Dimethylaniline Original

-

Upload

siddhesh-phansekar -

Category

Documents

-

view

71 -

download

0

Transcript of Dimethylaniline Original

MANUFACTURING OF DMA

MAHATMA GANDHI MISSION’S

COLLEGE OF ENGINEERING & TECHNOLOGY

KAMOTHE, NAVI MUMBAI.

ACADEMIC YEAR : 2011-2012.

PROJECT REPORT

ON

MANUFACTURE OF “DIMETHYL ANILINE”

UNDER THE GUIDANCE OF

Prof : ANIL RANVEER

SUBMITTED BY-

SIDDHESH A. VEDANTE

SIDDHESH A. PHANSEKAR

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 1

MANUFACTURING OF DMA

Department of Chemical Engineering

MAHATMA GANDHI MISSION’S

COLLEGE OF ENGINEERING & TECHNOLOGY

KAMOTHE, NAVI MUMBAI.

CERTIFICATE

This is to certify that the following students,

SIDDHESH A. VEDANTE

SIDDHESH A. PHANSEKAR

have successfully completed the project report entitled “DIMETHYL ANILINE” during

the prescribed period in the academic year 2010-12. This Project report is submitted in the

partial fulfillment of “BACHELOR OF CHEMICAL ENGINEERING” of Mumbai

University.

GUIDE EXAMINER

( Prof. ANIL RANVEER )

HEAD OF DEPARTMENT PRINCIPAL

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 2

MANUFACTURING OF DMA

ACKNOWLEDGEMENTS

This project would never have seen the light of the day if it hadn’t been for support and

encouragement of multitude of very exemplary people.

We would like to sincerely thank my guide Prof. ANIL RANVEER who is the driving force

behind this project and discussion with him proved to be enlightening.

We express our sincere gratitude toward our principal Dr. GEETHA JAYARAJ & Head

of Chemical Engineering Department Dr. C K MISTRY , for providing us with the opportunity

to chose this project. We would be failing our duty if we do not acknowledge the help extended

by professors of Chemical Department of MGM’S college of engineering and technology. Our

heart felt gratitude to library and their staff member.

SIDDHESH A. VEDANTE

SIDDHESH A. PHANSEKAR

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 3

MANUFACTURING OF DMA

Table of Contents

CHAPTER 1: INTRODUCTION 5

1.1 DIMETHYLANILINE 6

1.2 HISTORY 8

CHAPTER 2: PHYSICAL AND CHEMICAL PROPERTIES 9

2.1 CHEMICAL AND PHYSICAL DATA 10

CHAPTER 3: MATERIAL SAFETY AND DATA SHEET 12

3.1 MSDS 13

CHAPTER 4: APPLICATION 20

4.1 APPLICATION 21

CHAPTER 5: MANUFACTURING PROCESS 23

5.1 PROCESSES 24

CHAPTER 6: PROCESS DESCRIPTION 25

6.1 RAW MATERIALS 26

6.2 DETAILS OF SELECTED PROCESS 27

6.3 PROCESS FLOW DIAGRAM 32

BIBLIOGRAPHY 33

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 4

MANUFACTURING OF DMA

CHAPTER 1

INTRODUCTION

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 5

MANUFACTURING OF DMA

1.1 Introduction Of Dimethylaniline

N,N-Dimethylaniline (DMA) is an organic chemical compound, a substituted derivative of

aniline. It consists of a tertiary amine, featuring dimethylamino group attached to a phenyl group.

This oily liquid is colourless when pure, but commercial samples are often yellow. It is an

important precursor to dyes such as Crystal violet.

N, N- Dimethylaniline is used as an intermediate in the manufacture of dyes and other products

and as a solvent for special purposes, a rubber

vulcanizing agent and a stabilizer. It has been

detected in ambient water and soil in the vicinity

of industrial facilities N, N-Dimethylaniline can be

detected in air by adsorption on silica gel,

desorption with ethanol and analysis by gas

chromatography and flame ionization detection.

The limit of detection is 10 l1g/sample Amines

can be liberated during the manufacture of rubber,

especially by vulcanization and by other thermal

degradations. A method was described for the

determination of free aromatic amines.

Including N,N-dimethylaniline, using high-temperature glass-capillary gas chromatography and

nitrogen-selective detection (thermionic specific detector), with detection limits of 10-20 pg.

