0 7 7

033 5.72 1 0 0 0 7 8

633 82 0 1 0 0 7 8

543 57.82 0 0 0 01 0 01

5.943 521.92 1 0 0 01 0 11

273 13 0 0 0 0 8 8

5.673 573.13 1 0 0 0 8 9

5.973 526.13 0 0 0 11 0 11

5.814 578.43 0 0 0 0 9 9

324 52.53 1 0 0 0 9 01

564 57.83 0 0 0 0 01 01

TRAHCHTGNELNOITCESTNEVnoitceSlanimoN)sehcni(htgneL 6 21 42 63 84 T

OTAL

QTY

noitceSteN)sehcni(htgneL 2/1-4 2/1-01 2/1-22 2/1-43 2/1-64

tneVfothgieH snoitceStneVforebmuN

sehcni tf

5.4 573.0 1 0 0 0 0 1

9 57.0 2 0 0 0 0 2

5.01 578.0 0 1 0 0 0 1

51 52.1 1 1 0 0 0 2

5.91 526.1 2 1 0 0 0 3

12 57.1 0 2 0 0 0 2

5.22 578.1 0 0 1 0 0 1

5.52 521.2 1 2 0 0 0 3

5.13 526.2 0 3 0 0 0 3

5.43 578.2 0 0 0 1 0 1

5.73 521.3 1 1 1 0 0 3

5.34 526.3 0 2 1 0 0 3

54 57.3 0 0 2 0 0 2

5.64 578.3 0 0 0 0 1 1

5.94 521.4 1 0 2 0 0 3

15 52.4 1 0 0 0 1 2

5.55 526.4 0 1 2 0 0 3

75 57.4 0 0 1 1 0 2

66 52.5 0 2 2 0 0 4

5.76 526.5 0 0 3 0 0 3

96 57.5 0 0 0 2 0 2

27 6 1 0 3 0 0 4

5.37 521.6 1 0 0 2 0 3

5.97 526.6 0 1 0 2 0 3

18 57.6 0 0 0 1 1 2

09 5.7 0 2 1 0 1 4

5.19 526.7 0 0 2 0 1 3

39 57.7 0 0 0 0 2 2

69 8 1 0 1 2 0 4

5.79 521.8 1 0 0 0 2 3

201 5.8 2 0 0 0 2 45.301 526.8 0 0 0 3 0 3

801 9 1 0 0 3 0 4

411 5.9 0 2 0 0 2 4

711 57.9 1 0 5 0 0 6

5.811 578.9 1 1 0 3 0 5

621 5.01 0 0 1 3 0 4

5.031 578.01 1 0 1 3 0 5

531 52.11 0 0 6 0 0 6

831 5.11 0 0 0 4 0 4

5.931 526.11 0 0 0 0 3 3

5.241 578.11 1 0 0 4 0 5

Vertical (Straight) Installation

Determine the number of straight vent sec-tions required. 4-1/2" (114 mm), 10-1/2" (267mm), 22-1/2" (572 mm), 34-1/2" (876 mm)and 46-1/2" (1181 mm) net section lengths areavailable. Plan the vent lengths so that a jointdoes not occur at the intersection of ceiling orroof joists. Refer to the Vent Section LengthChart on this page.

SV4.5CGV-1Termination SV4.5FA OR

SV4.5FB FlashingAND SV4.5SCSTORM COLLAR

*SV4.5VFFirestop/Spacer

SV4.5L6/12/24/36/48Vent Sections

40' Max(12.2 M)

1" (25.4 mm)MinimumClearance toCombustibles

*When using Secure Flex,use Firestop/Spacer

SF4.5VF

13NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Figure 19

Support Straps(Plumber’s tape)

8 feet (2.4 m)Maximum

Blocking

Figure 18

Figure 17

Figure 16

B. Attach vent components to appliance -Secure Vent SV4.5 direct vent system compo-nents are unitized concentric pipe componentsfeaturing positive twist lock connections (seeFigure 17 ).

All of the appliances covered in this document arefitted with collars having locking inclined chan-nels. The dimpled end of the vent components fitover the appliance collar to create the positivetwist lock connection.

First VentComponentAlign the dimple (four places)with the opening of the lockingincline channel on appliancecollar. Twist vent componentclockwise to engage and seal.

LockingIncline Channel

Dimple

Appliance collar

Vent / Appliance CollarConnection

Align the dimple (four places) of theupper vent section with the opening ofthe locking incline channel on thelower vent section. Twist ventcomponent clockwise to engage andseal until arrow and dimple align.

LockingIncline Channel

Dimple

ArrowConnected

Vent Sections

Vent / Vent SectionConnection

Arrow

Arrow

To attach a vent component to the appliancecollar, align the dimpled end over the collar,adjusting the radial alignment until the fourlocking dimples are aligned with the inlet of thefour inclined channels on the collar (refer toFigure 17 ). Push the vent component againstthe collar until it fully engages, then twist thecomponent clockwise, running the dimplesdown and along the incline channels until theyseat at the end of the channels.

The unitized design of the Secure Vent com-ponents will engage and seal both the innerand outer pipe without the need for sealant orscrews. If desired, a #6 x 1/2" screw may beused at the joint, but is not required as the pipewill securely lock when twisted.

C. Attach vent components to each other -Other vent sections may be added to the previ-ously installed section in accordance with therequirements of the vertical vent figures andtables. To add another vent component to alength of vent run, align the dimpled end over theinclined channel end of the previously installedsection, adjusting the radial alignment until thefour locking dimples are aligned with the inlets ofthe four incline channels of the previous section.

10¹⁄₂” Min.(267 mm)

10¹⁄₂” Min.(267 mm)

Push the vent component against the previoussection until it fully engages, then twist thecomponent clockwise running the dimples downand along the incline channels until they seat atthe end of the channels. This seating positionis indicated by the alignment of the arrow anddimple as shown in Figure 18.

