Diesel Progress June 2012

-

Upload

mauricio-ramirez -

Category

Documents

-

view

181 -

download

16

Transcript of Diesel Progress June 2012

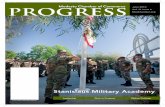

GLOBAL – PRODUCTS • TECHNOLOGY • INDUSTRY NEWS

DIESEL PROGRESS iINTERNATIONAL June 2012

www.dieselprogress.com

Tier 4 Final Engines From Perkins

Cummins’ Smallest Diesel

DAF Gears UpFor Euro 6

page 36

Doosan’s stage 3b LoaDers

page 20

More JCb MaChines

page 18

new hoLLanD roLLs out new equipMent

DPI_JuneCover.indd 1 5/8/12 11:06 AM

Worldview

Since the beginning of the Emissions Era, one of the most constant hopes is that at some point there would be har-monization — a single set of universal exhaust emissions standards to span the globe, rendering the idea of regu-lated and lesser or non-regulated mar-kets a thing of the past.

Harmonization makes nothing but sense. It allows for a better use of re-sources of all types — financial, materi-al, intellectual. It would make life easier for manufacturers of engines, vehicles and equipment, fuel suppliers, mainte-nance people — the list of beneficiaries is substantial, not to mention the gains in efficiency and productivity the own-ers and operators would see by using the latest and greatest technologies.

Yet while the regulatory environ-ment in the industrialized areas have perhaps moved closer, it’s become more clear than ever that at least for the foreseeable future — decades and decades — the idea of harmonization is something that won’t happen. And that’s for any number of reasons, not all of them technical.

In the U.S., Europe and Japan, en-vironmental standards, once estab-lished, are essentially cast in stone. In other regions, they have proven to be a little more malleable.

The fact that we’re still a long way from harmony on emissions has been highlighted in recent months by the fact that several engine manufacturers have gone to great lengths to develop engines that can be either-or in an emissions sense. Engine development is costly and they wouldn’t have taken that path if they didn’t see a patchwork of standards remaining.

You can’t expect developing societ-ies to pay too much attention to green-house gases when a large segment of their populations still lack houses, food or jobs. And because of that, harmo-nization of emissions regulations will probably remain an unwritten tune. dpi

Diesel Progress ® International Edition

Editorial & SalESMichael J. Osenga ........................... PublisherMichael J. Brezonick ........... Associate PublisherDawn M. Geske .........................Editor-In-ChiefIan Cameron ...............Regional Manager/EditorRoberta Prandi ...........Regional Manager/EditorBo Svensson ........ Field Editor/Business ManagerJack Burke ............................ Managing EditorChad Elmore ..............................Senior EditorJoseph M. Kane .....................Associate EditorBrent D. Haight.......................Associate EditorPatrick Crow ........................ Associate EditorMike Rhodes .........................Associate EditorDJ Slater ..............................Associate EditorNiki Trucksa ................... Advertising ManagerSue M. Bollwahn ............... Circulation ManagerBill Siuru ................................... Field EditorDr. W. Fleischfresser ..........Hydraulic Consultant

PUBliCatioN StaFFMarisa J. Roberts ...............Production ManagerBrenda L. Burbach .....................Graphic ArtistCarla D. Lemke ..........................Graphic ArtistAmanda J. Ryan .........................Graphic ArtistAlyssa Loope ...........................Graphic Artist

SalES oFFiCESPUBliCatioN HEadQUartErS20855 Watertown Road, Suite 220Waukesha, WI 53186-1873, U.S.A.Telephone: +1 262-754-4100 Telefax: +1 262-754-4175

GErmaN oFFiCELisa Hochkofler ................ Advertising ManagerGabriele Dinsel ................. Advertising ManagerNiemöllerstr. 973760 Ostfildern, GermanyTelephone: +49 711 3416 74 0 Telefax: +49 711 3416 74 74

italiaN oFFiCERoberta Prandi ............Regional Manager/EditorVia Fitta 21 AI-38062 Arco, ItalyTelephone: +39 0464 2430891 Telefax: +39 0464 244529

SCaNdiNaviaN oFFiCEBo Svensson ........ Field Editor/Business ManagerDunderbacksvagen 20612-46 Finspong, SwedenTelephone: +46 70 2405369 Telefax: +46 122 14787

UNitEd KiNGdom oFFiCEIan Cameron ...............Regional Manager/EditorLinda Cameron ................. Advertising Manager40 Premier AvenueAshbourne, DerbyshireDE6 1LH, United KingdomTelephone: +44 20 31 79 29 79 Telefax: +44 20 31 79 29 70

JaPaNESE oFFiCEAkiyoshi Ojima ...................... Branch Manager51-16-301 Honmoku Sannotani, Naka-kuYokohama, 231-0824, JapanTelephone: +81 45 624 3502 Telefax: + 81 45 624 3503

CHiNESE oFFiCES.H. Mok .............................. Branch ManagerRm 1405, Kowloon Building555 Nathan RoadKowloon, Hong KongTelephone: +852 3118 7930 Telefax: +852 3110 3572

Diesel & Gas Turbine PublicationsMichael J. Osenga .................. President & CEOMichael J. Brezonick ..... Executive Vice President

MEMBER OF BPA WORLDWIDE® PRINTED IN THE U.S.A.Reprints of all articles published in Diesel Progress

International are available. Please address inquiries to:[email protected]

Tel: 262-754-4147 • Fax: 262-754-4177

BY IAn CAmEron,Ashbourne, England

BY mIkE BrEzonICk, Waukesha, Wisconsin, U.S.A.

UnchainedMelody

ConneCt With Diesel ProgressYou can read Diesel Progress International electroni-cally or in print. This year Diesel Progress Interna-tional has expanded to 10 issues annually from six. The four additional issues will be delivered only in the electronic format in February, April, June and October. In the months where there are both print and digital editions, the two are identical in content. However, the electronic version, delivered via e-mail, allows you to immediately connect with articles and advertisers in every issue through the Internet or e-mail. But you have to have a subscription to do all that. And, to do that, go to:http://www.dieselprogress.com/subscribe.asp

DIESEL PROGRESS® INTERNATIONAL EDITION by Diesel & Gas Turbine Publications, 20855 Watertown Road, Waukesha, WI 53186-1873. Copyright 2012 DIESEL & GAS TURBINE PUBLICATIONS. E-mail: [email protected].

WhAT’S INSIDE …

GLOBAL – PRODUCTS • TECHNOLOGY • INDUSTRY NEWS

DIESEL PROGRESS iINTERNATIONAL

2 Worldview4 Two-Stage Turbochargers In Asian Trucks6 DAF Gears Up For Euro 68 Getting Global Access9 Diesel hR10 Volvo Penta’s Bi-Fuel Engine11 Dateline12 Greaves Entertains Engine Expansion Plans13 Brazil Notebook — CNh Expands Production In Argentina16 New U-Style hydraulic Transmission18 Intermat Unveilings20 JCB Keeps New Machines Coming21 New Development In Diesels22 Engine Unveilings From Perkins24 Vibrabsorber Shakes Off Vibration25 Powerlines26 Scania Boosts Asian Presence28 New Life For Worn Cylinder Liners30 India Notebook — BharatBenz Truck Line Unveiled33 Making heat Out Of A Pigsty34 Lynx Is Free In The Wild36 New Doosan Stage 3b Loaders38 Perkins Expands Manufacturing In India39 New Power Distribution Modules For

Ag And Forestry Equipment 40 International Business Report — Volvo, Deutz

Sign MoU … Mitsubishi Enters Chinese Joint Venture … Cummins Buys SCR Doser Company … Manitowoc Sells Direct From The U.K. …

member of

www.dieselprogress.com

Follow dieselprogress on

Cover designed by Marisa roberts

offiCial PubliCation of

EUroMoT

GETTIN

G G

LOBA

L AC

CESS

DA

F GEA

RS UP FO

R EU

RO 6

CN

h ExPA

ND

S PROD

UC

TION

IN

ARG

ENTIN

A

1386Thirty minutes after it was revealed

that Britain has plunged into the first double-dip recession since 1975 a press release arrived from the Intermat trade show organizers saying the event “heralded the 2012 recovery”.

It was hard to get excited about the release given the gloomy economic circumstances found in many parts of the world.

But the organizers of the Paris con-struction show remained bullish say-ing “The 9th Intermat confirmed the re-covery of the construction equipment sector, with a clear upturn in business worldwide …”

okay, it was a good event with more than 200 000 visitors attending.

most noticeable was the huge in-crease in the exhibitor numbers from China whose pavilions outside of the main halls were often breathtaking.

Everywhere, it seemed, there was an equipment maker with a huge array of products on show — and in many cases there was little to differentiate compet-ing offerings. manufacturers which, just a few years ago, were on the fringes of the equipment supply scenario were housed in monolithic temporary build-ings on the showground complete with the obligatory glitzy show trimmings.

