DEUTZINSIDE - DEUTZ · PDF file2 DEUTZINSIDE 3 I 2014 ... and ZW120 series with DEUTZ TCD 3.6....

Transcript of DEUTZINSIDE - DEUTZ · PDF file2 DEUTZINSIDE 3 I 2014 ... and ZW120 series with DEUTZ TCD 3.6....

DEUTZINSIDEThe magazine of DEUTZ AG Edition 3 I 2014

ANNIVERSARY150 Years of DEUTZ –WE celebrate

SAFETY & QUALITYDEUTZ Rental Power – Minimising service costs

The foundation for success

CONTENTS

2 DEUTZINSIDE 3 I 2014

TITLEThe foundation for success How DEUTZ has sustainably aligned itself

IMPRINT DEUTZ INSIDE, Edition 3/2014

Published by: DEUTZ AG, Ottostraße 1, 51149 Cologne (Porz-Eil)

Person responsible: Janina Decker, Public Relations

Director: Janina Decker, Phone: +49 (0)221 822 24 93, Fax: +49 (0)221 822 15 24 93, E-Mail: [email protected]

Editorial team: Janina Decker (DEUTZ AG), Jan Dimog/Markus Fischer (Diamond media GmbH)

Design: Diamond media GmbH, Miria de Vogt, Susanne Wimmer

Printing: Druckerei Engelhardt

Picture credits: Deutzfreunde Thannhausen/Johannes Brandl, Janina Decker, DEUTZ AG, fotolia.com, SDLG/CJD Equipment/Robert Garvey, shutterstock.com, Stute Logistics, Ludger Wunsch

The PEMS technologyFrom the test bench to the tried-and-tested customer application .....................p30

FASCINATION & VISION

150 Years of DEUTZ – WE congratulate! DEUTZ INSIDE shows you some of the nicest birthday wishes. ..........p32

IN BRIEF

Caterpillars and round hood tractorsMeeting of the "Deutzfreunde Thannhausen" in Bavaria .................p34

Did you know that...… a swimming vintage model arrived at its final resting place after more than 100 years of service? ..........................................p34

NEWS

Reports and informationabout DEUTZ ..................................p4

FAIRS

DEUTZ at InnoTrans 2014 ...............................p6

DEUTZ at SMM Hamburg ...............................p6

Electra Mining Africa:DEUTZ engines below ground ..........p7

ANNIVERSARY

150 Years of DEUTZWE celebrate! ...................................p8

Soap Stars made by DEUTZThe DEUTZ soap box derby ...........p12

TITLE

The foundation for success How DEUTZ has sustainably aligned itself ....................................p14

INNOVATION & TECHNOLOGY

DEUTZ engines for products from the Middle KingdomConstruction machines of the Chinese manufacturer SDLG ..........p18

Fit for series-production readinessDevelopment of SCR software for the after-treatment of exhaust gases EU Tier IV/ US EPA Tier4 ......p20

SAFETY & QUALITY

The premium platform ..................p22

DEUTZ Rental Power –Minimising service costs Engines for construction machines in the leasing business ....................p24

TEAM & CHANCES

DEUTZ trains "The Best" .....................................p27

The DEUTZ apprenticesof the anniversary year! Take-off for the vocational training ............................................p28

PEOPLE & MARKETS

Look who's tacking The carpenters from the Stute Logistics partner company in the Cologne-Porz DEUTZ plant ...............................................p30

3

150 Years of DEUTZWE celebrate!

p14

p8

p24

EDITORIAL

DEUTZ Rental Power – Minimising service costs Engines for construction machines in the leasing business

Dear readers,

Under the mot-to, "150 Years of DEUTZ – The Origin of High-Tech", we celebrated the no-table birthday of our company with a fes-tive employee party at our site in Colog-ne-Porz on the 20th of September. All employees and their families had been invited, and we will look back on this day with pleasure for a long time (see article on page 8). As the executive board of DEUTZ AG, we would like to take the occasion of the end of our anniversary year to thank all of you who have helped make our company a long-lasting success over the years. And that includes precisely those who celebrated with us this year: our customers, partners and employees.

Whilst our anniversary was an occasion for celebration, the economic news over the past months have again been cloudier. Against this backdrop, our new orders were €330 million lower than expected in the third quarter of 2014. Revenue, in contrast, was boosted to €424.5 million, which is 11.4% more compared to last year's quarter, and was able especially to profit from the change in emissions standards for engines under 130 kW – which came into force in Europe on 1 October 2014 – and from the resulting effects of the advance production of engines, which will lead to reduced demand from our customers in the coming quarters. The operating profit (EBIT) in the third quarter of 2014 improved to €23.1 million, before the unexpected charge against earnings for warranty costs of €20.4 million was taken into account. Given the general economic slowdown, we now anticipate approx. €1.5 billion in revenues for the current fiscal year and predict an operating EBIT yield margin (before one-off items) of about 2 per cent.

What can you, as our customer, expect from DEUTZ in the upcoming new year? That you will receive engines which have been developed in compliance with the most strict, valid emissions standards in the world. This will enable you to implement drive solutions with a secure future for practically any purpose imaginable and independently of the global region in which the DEUTZ engine is being used. That is the status quo for which DEUTZ has created all necessary conditions in the recent past. We think that this is a very key topic and have dedicated the feature article of our magazine to it (p. 14).

We will regularly report about how we achieve success together with our customers by supplying engines which exactly meet their needs. The Chinese construction machine manufacturer SDLG, which is also targeting strictly regulated markets with Tier 4 engines from DEUTZ, among others, is a good example of this (p. 18). We would also like to introduce you to the DEUTZ Rental Power brand. In the future, we will be consolidating our compact engines together under this brand name, which, thanks to their extreme robustness and the long intervals between maintenance, are especially suitable for the requirements of the machine leasing business (p. 24).