D. Install firestop/spacer at ceiling - When usingSecure Vent, use SV4.5VF firestop/spacer at ceil-ing joists; when using Secure Flex, use SF4.5VFfirestop/spacer. If there is living space above theceiling level, the firestop/spacer must be installedon the bottom side of the ceiling. If attic space isabove the ceiling, the firestop/spacer must beinstalled on the top side of the joist. Route the ventsections through the framed opening and securethe firestop/spacer with 8d nails or other appro-priate fasteners at each corner.

Remember to maintain 1" (25 mm) clearanceto combustibles, framing members, and atticor ceiling insulation when running verticalchimney sections.

E. Support the vertical vent run sections -Support the vertical portion of the venting sys-tem every 8 feet (2.4m) above the fireplace ventoutlet using field provided support straps (con-ventional plumber's tape). Secure the plumber'stape to the framing members with nails or screws.

Loop the tape around the vent, securing theends of the tape to the framing. If desired,sheet metal screws #6 x 1/2" length may beused to secure the support straps to the ventpipe . See Figure 19.

Where required, a telescopic vent section(SV4.5LA) may be used to provide the in-staller with an option in installing in tight andconfined spaces or where the vent run madeup of fixed length pieces develops a joint in aundesirable location, or will not build up to therequired length. The SV4.5LA Telescopic VentSection has an effective length of from 1-1/2"(38 mm) to 7-1/2" (191 mm). The SV4.5LA isfitted with a locking inclined channel end (iden-tical to a normal vent section component) anda plain end with 3 pilot holes. Slip the plain endover the locking channel end of a standardSV4.5 vent component the required distanceand secure with three screws.

Maintain a minimum 1" (25 mm) clearance tocombustible materials for all vertical elements.Clearances for all horizontal elements are 3"(76 mm) on top, 1" (25 mm) on sides and 1"(25 mm) on the bottom.

A. Frame ceiling opening - Use a plumb linefrom the ceiling above the appliance to locatecenter of the vertical run. Cut and/or frame anopening, 10-1/2" x 10-1/2" (267mm x 267mm)inside dimensions, about this center mark(Figure 16 ).

14 NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Figure 21

Figure 22

Figure 24

Figure 23

K. Install the vertical termination - The finalstep involves installation of the SV4.5CGV-1Vertical Termination. Extend the vent sections tothe height as shown in the "Vertical vent termina-tion section" on page 9. The SV4.5CGV-1 Ver-tical Termination (Figure 24 ) installs in the exactsame fashion as any other Secure Vent section.Align the termination over the end of the previ-ously installed section, adjusting the radial align-ment until the locking dimples of the terminationare aligned with the inlets of the four inclinechannels of the last vent section. Push thetermination down until it fully engages, thentwist the termination clockwise running thedimples down and along the incline channelsuntil they seat at the end of the channels.

I. Install the roof flashing - Extend the ventsections through the roof structure. Install theroof flashing over the vent section and positionsuch that the vent column rises vertically (usecarpenters level) (Figure 22 ). Nail along perim-eter to secure flashing or adjust roofing to over-lap the flashing edges at top and sides only andtrim where necessary. Seal the top and bothsides of the flashing with waterproof caulking.

If the vent system extends more than 5' (1.5 m)above the roof flashing, stabilizers may be nec-essary. Additional screws may be used at sectionjoints for added stability. Guide wires may beattached to the joint for additional support onmultiple joint configurations.

G. Continue installation of horizontal/inclinedsections - Continue with the installation of thestraight vent sections in horizontal/inclined runas described in Step C. Install support strapsevery 5' (1.52 m) along horizontal/inclined ventruns using conventional plumber’s tape. It isvery important that the horizontal/inclinedrun be maintained in a straight (no dips) andrecommended to be in a slightly elevatedplane, in a direction away from the fireplaceof 1/4" rise per foot (20 mm per meter) which isideal, though rise per foot run ratios that aresmaller are acceptable all the way down to at ornear level. Use a carpenter’s level to measurefrom a constant surface and adjust the supportstraps as necessary.

It is important to maintain the required clear-ances to combustibles: 1" (25 mm) at all sidesfor all vertical runs; and 3" (76 mm) at the top,1" (25 mm) at sides, and 1" (25 mm) at thebottom for all horizontal/inclined runs.

H. Frame roof opening - Identify location forvent at the roof. Cut and/or frame opening perRoof Framing Chart and Figure 21.

J. Install the storm collar - Install the stormcollar, supplied with the flashing, over thevent/flashing joint. See Figure 23. Loosen thestorm collar screw. Slide collar down until itmeets the top of the flashing. Tighten theadjusting screw. Apply non-combustible caulk-ing or mastic around the circumference of thejoint to provide a water tight seal.

C

D

StormCollar

Figure 20

F. Change vent direction to horizontal/in-clined run - At transition from or to a horizon-tal/inclined run, install the SV4.5E45 andSV4.5E90 elbows in the same manner as thestraight vent sections. The elbows feature atwist section to allow them to be routed aboutthe center axis of their initial collar section toalign with the required direction of the nextvent run element. Twist elbow sections in aclockwise direction only so as to avoid thepossiblity of unlocking any of the previouslyconnected vent sections. See Figure 20.

SV4.5E90(90° Elbow)

7 ⁵⁄₈"(194 mm)

Swivel Joint(360° swivel)

4 ¹³⁄₁₆"(122 mm)

SV4.5E45(45° Elbow)

Swivel Joint(360° swivel)

Framing Dimensions for Roof

Pitch C D

0/12 10-1/2 in. 10-1/2 in.(267 mm) (267 mm)

6/12 10-1/2 in. 12 in.(267 mm) (305 mm)

12/12 10-1/2 in. 17-3/4 in.(267 mm) (451 mm)

15NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Figure 25 - Top Vent - STRAIGHT

Figure 26 - Top Vent - TWO 90 DEGREE ELBOWS

VERTICAL VENT FIGURES/TABLESNote: Secure Vent (rigid vent pipe) is shownin the figures; Secure Flex (flexible vent pipe)may also be used.