For a buyer seeking a particular piece of kit there were countless oEms able to fulfill their needs. But it begged the question — who is going to buy all of this equipment?

Scratch beneath the surface and it seems there are too many oEms com-peting for business. Can they all con-tinue to survive?

Despite the Intermat assurances, the Construction Products Association, representing the Uk’s manufacturers and suppliers of construction products, recently said construction output will fall by 3% this year, will remain flat in 2013 before private sector work strengthens and drives a return to growth in 2014. Something has got to give. dpi

Who’s Right?

DPIWorldview_ToC.indd 1-2 5/11/12 9:08 Am

The 5.9-L inline six-cylinder die-sel engine from Hyundai Motor Co. (HMC) — currently power-ing medium-duty urban buses

and trucks in South Korea including the Aero Town, Green City and Mega Truck models — will be equipped with BorgWarner’s two-stage R2S turbo-charging technology.

BorgWarner said the 194 kW diesel is the first commercial vehicle engine in Asia equipped with a two-stage turbocharging system that boosts performance and fuel economy, while helping the engine comply with Euro 5 emissions standards.

”We value our successful partner-ship with Hyundai and are pleased to support optimum solutions for efficient and powerful engines in Asia’s rapidly expanding commercial diesel market,” said Pete Kohler, president and gen-eral manager, BorgWarner Turbo Sys-tems Commercial Diesel Products.

BorgWarner’s R2S turbocharging

system consists of two series-connect-ed B series turbochargers and features a BorgWarner compact brushless ac-tuator controlling the wastegate. The system enables the engine to reach a maximum torque of 981 Nm at 1400 r/min and delivers continuously high boost pressure over the entire engine speed range, said BorgWarner. To withstand the high external forces of medium- and heavy-duty applications, the high-pressure compressor stage is equipped with a milled aluminum wheel.

Two-STage TurbochargerS in aSian TruckS

Diesel Progress international 4 june 2012

engine TechnoLogY

The BorgWarner R2S two-stage turbocharging technology will boost the 5.9 L six-cylinder Hyundai diesel engine for commercial vehicle ap-plications in Asia.

contact borgwarner

BorgWarner is a supplier of turbo-charging systems in the engine output range of 20 to 1000 kW per exhaust gas turbocharger. It offers a variety of products for commercial vehicles, passenger cars, industrial equipment, locomotives and marine engines. The company is headquartered in Kirch-heimbolanden, Germany. dpi

Your Tier 4 power solution is built on 80 years of engineering expertise.

Easy to integrate into your machine design, our dependable power solutions consistently deliver high performance for you.

Working with the world’s leading construction equipment manufacturers, our Tier 4 solutions are designed with you in mind.

www.tier4air.comThe new Perkins Tier 4 engines. The heart of every great machine.

reli bilityTrust,

and reputat ion. Your machine can have it al l .

innovationyears80 of

Perkins_Construction_No DL.indd 1 5/3/12 1:37 PMDPI405.indd 1-2 5/8/12 11:10 AM

ture that is really needed. This reduc-es hydraulic losses to a minimum.”

The common rail system of the new engine allows high injection pressures of up to 2500 bar and provides the opportunity to use pre- and post-injection or a combination of both, the company said.

Borsboom added that this results in finer atomization and more possibili-ties to optimize combustion, ensuring the lowest possible emissions and noise levels, and the lowest possible fuel consumption.

“The highly advanced engine soft-ware and new sensors and actuators also play an important role in this re-spect, functioning even faster and more accurately to ensure that the best pos-sible mixture of air, exhaust gases and

fuel is injected at all times. This is also key in achieving maximum efficiency and low emissions,” he added.

According to DAF, the company claimed the main advantage of using a turbocharger with variable geometry is that the engine can benefit continuously and across its entire r/min range, with the best turbo efficiency for maximum performance. “The variable geometry turbo was also required to optimize the effectiveness of exhaust gas recircula-tion, especially at low r/min,” said Bors-boom. “This technology allows us to carefully set the amount of exhaust gas-es diverted back into the engine, which also helps fuel efficiency.”

To meet Euro 6, DAF is using a com-bination of EGR and aftertreatment technologies, such as an SCR catalytic converter and an active soot filter with the company reporting that in addition to achieving the right exhaust gas mix-ture, the aim was to create an optimum temperature in the filter to regenerate the collected particulate.

“The starting point is to allow as much passive regeneration as possi-ble by getting the engine to create the ideal circumstances for this to hap-pen,” said Borsboom. “That is why the exhaust manifold, as well as the most essential parts of the exhaust system have been encapsulated.”

If the temperature of the exhaust gas-es drops too low in any given situation, the engine will switch to active regen-eration. A seventh injector, positioned behind the turbo and ahead of the soot filter, has been added to the engine for this purpose. It injects fuel into an oxida-tion catalytic converter in the exhaust, to generate the right amount of heat.

Also the SCR catalytic converter has been optimized for temperature, said DAF, adding that thanks to its in-novative coating, it is able to achieve a maximum effect across a wider range of temperatures, which means that the engine can function optimally and in the most efficient way, making sure that exhaust gases enter the SCR cat-alytic converter at the right tempera-ture as much as possible.

For its Euro 6 technology DAF said it has implemented innovations in all areas. New is a single poly-V belt and a fan mounted directly on to the crankshaft without a coupling shaft which, DAF said saved on mainte-nance costs, improved reliability and reduced weight and fuel consumption.

A larger oil sump volume also allows service intervals of 150 000 km with Euro 6. It is made of composite mate-rial to reduce weight and noise levels. The fuel filter and water separator have been combined into a single unit which is mounted directly on the engine for ease of maintenance, and the oil cooler — combined with the oil filter — is now made from stainless steel to increase its robustness. The Euro 6 engine en-ters production in early 2013, with out-puts of 300, 340 and 375 kW.

Ray Ashworth, managing director of U.K.-based DAF Trucks Ltd. said, “This is a clear demonstration that DAF has the technology ready for Euro 6 and in-deed learnt a lot from its sister product — the EPA10 MX engine.

“Whilst that engine uses the technol-ogy platform and SCR and EGR, to-gether with a closed type particulate fil-ter, our new Euro 6 engine is very much more sophisticated. The integration of the aftertreatment system using over 40 sensors, 14 control units and common rail fuel injection running at 2500 bar pressures and variable geometry tur-bocharger technologies make this new MX13 Euro 6 engine a much more com-plex product development challenge.

“All this Euro 6 development doesn’t mean we’ve stopped Euro 5 develop-ment. We will carry on building Euro 5 alongside Euro 6 in the coming years because DAF is a very different com-pany to that of only five years ago. Many parts of the world remain happy with Euro 3 or Euro 5 technology in-cluding our new markets of Brazil, In-dia and China where PACCAR has in-vested heavily over recent years.” dpi

Diesel Progress international 7 june 2012

DAF GeArs Up For Euro 6

Launches 12.9 L PACCAR MX-13 engine family rated 300 to 375 kW; enters production in early 2013

By Ian Cameron

Netherlands-based DAF Trucks has announced a new engine generation developed for Euro 6 emissions legislation. The

company has launched a 12.9 L Euro 6 PACCAR MX-13 engine that uses com-mon rail technology and a turbo with variable geometry. It also features ex-haust gas recirculation (EGR) together with selective catalytic reduction (SCR) technology and an active particulate filter.

According to Ron Borsboom, mem-ber of the DAF Trucks N.V. Board of Management and with responsibility for product development, a quarter of the Kenworth and Peterbilt trucks, which are made by PACCAR, supplied in the United States since the summer of 2010 are equipped with the six-cylinder 12.9 L PACCAR MX engine with EPA ‘10 speci-fications. DAF Trucks N.V. is a subsidiary of American company PACCAR Inc. and has factories in Eindhoven, Netherlands and Westerlo, Belgium.

“The PACCAR MX-13 engine is ultra clean,” said Borsboom. “This engine complies with current North American legislation, which emissions values

durability, as many functions as pos-sible have been integrated.

“For example, plumbing has been cast into the cylinder block and head and the two pump units that generate pressure in the common rail system have been integrated into the block, which means they can be actuated by the same cam-shaft that drives the valves.

“The fuel in the central pipe is sup-plied using smart dosing controls to ensure optimum efficiency by only compressing the amount of fuel mix-

come close to those set out in Euro 6. We have therefore been able to build up vast experience of technologies we will now be applying in Europe for Euro 6, such as EGR, a variable geometry turbo and an active soot fil-ter. We have further developed these technologies, focusing in particular on how we can best integrate them into the European vehicle configuration.

“A good example is the higher posi-tion of the EGR cooler, which allowed us to place the turbo closer to the block, further reducing the overall size of the engine. In addition, we will of course also be applying technologies to the Euro 6 PACCAR MX-13 engine that has recently been introduced as part of our program for Euro 5. An en-capsulated exhaust manifold for even better turbo efficiency and optimized piston rings and cooling are just a few examples of these technologies.