We would like to wish you and your family a happy Christmas and a good start to the New Year.

With kind regards,

Your Your YourDr. Helmut Leube Dr. Margarete Haase Michael WellenzohnYou can find DEUTZ

INSIDE online here.

4 DEUTZINSIDE 3 I 2014

NEWS

DEUTZ starts cooperation with Hitachi Construction Machinery

DEUTZ at Bauma China 2014

NEWS

5

New press speaker at DEUTZ

Anniversary of service

In addition to his existing functions, and as of 1 November 2014, Christian Krupp, Division Head of Finances and Investor Relations at DEUTZ AG, has now also assumed responsibility as the Head of DEUTZ Corporate Communication.

The 46-year-old has already been with DEUTZ AG in Cologne since 2005. From 2008 to 2009, Christian Krupp was employed as the Chief Financial Offi-cers at the American subsidiary DEUTZ Corporation in Atlanta. As of 2009, as the President & Chief Executive Officer, he headed the DEUTZ subsidiary in the US state of Georgia, until assuming the position of Head of Finances and Investor Relations at DEUTZ AG in Cologne in 2011.

With the position as the Division Head of Corporate Communication, Christian Krupp also assumes the role of press speaker for DEUTZ AG.

4-5 January 2015 United Rentals Construction Rental Minneapolis USA 3-6 February 2015 WOC Off-highway mobile Las Vegas USA23-25 February 2015 The Rental Show Construction Rental New Orleans USA2-4 March 2015 MEED Gen sets Dubai UAE

Date Event Segment City Country

Trade fairs January to March 2015

19 March 2015 Balance sheet press conferenceAnalyst conferencePublication annual report 2014

Financial calendar January to March 2015

DEUTZ Australia has signed a dealer contract with MTU Detroit Diesel Australia. The agreement is part of a product and service cooperation of both companies.

With the DEUTZ engines, MTU Detroit Diesel Aus-tralia expands its product portfolio in the class of output powers from 12-500 kW. At the same time, with this agreement, MTU Detroit Diesel Australia ex-pands the reach of its existing scope of services and support for the customers via the dealer network.

"Due to our comprehensive network and in accordance with our vision of "Professional Power People", we can offer DEUTZ and its customers technical support at the highest stage, thanks to our in-house engine experts," says Greg Gilkes, Manager Off-Highway Markets of MTU Detroit Diesel Australia. "For us, the agreement is an important component of our current business strategy and places us in a position to expand our product and support offer in Australia. What is more, by means of this we also expand our dealer network, thus being able to offer our customers even more on-site support," says Craig Chamberlin, Managing Director of DEUTZ upon signing of contract. "The DEUTZ brand is firmly established on the market, and our engines optimally complement the current range of services and product mix of MTU Detroit Diesel Australia."

In future, DEUTZ products and services can be obtained via the branch network of MTU Detroit Diesel Australia, which has more than 19 locations throughout the country.http://deutz.com.au

On 21 November 2014, at the location Cologne-Deutz, the component produc-tion business invited its staff members who celebrated their 25-year and 40-year anniversary of service to the canteen in Deutz. During this pleasant get-together with a small group of people, the 17 DEUTZ employees were given the chance to share anecdotes on their professional lives to date and make mutual memories come alive.

DEUTZ expands dealer network in Australia

With Hitachi Construction Machinery Co., Ltd. (HCM), one of the worldwide largest construction machine producers, DEUTZ has succeeded at winning a new partner for the long-term cooperation in the con-struction machine segment. As of April 2014, the Japanese Group has been equipping its wheel loaders of the ZW100 and ZW120 series with DEUTZ TCD 3.6. By means of the cooperation with HCM, DEUTZ successfully strengthens its inter-national presence, particularly on the Japanese market. The Japanese machine-construction group produces the world's largest range of hydraulic ex-cavators, from one-ton mini excavators right up to 811-ton exploitation excava-tors. Apart from excavators, the com- pany also delivers wheel loaders, rigid-frame dumper trucks and additional construction machines for special ap-plications. HCM has production locations in Europe, the USA and Asia. Since April 2014, the wheel loaders of the ZW100 and ZW120 series are equipped with DEUTZ engines of the TCD 3.6 series. As a result of its very compact engine design as well as a customer-oriented, modular system of optional attachments, the water-cooled 4-cylinder series engine, with peak capacity ranging from 55.4 to 90 kW at 2,300 rpm-1 rated speed, will reduce installation costs for customers. TCD 3.6 series engines are equipped with a modular exhaust gas after-treatment system (DOC) that can be attached to the engine as an option, thereby optimally simplifying device integration. The TCD 3.6 comes with a charge air cooler and only needs an oxidation catalyst to meet the requirements of EU 3B and US EPA Tier 4 interim emission categories.

"We are pleased that Hitachi Construc-tion Machinery relies on DEUTZ engines for its wheel loaders. This cooperation highlights the robustness and versatility of our engines in a great variety of differ-ent application segments," says Michael Wellenzohn, Director of Sales and Mar-keting at DEUTZ.

In November 2014, DEUTZ presented itself with its Chinese Joint Venture DEUTZ (Dalian) Engine (DDE) at Bauma China 2014, the most important Asian trade fair for construction machines. In the Shanghai New International Expo Centre, DEUTZ presented its products for the new Chinese exhaust emission

tier 3 (China Tier III), which will apply as of October 2015. Thanks to the tightening of the legal specifications and the increasing demand for modern engine techn ology as-sociated with this, DEUTZ also has the possibility of winning more market shares, due to its highly-developed products.