Note: It is very important that the horizontal/inclined run be maintained in a straight (nodips) and recommended to be in a slightlyelevated plane, in a direction away from thefireplace of 1/4" rise per foot (20 mm permeter) which is ideal, though rise per foot runratios that are smaller are acceptable all theway down to at or near level.

Note: SV4.5VF (Secure Vent), SF4.5VF (Se-cure Flex) firestop/spacer must be used any-time vent pipe passes through a combustiblefloor or ceiling. SV4.5HF (Secure Vent),SF4.5HF (Secure Flex)firestop/spacer must beused anytime vent pipe passes through a com-bustible wall.

Note: Two 45 degree elbows may be used inplace of one 90 degree elbow. The same rise torun ratios, as shown in the venting figures for90 elbows, must be followed if 45 degreeelbows are used.

AELBATV M MUMINI H mumixaM

teef )sretem( teef )sretem(

1* )503.0( 5 )25.1(

2 )016.0( 01 )1.3(

3 )419.0( 51 )56.4(

4 )22.1( 02 )2.6(

V+V 1 .xaM)m4.21(teef04=H+H .xaM)m2.6(teef02=

Figure 27 - Top Vent - THREE ELBOWS

BELBAT

V M MUMINIH H+ 1

mumixaM

teef )m( teef )m(

1 )503.0( 5 )25.1(

2 )016.0( 01 )1.3(

3 )419.0( 51 )56.4(

4 )22.1( 02 )2.6(

H+H 1 .xaM)m2.6(teef02=V+V 1 H+H+ 1 teef04=

.xaM)m4.21(

40 feet (12.2 meters)Maximum*Ceiling

Firestop/Spacer(SV4.5VF)

*When usingSecure Flex, useFirestop/Spacer

SF4.5VF

V

H1

H

V1

*CeilingFirestop/Spacer(SV4.5VF) **Wall

Firestop/Spacer(SV4.5HF)

*When using Secure Flex,use Firestop/Spacer

SF4.5VF

**When using SecureFlex, use Firestop/Spacer

SF4.5HF

WARNING: UNDER NO CIRCUM-STANCES MAY SEPARATE SECTIONSOF CONCENTRIC FLEXIBLE VENT PIPEBE JOINED TOGETHER.

*When developing chimney systemswith horizontal runs (H) that end witha vertical run (V1), it is allowable touse an elbow attached directly to thetop collar. Count the elbow attachedto the collar as 1 foot of (V) run.

H

V

V1

*CeilingFirestop/Spacer

(SV4.5VF)

**WallFirestop/Spacer

(SV4.5HF)

**When using SecureFlex, use Firestop/Spacer

SF4.5HF

*When using Secure Flex,use Firestop/Spacer

SF4.5VF

16 NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

VerticalRise

SV4.5E90Elbow

Horizontal / Inclined RunSV4.5 HTTermination

Firestop/Spacer

SV4.5L6/12/24/36/48Vent Sections

Support Bracket SpacingEvery 5 ft (1.52 m)

See Figure 19 on page 13 forvertical vent section support.

SV4.5 HTTermination

SupportBracketsBuilding

SupportFraming

Ceiling

Fireplace

ExteriorWall

ExteriorWall

TYPICAL HORIZONTAL VENT INSTALLATION

Figure 28Secure Vent SV4.5 direct vent system compo-nents are unitized concentric pipe componentsfeaturing positive twist lock connection, (refer toFigure 17 on page 13). All of the appliancescovered in this document are fitted with collarshaving locking inclined channels. The dimpledend of the vent components fit over the appliancecollar to create the positive twist lock connection.

A. Plan the vent run -Analyze the vent routing and determine thetypes and quantities of sections required4-1/2" (114 mm), 10-1/2" (267 mm), 22-1/2"(572 mm), 34-1/2" (876 mm) and 46-1/2" (1181mm) net section lengths are available. Plan thevent lengths so that a joint does not occur at theintersection of ceiling or roof joists. Make al-lowances for elbows as indicated in Figure 20on page 13. Maintain a minimum 1" (25 mm)clearance to combustibles on the vertical sec-tions. Clearances for the horizontal runs are; 3" (76mm) on top, 1" (25 mm) on sides, and 1" (25 mm)at the bottom.

B. Frame exterior wall opening -Locate the center of the vent outlet on theexterior wall according to the dimensions shownin Figure 4 on page 5. Cut and/or frame anopening, 10-1/2" x 12-1/8" (267 mm x 267mm) inside dimensions, about this center.

C. Frame ceiling opening - If the verticalroute is to penetrate a ceiling, use plumb lineto locate the center above the appliance. Cutand/or frame an opening, 10-1/2" x 10-1/2"(267 mm x 267 mm) inside dimensions, aboutthis center (refer to Figure 16 on page 12 ).

D. Attach vent components to appliance - Toattach a vent component to the appliance collar,align the dimpled end over the collar, adjusting theradial alignment until the four locking dimples arealigned with the inlets of the four incline channelson the collar (refer to Figure 17 on page 13).

G. Support the vertical run sections -See Section E on page 13.

Push the vent component against the collar until itfully engages, then twist the component clockwise,running the dimples down and along the inclinechannels until they seat at the end of the channels.The unitized design of the Secure Vent compo-nents will engage and seal both the inner and outerpipe elements with the same procedure. Sealantand securing screws are not required.