“The block has been redesigned for even better stiffness and like the cylinder head it is made of strong compact graphite iron. With a view to ensuring maximum reliability and

Diesel Progress international 6 june 2012

ENGINES

contact DaF

DAF Trucks has announced the 12.9 L PACCAR MX-13 engine for Euro 6. The engine has outputs of 300, 340 and 375 kW and incorporates exhaust gas recirculation (EGR), selective catalytic reduction (SCR) and an active particulate filter.

According to DAF the Euro 6 PACCAR MX-13 engine uses common rail technology and a turbo with vari-able geometry, allowing the engine to benefit continu-ously and across its entire r/min range, with the best turbo efficiency for maximum performance.

DPI404.indd 1-2 5/11/12 2:30 PM

GettinG global access

Worldwide availability for Trimble CenterPoint RTX correction service

Trimble has made its CenterPoint RTX (real-time extended) correction serv-ice available worldwide for agricultural customers. The global positioning

serv ice (GPS) and global navigation satellite system (GLONASS)-enabled service is de-livered via cellular communication and is cur-rently certified for use in 38 countries.

The Centerpoint RTX correction service combines RTX positioning technology with cellular communications delivery. Accuracy of the RTX service is within 4 cm, Trimble said, adding that the service is best suited for farms located anywhere in the world and farms outside of real-time kinematic (RTK) base station coverage areas. The service is used with row crops and other applications requiring 4 cm horizontal accuracy.

“Trimble has been developing technology and positioning solutions for a variety of ap-

Diesel Progress international 8 june 2012

lite signal becomes lost, the machine is able to work for up to two minutes without access, Trimble said.

Expanding the RTX service glob-ally further extends Trimble’s portfolio of correction services, which also in-cludes the CenterPoint RTK, Center-Point VRS and OmniSTAR VBS, HP, XP and G2.

Trimble said the CenterPoint RTK service is designed for farms located within 13 km of an established RTK base station or base station network. It is best suited, Trimble said, for uses without line-of-sight obstructions such as hilly terrain or an abundance of trees. Applications include use in row crop farming, strip tilling, land level-ing and drainage work, which require horizontal and vertical accuracy. The service provides 2.5 cm accuracy.

The Centerpoint VRS service also has 2.5 cm accuracy. It is designed for farms in areas with robust cellular cov-erage and operations spread out over a large geographic area. The service is used with row crops and other ap-plications requiring 4 cm accuracy.

Trimble’s OmniSTAR HP service provides accuracy from 5 to 10 cm and is suited to broad acre seeding, spraying and harvesting applications. The OmniSTAR XP service has accu-racy to 7.6 to 10 cm and is typically used in broad acre spraying and land-tillage applications in areas with open view of the sky at all times.

The OmniSTAR G2 service also has accuracy to 7.6 to 10 cm. It is designed for users requiring more reliable cover-age time by using the GLONASS satel-lites in addition to standard GPS. This is for use in operations with open view of the sky at all times.

The OmniSTAR VRS provides 1 m of accuracy and targets operators that want a quick start-up time and don’t need the highest level of accuracy or repeatability, Trimble said. It is used with broad acre crop spraying and till-age applications. dpi

TELEMETRY

Diesel Progress international 9 june 2012

ContaCt trimble

FINNRADIATOR: Finnradiator Ltd. appointed Juho Partanen as its sales director. Previously, Partanen worked as export direct for the company for more than two years. In this new position, Partanen is responsible for Finnradiator’s domestic and international customers.

New GM AtCummins Marine

Cummins Inc. has named Jenny Bush general manager for its Commercial Marine Business headquartered in Charleston, South Carolina, U.S.A. She will be responsible for all commercial marine business activities for the Engine Business Unit (EBU) globally, in cluding business development and support, and will report directly to Mark Levett, vice president of the High Horsepower Engine Business.

She succeeds Geoff Conrad, who will serve as the QSK95 Account Executive for Commercial Marine. In this role, Conrad will be responsible for the marketing and product introduction for the new large engine platform announced in November.

Bush has been with Cummins for more than 15 years, serving in a variety of leadership roles within the business including service engineering for the oil & gas and automotive markets and distribution technical support in Europe, the Middle East and Africa. Most recently, she led global purchasing and operations for Cummins Generator Technologies.

GAC: Governors America Corp., a provider of engine governing and system controls, has hired Marko Jocic as its vice president of sales and marketing. He is responsible for leading sales and marketing initia

tives for the company. Jocic joined Governors in 2009 as the marketing manager for the Fuel & Ignition Management Systems (FIMS) product line. Prior to that, he served in technical roles in design, service and applications engineering with several companies, such as JLG Industries, McNeilus Companies, Cummins MerCruiser Diesel and Stanadyne Corp.

TOPCON: Topcon Precision Agriculture (TPA) has named Leandro Crum-menauer as its technical manager in South America. In this position, Crummenauer will serve the South American market and establish shortterm and longterm goals and objectives for TPA in the area. C r u m m e n a u e r previously spent the past five years as a technology specialist for BASE Assessoria Agronômica in Silveira Martins – RS, Brazil. In that role, he gained experience with precision agriculture products by performing support, demonstrations, training and field tests for machine control products for AGCO of Brazil.

JACOBS: Thomas Howell has been appointed director of New Technology at Jacobs Vehicle Systems, a global supplier of commercial vehicle heavy

duty diesel engine retarding and valve actuation systems. Prior to joining Jacobs, Howell spent 15 years at Ricardo in which he held various roles of increasing respon

sibility, with his latest position chief engineer, engines, where he was responsible for business development, technical leadership and commercial delivery for projects ranging from clean sheet engine design to waste heat recovery demonstrator.

dieselhr

L. Crummenauer

J. Bush

T. Howell

M. Jocic

uses Farm Works office software and can be used with any equipment brand, Trimble said. The RTX service is also compatible with Trimble’s AG-732 GNSS receiver.

Using the modem, the CenterPoint RTX correction service delivers global naviga-tion satellite systems (GNSS)-enabled repeatable corrections to farm equipment located anywhere in the world. Trimble said corrections can be sent to the cen-tral swath of North America via satellite or worldwide via the mobile data network. GLONASS satellite access is unlocked for free for the duration of the subscription.

Initialization is as quick as a minute in certain parts of the world, Trimble said. Start-up initialization can also be de-creased to less than five minutes at the beginning of each day by starting a tractor in the same place it was shut off. If a satel-

plications and industries for decades,” said Patricia Boothe, general manager of Trim-ble’s Positioning Services Division. “Over time, we have expanded our service offer-ings to include a broad range of solutions to satisfy users’ needs. Now Trimble offers a unique service — worldwide real-time 4 cm corrections. While the CenterPoint RTX service is initially being offered for agricul-ture applications, we look forward to offering global solutions and services across a vari-ety of applications and markets.”

Ag customers subscribing to the service need Trimble’s DCM-300 modem and a cel-lular data plan to activate the RTX service. The DCM-300 modem provides wireless 3G connectivity. It can also be used for wireless data transfer between the Trimble FmX and CFX-750 displays, which the RTX service is also compatible with. The modem

DPI383.indd 1-2 5/11/12 2:34 PM

Need more information on industry shows? Turn to www.dieselprogress.com

*Indicates shows in which Diesel Progress International Edition will participate.

Follow dieselprogress on

*May 29-June 2 ConExpo Russia at CTTCrocus International Exhibition CenterMoscow, RussiaThe Association of Equipment Manufac-turers (AEM)6737 West Washington St., Suite 2400Milwaukee, Wisconsin 53214-5647 U.S.A.Tel: +1 (414) 298-4141Fax: +1 (414) 272-2672E-mail: [email protected]: www.conexporussia.com

*June 12-14Power-Gen Europe 2012Koelnmesse, Cologne, GermanyPennwell Global Energy GroupPennwell House, Upshire EN9 3RS, U.K.Tel: +44 1992 656 610Fax: +44 1992 656 700E-mail: [email protected]: www.powergeneurope.com

*Sept 18-21 InnoTrans 2012Messe Berlin, Berlin, GermanyMesse Berlin GmbHMessedamm 2214055 Berlin, Germany

Tel: +49 30 30 38 2376Fax: +49 30 30 38 2190E-mail: [email protected]: www.innotrans.de

*Sept 20-27IAA Commercial Vehicles 2012Messegelaende Hannover, Hannover, GermanyVDA Verband der AutomobilindustrieWestendstr. 61, 60325 Frankfurt/Main, GermanyTel: +49 69 975 07-0Fax: +49 69 975 07-261E-mail: [email protected]: www.iaa.de