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 6

MANUFACTURING OF DMA

A

BRIEF

HISTORY

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 7

MANUFACTURING OF DMA

1.2 HISTORY

DMA was first reported in 1850 by A. W. Hofmann, who prepared it by heating aniline and

iodomethane:

C6H5NH2 + 2 CH3I → C6H5N(CH3)2 + 2 HI

DMA is produced industrially by alkylation of aniline with methanol in the presence of an acid

catalyst:

C6H5NH2 + 2 CH3OH → C6H5N(CH3)2 + 2 H2O

Similarly, it is also prepared using dimethyl ether as the methylating agent.

Dimethylaniline undergoes many of the reactions expected for an aniline, being

weakly basic and reactive toward electrophiles. N, N-Dimethylaniline is produced commercially

by heating aniline at 300°C with

Methanol in the presence of a catalyst at high pressure; sulfuric acid, phosphoric acid or

Alumina can be used as the catalyst (Northcott, 1978; Rosenwald, 1978; Budavari, 1989).

N, N- Dimethylanilne is produced by one company each in France, Germany, Hungary,Korea,

Spain and the USA, by two companies in Japan and The United Kingdom and by four companies

in India (Chemical Information Services, 1991).

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 8

MANUFACTURING OF DMA

CHAPTER 2

PHYSICAL

AND

CHEMICAL

PROPERTIES

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 9

MANUFACTURING OF DMA

2.1 Chemical and physical data

N,N-Dimethylaniline (DMA) is colourless or pale yellow to brown, oily liquid with

characteristic amine-like odor. DMA is less dense than water and insoluble in water. Freely

soluble in alcohol, acetone, benzene, chloroform, diethyl ether, ethanol and acid solution. Stable

under ordinary conditions of use and storage. Combustible. DMA is a weak base incompatible

with strong oxidizing agents, strong acids, acid chlorides, acid anhydrides, chloroformates,

halogens. It emits toxic fumes of nitriogen oxides, carbon oxides, and aniline when heated to

decomposition. (C8H11N) MoL. wt: 121.18.

Synonyms, structural and molecular data

Chem. Abstr. Sem Reg. No.: 121-69-7

Chem. Abstr. Name: N,N- Dimethyl benzenamine

IUPAC Systematic Name: N,N-Dimethylaniline

Synonyms: (Dimethylamino )benzene; N,N-dimethylaminobenzene; dimethylanilne;

dimethylphenylamine; N,N-dimethylphenylamine

Chemical and physical properties

(a) Description: Yellowish to brownish oily liquid (Sax & Lewis, 1987)

(b) Boiling-point: 192-194 °C (ElIer, 1985; Lide, 1991)

(c) Melting-point: 2-2.45 °C (ElIer, 1985; Lide, 1991)

(d) Density: 0.956 g/ml at 20°C (Eller, 1985)

(e) Refractive Index: 1.5580

(f) Spectroscopy data: Infrared, ultraviolet and nuclear magnetic resonance spectral data have

been reported (Sadtler Research Laboratories, 1980; Pouchert, 1981, 11983; US Nation9al

Toxicology 9Pro 1)gram., 1989; Sadtler .Research Laboratories, if Solubilty: Insoluble in water

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 10

MANUFACTURING OF DMA

(2-14 g/l at 25°C). Since N,N-dimethyl aniline is a basic compound, its solubility is dependent

on the pH of the aqueous medium: its solubility in water at pH ).

7 is lower than that in water of pH .: 5. The data on aqueous solubility reported in the literature

thus vary widely (US Environmental Protection Agency, 1986). Soluble in acetone, benzene,

chloroform, diethyl ether and ethanol (Amoore & Hautala, 1983; Dragun & Hellng, 1985; Sax &

Lewis, 1987; Lide, 1991)

(g) Volatility: Vapour pressure, 1 mm Hg (133 Pal at 29.5 °C (Lide, 1991)

(h) Stability: Slowly oxidizes and darkens in air; can react with nitrous acid to form ring-

substituted nitroso compounds (US Environmental Protection Agency, 1986)

(i) Octanol/water partition coeffcient (P): 2.31 (Hansch & Leo, 1979)

(j) Conversion factor: mg/m3 = 4.95 x ppm1.