E. Attach vent components to each other -Other vent sections may be added to the previ-ously installed section in accordance with therequirements of the vent tables. To add anothervent component to a length of vent run, align thedimpled end of the component over the inclinedchannel end of the previously installed section,adjusting the radial alignment until the four lock-ing dimples are aligned with the inlets of the fourincline channels of the previous section. Pushthe vent component against the previous sectionuntil it fully engages, then twist the componentclockwise running the dimples down and alongthe incline channels until they seat at the end ofthe channels.This seating position is indicatedby the alignment of the arrow and dimple asshown in Figure 18 on page 13.

F. Install firestop/spacer at ceiling -When using Secure Vent, use SV4.5VF firestop/spacer at ceiling joists; when using Secure Flex, useSF4.5VF firestop/spacer. If there is living spaceabove the ceiling level, the firestop/ spacer must beinstalled on the bottom side of the ceiling. If atticspace is above the ceiling, the firestop/ spacer mustbe installed on the top side of the joist. Route thevent sections through the framed opening andsecure the firestop/spacer with 8d nails or otherappropriate fasteners at each corner.

I. Continue installation of horizontal/inclinedsections - Continue with the installation of thestraight vent sections in horizontal/inclined runas described in Step E. Install support strapsevery 5 ft. (1.52 m) along horizontal/inclinedvent runs using conventional plumber’s tape.See Figure 28. It is very important that thehorizontal/inclined run be maintained in astraight (no dips) and recommended to be ina slightly elevated plane, in a direction awayfrom the fireplace of 1/4" rise per foot (20 mmper meter) which is ideal, though rise per footrun ratios that are smaller are acceptable all theway down to at or near level. Use a carpenter’slevel to measure from a constant surface andadjust the support straps as necessary.

Both of these horizontal vent systems terminatethrough an outside wall. Building Codes limit orprohibit terminating in specific areas. Refer toFigure 14 on page 10 for location guidelines.

Figure 28, and Figures 31 to 33 on pages 16,18 and 19 and their associated Horizontal VentTable illustrate the various horizontal ventingconfigurations that are possible for use withthese appliances. Secure Vent pipe applica-tions are shown in these figures; Secure Flexpipe may also be used. A Horizontal Vent Tablesummarizes each system’s minimum and maxi-mum vertical and horizontal length values thatcan be used to design and install the ventcomponents in a variety of applications.

HORIZONTAL (OUTSIDE WALL)TERMINATION SYSTEM

H. Change vent direction - At transition fromor to a horizontal/inclined run, install theSV4.5E45 and SV4.5E90 elbows in the samemanner as the straight vent sections. Theelbows feature a twist section to allow themto be routed about the center axis of theirinitial collar section to align with the re-quired direction of the next vent run element.Twist elbow sections in a clockwise direc-tion only so as to avoid the possiblity ofunlocking any of the previously connectedvent sections. See Figure 20.

Remember to maintain 1" (25 mm) clear-ance to combustibles, framing members,and attic or ceiling insulation when runningvertical chimney sections.

17NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Firestop/Spacer (SV4.5HF) shownon the exterior side of the wall. It

may also be installed on theinterior side. SV4.5 HT

Termination

10¹⁄₂"(267mm)

7"(178)

5¹⁄₈"(130 mm)

12¹⁄₈"(308 mm)

Note: Centerline of Vent Piping isNOT the Same as the Centerline of

the Framed Opening.

6 to 48 inch Vent Section,Telescopic vent section,

Elbow or Appliance Collar

See Figure 4 on page 5for Min. Distance to Base

of Appliance.

Base of Appliance

3"(76 mm)

1"(25.4 mm)Adapter

SV4.5RCH

IMPORTANT: The vent termination is hotwhile in operation and for a period of timefollowing use of the fireplace. To preventcontact with hot surfaces, we recommendthe use of a Termination Guard. This can bepurchased at your local dealer.

Horizontal terminations have been designed to perform in a wide range of weatherconditions. Our terminations meet or exceed industry standards.

When selecting the locations of your horizontal terminations, do not place thetermination where water from eaves and adjoining rooflines may create a heavy flowof cascading water onto the termination cap. If the cap must be placed where thepossibility of cascading water exists, it is the responsibility of the builder to direct thewater away from the termination cap by using gutters or other means.

Take care to carefully follow the installation instructions for the termination, includingthe use of silicone caulking where required.

Figure 29

Figure 30

Siding

Stucco1¹⁄₄" Maximum Recess ofEither Square Termination intoExterior Finishing Material

Exterior Surface ofFraming

5 in. to 9 ¹ ₄ in.(127 to 235 mm)

Exterior Surface of Siding

Minimum wall thickness5 in. (127 mm)

Interior Surface ofFinished Wall

Maximum wall thickness9¹ ₄ in.(235 mm)

SV4.5HTSquare

Termination

Maximum Extent ofVent Run SectionsRelative to ExteriorSurface of Framing

Last Vent Section. UseT e l e s c o p i c V e n tSection (SV4.5LA), IfNecessary

AdapterSV4.5RCH

(Provided With TheTermination)

SV4.5HTSquare Termination

Venting Connection and Exterior Wall Recessing of theHorizontal Square Termination (SV4.5HT).

Note: Venting terminals shall not be recessed intoa wall or siding.

It is important to maintain the required clear-ances to combustibles: 1" (25 mm) at all sidesfor all vertical runs; and 3" (76 mm) at the top,1" (25 mm) at sides, and 1" (25 mm) at thebottom for all horizontal/inclined runs

J. Assemble vent run to exterior wall - If notpreviously measured, locate the center of thevent at the exterior wall. Prepare an opening asdescribed in Step B. Assemble the vent systemto point where the terminus of the last sectionis within 5 in. (127 mm) to 9-1/4 in. (235 mm)inboard of the exterior surface to which thetermination is to be attached, see Figure 30. Ifthe terminus of the last section is not within thisdistance, use the telescopic vent sectionSV4.5LA, as the last vent section. For wallthicknesses greater than that shown in Figure30, refer to Table 3 on page 18. This table liststhe additional venting components needed (inaddition to the termination and adapter) for aparticular range of wall thicknesses.