Sept 25-28MDA RussiaAll-Russian Exhibition Center (V.V.C)Moscow, RussiaDeutsche MesseMessegelaende, 30521 Hannover, GermanyTel: +49 511 89-0Fax: +49 511 89-32626E-mail: [email protected]: www.mda-russia.com

Oct 10-13 AgrosalonCrocus Exhibition Centre

Moscow, RussiaIFW Expo Heidlberg GmbHLandfriedstr. 1a, 69117, Heidlberg, GermanyTel: +49 6221 1357-17E-mail: [email protected]: http://agrosalon.com

Oct 18-21 SAIE 2012BolognafiereBologna, ItalyBolognaFiere s.p.a.Viale della Fiere 20, 40127 Bologna, ItalyTel: +39 051 282111Fax: +39 051 6374013E-mail: [email protected]: www.saie.bolognafiere.it

*Nov 27-30 Bauma China 2012International Trade Fair for Construction Machinery, Building Material Machines, Construction Vehicles and EquipmentShanghai New International Expo CenterShanghai, ChinaMesse Muenchen GmbHMessegelaende, 81823, Munich, GermanyTel: +49 89 949 20251Fax: +49 89 949 20259E-mail: [email protected]: www.bauma-china.com

VolVo Penta’s Bi-Fuel engine

New dual-fuel 16 L Tier 4 interim engine targeted for applications in the oil and gas exploration markets

By Bo SvenSSon

Volvo Penta is launching what it calls a “bi-fuel” engine tar-geted at the global oil, gas and construction industries.

The fuels involved are a precision blend of natural gas and diesel fuel. Thus, the new Volvo Penta model TWG1663GE is expected to provide fuel-cost savings, high power density, along with advanced SCR to meet EPA Tier 4 interim, as well as Cali-fornia Air Resources Board (CARB) emissions regulations.

The TWG1663GE is a four-stroke, inline, six-cylinder configuration avail-able for 1800 r/min, 60 Hz operation. With a generator efficiency of 94%, the engine can produce 559 kWe in prime power applications and 615 kWe in standby use. Mechanically, the engine can produce 595 kW for prime power and 654 kW in standby.

Fuel blending and combustion con-trol is integrated into the Volvo Engine Management System (EMS).

The Volvo Penta bi-fuel principle enables this heavy-duty diesel base engine to operate on ratios of up to 70% natural gas and 30% diesel fuel under normal loads, and slightly less natural gas during higher loads. The TWG1663GE can also run exclusively on diesel fuel.

“Bi-fuel technology is attractive to many industries, but bi-fuel Tier 4i power — in markets where natural gas is readily available — helps the U.S. aim for energy independence in an environmentally friendly way,” said Apple. “With the boom in natural gas recovery across the United States, the industry needs the high power ca-pability, low operating costs and Tier 4i compliance.”

The 144 mm bore and 165 mm stroke provide the 16.1 L displace-ment. The compression ratio is 16.5:1. Weight is listed by Volvo Penta at 1700 kg.

“Volvo Penta developed the TWG1663GE with off-the-grid power generation in mind, which specifically serves the expanding U.S. oil and gas markets and the unconventional gas well stimulation industry,” said Bob Apple, vice president of Volvo Penta’s industrial engine business in North America.

The engine is 100% Volvo Penta, with no add-on systems required. In operation, natural gas is introduced upstream of the turbochargers and an electronic air valve controls the amount of natural gas mixed. Engine compression ignites the diesel fuel, which in turn ignites the natural gas.

Diesel Progress international 10 june 2012

Volvo Penta said it developed the new dual-fuel TWG1663GE with off-the-grid power generation in mind, which specifi-cally serves the expanding U.S. oil and gas markets. The engine is shown here fitted with an electric generator, which is nor-mally not supplied by Volvo Penta.

Volvo Penta said emissions out-put meets U.S. EPA and CARB Tier 4i limits, regardless of how the engine blends the two fuels. Like the complete Volvo Penta Tier 4i prod-uct range, the TWG1663GE utilizes

Dual-Fuel engines

Diesel Progress international 11 june 2012

contact volvo

Volvo Penta’s new four-stroke, inline, six-cylinder model TWG1663GE dual-fuel engine is available for 1800 r/min, 60 Hz operation. It can operate on ratios of up to 70% natural gas and 30% diesel fuel un-der normal loads, and slightly less natural gas during higher loads. It can also run exclusively on diesel fuel.

Volvo’s SCR technology to reduce NOx and particulate emissions.

SCR is found in Volvo, Mack and Renault truck brands within the Volvo Group, as well as in Volvo Penta’s off-

road engines.Sharing the same power rating

as the recently launched TWD1663GE diesel version, the TWG1663GE bi-fuel engine is a Tier 4i product

that utilizes two-stage turbocharg-ing to provide the power density and load acceptance.

“Adding bi-fuel technology to this engine allows us to deliver our Tier 4i product range to industries where natural gas is plentiful and high power density is critical,” said Apple. dpi

dateline

DPI360.indd 1-2 5/11/12 2:35 PM

Diesel Progress international 13 june 2012

brazilnotebook

by Mauro belo Schneider

CNH is investing US$100 mil-lion to increase its produc-tion in Cordoba, Argentina. Following a meeting with the

Argentina President Cristina Kirch-ner, Sergio Marchionne, Fiat’s CEO, (Fiat is the parent company of CNH) announced the manufacturing expan-sion that includes three ranges of combines, two tractors, diesel engines and drapers (the platform that cuts the beans at the front part of the combine).

The 40 000 m2 Cordoba plant will begin full operations by the end of this year. Sixty jobs have already been added, as the assembly of CKD combines and tractors have started at the Iveco site.

“We are already manufacturing these products at Iveco’s plant with

pieces imported from Brazil,” said Ricardo Ribeiro, CNH purchasing di-rector in Brazil, in an exclusive inter-view with Diesel Progress Interna-tional. “When the factory is ready, we will manufacture components locally and will have Argentinean suppliers.”

The combines manufactured at the site will be branded New Holland or Case IH. Two types of tractors will be produced: one of medium and the oth-er of high power, 134 kW and 149 kW.

“In 2014 we will accelerate the pro-duction to get into 2015 with 2500 trac-tors and 1500 combines being manu-factured a year,” Ribeiro said. CNH also has an agreement with the Argen-tinean government to reach 40% local content by the end of 2013, he said.

Ribeiro explained that CNH decided to increase its production in Argentina because the group already has a Fiat site in the country, which manufactures Iveco trucks. “We are also reactivating

our Fiat Powertrain plant that was de-activated since last year,” he said.

The decision was also accelerated because of the foreign trade policies in South America that is impacting the dispatch of ag machinery manufac-tured in Brazil for Argentina.

“We had plans to expand in Argenti-na for some time and it made us hurry even more,” Ribeiro said. “Of course there is something to do with the de-mand of the Argentinean government of balancing the balance of trade be-tween the two countries.” He said that the Argentinean output will serve the South American market, but Brazil will continue being served by the Curitiba (for tractors and combines) and Soco-caba (combines) plants.

According to Ribeiro, the expecta-tion of the Brazilian market this year is of stability, compared to 2011. “We will have a market of 65 000 agriculture

CNH ExpaNds produCtioN iN argENtiNa

Argentina President Cristina Kirchner and Sergio Mar-chionne, CEO of Fiat (right), jointly announced a manufac-turing expansion for CNH in Argentina that includes three ranges of combines, two tractors lines as well as diesel engines and drapers.

Mauro Belo Schneider is a Diesel Progress cor-respondent based in Porto Alegre, Brazil. His e-mail is [email protected].

Greaves entertains EnginE Expansion plans

Considers entering light-, medium- and heavy-duty truck engine market

by ian caMeron

indian engine company Greaves Cotton is examining plans to enter the truck engine market. The com-pany has confirmed that it is con-

sidering producing engines for light-, medium- and heavy-duty trucks with-in a two to three year timeframe. It has also studied the prospect of manufacturing engines for the pas-senger car industry.

Mumbai-based Greaves, the par-ent of German company Greaves Farymann Diesel which is located in Lampertheim, manufactures a wide range of industrial products for Indian and overseas companies including diesel and petrol engines, gen-sets, pump sets and construction equip-

The company said it is targeting both the sub-1 tonne truck market and is also examining the 2 tonne plus truck segment.

Greaves Farymann engines are in the 3 to 160 kW power range and the company recently said the Fary-mann portfolio is being extended in cooperation with Greaves Cotton and will include three- and four-cylinder models for stationary ap-plications, some already compliant with Tier 3 emissions regulations. In the lower power range, Greaves Farymann is working to make its single-cylinder diesel engines from 2 to 12 kW suitable for constant speed applications. dpi

ment such as concrete mixers, con-crete pumps, batching plants, vibra-tory compactors, wheel loaders and motor graders.

The company’s industrial engine division supplies units for a vari-ety of applications such as marine, agricultural equipment, generator sets, firefighting pump sets, cranes, forklifts and rail cars. The engines are produced at Indian factories in Pune, Aurangabad, Gummidipoondi, and Ranipet.