One of the product highlights was the TCD 2013 L6 2V, which offers 200 kW performance and has a torque of up to 1,100 Nm, making it perfectly suited for use in large wheel load-ers of the 5 ton class. Additional examples of application for the 7.2 litre units are found, among others, in excavators in the area of 25 to 30 tons as well as rollers and road pavers. Thanks to the modern DEUTZ Common-Rail (DCR®) injection system and the electronic engine controller (EMR 3), TCD 2013 is exceptionally efficient. The result is a specific consumption of 205 g of diesel per kWh. In Europe, the engine is used by leading OEMs on a wide front and is one of the most successful products in this market segment. For compact applications, DEUTZ, among others, offers the D 2011 L4i, which, e.g. is used in lift trucks, small construction machines and compressors. With a performance of 46 kW and 190 Nm torque, the engine is primarily characterised by its integrated cooling system without front-end radiator. Thus installation is significantly simplified and space is saved.

Furthermore, with the TCD 2.9 L4 and the TCD 7.8 L6, DEUTZ presented two highly-developed engines of the EU Tier IV. This exhaust emission tier, which is currently the high-est available, is attained by a modular-configurable exhaust after-treatment system. By using the example of the TCD 7.8, DEUTZ presented two components from this so-called DVERT®-construction set – the diesel particulate filters (DPF) and the selective catalytic reduction (SCR) – at the trade fair.

In China, the fourth emission stage is only anticipated after 2020. For the local deploy-ment, the engines now already provide an outlook on the technological future. Currently, first and foremost, they are targeted at use in export products for Europe, the USA and Japan, where the emission legislation has reached the fourth Tier since 2014. For the Chinese market, the engines will be available without after treatment of exhaust gases, as China Tier III variant, so that devices for the Chinese and export market can be exported identical in construction.

The staff members of the component production business who are celebrating their work anniversaries at the Cologne-Deutz location

Global Quality Excellence Award for DEUTZ

In December 2014, DEUTZ AG was honoured with the "Award for Global Quality Excellence" by the University of St. Gallen. With the prize, which was

awarded within the context of a benchmarking comparison, the University dis-tinguished DEUTZ AG for exemplary results in the fields of quality organisa-

tion, culture & communication, data management & knowledge transfer, supplier management and management commitment. A detailed report on this will follow in the next DEUTZ INSIDE.

6 DEUTZINSIDE 3 I 2014

FAIRSFAIRS

7

For the first time ever, from 23 to 26 September 2014, DEUTZ AG par-ticipated in InnoTrans, the international trade fair for traffic technology in Berlin. Here, DEUTZ provided its customers an opportunity to obtain information on the entire range in the field of new engines, installation consultation and service.

In the power range up to 390 kW DEUTZ presented the high-per-formance TCD 12.0, representative for its new engine generation. The water-cooled 6 cylinder V-engine covers the upper power range up to 390 kW and is turbo-charged and charge-cooled. Designed for high loads, it impresses with its robust design and an unrivalled compact construction. Optimal engine performance with low fuel consumption are the result of the powerful common rail injection system combined with the electronic engine control (EMR 4) with intelligent connection to the drive management system. Engine and exhaust gas after-treat-ment are geared to the optimum efficiency of the overall system and therefore ensure that fuel and overall operational costs are kept to a minimum. As a result of the SCR technology, there is no need for larger cooling surfaces and fuel consumption is reduced when compared to Tier 3 engines. Furthermore, the exhaust gas after-treatment system is maintenance-free.

In the past, DEUTZ had built more than 10,000 shunting locomotives and mine locomotives itself. Today, the DEUTZ engines up to 520 kW are used mainly in the compact and flat V-construction, in particular for rail cars, smaller shunting locomotives, multi-engine systems on mainline locomotives, or for the use in track construction machines worldwide. In so doing, apart from their robustness, they convince with a low weight, high power density and service life.

From 15 to 19 September 2014, in cooperation with the South African DEUTZ DIESEL POWER (DDP), DEUTZ presented its products at the Electra Mining Africa in Johannesburg. The trade fair addresses experts in the fields of mining, the building industry, electrical engineering and energy.

With the D914, DEUTZ presented an air-cooled 3- to 6-cylinder naturally aspirated engine in Johannesburg, with a power range of 43 to 129.9 kW. The engine is characterised by low noise emissions as well as by means of acoustically optimised com-ponents, whilst at the same time displaying very quiet running and durability. On top of this, the highly compact construction also reduces the installation costs.

In addition, DEUTZ presented the water-cooled 4-cylinder in-line engine TCD 4.1. With a performance of 115 kW and the DEUTZ Common-Rail (DCR®) injection system, as well as elec-tronic engine control (EMR 4), the engine ensures a high per-formance with low fuel consumption. The TCD 4.1 has a modu-lar exhaust after-treatment system (AGN) with components from the DVERT® construction kit and optional configuration variants.

For the OEM, this means a high level of flexibility with the device integration.

DEUTZ presented another highlight with the BFM 2011 Telco engine. This generator is designed for use in the field of tele-communication – for example for the operation of mobile radio masts. The power unit is available as an oil-cooled 2-, 3- and 4-cylinder naturally aspirated engine in unit construction. Fur-thermore, the 4-cylinder-variant is also available with turbo-charging and, optionally, intercooling. Due to the minor mainte-nance needs and low level of wear and tear, the operating costs are minimised. By means of this, long oil change intervals of up to 1,000 operating hours are possible.

DEUTZ presented itself at the SMM, the world's leading trade fair for the maritime industry, from 9 to 12 September. Every two years, branch representatives and specialists from across the world meet in Hamburg.