K. Attach termination adapter - Attach theadapter (adapter - SV4.5RCH - provided withthe termination) to the vent section or tele-scoping vent section), elbow or appliance col-lar as shown in Figure 29 in the same manneras any SV4.5 vent component (refer to Step E).

L. Install Firestop/Spacer at exterior wall -When using the square termination, installSV4.5HF (Secure Vent), SF4.5HF (Secure Flex)Firestop/Spacer over the opening at the exte-rior side of the framing, long side up, with the3 inch spacer clearance at the top as shown inFigure 29, and nail into place. (The Firestop/Spacer may also be installed over the openingat the interior side of the framing).

1. Install the square termination (SV4.5HT-2)- For the last step , from outside the exteriorwall, slide the collars of the termination onto theadapter (the outer over the outer and the innerinside the inner) until the termination seatsagainst the exterior wall surface to which it willbe attached. Orient the housing of the termina-tion with the arrow pointed upwards. Securethe termination to the exterior wall.

Orient the housing of the termination with thearrow pointed upwards. Secure the termina-tion to the exterior wall.

SFHRK Snorkel Cap –The snorkel cap is de-signed to be fitted into a basement windowbox. The SFHRK cap is for use with flex ventpipe. The SV4.5HRK14 and SV4.5HRK36 arefor rigid vent pipe.

Installing the Square Horizontal Termination (SV4.5HT-2).

18 NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

H

V

**Wall Firestop/Spacer(SV4.5HF)

**When using SecureFlex, use Firestop/Spacer

SF4.5VF

*CeilingFirestop/Spacer

(SV4.5VF)

*When using Secure Flex,use Firestop/Spacer

SF4.5HF

3ELBATllaWroiretxEsuoiraVrofderiuqeRstnenopmoCgnitneV

tiKnoitanimreTerauqSehTgnisUnehW,sessenkcihT)TH5.4VS(

deriuqeRstnenopmoCgnitneV sessenkcihTllaWroiretxEmm(sehcni )

ylnOtiKnoitanimreT 4/19ot5 )532ot721(tnev.ni6dnatiKnoitanimreT

)6L5.4VS(noitces )943ot532(4/331ot4/19

tnev.ni21dnatiKnoitanimreT)21L5.4VS(noitces )205ot004(4/391ot4/351

cipocseleTdnatiKnoitanimreT.ni6dna)AL5.4VS(noitces

)6L5.4VS(noitcestnev)725ot372(4/302ot4/301

Figure 31 - Top Vent - ONE 90 DEGREE ELBOW -ELBOW CONNECTION NOT DIRECTLY AT APPLIANCE

See Table 3 as an aid in venting component selectionfor a particular range of exterior wall thicknesses.

HORIZONTAL VENT FIGURES/TABLES

Note: Secure Vent components (rigid ventpipe and terminal) are shown in the figures;Secure Flex components (flexible vent pipeand terminal) may also be used.

Note: Two 45 degree elbows may be used inplace of one 90 degree elbow. The same rise torun ratios, as shown in the venting figures for90 elbows, must be followed if 45 degreeelbows are used.

Note: It is very important that the horizontal/inclined run be maintained in a straight (no dips)and recommended to be in a slightly elevated plane, in a direction away from the fireplace of1/4" rise per foot (20 mm per meter) which is ideal, though rise per foot run ratios that are smallerare acceptable all the way down to at or near level.

Square termination(SV4.5HT-2) shown.

Note: SV4.5VF (Secure Vent), SF4.5VF (SecureFlex) firestop/spacer must be used anytime ventpipe passes through a combustible floor or ceil-ing. SV4.5HF (Secure Vent), SF4.5HF (SecureFlex) firestop/spacer must be used anytime ventpipe passes through a combustible wall.

ELBAT CmuminiMV mumixaMH

teef )m( teef )m(

1 )503.0( 4/13 )86.1(

2 )16.0( 01 )1.3(

3 )419.0( 51 )56.4(

4 )22.1( 02 )2.6(

.xaM)m4.21(teef04=H+V.xaM)m2.6(teef02=H

WARNING: UNDER NO CIRCUM-STANCES MAY SEPARATE SECTIONSOF CONCENTRIC FLEXIBLE VENTPIPE BE JOINED TOGETHER.

19NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

V

H

H1

*Wall Firestop/Spacer(SV4.5HF)

*Wall Firestop/Spacer(SV4.5HF)

*When using Secure Flex,use Firestop/Spacer

SF4.5HF

**CeilingFirestop/Spacer

(SV4.5VF)

**Note - When usingSecure Flex, use

Firestop/Spacer SF4.5VF

DELBATV M MUMINI H + H1 mumixaM

teef )m( teef )m(

1 )503.0( 4/13 )86.1(

2 )016.0( 01 )1.3(

3 )419.0( 51 )56.4(

4 )22.1( 02 )2.6(

H+H+V 1 .xaM)m4.21(teef04=H+H 1 .xaM)m2.6(teef02=

EELBATV M MUMINI H mumixaM

teef )m( teef )m(

1 )503.0( 4/13 )86.1(

2 )016.0( 01 )1.3(

3 )419.0( 51 )56.4(

4 )22.1( 02 )2.6(

V+V 1 H+H+ 1 )m4.21(teef04=.xaM

H+H 1 .xaM)m2.6(teef02=V

H

H1

V1

**Wall Firestop/Spacer(SV4.5HF)

*CeilingFirestop/Spacer

(SV4.5VF)

*When using Secure Flex,use Firestop/Spacer

SF4.5VF**When using Secure

Flex, use Firestop/SpacerSF4.5HF

**Wall Firestop/Spacer(SV4.5HF)

Figure 32 - Top Vent - TWO 90 DEGREE ELBOWS

Figure 33 - Top Vent - THREE 90 DEGREE ELBOWS

See Table 3 on page 18 as an aid in venting component selection for a particular range of exterior wall thicknesses.