Greaves is also a supplier of small diesel and petrol engines for auto-motive applications such as three wheelers and small four wheel com-mercial vehicles.

Diesel Progress international 12 june 2012

iNdustry NEws

Greaves Cotton produces engines for a variety of applications such as marine, agricultural equipment, generator sets, firefighting pump sets, cranes, forklifts and rail cars. Its subsidiary Greaves Farymann produces 3 to 160 kW en-gines including this four-cylinder inline turbocharged 275 WT diesel engine rated 55 kW at 1500 r/min.

continued on page 14

DPI415.indd 1-2 5/7/12 4:45 PM

nents that are exported to MWM units in Brazil and the United States. Furthermore, this plant has all the engine assembly and dynamom-eter test structure, the company said.

The Jesus Maria plant intends to manufacture, initially, industrial and bus engines. Production numbers and the amount of money to be invested were not disclosed.

Navistar, JAC To Commercialize Trucks In Brazil

Navistar International Corp. and China’s Anhui Jianghuai Automobile (JAC) announced that the two companies have signed letters of intent to commercialize light- and medium-duty truck lines in Brazil.

Under the deal, JAC would export certain light- and medium-duty cab-over commercial trucks to complement the existing medium- and heavy-duty aero-nose com-mercial trucks sold under Navistar’s International truck brand in Brazil.

According to Navistar’s South American CEO, Waldey Sanchez, the partnership would allow International to in-crease its portfolio of truck models.

“We have an ongoing partnership with JAC to pro-duce MaxxForce diesel engines and this new agree-ment adds further collaboration between our compa-nies,” said Sanchez. “This agreement will result in new business opportunities for Navistar’s International truck dealer network in Brazil, boosting our product portfolio with new truck models.”

Navistar International has operated in Brazil since 1998, in Caxias do Sul, Rio Grande do Sul State. Currently, the company manufactures and commercializes two models in

colock, which blocks the vehicle start-ing in case the driver presents drunk-enness signs.

The urban bus line also has new features including the new Ecolife au-tomatic transmission box as well as a new acceleration control system. The Ecolife transmission reduces the fuel consumption up to 6%, Volvo said, along with other operational costs.

Uruguay’s Patriarca To Build In Brazil

The Uruguayan bus body builder Patriarca announced that is going to construct a 15 000 m2 plant in Bagé, Rio Grande do Sul State, Brazil, with an initial investment of around US$6.0 million (Rs11 million).

Patriarca manufactures compo-nents, final bus bodies, microbuses, school buses, road buses and others. The company intends to start working at the site in the second half of 2012 and forecasts production could start about 24 months after the startup. An-nual production is expected to be 540 buses a year. Most of the production is expected to be used in the Brazilian market, though a percentage will be exported, Patriarca said. dpi

machines. CNH has a market share of 23% in tractors and 35% in combines. In the construction field, we have a market share of 26% and the expec-tation is an increase of 12 to 15% this year.”

Initially, CNH planned to launch two ranges of tractors and one of com-bines. However, after the meeting be-tween Kirchner and Marchionne, the plan changed and the production of drapers of 4 or 5 m was confirmed. “It was presented as an expansion, a second phase of the investments in Argentina,” Ribeiro said.

Some days before announcing the expansion of the production in Ar-gentina, CNH also said it is going to build a new plant in Brazil, in Montes Claros, Minas Gerais State. The in-vestment at the site was US$350 mil-lion (Rs600 million).

The company intends to manufac-ture construction equipment at the site. A memorandum was signed in Tu-rin, Italy. Fiat has had factories in Bra-zil since 1970 and manufactures both Case and New Holland Construction branded products in the country.

The plant is expected to begin op-eration in 2014. About 2700 jobs will be generated. The total area of the complex in Montes Claros will reach 2 million m2.

MWM To Restart Diesel Production In Argentina?

MWM said it is evaluating restart-ing bus diesel engine production at its Jesus Maria, Cordoba facility (pictured) in Argentina. Full details were not disclosed, but MWM, which is a Navistar subsidiary, issued an official statement about the subject. The announcement was made in Canoas, Rio Grande do Sul State, Brazil, during the opening ceremo-ny of a new diesel engine line for Chevrolet cars.

MWM International said that it is evaluating restarting engine produc-tion in Jesus Maria, Argentina. This plant is dedicated to the production of diesel engine systems and compo-

MWM’s Jesus Maria, Cordoba facility in Argentina.

Volvo Bus Introduces New Chassis Line

Volvo Bus Latin America introduced a new line of chassis in Brazil. The mod-els will be used in eight urban and six road vehicles — all powered by Volvo selective catalytic reduction (SCR) die-sels to meet Proconve P7/Euro 5 rules.

The new chassis will be available in 4X2 versions for the B340R and B380R models; as 6X2s — the mod-els B380R, B420R and B450R (pic-tured) models; and 8X2 for the models B420R and B450R.

“The new chassis are lighter, allow-ing a bigger volume of loads, and they result in an economy of up 12% in the consumption of fuel comparing to the previous models,” said José Luis Gon-çalves, manager of the road bus line for Volvo Bus Latin America.

The new buses also come to the market with a new suspension system, offering more stability and comfort. Fur-ther, the chassis’ are equipped with the I-Shift electronic gearbox and with an intelligent ABS/EBS brake system that, in an emergency sends more pressure to the wheel, increasing its efficiency.

Another interesting feature is the presence of a breathalyzer called Al-

brazilnotebook

the Brazilian market, the heavy International 9800i model as well as the International DuraStar.

“As we await the final authorizations of our joint venture agreements with JAC, we are excited to enter the Chinese market and bring our expertise to China,” said Troy Clarke, president, Navistar Asia Pacific. “As part of the next stage of our collaboration, we’re excited for the op-portunity to import JAC trucks into a key growth market like Brazil.”

Navistar International Corp. and China’s Anhui Jianghuai Automobile (JAC) announced that the two companies have signed letters of intent to commercialize light- and medium-duty truck lines in Brazil.

DPI415.indd 3-4 5/11/12 2:41 PM

By Bo SvenSSon

Sauer-Danfoss has introduced the LDU20 U-Style hydrau-lic transmission for applica-tions such as zero-turn mow-

ers, golf equipment, compact and sub-compact tractors, and specialty agricultural machines. Integrating a closed-circuit variable displacement piston pump with direct displacement control and a fixed motor in a single U-style housing, the compact LDU20 offers OEM equipment designers an easy-to-install package.

Developed for vehicles with an ex-ternal charge source, the LDU20 at-taches directly to the housing of a customer’s transmission, eliminating hosing and piping, which is designed for space savings and simplified in-stallation. The utilization of a common charge pump for flow to the steering or work functions offers the added ben-efit of reducing overall vehicle cost,

Sauer-Danfoss said. Dimensions of the LDU20 are 170 mm long, 180 mm wide and 240 mm high.

“The package size, performance and the installation cost of the LDU20 have been optimized to fulfill the demand of OEMs and their end users,” said Toshihiro Naruse, prod-uct marketing manager for Sauer-Danfoss. “While most shaft center-lines in the industry measure more than 100 mm, the LDU20 has a shaft centerline of 85 mm. This is the same as traditional Bantam Duty U-style transmissions and offers more power density.”

By reducing friction from the piston- cylinder block-bore interface, the LDU20 piston architecture is engi-neered to improve fuel efficiency, re-duce oil temperature and extend oil life with an overall efficiency of ap-proximately 80%.

New U-Style HydraUlic traNSmiSSioN

Diesel Progress international 16 june 2012

moBile HydraUlicS

Sauer-Danfoss’ LDU20 U-Style hydraulic transmission offers higher efficiency, lower noise and reduced vibration for application in zero-turn mowers, golf equipment, com-pact and sub-compact tractors, and spe-cialty agricultural machines.

The LDU20 design features re-duced noise and vibration to ensure a comfortable working environment for the operator and is compliant with applicable noise regulations. A low operating force of a maximum 25 Nm at 2500 rpm, 300 bar, further ensures a comfortable working environment, Sauer-Danfoss said.

Transmissions are often installed directly beneath where an operator is seated, where noise and operating vibration can adversely impact com-fort and productivity. Operator comfort and productivity have been prioritized throughout the development process, said Naruse. A trunnion journal bear-ing helps reduce resonance between swash-plate vibration and the linkage of the vehicle. dpi

contact sauer-danfoss

The c rea t ion of f resh T ie r 4 power Solut ions.

Our Tier 4 engines give you what you need. Our Technology Integration Workshops involve our customers from concept to delivery, in a new way of working together. So you can expect dependable power, backed by flexible, fully integrated engine solutions – providing a more productive machine, operating with a lifetime of low cost.