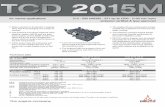

DEUTZ presented two marine engines at the trade fair: the BF4M 1013M and the TCD 2015M. The water-cooled 4-cylinder in-line engine 1013 M with turbocharging and intercooling performs up to 95 kW. The robust engine design allows for use anywhere in the world, even with high sulphur fuels. Furthermore, the compact construction as well as a customer-oriented, modular system of optional add-on components reduce the installation costs. What is more, the engine-driven cooling-water pumps simplify the installation with keel and raw water cooling.

The second engine – the TCD 2015M – provides between 210 and 500 kW, as V6 or V8 version. The marine engine has a solenoid-valve injection system (MVS) and the electronic engine control (EMR3) with intelligent connection to the drive management, by means of which it combines best engine performance with low fuel consumption. What is more, the low maintenance costs and the high service life also reduce the operating costs.

DEUTZ at InnoTrans 2014 Electra Mining Africa:DEUTZ engines below ground

DEUTZ at SMM Hamburg

8 DEUTZINSIDE 3 I 2014

ANNIVERSARY

About 5,000 DEUTZ members and their families could look forward to a highly multi-faceted day, in keeping with the motto of "150 years of DEUTZ – We cel-ebrate".

Following the festive welcome by the DEUTZ CEO, Dr Helmut Leube, and the musical introduction by the DEUTZ choir, the time had come for numerous visitors to discover the DEUTZ premises during beautiful weather, where they could enjoy the numerous attractions found on it.

Apart from a colourful entertainment programme, where, among others, a sing-along event was organised with the popular Cologne-based artist Björn Heuser, as well as different dance and juggling workshops for the little visitors, one of the absolute highlights of the day was the DEUTZ soap box derby. Already several months earlier, the participating teams were eagerly working on their vehicles, and now the opportunity had come to present them to the onlookers (also see the report on p. 12).

9

ANNIVERSARY

During a bright sunny day and with loud vocal support from the teams' pit crews, the creatively designed vehicles with names such as "dä flöcke Otto" or the "Möhrchen-Racers" were racing along the specially constructed racing track, after which the racing times were metic-ulously recorded. Ultimately, "The Flying Deutzmen" did its name justice and pre-vailed with a record time of 16:13 sec-onds. Yet the "OTTO 1" team could also celebrate, as it received the prize for design and creativity, and so could the

In 1864, Nicolaus August Otto and Eugen Langen signed the memorandum of as-sociation for the "N.A. Otto & Cie." and thus laid the foundation for the motorisation of the world. Today, 150 years later, the DEUTZ employees came together in the head-quarters in Cologne-Porz to celebrate their company's notable birthday with a large em-ployee party.

Wecelebrate!

Years of DEUTZ

ANNIVERSARY ANNIVERSARY

10 DEUTZINSIDE 3 I 2014 11

the numerous colourful Tuk-Tuk taxis, among others to the DEUTZ education centre, the DEUTZ choir, the anniver-sary association and to pronova BKK. Another genuine highlight was the live show of the DEUTZ plant fire brigade. What is the correct behaviour when hot fat starts burning or how do I kill a fire in the correct way? The DEUTZ fire bri-gade was happy to provide answers to

chines and engines was awaiting a large number of visitors in front of the Tech-nikum, where historic promotional films provided information on their use. Those wishing to step on the gas themselves and for whom it was not enough simply to be an onlooker, could do this on the especially created tractor course. But also those who didn't wish to become active, were safely chauffeured from one information booth to the next by one of

history of engine building also played an important role. After all, it was founded in DEUTZ 150 years previously, and thus the visitors were also afforded the op-portunity of experiencing the first atmos-pheric gas-powered engine of Otto's "No. 1" from 1867 as well as "Otto's New Engine", the four-stroke test en-gine from 1876, live and in action in the company's own "Technikum" museum. An extensive exhibition of historical ma-

"PT-3-10-20" crew, which was awarded the prize for the best fan group.

Those wishing to gain a behind the scenes impression of an engine con-structor, could join a guided tour through the production area and hereby not only take a look at the modern manufactur-ing processes of the plants. However, it was not only the future that was at the centre of attention on this day, as the

such questions and presented what is to be done in the event of emergencies.

The visitors were also anxious to find out who would be drawn as the main winner of the small car special prize in the competition draw. Gerald Leyh an-swered all questions correctly and, at the end of the day, could call a brand-new VW Up his own. There can be no

doubt that Otto and Langen would have been astonished if they could have ex-perienced what has become of their small workshop in the Cologne Servas-gasse.

11

12 DEUTZINSIDE 3 I 2014

ANNIVERSARYANNIVERSARY

Their construction is remarkably simple, yet they have remained one of the most popular attractions for many years: the soap boxes. To start with, it only requires numerous chipboards, steering systems and a rigid axle; all of these must then be combined into a kit, and then you have the ingredients for the con-struction of one of the four-wheel small vehicles. Thus it comes as no surprise that the DEUTZ employees were also keen to impress the about 5,000 visitors at this year's em-ployee festival, with their self-con-structed "boxes". DEUTZ INSIDE has selected the nicest photos for creative vehicles.