HORIZONTAL VENT FIGURES/TABLES(continued)

Square termination (SV4.5HT-2) shown.

See Table 3 on page 18 as an aid in venting component selection for a particular range of exterior wall thicknesses.

Square termination (SV4.5HT-2) shown.

20 NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

5" (127 mm)Radius Minimum

SF-12 or SF-18 Flexible Vent Section

GEARCLAMPS

Adapter(SV4.5RF)

Apply ONLY MIL-PAC BLACK HIGHTEMPERATURE SEALANT (Catalog No.10K81) to the outside surface of bothcollars of the adapter (be especiallycareful to fill the grooves of the outercollar to be covered by the flexiblepipe) and slide flexible pipe overinner and outer adapter collars.

NOTE: OUTER PIPE IS PULLED AWAY TOSHOW THE DETAIL OF THE INNER PIPE

FLEX VENT

1³⁄₄ in. (44 mm)Flexible Pipe and

Adapter OuterCollar Overlap 1³⁄₄ in. (44 mm)

Flexible Pipe and Adapter InnerCollar Overlap

SECURING SCREW(3 PLACES EQUIDISTANT

JUST BELOW GEAR CLAMP)

Attach Adapter to ApplianceCollar, or Secure Vent Sections

SECURING SCREW(3 PLACES EQUIDISTANT

JUST BELOW GEAR CLAMP)

Figure 35

Figure 34

VERTICAL OR HORIZONTAL VENTING USINGSECURE FLEX KITS AND COMPONENTS

Secure Flex venting kits and components maybe used in any venting application where rigidSecure Vent (SV4.5) direct vent componentscan be used. All restrictions, clearances andallowances that pertain to the rigid pipingapply to the flexible venting. Secure Flex kitsmay not be modified; also, under no circum-stances may separate sections of flex pipebe joined together. Secure Flex kits may beadded to the end of a vent run made up of rigidSecure Vent (SV4.5) vent sections providedthat doing so does not violate any of theventing length, height, routing, horizontal tovertical ratio requirements or clearance con-siderations detailed in this manual.

Secure Flex kits come with an included adapterthat can be fitted to the appliance collar or theinclined channel end of the last Secure Vent(SV4.5) vent section in a rigid system in theexact same fashion as any other Secure Ventsection. Align the dimpled end of the adapterover the previously installed section or appli-ance collar, adjusting the radial alignment untilthe four locking dimples of the adapter arealigned with the inlets of the four incline chan-nels of the last vent section or collar. Push onthe adapter until it fully engages, then twist theadapter clockwise running the dimples downand along the incline channels until they seat atthe end of the channels.

Attach the flexible vent to the adapter asfollows (also see Figure 34 ):

A. Install the Inner Flex Pipe -

1. Install the small gear clamp loosely aroundthe inner flexible vent pipe, push it back out ofthe way.2. Apply a bead of Mill-Pac Black (700°F)high temperature sealant - Catalog No.10K81) to the inner adapter collar, approxi-mately 1/2 inches from the end.3. Pull and extend the inner flexible vent pipe.4. Slide the inner flex pipe over the adaptercollar. Ensure the flexible vent pipe completelyengages the adapter collar to a distance of 1³⁄₄

inch from the end, and that it is free fromdamage or tears.5. Slide the gear clamp down and tighten itfully to secure the flexible vent to the adapterinner collar approximately ³⁄₄ inch from the endof the flex.6. Install three screws 120 degrees apart throughthe flexible vent pipe and into the adapter collarjust below the gear clamp to provide additionalsecurity to the connection.

B. Install the Outer Flex Pipe -1. Install the large gear clamp loosely aroundthe outer flexible vent pipe, push it back out ofthe way.2. Apply a bead of Mill-Pac Black (700°F) hightemperature sealant - Catalog No. 10K81) tothe outer adapter collar; to the grooves of thecollar which extend approximately 1 inch fromthe end and to the flat surface, approximately1³⁄₈ inches from the end.3. Pull and extend the outer flexible vent pipe.4. Slide the outer flex pipe over the adaptercollar. Ensure the flexible vent pipe completelyengages the adapter collar to a distance of 1³⁄₄

inches from the end, and that it is free fromdamage or tears. 5. Slide the gear clamp down and tighten itfully to secure the flexible vent to the adapterouter collar approximately ³⁄₄ inch from the endof the flex.6. Install three screws 120 degrees apartthrough the flexible vent pipe and into theadapter collar just below the gear clamp toprovide additional security to the connection.

C. Route Flex Vent -Ensure that the flex vent is properly routed toprovide the required clearance. Do Not allowthe flexible vent to bend in a radius tighter than5" (127 mm). Refer to Figure 35. Supporthorizontal sections of flex with metal straps at2 foot (0.61 m) intervals.

Note: Secure Flex vent must be attached toSecure Flex terminations only. DO NOTsubstitute Secure Vent terminations or theSecure Vent adapter for Secure Flex compo-nents. The collars of Secure Flex termina-tions and adapters have a different circum-ference than that used with the Secure Ventpipe. Additionally, Secure Flex componentshave an extended length center tube for usein attaching the flexible vent.