Who says you can’t have it all? Find out how you can by visiting

www.tier4air.com/DPIThe new Perkins Tier 4 engines. Blue sky thinking in every way.

Perkins.indd 1 12/9/11 9:05 AMDPI388.indd 1-2 5/8/12 11:21 AM

The Paris, France-based 2012 Intermat international con-struction exhibition wrapped up with more than 200,000

visitors which organizers said was a 15.8% increase over 2009. Among the new product launches announced at Intermat was a range of new Stage 3b compliant construction vehicles by New Holland.

Antonio Strati, product manager of New Holland’s Marketing Europe Construction Equipment, said that 90% of the New Holland range is ready for Stage 3b. The full offering will be completed by the end of 2012.

For Stage 3b compliance New Hol-land relies on the selective catalytic re-duction (SCR) solution by sister com-pany FPT Industrial. With this solution, Stage 3b emissions standards are met without a diesel particulate filter (DPF) and exhaust gas recirculation (EGR). The company said that the optimized combustion, delivers more power with less fuel, while the cooling and oil sys-tems are not affected.

New from New Holland were the C Series crawler excavators and wheel loaders, a complete four model back-hoe loader range and the compact LM625 telehandler for urban con-struction sites. Also on display was the next generation E140C SR short radius excavator, which will reach the markets later in the year.

Turkish Manufacturers Launch Construction Equipment

Intermat was also the stage for the launch of two new vehicles by two Turk-ish manufacturers, stating the impor-tance of the Parisian show for the Afri-can and Middle East markets — both of key importance for Turkish companies.

Hidromek officially launched its new Gen series crawler excavators, together with the new Maestro series backhoe loaders; a range of Stage 3b vehicles featuring 4.5 L John Deere engines and ZF powershift trans-missions (see more in the January and March 2012 issues of Diesel Progress International).

The second Turkish manufacturer, Sanko Makina, introduced a new MST backhoe loader that complies with Stage 3b regulations. The back-hoe loader is equipped with an electronically-controlled Perkins 1204E en-gine, NO

x reduction system and diesel particulate filter (DPF).A third Turkish OEM, Çukurova, was also exhibiting a selection of its

excavators, wheel loaders, backhoe loaders and forklifts. Included in the display was the 880 Grande backhoe loader, equipped with a Perkins 1104D-44T turbocharged engine. Gül Nalçaci, export sales director at Çukurova, said the 880 Grande is a popular vehicle for low-regulated markets and over 150 units have been sold among Tunisia, Georgia and Taiwan (for the Taiwan military). New target markets for this machine are South America and Europe. Nalçaci added that Çukurova, a long-standing customer of Perkins engines, has started to also adopt John Deere engines for some of its vehicle models.

Intermat UnveIlIngsOEMs launch new construction equipment; Stage 4 announcements from engine manufacturers

Diesel Progress international 18 june 2012

IndusTry news

The new 12.7-tonne W130C wheel loader by New Holland complies with Stage 3b regulations with a 6.7-L, six-cylinder high-pressure common rail engine by FPT Industrial and selective cata-lytic reduction (SCR) technology with no need for a diesel particulate filter.

Engine AnnouncementsJohn Deere unveiled its engine solutions for the Stage 4

emissions regulations, making the product announcement well before the Intermat show.

John Deere has introduced a selective catalytic reduction (SCR) system to its Stage 3b engine platform from 56 to 560 kW. John Deere said that exhaustive research and testing de-termined that an application-specific SCR system that is well integrated with the proven Stage 3b engine platform will be the best solution to achieve Stage 4 emissions compliance while delivering the power, performance, ease of operation, fluid ef-ficiency, reliability and economical operating costs that custom-ers expect from the company.

Notably, the Integrated Emissions Control system by John Deere will allow the engines to utilize less urea than alternative

Stage 3b SCR solutions. Lower urea consumption will grant a smaller fluid tank and have a smaller impact on the vehicle layout, as well as longer urea filter service intervals.

Also at Intermat, Deutz previewed its lineup for the Stage 4 emissions regulations. Included in the range is a four-cylinder TCD 2.9 L4 with cooled external EGR and the four-cylinder TCD 3.6 L4, a 97 kW engine which has performance comparable to that of a supercharged 4.5 L Stage 3 en-gine, Deutz said.

Above 80 kW, Deutz offers the TCD 4.1 L4 with sealed DPF and the TCD 6.1 L6 featuring its common rail high pressure injection system. At the top of the range sits the turbocharged TCD 7.8 L6 engine with cooled ex-ternal EGR and 2000 bar Deutz com-mon rail injection, and the TCD 12.0 V6 engine featuring an electronically controlled wastegate turbocharger.

Deutz’s strategy for meeting the more stringent emissions regulations incor-porates its the modular Dvert solution, which combines engine and exhaust gas technologies to meet the market and individual customer requirements.

Also displaying Stage 4 engines was FPT Industrial, which showed its full line for construction applications, based on the F5, NEF and Cursor engine families, ranging from 40 to

500 kW. For Stage 4, FPT Industrial is using its SCR-Only technology. For packaging constraints typical for small sized industrial machines and for low displacement engines, the company said it can adopt a different approach, using a small SCR system together with light externally-cooled EGR.

Showcasing a range of small-dis-placement diesel engines, Kohler dis-played its KDI diesels with three engine models; the 1.9, 2.5 and 3.4 L, to be launched between the end of 2012 and end 2014. The new range has been developed and will be manufactured at the Lombardini’s Italian headquarters in Reggio Emilia. These engines will meet Stage 3b and Stage 4 regulations with an electronically-controlled com-mon rail system and two-stage cooled EGR, without the need of a DPF.

German manufacturer Hatz intro-duced its new three- and four-cylinder engines at the exhibition for Stage 3b emissions regulations under 56 kW. The previous series have undergone a technical upgrade and will be fitted with DPFs. The new three-cylinder 3M43 and 3L43C engines will adopt EGR to meet Stage 3b, while the four-cylinder 4M43 and 4L43C were already featuring EGR in the previous models. The 4L42 and 4M42 engines and will only need the addition of a DPF, Hatz said. dpi

Diesel Progress international 19 june 2012

John Deere will introduce a selective catalytic reduction (SCR) sys-tem to its Stage 3b engine platform from 56 to 560 kW to meet the Stage 4 emissions level.

DPI414.indd 1-2 5/11/12 4:16 PM

JCB Keeps New MaChiNes CoMiNg

JCB used Intermat to introduce a batch of new products — its second such launch this year following an event in Spain in

February. Among the new machines unveiled were two new wheeled load-ers, which JCB said offers significant-ly reduced operating costs resulting from improved fuel efficiency and en-gine technology that doesn’t require a diesel particulate filter (DPF) or selec-tive catalytic reduction (SCR).

The 427 and 437 wheeled loaders will replace the 426 and 436 models. Both machines are scheduled to go into production in autumn 2012. Their launch follows the unveiling of the new JCB 457 wheeled loader earlier this year. The 427 and 437 models have a Stage 3b compliant 6.7 L Cummins QSB engine.

Also introduced was the 8018CTS mini excavator, which goes into pro-duction in the summer. The excavator competes in the 1.5 tonne sector and has a 14.2 kW Perkins engine.

JCB displayed its first Loadall ma-chine capable of lifting loads to 20 m. The JCB 540-200 has a lift capacity of 4 tonnes and is powered by a JCB Dieselmax engine.

The company also completed its lineup of 17 new generation skid-steer and compact track loaders

Diesel Progress international 20 june 2012

CONSTRUCTION EQUIPMENT

JCB’s 8018CTS mini excavator goes into production this summer. It competes in the 1.5 tonne sec-tor and is powered by a 14.2 kW Perkins engine.

For More inForMation on JCBwww.jcb.com

with the launch of five small plat-form, vertical lift models. The new Perkins-powered machines — the 175, 190 and 205 skid-steer load-ers and the 190T and 205T compact track loaders — all use a vertical lift version of the JCB Powerboom sin-gle arm, providing maximum reach at full height. dpi

With Intermat as its backdrop, Cummins took the wraps off the new QSF2.8 engine rated 37 to 55 kW. The 2.8

L four-cylinder engine was displayed with a fully passive Cummins Com-pact Catalyst aftertreatment system, designed to meet Tier 4 final and EU Stage 3b emissions regulations.

The QSF2.8 is the smallest engine to be introduced by Cummins for the off-highway industry with full-authority electronic controls driving a high pressure common rail (HPCR) fuel system. The company said this capa-bility brings the performance charac-teristics of larger Cummins engines to compact equipment below 56 kW for the first time.

Cummins electronics drive the HPCR system to enable multiple fuel injection events with over 1600 bar capability, achieving cleaner combus-tion with improved fuel efficiency. The Cummins Compact Catalyst after-treatment has been specifically devel-oped by Cummins for Tier 4 applica-tions as a maintenance-free, “fit and forget” system ideally suited for use in rental equipment. Without the cata-lyst, the same QSF2.8 base engine meets all other emissions require-ments, including Tier 3 and Stage 3a, to provide a single, global platform for all applications.