Soap StarsMade by DEUTZ

We apply full throttle!The DEUTZ soap box derby

As the oldest engine producer on earth, DEUTZ has made history and cel-ebrated its 150th anniversary this year. The company's role as a pioneer in the development of path-breaking drive technologies is confirmed time and again. Today, emission reduction and re-source conservation are the top topics for everyone who has anything to do with engines. DEUTZ engines are developed in accordance with the most stringent applicable emission regulations world-

wide. In this regard, the expansion of the product range, right up to complete engine systems, is becoming increas-ingly important. Such a system exists in the latest US Tier 4/EU Tier IV emission stage, apart from the combustion engine from the after treatment of exhaust gases and an electronic engine control. To be in a position to set up complete engine systems for a great variety of application fields and markets with varying degrees of regulation, DEUTZ has created a mod-ular concept that goes by the name of DVERT® – DEUTZ Variable Emission Re-duction Technology. Virtually all elements of the DVERT® modular system can be combined with one another to attain the desired result regarding engine power, compliance of emission limit values and competitiveness.

As significant new developments that are equipped with DVERT® components for all present-day and future requirements, DEUTZ launched the TCD 2.9 and TCD 3.6 engine series on the market in 2012, which have enjoyed great popularity with the customers ever since. Apart from the state-of-the-art after treatment of ex-haust gases, they follow the trend toward downsizing: It is about exceptionally compact engines with higher power den-sity, low fuel consumption and powerful torque delivery – for maximum efficiency.

Technology driver hybrid

In the field of drive engineering, it can be said that the "hybrid" phrase has virtually become a kind of magic word. Known in public awareness, due to the discus-sion revolving around the future of car propulsions, hybrid technology is also a major topic with mobile work machines. DEUTZ has developed solutions that are

nothing to sneeze at, both in the field of "electronic hybrid" as well as with hydraulic start-stop systems. On the one hand, there would be the handler excavator with a hybrid system, which consists of a DEUTZ diesel engine and electric system components. An engine generator that is flange-mounted to the combustion engine, feeds electric energy into a so-called SuperCap Pack, which serves as an energy storage. The electric drive derives its energy for the swivelling of the excavator-upper structure from it, whilst electricity is fed back into the Su-perCap Pack during the braking of the swivel movement.

On the other hand, the wheel loader solution that was seen at Bauma 2013, works with hydraulics: Using a start-stop hybridisation, the DEUTZ engine auto-

matically switches off at zero load, and upon loading is immediately restarted via the hydraulics. This efficiently avoids the typical long idle times found in the com-pact construction machinery. Fuel costs and emissions are significantly reduced.

It doesn't always have to be mineral oil

Another important aspect is that, with biogenic fuels, an alternative to mineral oil-based diesel is offered, yet with the simultaneous benefit of resource con-servation. DEUTZ takes a worldwide leading role in the development of diesel engines that are operated with biogen-ic fuels. Biodiesel and vegetable oil fuel can be attractive, especially for agricul-tural engineering. Economic reasons play a role in this regard, but so does that fact that the agriculture sector di-rectly participates in the value-added chain with regard to the production of alternative fuels. The use of biodiesel to

15

TITLE

In the past years, DEUTZ has laid the foundations to continue on its path of success in 2015 and beyond. DEUTZ INSIDE highlights the key factors that are decisive for this: state-of-the-art technical innovations, ongoing in-vestments in capacities and know-how and, ultimately, as the result, a product range that is consistently aligned to the required mission scenarios – because the customers' needs take centre stage.

TITLE

14 DEUTZINSIDE 3 I 2014

How DEUTZ has sustainably aligned itself

The foundation for success

seized the opportunity to optimise the speed of the new TCD 2.9 and TCD 3.6 series' acceptance runs in the test field, thereby increasing the throughput. Cus-tomers benefit from this measure in the form of prompt delivery. Following the safeguarding by the corresponding tech-nical investigations, the test programme for each individual engine could be re-duced from five minutes to two, yet with-out having to make any concessions re-garding quality assurance. This measure is embedded in a large-scale project that will be continued in 2015, and in which five additional, in part simultaneously running, steps are included: the partial retrofitting of the test benches with mod-ern measurement equipment, ensuring the permanent engine provision of the test benches by means of driverless transport vehicles, set-up optimisation by means of reclocking, the reduction of revisions and – as the final result – im-proving the availability of the plants.

Consistent alignment to customer segments

Technology innovations plus location investments – this is the recipe based on which DEUTZ has created an engine programme that is aligned to market segments and thus to the specific re-quirements of the respective customers. For the field of mobile work machines, with the core segments of construction industry and material handling, DEUTZ produces high-performance, eco-nomically efficient and robust engines that have already proven themselves millions of times. The mentioned hybrid solutions from this field of application point out how DEUTZ actively partic-ipates in the future of the combustion engine. Equally, DEUTZ is a tried-and-tested partner for numerous agricultural machine producers. With a growing global population, efficiency improve-ments in the agricultural sector are es-sential. DEUTZ has also played a role in

this, with drive solutions for machines that cover everything from the high-per-formance harvesting machine right up to the small tractor for development regions.

DEUTZ engines make people mobile, yet also allow the flow of traffic and com-modities. Therefore, they are deployed in diesel-driven trains in Israel, in motor coaches in Turkey or on pusher boats in Sudan – to mention merely three inter-national examples. And sometimes they even assist entirely different types of tech-nology, facilitating their breakthrough: By means of example, the mobile telecom-munication market is booming in Africa. In areas that have no area-wide electric-ity grid for feeding the transmitter masts, Gen Sets, which are equipped with so-called Telco-engines by DEUTZ, generate the necessary energy. Thus, DEUTZ has the right engine for every purpose. Cus-tomers all over the world can rely on this – in 2015 and beyond.

generate regional material cycles enjoys great acceptance both in politics and by the public. With its extensive release of engines for biodiesel applications, DEUTZ supports the commercialisation and sale of sustainably produced bio-fuels.