D. Attach Flex Vent to Termination -Secure Flex components can be purchasedseparately and attached to bulk lengths ofSecure Flex flexible tubing cut to size at thejob site. When using this method connect theflex vent only to Flex Vent terminations, notSecure Vent terminations. Secure the flexiblevent to the Secure Flex terminations in thesame manner (see Figure 34) as it was at-tached to the adapter.

21NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Step 4. FIELD WIRING

Note: This appliance must be connected to themain power supply.

The junction box assembly is located insidethe control compartment close to the frontright side corner (see Figure 36 ). This junc-tion box contains a standard electrical junctionbox, pre-wired duplex receptacle, a cover plateand a conduit fitting (clamp connector). Ifdesired, the whole junction box assembly maybe moved to the left hand side of the controlcompartment. A knock-out is provided on thecabinet wrapper for positioning.

1. Route a 3-wire 120Vac 60Hz 1 ph powersupply to the appliance.

2. Remove the metal cover plate and the duplexreceptacle from the junction box assembly.

3. From the outside of the fireplace, loosenclamp screws on the conduit fitting. Run powersupply wires (including the ground supply wire)through conduit fitting. Tighten mounting nutof conduit fitting.

4. Connect the power supply wires to the duplexreceptacle as shown in Figure 37.

5. Reassemble duplex receptacle and coverplate on junction box. Tighten conduit fittingclamp screws to secure supply wires.

6. Insert the control circuit plug from the gasvalve into the duplex receptacle. Figure 37

BLOWER

BK

BK

G

G

W

W

WGAS

VALVE

JUNCTIONBOX

FACTORY WIRED

FIELD WIRED

BK GW

GasStub

¹ ₂" x ³ ₈" FlareShut-Off Valve

³ ₈" Flex Tubing

³ ₈" NPT x ³ ₈Flare Fitting

³ ₈" Nipple

³ ₈" Union

³ ₈" Close Nipple

³ ₈" Shut-Off Valve

¹ ₂ x ³ ₈ "Reducer

GasValve

Gas Flex Line Connector

Figure 38- GAS CONNECTION

A manual shut off valve is also provided withthe flex line. The gas control valve is locatedin the lower control compartment (refer toFigure 44). The RF control millivolt valvehas a 1/2" (13 mm) NPT thread inlet port.

Secure all joints tightly using appropriatetools and sealing compounds (ensure pro-pane resistant compounds are used in pro-pane applications).

Turn on gas supply and test for gas leaks,using a gas leak test solution (also referred toas bubble leak solution).

Note: Using a soapy water solution (50% dishsoap, 50% water) is an effective leak testsolution but it is not recommended, becausethe soap residue that is left on the pipes/fittings can result in corrosion over time. Neveruse an open flame to check for leaks.

A. Light the appliance (refer to the lightinginstructions label in the control compartmentor in the Homeowner's Care and OperationInstructions).

B. Brush all joints and connections with thegas leak test solution to check for leaks. Ifbubbles are formed, or gas odor is detected,turn the gas control knob to the “OFF” posi-tion. Either tighten or refasten the leakingconnection and retest as described above.

C. When the gas lines are tested and leak free,be sure to rinse off the leak testing solution.

D. When the gas lines are tested and leak free,observe the individual tongues of flame on theburner. Make sure all ports are open andproducing flame evenly across the burner. Ifany ports are blocked, or partially blocked,clean out the ports.

Junction Box

Figure 36

Step 5. CONNECTING GAS LINE

Make gas line connections. All codes require ashut-off valve mounted in the supply line. Fig-ure 38 illustrates two methods for connectingthe gas supply. The flex-line method is accept-able in the U.S., however, Canadian require-ments vary depending on locality. Installationmust be in compliance with local codes.

These appliances are equipped with a gas flexline for use (where permitted) in connectingthe unit to the gas line. A gas flex line isprovided to aid in attaching the direct ventappliance to the gas supply.

The gas flex line can only be used where localcodes permit. See Figure 38 for flex linedescription. The flex line is rated for bothnatural and propane gas.

WARNING: THIS APPLIANCE IS EQUIPPEDWITH A THREE-PRONG (GROUNDING)PLUG FOR YOUR PROTECTION AGAINSTSHOCK HAZARD AND SHOULD BEPLUGGED DIRECTLY INTO A PROPERLYGROUNDED THREE-PRONGED RECEP-TACLE. DO NOT CUT OR REMOVE THEGROUNDING PRONG FROM THIS PLUG.

22 NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

INSTRUCTIONS FOR RF COMFORTCONTROL VALVE

The Comfort Control Valve allows remote con-trol of temperature, fan and flame appearance.

Note: The antenna should hang in free air andaway from any grounded metal.

Operation (refer to Figure 39 )

Step 1. If the manual switch is in the remoteposition, switch it to LOCAL.

Step 2. Turn the Pilotstat knob counter-clockwise from OFF to the PILOT position,push the knob down and hold it in position.The pilot valve will open and allow gas to flowto the pilot burner.

Step 3. Actuate the plunger on the piezo(several times if necessary) until the pilotburner is lit. When the pilot burner is lit, theLED on the control will come on after ap-proximately 40 seconds. The receiver/valveis fully powered.

Step 4. Release the knob. The shaft willmove forward. The pilot burner should nowstay burning. If the pilot burner goes out,repeat Steps 2 and 3.

Step 5. Turn the knob counterclockwise tothe ON position. If the manual switch is in theLOCAL position, the main burner will turn onimmediately.

Step 6. ON the initial use of a transmitter, arecognition operation is required between thereceiver/valve and transmitter. Change the switchfrom LOCAL to REMOTE. Press the fan or flamebutton on the transmitter within 30 seconds.The LED will blink indicating the transmitter willnow work with the receiver/valve. If the switchcontinues in the REMOTE position, the transmit-ter will now control the main valve, flame modu-lation level and fan control.