The QSF2.8 weighs 230 kg due to the sculpted design of the high-strength cast-iron block and the use of composite material for features such as the valve cover. The engine also has a rear geartrain, providing greater mounting stiffness and lower gear noise, said Cummins.

With a 37 kW output at 2500 r/min the naturally aspirated QSF2.8 pro-vides a sufficiently low-weight and space-efficient envelope to replace engine installations down to 2.2 L in size while bringing a higher level of in-herent durability, said Cummins. The engine delivers a peak torque of 160 Nm with over 80% of this available at 900 r/min for applications requiring a fast response at a low speed.

For constant speed generator ap-plications, the QSF2.8 is available with a prime power output of 40 kVA at 50 Hz and 36 kWe at 60 Hz. The compact configuration of the QSF2.8 makes the engine suitable for towable and portable units.

According to Cummins, its after-treatment enables a smaller, easier and more flexible equipment installa-tion than diesel particulate filters often used by many other engines below 56 kW looking to meet the Tier 4 final/Stage 3b requirements. The catalyst is a flow-through device requiring no ash-cleaning service, no sensors, and no operational lamps in the equip-ment cab. dpi

Diesel Progress international 21 june 2012

New DevelopMeNt iN DieselsCummins introduces smallest off-highway engine with the QSF2.8 rated 37 to 55 kW

ContaCt CuMMins

Cummins has introduced the 2.8 L four-cylinder QSF2.8 engine rated 37 to 55 kW. This is the smallest engine to be introduced by Cummins for the off-highway industry. It features full-authority electronic controls driving a high pressure common rail fuel system.

ENGINES

DPI408.indd 1-2 5/11/12 2:55 PM

By Ian Cameron

Among the engine unveilings at Intermat were the new four- and six-cylinder Stage 4/Tier 4 final compliant die-

sels from Perkins with “specially op-timized” selective catalytic reduction (SCR) technology.

The 1204F, a 4.4 L four-cylinder aftercooled engine, comes in two ver-sions. The single turbo aftercooled 1204F-E44TA produces 110 kW, which Perkins said gives improved fuel economy while offering great power and torque. The twin turbo, af-tercooled model — the 1204F-E44T-TA — offers up to 130 kW and has twin turbochargers mounted in series, for extra power density, low speed torque and faster transient response, the company said.

Perkins said it has focused on mini-mizing the cost of transitioning ma-chines from Stage 3b/ Tier 4 interim

EnginE UnvEilings From PErkinsCompany launches four-cylinder 1204F and six-cylinder 1206F Stage 4/Tier 4 final engines

Diesel Progress international 22 june 2012

contact perkins

ENGINES

The 4.4 L four-cylinder 1206F-E70TA from Perkins comes in two versions; the single turbo aftercooled 1204F-E44TA that pro-duces 110 kW and the twin turbo, aftercooled 1204F-E44TTA rated 130 kW.

size of the DOC/SCR module means it can be mounted in a variety of remote locations, freeing up space in the engine bay, especially in more compact equip-ment. Perkins also offers the option of a service-free diesel particulate filter (DPF) to meet specific OEM requirements.

Perkins also took the wraps off its new range of six-cylinder Stage 4/Tier 4 final engines. At the top of the range is the twin turbo 1206F-E70TTA; a 7 L six-cylinder unit, capable of producing 225 kW. This is designed to give OEMs the choice of the same power from a

smaller engine package, which devel-ops 1280 Nm of torque at 1400 r/min

The engine features twin turbo-chargers — one small, one large —mounted in series. Perkins said the smaller first stage turbo accelerates quickly for low speed response while the larger second stage turbo provides the high airflow required to provide op-timized power density.

For OEMs wanting lots of torque at low speeds the new single turbo 1206F-E70TA offers up to 151 kW at 2200 r/min with maximum torque of 870 Nm at 1400 r/min. Perkins said it has mini-mized the impact of the aftertreatment

Diesel Progress international 23 june 2012

to the latest regulations by maintaining a high carry over of components from the previous stage/tier. It also kept similar cooling packages and retained compact dimensions for the engine en-velope, reducing the need for OEMs to undergo costly machine redesign.

Both 1204F models use aftertreat-ment comprising a diesel oxidation catalyst (DOC)/SCR module which the company said removes the need for any regeneration strategy since the formula-tion of particulate emissions is prevented in the combustion process. The small

required to meet Tier 4 final/Stage 4 re-quirements, in particular the significant reduction in NOx. It said it achieved this by packaging the DOC/DPF canister and the SCR system into one integrat-ed module, which can be positioned re-motely in a machine chassis or directly on top of the engine.

The aftertreatment module in-cludes flexible inlet and outlet op-tions, pre-installed electronics and diesel exhaust fluid (DEF) hook ups. For tight installations a fully insu-lated aftertreatment module is avail-able that lowers the surface temper-ature. The DPF now uses passive regeneration, which is transparent to the operator and service free.

Perkins said the 1206F delivers an estimated 5% better fuel consumption

over previous models that incorpo-rate diesel and DEF necessary for the SCR technology.

In separate announcements Perkins said it has completed its program for meeting the applicable U.S. and EU emissions regulations for its engines in the 56 to 130 kW power band, having obtained the certification of its 854E-E34TA engine to Tier 4 interim/Stage 3b and CARB emissions legislation.

Perkins also announced that it has expanded its range of Industrial Open Power Units with the launch of the Tier 4 interim/Stage 3b com-pliant 854E-E34TA. It is a 3.4 L four-cylinder, turbocharged, air-to-air charge cooled unit capable of producing 74.5 kW and 420 Nm of torque at 1400 r/min. dpi

DPI406.indd 1-2 5/8/12 11:35 AM

gi. “In some cases it is possible to reach limits of dynamic stiffness that are two and even three times greater than the static stiffness.”

The damping coefficient depends basically on the compound used in manufacturing of the anti-vibration mount. It is a crucial parameter that must be addressed when designing anti-vibration suspensions, he said.

As for long-term behavior of the damping element, if an elastomeric element is under a static load, this load produces a progressive in-crease in deformation. This phenom-enon may be important in a wide va-riety of applications, from mounts for buildings to engine mounts.

This creeping effect depends on the geometry of the mount, and above all on the way the rubber is worked, Lopetegi said.

“Dynamic stiffness can only be es-tablished by measurement on a dy-namic test bench. Similarly, the damp-ing coefficients of compounds are further values that can be measured with this type of machine,” he said.

“One concept that must be taken into account when designing an anti-vibration mount is its durability. A dy-namic testing machine allows us to conduct fatigue tests that reproduce the real working conditions of the part so that its useful life can thus be predicted accurately,” he added.

The computing tools at AMC- Mecanocaucho can also generate virtual models of solid rigid multiples and study how they interact with each other and with the environ-ment. As a result, the company can ascertain the natural frequencies of the system that are important to pre-vent them from coinciding with the excitation frequencies so as not to have resonance problems.

The full theory on vibration insulation is available on AMC-Mecanocaucho’s website, www.mecanocaucho.com. dpi

Vibrabsorber ShakeS Off VibratiOn Rubber-metal anti-vibration supports used in mobile and stationary applications

with especially high damping requirements

By RoBeRta PRandi

For over 40 years AMC-Mecanocaucho has been developing rubber-metal anti-vibration supports. The company’s product portfolio is used in applications

that include power generation, air compressors and blowers, pumps and pumping equipment, mobile equipment and marine propulsion.

The AMC-Mecanocaucho Vibrabsorber is particularly used in stationary gen-sets where an isolation efficiency above 95% is a must. Typical applications include hospitals, residential areas and libraries.

The Vibrabsorber design features sup-ports made of springs, with a mechanical anchoring system for static applications that isolates low-frequency vibrations. The de-sign also features an inverted double cone inside the spring that limits the compression of the spring in case of an unexpected over-load, acting as an end-of-stroke buffer.

Diesel Progress international 24 june 2012 Diesel Progress international 25 june 2012

DRIVETRAIN TECHNOLOGY FOR TIER 4

ContaCt aMC-MeCanoCauCho

AMC-Mecanocaucho uses dy-namic test benches to determine the stiffness of anti-vibration mounts, as well as the damping coefficients of compounds.

PoweRlines

Meritor inc., a global supplier of drivetrain components and systems for the commercial vehicle and industrial markets, recently opened a new ASEAN Aftermarket Distribution and Customer Service Center in Jurong Town, Singapore. With the ability to serve Indochina, Indonesia, Philippines, Ma-laysia, Singapore and Thailand, the new facili-ty will provide commercial vehicle axle, brake, driveline and suspension parts — under the Meritor, TruckTechnic, Euclid and Mascot brands — to distributors in the region, along with thousands of end-user truck operators. The company has also established facilities in India, China and Australia, all of which will be managed by the Singapore headquarters.