Another form of diesel-substitution is the use of gas as a fuel. With the abbre-viation of TCG, DEUTZ has developed a number of engine series that are operat-ed in standard series with natural gas or, under certain prerequisites, liquid gas such as, e.g. propane. As stationary en-gines, they prove their worth worldwide, in part under extreme conditions, from pump drive for agricultural irrigation, right up to electricity generation on off-shore platforms.

Strengthening of the modern product range

At DEUTZ, location investments also go hand in hand with product develop-ments and optimisations. Thus the new construction of a building for research and development at the location Co-logne-Porz is exemplary of how DEUTZ pursues the goals of environmental efficiency and resource conservation, also beyond the engine product: The building attains energetic standards that even exceed those required by the Ger-man Energy Saving Ordinance.

As an investment in the field of produc-tion, the commissioning of a modular as-sembly unit is to be emphasised, which extended the production capacities as of the middle of 2012. Initially aligned to the new TCD 2.9 and TCD 3.6 series, the 2011 series was subsequently ad-ditionally migrated to this line. Hence, in light of the increasingly more stringent emission legislation, it strengthens the capacities of DEUTZ exactly where a special area of focus is found today: with compact engines that have up to four litres of cylinder capacity. In its construction, the new assembly unit heeds the tried-and-tested and timeless principle that quality is always the most important priority: Inline tests, meaning

quality tests in the running process such as, e.g. a leak test, constitute a part of this. This is done with the goal of elimi-nating errors to the greatest extent pos-sible, right from the outset.

Savings potential without any loss in quality

Apart from the productions plants, DEUTZ also invests in the optimisation of its processes. A highly topical example is the test field in the parent plant: Every engine that leaves the halls in Cologne-Porz is subjected to a hot test, where its parameters are documented. Nothing has changed. However, the Production and Development Divisions' experts

TITLE

16 DEUTZINSIDE 3 I 2014 17

TITLE

INNOVATION & TECHNOLOGY

1918 DEUTZINSIDE 3 I 2014

INNOVATION & TECHNOLOGY

Domiciled in the Shandong province, SDLG is one of the leading const-ruction machine producers in China. And this is no mean feat, because hardly any other country on earth has more construction activity than the largest economy on earth, quite apart from the fact that export is also an important mainstay for SDLG. The product range emphasis is on wheel loaders and excavators. Among others, they rely on DEUTZ engines for their propulsion.

China has long been more than the "Workbench of the World", as it was perceived at times. Although, among others, the most densely populated country on earth is still providing its vir-tually unlimited work resources to allow Western companies to outsource their production in a cost-efficient manner, China is also producing and launching strong brands itself, whose products are successful on the global markets. For example, the construction machines of SDLG. The Shandong Lingong Con-struction Machinery Co. Ltd., which is the company's full name, has its head-quarters in Linyi, a city of more than a million people in the province of Shandong, about half-way between the m e t ro p o l i s e s of Peking and S h a n g h a i . Founded in 1972, SDLG today operates a plant in Linyi that was com-pleted in 2005 and which has a surface of more than two million square metres. About 30,000 wheel loaders leave the halls every year, in addition to excavators, single-drum rollers, graders and back-hoe loaders. The products are offered in about 40 countries. Focal areas are in North and South America, Africa, India, Australia, Russia, the Near East and, needless to say, the domestic Chinese market.

Engines for different markets

Wheel loaders are on offer with live loads between one and seven tons. They have not only proven their worth on construc-tion sites, but also with the extraction of mineral resources in surface mining and everywhere where material is to be heaved and loaded, from agriculture right up to recycling operations.

Among others, SDLG is supplied by means of a joint venture with DEUTZ involvement: For the export in coun-

tries with the Tier-3 emission standard, engines by DEUTZ (Dalian) Engine Co., Ltd. are used. This joint venture was founded in 2007 together with First Automotive Works (FAW), one of the leading automobile producers in China. As the company name reveals, it has its headquarters in the harbour city of Dalian, in the Liaoning province. The engines for the SDLG excavators also come from DEUTZ Dalian. For its latest and most modern wheel loader genera-tion, which satisfies the emission stage Tier 4 and which is intended for export to North America, SDLG has selected the engines of DEUTZ AG from Europe.

Future-oriented DEUTZ presence in China

The success of manufacturers such as SDLG on the domestic market and in export underscores the growing signifi-cance of China as a location that delivers construction machines and other quality products for the global market. DEUTZ is one of the companies that realised early on already that China is not simply a country where, within the context of an off-shoring strategy, one can quickly and cheaply use the offer of production services. Rather, it has understood that a gigantic sales market has also come into being there. For this reason, DEUTZ built up own production capacities in the country with its joint ventures. For DEUTZ, China remains the market with the largest growth potential. Because, in future, the demand for engines that

comply with the Tier 4 exhaust emis-sion standard will also increase with the OEMs in Asia. Regarding the emission levels, it is especially the stringently reg-ulated western markets that can be tar-geted with these engines – as previously mentioned, this is a path that SDLG is already taking.

Both international OEMs who produce in China and Chinese manufacturers are ideally equipped for the globalisation in the construction machine sector, when they resort to DEUTZ engines. At least Bernd Freudenmann, Asia expert in international DEUTZ sales, has made

the experience: "Especially in China, where the construction machine market has outstanding significance, DEUTZ is perceived as one of the most important suppliers of diesel engines."

DEUTZ engines for products from the Middle KingdomConstruction machines of the Chinese manufacturer SDLG

Also Tier 4 engines, here a DEUTZ TCD 6.1, are used in the SDLG construction machines.

As the propulsion for wheel loaders of the three ton class, SDLG uses engines of the 226B variety, produced by Weifang Weichai-Deutz Diesel Engine Co., Ltd.