TRANSPORTATION

PACKING: 180 Kg in Drum

HAZARD CLASS: 6.1 (Packing group: II)

UN NO.: 2253

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 11

MANUFACTURING OF DMA

CHAPTER 3

MATERIAL

SAFETY

DATA

SHEET

(M.S.D.S.)

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 12

MANUFACTURING OF DMA

3.1 Material Saftey And Data Sheet

Section 1: Chemical Product and Company Identification

Product Name: N,N-Dimethylaniline

Catalog Codes: SLD3868

CAS#: 121-69-7

RTECS: BX4725000

TSCA: TSCA 8(b) inventory: N,N-Dimethylaniline

CI#: Not available.

Synonym: Xylidine

Chemical Formula: C8H11N

Section 2: Composition and Information on Ingredients

Composition:

Name CAS # % by Weight

{N,N-}Dimethylaniline 121-69-7 100

Toxicological Data on Ingredients: N,N-Dimethylaniline: ORAL (LD50): Acute: 1410 mg/kg

[Rat]. DERMAL (LD50): Acute:1770 mg/kg.

Section 3: Hazards Identification

Potential Acute Health Effects:

Very hazardous in case of ingestion. Hazardous in case of skin contact (irritant, permeator), of

eye contact (irritant), of inhalation.

Potential Chronic Health Effects:

Hazardous in case of skin contact (irritant, permeator), of eye contact (irritant), of inhalation.

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 13

MANUFACTURING OF DMA

CARCINOGENIC EFFECTS: Not available.

MUTAGENIC EFFECTS: Not available.

TERATOGENIC EFFECTS: Not available.

DEVELOPMENTAL TOXICITY: The substance is toxic to blood, kidneys, liver. Repeated or

prolonged exposure to the substance can produce target organs damage

Section 4: First Aid Measures

Eye Contact: Check for and remove any contact lenses. Immediately flush eyes with running

water for at least 15 minutes, keeping eyelids open. Cold water may be used. Do not use an eye

ointment. Seek medical attention.

Skin Contact: After contact with skin, wash immediately with plenty of water. Gently and

thoroughly wash the contaminated skin with running water and non-abrasive soap. Be

particularly careful to clean folds, crevices, creases and groin. Cold water may be used. Cover

the irritated skin with an emollient. If irritation persists, seek medical attention. Wash

contaminated clothing before reusing.

Serious Skin Contact: Wash with a disinfectant soap and cover the contaminated skin with an

anti-bacterial cream. Seek immediate medical attention.

Inhalation:

Allow the victim to rest in a well ventilated area. Seek immediate medical attention.

Serious Inhalation: Evacuate the victim to a safe area as soon as possible. Loosen tight clothing

such as a collar, tie, belt or waistband. If breathing is difficult, administer oxygen. If the victim is

not breathing, perform mouth-to-mouth resuscitation. Seek medical attention.

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 14

MANUFACTURING OF DMA

Ingestion: Do not induce vomiting. Examine the lips and mouth to ascertain whether the tissues

are damaged, a possible indication that the toxic material was ingested; the absence of such

signs, however, is not conclusive. Loosen tight clothing such as a collar, tie, belt or waistband. If

the victim is not breathing, perform mouth-to-mouth resuscitation. Seek immediate medical

attention.

Serious Ingestion: Not available.

Section 5: Fire and Explosion Data

Flammability of the Product: Combustible.

Auto-Ignition Temperature: 371°C (699.8°F)

Flash Points: CLOSED CUP: 63°C (145.4°F).

Flammable Limits: LOWER: 1.1%

Products of Combustion: These products are carbon oxides (CO, CO2).

Fire Hazards in Presence of Various Substances: Not available.

Explosion Hazards in Presence of Various Substances:

Risks of explosion of the product in presence of mechanical impact: Not available. Risks of

explosion of the product in presence of static discharge: Not available.

Fire Fighting Media and Instructions:

SMALL FIRE: Use DRY chemical powder. LARGE FIRE: Use water spray, fog or foam. Do

not use water jet.

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 15

MANUFACTURING OF DMA

Special Remarks on Fire Hazards: Not available.

Special Remarks on Explosion Hazards: Not available.

Section 6: Accidental Release Measures

Small Spill: Dilute with water and mop up, or absorb with an inert dry material and place in an

appropriate waste disposal container.