Manitowoc Cranes has a new factory in Brazil, located in Passo Fundo, a city in the southern state of Rio Grande do Sul. It is the company’s first crane factory in Latin America and will initially supply Grove rough-terrain cranes across the region. Manufacturing will begin in mid-April, and the first deliveries from the factory will take place in mid-June, the

company said. The factory’s design is tai-lored to local manufacturing methods and materials, but also includes operational elements and practices from Manitowoc’s other Grove production sites in Shady Grove, Pennsylvania, U.S.A., and Ni-ella Tanaro, Italy. The cranes produced at Passo Fundo will be 30% locally-sourced components with the other 70% imported from the United States. Manitowoc said its goal is to reverse these figures over the next three years. Currently, the facility has 55 full-time employees.

Honeywell sensing and Control (S&C) has received the Sup-plier Quality Excellence Process (SQEP) Platinum certification from Caterpillar Inc. Established in 2007, the Caterpillar SQEP recognizes suppliers’ performance against its quality and service standards. The award recognizes Honeywell’s service throughout 2011, including its technical support, delivery capabilities and perfor-mance during the past three years.

continued on page 32

The next step is test and dynamic charac-terization, for which AMC-Mecanocaucho utilizes its own laboratory with advanced dynamic testing equipment.

AMC-Mecanocaucho has also published an interesting theory on vibration insulation. Among the topics in the analysis are the evaluation of static and dynamic stiffness, damping coefficient and long-term behavior of the damping elements.

Static and dynamic stiffness comes into play as the stiffness of a rubber anti-vibra-tion mount changes when a dynamic force is applied to it. This parameter depends on architecture, the compound used and even the frequency of excitation.

“Generally speaking, dynamic stiffness is always greater than static stiffness, so calculations based on static stiffness may lead to wrong conclusions,” said Lopete-

The Vibrabsorber line is also available with a Sylomer mat to isolate mid-high frequency vibrations that are transmitted through the coils of metal springs. Such high and mid-range frequencies, if not isolated, can spread through the buildings or structures generating noise, the com-pany said.

Aitor Lopetegi, export manager of AMC-Mecanocaucho, explained the company’s evaluation process for an anti-vibration proj-ects. “We calculate our anti-vibration solu-tions by taking into account data such as weight, mount positions, type of machine and frequency of excitation.

“After studying each customer’s specific needs for the application and the isolation performance required, AMC-Mecanocau-cho can design new products according to the existing conditions,” Lopetegi said.

DPI365.indd 1-2 5/9/12 3:01 PM

SignpoSt goeS here

Bangalore, the capital of Karnataka state in southern India. Production is expected to start in early 2013. It is estimated that almost 800 people will be employed at the facility in the longer term.

The industrial operations will con-sist of final assembly of truck and bus chassis and bodywork and fitting out of complete vehicles. The head office of Scania’s Indian company, a service workshop and a central parts ware-house are also being built there. dpi

Scania has delivered trucks to Zoomlion since 2008 and they are fit-ted with Scania’s six-cylinder 309 to 345 kW engines.

Also in Asia, Scania announced earlier this year it is planning to invest in an industrial facility in Bangalore, India. The Scania Regional Product Centre, India, will also be the center of the company’s commercial opera-tions in the country. Scania’s aim, it said, is to sell about 2000 trucks, 1000 buses and 1500 engines per year in the Indian market within the next five years.

The facility is being constructed in an industrial area 40 km east of

Scania booStS AsiAn Presence

Scania increases engine supply deal with Doosan; receives another order from Zoomlion; builds Indian Regional Product Centre

By Ian Cameron

in a move which will bolster its posi-tion in Asia, and notably in China, Sweden’s Scania and South Korean equipment manufacturer, Doosan

Infracore, have agreed to increase their current supply deal. Starting in 2014, Scania will not only supply engines for Doosan’s articulated dump trucks and large wheel loaders but also other products within the Doosan range.

“In the long term, we are estimat-ing delivery of well over 3000 engines annually to Doosan Infracore,” said Robert Sobocki, senior vice president and head of Scania Engines. “This co-operation has strengthened our posi-tion in the growing Asian market.”

with exhaust gas recirculation (EGR) and selective catalytic reduction (SCR) technology, but without a par-ticulate filter. The newly developed engine platform is the same for all emissions levels ranging from Stage 2 to Stage 4.

Scania has also recently secured other sales success in China as con-crete pump manufacturer Zoomlion chose Scania’s trucks as a platform for its largest concrete pumps. In ad-dition to 375 trucks being delivered in April, the company has now ordered 435 more to be delivered before the end of June.

Doosan Infracore is already estab-lished within the Chinese market. Sev-eral models from a total of over 20 000 machines sold annually in China will be powered by Scania engines.

“We have tested Scania’s engines in our products and they meet our ex-pectations for reliability, outstanding performance and high fuel efficiency,” said Andrew H. Choi, sourcing direc-tor at Doosan Infracore. “We also ap-preciate Scania’s modular concept. One engine platform for all emission levels is of great benefit.”

Scania said its industrial engines will manage Stage 4 and Tier 4 final

Diesel Progress international 26 june 2012

inDUStrY neWS

contact scania

Scania and Doosan Infracore have agreed to increase their current cooperation agreement with Scania supplying engines for Doosan’s articulated dump trucks and large wheel loaders and other products within the product range starting in 2014.

DPI410.indd 1-2 5/11/12 3:52 PM

horizontally, the head ensures uniform powder application independent of its rotation angle.

“In this specific application, how-ever, the rotating head was inserted vertically into the cylinder bores via a five-axis system.”

One main argument for using the rotating iClad head was that, because of the sheer weight, it would be impos-sible to rotate a whole 700 kg diesel engine around a fixed processing head. Individually centering each cyl-inder was not a viable option either because of the costs involved.

Kalawrytinos said the aperture diam-eter of the cylinder bore is 178 mm; the lower area to be coated is situated at a depth of about 340 mm and consists of a ring segment about 60 mm high.

In this case, the rotating iClad head was vertically inserted into the cylin-der bore and can process the entire internal surfaces at a 90° angle.

The worn cylinder lining at the up-per and lower dead points was to be clad with a coating thickness of more than 1 mm. This called for the cladding of a stainless-steel alloy to ensure not only the necessary wear resistance but also good corrosion resistance in acidic and alkaline environments.

The worn bores were first machined to a specific dimension at the facility of LaserCo DT’s customer in order to remove all traces of wear and tear and to create a smooth surface for the laser cladding.

At ILT, the engine block was placed on a steel support, then aligned and adjusted. Dr. Andreas Weisheit, group manager cladding and heat treatment at ILT, and his team together with Ka-lawrytinos set up the rotating internal processing head.

Both outside cylinder bores in the lower damaged ring segments were

New Life For Worn Cylinder Bores iClad laser cladding technology with a new rotating head allows direct

reconditioning of diesel engine cylinder bores

By RoBeRta PRandi

Although laser cladding is a proven technology for repairing diesel en-gine parts, conventional heads are not always able to reach some in-

ternal contours or blind bores. The German specialist Pallas has developed a new tech-nique called iClad, which involves a minia-turized processing head for aperture diam-eters down to 26 mm and working depths up to 500 mm.

Each iClad head consists of three mod-ules: powder feed, main body and fiber plug. The working distance between head and component is just a few millimeters.

Depending on the processing point, the laser beam can exit either at an angle of 30°

bores by laser cladding of the upper and lower piston reversal points.

LaserCo DT’s Managing Director Hugues Desmecht asked the Fraunhofer Institute for Laser Technology (ILT), Aachen, Germany, to carry out a feasibility study. The study was carried out in cooperation with Pallas, who originally developed iClad jointly with ILT and now markets the system.

The study consisted of applying iClad laser cladding to two of the six damaged cylinder bores in an eight-cylinder diesel engine.

“In the new iClad, the rotary drive is in-tegrated into the head,” said Stephan Kala-wrytinos, managing director at Pallas. “Even when inserted

or 90°. Blind bores can be coated with a 30° head because the laser’s working point is in front of the head, Pallas said. On through bores, a 90° angle is used.

Recently, iClad was upgraded with a rotating head for repairing worn cylinder bores in a diesel engine. This version can treat internal contours of components with eccentric bores or nonrotationally sym-metric openings of 50 mm or more in di-ameter and with a depth of up to 500 mm, said Pallas.

The project started with the Belgian rail-way operator commissioning to Belgium-based Laser Coating Diamond Technology (LaserCo DT) to recondition worn cylinder

Diesel Progress international 28 june 2012

REMANUFACTURING

contact pallas

The iClad, developed by Pallas, is a miniaturized processing head for laser cladding in aperture diam-eters down to 26 mm and working depths up to 500 mm.