20 DEUTZINSIDE 3 I 2014 21

INNOVATION & TECHNOLOGY

With the introduction of the latest EU Tier IV/ US EPA Tier 4 emission stage, DEUTZ had the ambitious challenge of developing a complete in-house SCR software func-tionality that would support both engines with a cylinder capacity of <4 litres right up to the large V-engines with maximally 16 litres of cylinder capacity and which would work reliably in a great variety of different customer applications such as, e.g. construction and agricultural ma-chines. Also other after-treatment of ex-haust gas concepts, such as DOC+SCR, DOC/DPF+SCR, CSF+SCR or SCR only (SCR+SCR) are to be covered by only one software. An additional challenge was found in the fact that some customers use the EDC17 control unit and others the EMS/ACM control unit group. Here, too, both should contain the same SCR func-tionality and run with a uniform application of the software.

To ensure that all of these requirements pertaining to the own functional and soft-ware development would fit together with the tight time schedule of the EU Tier IV/ US EPA Tier4 roll-out, and that a sub-sequent serial production could be imple-mented as simply as possible, the SCR software, as well as all other functions, were developed in accordance with the so-called V-process. The V-process refers to a software development process that is state-of-art in the automobile environ-ment. The process guarantees seamless integration, from the compilation of the requirements to the development of the software, and right up to the software, test bench or vehicle tests and, in so doing,

reduces the error potential in the sub-sequent serial product. In close coopera-tion with the German technical inspection association (TÜV), the V-process was first adapted to the needs of DEUTZ AG. Sub-sequently, the web-based requirement management tool Polarion was rolled out. Software requirements can be created and administered in Polarion. The admin-istration of software amendments, tests and errors also ensue via this tool.

The „EAT-Coordinator” as the central interface

The spring of 2010 saw the official start of the software project. To start with, in a longer-lasting concept phase, the software architec-ture was determined, and the required de-mands were clarified in interdisciplinary teams. With this alignment, the dosage strategy con-cept was already devel-oped early on, accord-ing to which the AdBlue amount that was to be metered out is calculat-ed. The integration of the SCR-Software into other software com-ponents was aligned, whereat the so-called "EAT-Coordinator" came into being as the central interface to all software

At the end of 2010, after numerous op-erating hours with the prototypical soft-ware on the HIL, mock-up or test bench, the changeover date to serial software had arrived. Here, the forward-looking architecture and function development at the start of the project phase had a very positive effect, because, within a mere three weeks, the prototypical software could be imported into a serial software. As no model changes were required with the transition, the test benches could be continued with these, following a short testing phase. In this regard, the pre-viously implemented data supply was

components such as engine control, air pathway, DPF-software or HMI.

In so doing, great diligence was already required right from the outset, since the goal of software development always is to retain a consistent software model, from the prototypical development right up to serial development. Regarding adjustments to the serial system, dis-crepancies pertaining to the design of the software architecture, the concept or first function developments could lead to additional effort in subsequent development phases, e.g. with the

changeover from rapid prototyping to serial software. Under circumstances, applications and tests executed to date are then useless and would have to be repeated. Thanks to the high level of project experience and the mutual cooperation across all modules in the course of the development, this consis-tency could be preserved.

Following the completion of the planning and concept phase, the prototypical function development was executed. In this regard, the focus was on the func-tional implementation of requirements placed in software. In the course of developing the software, and for testing and development purposes, customer vehicles and engine test benches were made available, in addition to hardware in the loop and mock-up systems, par-ticularly in the first phase.

Testing on HIL and Mock-up

A hardware-in-the-loop-test bench (HIL) refers to a switch cabinet with high-per-formance computer and a number of different hardware interfaces, such as analogue voltage outputs and inputs, H-bridges and CAN-drivers. Real-time mathematical engine and exhaust gas after-treatment models are calculat-ed on it. Thus, the hardware–in-the-loop-test bench simulates the realistic behaviour of a DEUTZ engine for the control units software, as well as the associated after-treatment of exhaust gases. A sensible supplement to the HIL system is the self-developed mock-up. The mock-up is a self-developed mo-bile partition wall, to which all relevant SCR sensors and actuators are affixed. The mock-up offers the possibility of testing newly developed functions at a very early stage of development, on a number of different engine control units on real components. The data supply of diagnostic functions and their testing such as, e.g. a blocked metering valve, broken pumps or defective heating ca-bles can also be reliably executed on the mock-up. Apart from the testing of the function on the HIL and mock-up, the prototypical software functions were also tested on the engine test benches. Together with the department for the after treatment of exhaust gases, the SCR strategy was consistently rework-ed and expanded, and in the course of this, a first data supply was also rolled out.

INNOVATION & TECHNOLOGY

adopted 1:1 and the first C1 tests could be run after a mere five weeks.

In the winter of 2011, the first commis-sioning took place with a customer vehicle, under the auspices of the field testing. With two subsequent cold tests at the polar circle, engines, software and data supply could be tested under the most adverse conditions.

The OSM tool is another special feature in the DEUTZ software development. During the EU Tier IV/ US EPA Tier4 project, a PC programme was developed that also allows the simulation of the in-house control units' software on a PC. The benefit of this is found in the data supply and validation of the software in the office, yet without this requiring test bench time.

In the year of serial introduction, the SCR software consists of 13 software modules, about 37,000 lines of C-Code that, when printed, would fit onto about 750 pages of Din-A4 paper. For con-trolling the up to nine actuators, the SCR software has up to ten sensors at its dis-posal. For the adjustment of the software to the respective type of engine, the ap-plication engineer can access approx. 640 adjustment parameters and 900 software indicating elements.