Large Spill: Combustible material. Keep away from heat. Keep away from sources of ignition.

Stop leak if without risk. Be careful that the product is not present at a concentration level above

TLV. Check TLV on the MSDS and with local authorities.

Section 7: Handling and Storage

Precautions: Keep away from heat. Keep away from sources of ignition. Ground all equipment

containing material. Do not ingest. Do not breathe gas/fumes/ vapour/spray. Wear suitable

protective clothing In case of insufficient ventilation, wear suitable respiratory equipment If

ingested, seek medical advice immediately and show the container or the label. Avoid contact

with skin and eyes

Storage: Flammable materials should be stored in a separate safety storage cabinet or room.

Keep away from heat. Keep away from sources of ignition. Keep container tightly closed. Keep

in a cool, well-ventilated place. Ground all equipment containing material. Keep container dry.

Keep in a cool place.

Section 8: Exposure Controls/Personal Protection

Engineering Controls: Provide exhaust ventilation or other engineering controls to keep the

airborne concentrations of vapors below their respective threshold limit value. Ensure that

eyewash stations and safety showers are proximal to the work-station location.

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 16

MANUFACTURING OF DMA

Personal Protection: Splash goggles. Lab coat. Vapor respirator. Be sure to use an

approved/certified respirator or equivalent. Gloves.

Personal Protection in Case of a Large Spill: Splash goggles. Full suit. Vapor respirator.

Boots. Gloves. A self contained breathing apparatus should be used to avoid inhalation of the

product. Suggested protective clothing might not be sufficient; consult a specialist BEFORE

handling this product.

Exposure Limits:

TWA: 5 CEIL: 10 (ppm) from ACGIH (TLV) TWA: 25 CEIL: 50 (mg/m3) from ACGIHConsult

local authorities for acceptable exposure limits

Section 9: Toxicological Information

Routes of Entry: Dermal contact. Eye contact. Inhalation. Ingestion.

Toxicity to Animals: Acute oral toxicity (LD50): 1410 mg/kg [Rat]. Acute dermal toxicity

(LD50): 1770 mg/kg [Rabbit].

Chronic Effects on Humans: The substance is toxic to blood, kidneys, liver.

Other Toxic Effects on Humans: Very hazardous in case of ingestion. Hazardous in case of

skin contact (irritant, permeator), of inhalation.

Special Remarks on Toxicity to Animals: Not available.

Special Remarks on Chronic Effects on Humans: Not available.

Special Remarks on other Toxic Effects on Humans: Not available.

Section 10: Ecological Information

Ecotoxicity: Not available.

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 17

MANUFACTURING OF DMA

BOD and COD: Not available.

Products of Biodegradation:

Possibly hazardous short term degradation products are not likely. However, long term

degradation products may arise.

Toxicity of the Products of Biodegradation: The products of degradation are more toxic.

Special Remarks on the Products of Biodegradation: Not available.

Section 11: Disposal Considerations

Waste Disposal:

Section 11: Transport Information

DOT Classification: CLASS 6.1: Poisonous material.

Identification: N,N-Dimethylaniline : UN2253 PG: II

Special Provisions for Transport: Not available.

Section 12: Other Regulatory Information

Federal and State Regulations: Pennsylvania RTK: N, N-Dimethylaniline Massachusetts RTK:

N,N-Dimethylaniline TSCA 8(b) inventory: N,N-Dimethylaniline SARA 313 toxic chemical

notification and release reporting: N,N-Dimethylaniline CERCLA: Hazardous substances.:

N,NDimethylaniline

Other Regulations: OSHA: Hazardous by definition of Hazard Communication Standard

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 18

MANUFACTURING OF DMA

(29 CFR 1910.1200).

Other Classifications:

WHMIS (Canada): CLASS B-3: Combustible liquid with a flash point between 37.8°C (100°F)

and 93.3°C (200°F). CLASS D-1A: Material causing

Immediate and serious toxic effects (VERY TOXIC). CLASS D-2B: Material causing other

toxic effects (TOXIC).

DSCL (EEC):R21/22- Harmful in contact with skin and if swallowed. R36/38- Irritating to eyes

and skin.

HMIS (U.S.A.):

Health Hazard: 3

Fire Hazard: 2

Reactivity: 0

Personal Protection: h

National Fire Protection Association (U.S.A.):

Health: 3

Flammability: 2

Reactivity: 0

Specific hazard:

Protective Equipment:

Gloves. Lab coat. Vapor respirator. Be sure to use an approved/certified respirator or equivalent.