Step 7. If the manual switch is in the LOCALposition, the valve will be at the highest fixedpressure setting. The transmitter will controlthe fan only.

Shut Off Procedure

If the manual switch is in the REMOTE posi-tion, the transmitter can shut off the mainburner and fan. However, the control is still onand a command from the transmitter can turnon the main burner or fan.

To shut off the system, turn the pilotstat knobclockwise to the OFF position. This action closesthe main gas and safety valves. The transmitternow cannot turn on the main burner or fan.

Piezo Ignitor

Local/RemoteSwitch

AntennaPilotstatKnob

LED

Screw Cap Of PilotAdjustment

Display- Room Temperature- Set Temperature- Flame Height Level- Fan Speed Level- Countdown Timer- Low Battery

CountdownTimer

Flame

Fan

Up(Increases FlameHeight, Fan SpeedTimer, or Set Point)

Down(Decreases Flame,Fan Speed Timer,or Set Point)

Mode- Auto

- On- Off

TRANSMITTER OPERATION -(refer to Figure 40 )

Off Mode

In the OFF mode, the fireplace flame and fanare off, the display will show OFF and displaysthe room temperature. If the receiver is inREMOTE mode, the fireplace will shut off.

On (Manual) Mode

In the ON mode, the room temperature, flameand fan levels will be shown. MANUAL willappear next to both the flame and fan icons.

When the control is in the ON mode, the flameand fan levels, and the delay timer are changedwith the up and down buttons. To change theflame level, press the flame button followed byan arrow key. To change the fan level, press thefan key followed by an arrow key. Pushing thearrow key once will change the level by one unit.

Delay Timer Mode

The shut off delay timer has a maximum of 2(two) hours and a minimum of 0 (zero) min-utes. To change the timer level, press the timekey followed by an arrow key. Pushing the keyonce will change the timer by 10 (ten) minutes.

Auto Mode

In the AUTO mode, the room temperature, settemperature, flame and fan levels will be shown.AUTO will appear next to both the flame andfan icons.

When the control is in the AUTO mode, the mainburner will turn on/off or modulate based on theheat needed to maintain the set temperature.The flame level will change automatically tooptimize the heat output needed to maintain theset temperature. To change the set tempera-ture, press the up or down key. Pushing a keyonce will change the temperature by 1 (one)degree. The setting temperature range from40° F (4.5° C) to 90° F (32.0° C).

Figure 39

Figure 40

23NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

In the AUTO mode, the fan speed will increasewith increasing flame height or decrease withdecreasing flame height. "AUTO" is displayednext to the flame and fan icons.

Fan Override During Auto Mode

If a lower or higher fan speed is desired whenoperating in the AUTO mode, the fan speed canbe overridden by pushing the fan button fol-lowed by the up or down key.

Pushing a key once will change the fan level byone unit. In this mode "AUTO" is displayed nextto the flame icon and "MANUAL" is displayednext to the fan icon.

Change Between F/C Temperature Units

Push the up and down arrow keys simulta-neously for at least 3 seconds to toggle be-tween Fahrenheit and Celsius units.

Disable Thermostat Function

To disable the thermostat function in the AUTOmode, push the time and down key simulta-neously for at least 3 seconds.

To Change Batteries

1. Remove cover on the backside of the trans-mitter. Install 3 AAA batteries as shown insidethe cover and reattach the cover.

COMFORT VALVE WIRING DIAGRAM

2. Once steps 1 thru 3 in OPERATION arecompleted, receiver/valve and transmitter arenow ready. Press any button on transmitterfor recognition precess to occur between thereceiver/valve and transmitter.

3. Use functions as described in TRANSMIT-TER section.

Troubleshooting

Step 1. Locate LED light on valve.

Step 2. LED will blink after every valid commandreceived by the transmitter; this is not an error.

Step 3. Failure codes may occur anytime afterpilot burner is lit.

Step 4. Sequence is failure code followed bylight not blinking for 4 seconds.

Step 5. In the event of multiple failure codes,next failure code follows previous failure codeby approximately 3 seconds

If an Error Code 3 is observed while perform-ing the testing, complete the following:

Step 1. Make sure the spade connectors arepushed all the way on. If the Error Code 3 isstill showing, then go to the next step.

Step 2. Switch the front two thermopile leadswith the back two. Be sure the lead is con-nected to the spade with the white dot next toit (see Figure 41 ). If the Error Code 3 is stillshowing, replace the thermopiles.

If an Error Code 8 is observed while perform-ing the testing, complete the following:

Step 1. Confirm that the valve is not inREMOTE mode.

• If the valve is producing Error Code 8 and inREMOTE mode, the valve is defective andshould be replaced.

• If the valve is in LOCAL mode and producingError Code 8, then go to the next step.

Step 2. Slide the Remote/Local switch toREMOTE and reprogram valve recognition (re-fer to in Operation section). The Error Codewill clear itself after approximately 1 1/2 min-utes and return to normal operation.

LED Failure Code Service Action(Number Of Blinks)

8 Replace valve

7 Confirm stepper motorconnection exists

5 Confirm fan connectionexists and works

4 Confirm gas type; jumperin place

3 Replace thermopiles

2 Turn fan ON

1 No action required

NOTE: Some keys are not active. This isnormal.

AUTO PATH DIAGRAM

Figure 41 Figure 42

BLOWER

WHITE

BLACK

GREEN

BLACK

GREEN

F

MF

F M

REDWHITE

REDWHITE

VALVE

F

WHITE

WhiteDots

CAUTION: LABEL ALL WIRES PRIOR TODISCONNECTION WHEN SERVICING CONTROLS.WIRING ERRORS CAN CAUSE IMPROPER ANDDANGEROUS OPERATION. VERIFY PROPEROPERATION AFTER SERVICING.

24 NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Figure 45

ThermopileIgnitor Rod