Wear appropriate respirator when ventilation is inadequate. Splash goggles.

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 19

MANUFACTURING OF DMA

CHAPTER 4

APPLICATIONS

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 20

MANUFACTURING OF DMA

4.1 Applications

DYES

N, N-Dimethylaniline is used in the manufacture of Michler's ketone which is a chemical

intermediate used in the synthesis of many dyes and pigments, particularly auramine derivatives.

These pigments are used to dye paper, textiles, and leather. The main types of the dyes that can

be manufactured from DMA are alkali light yellow, alkali purple 5BN, alkali light green, alkali

turquoise blue, bright red 5 GN, bright blue. DMA is a key precursor to commercially important

triarylmethane dyes such as Malachite green or Crystal (Gentian) violet used as a histological

stain and in Gram's method of classifying bacteria.

PROMOTERS

DMA serves as a promoter in the curing of polyester and vinyl ester resins. This compound can

be used on its own with benzoyl peroxide (BPO) type catalysts or in combination with cobalt 6%

promoters with methyl ethyl ketone(MEKP) type catalysts. These systems give rapid cure at

room temperature. DMA helps the catalyst to start the chemical reaction. Promoters must never

be mixed directly with catalyst since a violent explosive reaction results.

STABILISERS

DMA is used as a stabilizer for colorimetric peroxidase determination.

FRAGRANCE

N,N-Dimethylaniline is used as an intermediate to manufacture vanillin.

PHARMA

DMA is used to manufacture cephalosporin V, madribon, sulphormethoxine and flucytosine in

medical industry. It is used as an acid scavenger in the synthesis of penicillins and

cephalosporins and has been reported as a contaminant of commercial preparations of those

antibiotics at levels of up to 1500 ppm.

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 21

MANUFACTURING OF DMA

Other Uses:

Specialty industrial solvent and rubber vulcanizing agent.

Reagent in chemical synthesis.

Catalytic hardener in certain fibreglass resins.

N,N-Dimethylaniline is used as an intermediate in the manufacture of dyes, Michler's

ketone and vanilin. It is also used as a specialty industrial solvent, a rubber vulcanizing agent

(see IARC, 1982b, 1987b), a stabilizer and an acid scavenger

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 22

MANUFACTURING OF DMA

CHAPTER 5

MANUFATURING

PROCESSES

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 23

MANUFACTURING OF DMA

1] BY ALKYLATION OF ANILINE:

REACTION:

C6H5NH2 + 2CH3OH →C6H5N(CH3)2 + 2H2O

Thus, aniline, with a considerable excess of methyl alcohol and a catalytic amount of sulfuric

acid, is heated in an autoclave at about 200oC for 5 or 6 hours at a high reaction pressure we get

dimethylaniline . Vacuum distillation is used for purification.

In the alkylation of aniline to dimethylaniline by heating aniline and methyl

alcohol, sulfuric acid cannot be used because it will form ether; consequently,hydrochloric acid is

employed, but these conditions are so corrosive that the steel used to resist the pressure must be fitted

with replaceable enameled liners.Thus in presence of Al2O3 as a catalyst is used.

2] BY NITRATION OF BENZENE:

REACTION:

Benzene ring in presence of H2SO4 reacts with nitric acid to give nitrobenzene and water. The

obtained nitrobenzene is subjected to hydrogenation in presence of palladium catalyst and ethanol gives

aniline. And further, aniline on reacting with methyl chloride or chloromethane produces N, N-Dimethyl

aniline.

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 24

MANUFACTURING OF DMA

CHAPTER 6

PROCESS

DESCRIPTION

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 25

MANUFACTURING OF DMA

6.1 Raw Materials Used

ANILINE

Aniline, phenylamine or aminobenzene is an organic compound with the formula C6H5NH2.

Consisting of a phenyl group attached to an amino group, aniline is the prototypical aromatic

amine. Being a precursor to many industrial chemicals, its main use is in the manufacture of

precursors to polyurethane. Like most volatile amines, it possesses the somewhat unpleasant

odour of rotten fish. It ignites readily, burning with a smoky flame characteristic of aromatic

compounds. Aniline is colorless, but it slowly oxidizes and resinifies in air, giving a red-brown

tint to aged samples.

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 26

MANUFACTURING OF DMA

PROPERTIES OF ANILINE

Molecular formula:C6H5NH2

Molar mass: 93.13 g/mol

Appearance: colorless liquid

Density : 1.0217 g/mL, liquid

Melting point: -6.3 °C, 267 K, 21 °F

Boiling point: 184.13 °C, 457 K, 363 °F

Solubility in water:3.6 g/100 mL at 20°C

Basicity (pKb): 9.3

Viscosity: 3.71 cP (3.71 mPa·s at 25 °C

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 27

MANUFACTURING OF DMA

METHANOL

Derived from natural gas, methanol is a hydrocarbon, comprised of carbon, hydrogen and

oxygen. Its chemical formula is CH3OH.

Methanol is an alcohol and is a colorless, neutral, polar and flammable liquid. It is miscible with

water,alcohols, esters and most other organic solvents. It is only slightly soluble in fats and oils.

Detailed physical and chemical properties of methanol are provided in the following pages.

Methanex produces methanol using a catalytic process with natural gas and steam as the

feedstocks. The natural gas is catalytically reformed to carbon oxides and hydrogen. The

resulting synthesis gas mixture is circulated under pressure and moderate temperature in the

presence of a metallic catalyst and converted to crude methanol. The crude methanol is distilled

to yield commercial chemical grade methanol.

Other common names for methanol include methyl alcohol, methyl hydrate, wood spirit, wood

alcohol, and methyl hydroxide.

Methanol is used as a building block for many chemicals and products. Other uses include

windshield washer antifreeze, fuels, waste water treatment and biodiesel production.

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 28

MANUFACTURING OF DMA

PROPERTIES OF METHANOL

Molecular formula:CH4O

Molar mass : 32.04 g mol−1

Appearance: Colorless liquid

Density: 0.7918 g cm−3

Melting point: -98--97 °C, 175-176 K, -144--143 °F

Boiling point: 65 °C, 338 K, 149 °F

Vapor pressure: 13.02 kPa (at 20 °C)

Acidity (pKa): 15.5[2]

Viscosity: 5.9×10−4 Pa s (at 20 °C)

Dipole moment: 1.69 D

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 29

MANUFACTURING OF DMA

6.2 MANUFACTURING OF DIMETHYLANILINE (DMA) BY

ALKYLATION OF ANILINE

A method for the production of dimethylaniline which consist alkylation of aniline with

use of methanol.

First methanol is passed through heat exchanger to rise the temperature to 2600 C.

Then it is passed to the reactor to convert it into dimethylether gas in presence of alumina

(Al2O3)a instead of sulphuric acid as a catalyst , because sulphuric acid is corrossive

towards the reactor vessel.

REACTION:

2CH3OH → CH3-O-CH3+H2O

METHANOL DIMETHYLETHER

The effluent from the reactor is passed to ETP and DME gas is passed to autoclave.

Here, it is mixed with aniline at high temperature and high pressure of 540 psi (3.7

MPa)about 5 to 6 hours.

REACTION:

CH3-O-CH3+C6H5NH2 → C6H5N(CH3)2+H2O DIMETHYLETHER ANILINE DIMETHYLANILINE

At the end of reaction we get dimethylaniline , which we need to purify.

To purify the mixture from autoclave, it is passed through series of vaccum distillation

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 30

MANUFACTURING OF DMA

coloumn. Thus, pure dimethylaniline is formed and passed to further processes and

storage.

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 31

MANUFACTURING OF DMA

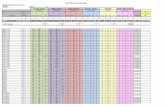

6.3 PROCESS FLOW DIAGRAM FOR DIMETHYLANILINE

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 32

MANUFACTURING OF DMA

Bibliography

ROBERT THORNTON MORRISON AND ROBERT NEILSON BOYD,ORGANIC CHEMISTRY,SIXTH EDITION.

JAMES G. SPEIGHT, CHEMICAL AND PROCESS DESIGN HANDBOOK.

Webliography

www.google.com

www.wikipedia.com

www.britannica.com

www.compositesaustralia.com

toxnet.nlm.nih.gov

ScienceLab.com

MGM’s College of Engineering & Technology Kamothe, Navi Mumbai (2011-12). Page 33