Development of SCR software for the after treatment of ex-haust gases EU Tier IV/ US EPA Tier4 from the concept to series-production readiness

Fit for series-production readiness

Mock-up to the connection of serial components with the mathematical models of the hardware in the loop test bench (HIL)

The chart shows the EU Tier IV/ US EPA Tier4 concept with all SCR system-determined sensors and actuators. All shown sensors are processed by the SCR software, to control the corresponding actuators. The goal of this is to reduce the nitrogen oxide emissions to a minimum.

Hardware in the loop test bench with a number of different hardware interfaces.

22 DEUTZINSIDE 3 I 2014 23

SAFETY & QUALITYSAFETY & QUALITY

The premium platformDEUTZ AG has decided to process im-portant parts of its supplier communi-cation via the SupplyOn collaboration platform. The dialogue between sup-pliers and DEUTZ is simplified by the portal usage and becomes more trans-parent; processes are optimised and the administrative effort is reduced.

"Also in future, DEUTZ AG will solidify and expand its competitiveness. For this, business processes are further optimised and developed more efficiently, both in-ternally and externally. Already today, a closer involvement of our suppliers plays a major role. DEUTZ AG has taken the decision to process cross-company business processes with the support of SupplyOn. The decision for SupplyOn, as one of the leading supplier platforms, significantly contributes to the stand-ardisation of our worldwide processes,"

explains Gerhard Gehweiler, Senior Vice President of Purchasing at DEUTZ, in the supplier brochure with the title of "Sup-plier Portal SupplyOn“.

In the brochure, DEUTZ points out the prerequisites, methods and implemen-tation instructions that are required for the realisation of the mutual goals. These goals are: using the portal for the standardisation of communication between suppliers and DEUTZ, mak-ing it more transparent; optimisation of processes and reduction of the admin-istrative effort. Together with the sup-pliers, DEUTZ is already successfully using different SupplyOn applications in the fields of quality, complaint and sup-plier management. Numerous thousand suppliers worldwide have already been registered for the mentioned services at SupplyOn.

The DEUTZ suppliers' information day

In the past summer, DEUTZ initiated the suppliers information day with Sup-plyOn. The reason for this was not only to speak about the variety of different application fields but also to offer the suppliers the opportunity for discussion and exchange regarding the applica-tions, the purpose and the added value of the portals. The intention was for the suppliers to enter their master data for the SupplyOn complaints management (Services Problem Solver) and perform-ance monitor (Performance Overview), so as to start the roll-out by DEUTZ. The subsequent feedback of the suppliers regarding the information day was pos-itive and satisfactory. Strategic suppliers could be convinced of the benefits. Also in future, DEUTZ is interested in em-barking on the path of digital transition in cooperation with its suppliers, so that additional, possibly still undecided, sup-pliers will participate in the registration.

SupplyOn AG, with headquarters in Hallbergmoos near Munich and 140 employees, is the supply-chain col-laboration platform of globally acting companies. Numerous additional manufacturing companies use Sup-plyOn as a central online platform. This is done to ensure that business processes with their suppliers and service providers are managed in a structured, transparent and secure manner across all continents. In the manufacturing industry, with the em-phasis on automobile, aerospace, railway and transport, machine and plant construction, as well as high-tech and electronics, SupplyOn has established a corporate network that connects about 12,000 companies from 70 countries with one another. In this globe-spanning network, among others, lies the greatest added value of SupplyOn, because, just like with social networks, the benefit of a pro-fessional web platform is found first and foremost by the community that has networked itself via this medium.

About SupplyOn

Prerequisite: "Zero Defect Quality"

As an independent engine producer, customer satisfaction, as a result of qual-ity in all aspects, is a decisive success factor for DEUTZ and thus also for its suppliers, whose products are incorpo-rated in DEUTZ engines. In so doing, "Zero Defect-Quality" for all deliveries is an essential requirement, which can only attained and secured by means of mu-tual efforts on the part of DEUTZ and its suppliers. Avoidance, instead of the dis-covery of errors, and continual improve-ments to the complete process chain (customer enquiry, offer, order, product creation, start of production, serial deliv-ery and field operation) are essential re-quirements that DEUTZ must and would like to satisfy with the active help of its suppliers.

You can obtain additional information in the DEUTZ "Supplier Portal Sup-plyOn" brochure on the DEUTZ Website (www.deutz.com) at "supplier".

24 DEUTZINSIDE 3 I 2014 25

Modern work machines, as produced by DEUTZ customers for use on con-struction sites and in material handling, are complex systems that become increasingly more sophisticated with every new device generation. The refers to the performance at work and to the life cycle assessment with regard to resource conservation and emission reduction. It goes without saying that high tech and quality has its price. For the users, every new machine means a significant investment that needs to be carefully considered. Especially when the machine utilisation is difficult to fore-cast – a situation that every building contractor knows. Therefore, increas-ingly, both machine producers as well as their sales and service partners are shifting toward letting their mobile work machines to the users for a limited time. As this trend was first noticed in the USA, the English phrase of "Rental Business" has established itself. Also the DEUTZ Corporation in Atlanta has systematically expanded the business with Rental Power since the nineties, with special support by the DEUTZ new engine and service organisation.

Typically, the rental machines vary be-tween small and medium-sized devices under 100 kW of engine power. In this field the demand is large enough and the machine costs clear, so as to ensure good utilisation. From the view of an engine producer, the "Rental" business segment is particularly demanding. This is because those who let machines must be able to be certain that these will reliably perform the estimated op-erating hours, so that the procurement costs can rapidly be realised again. On the other hand, the end customer who

rents the machines is solely interested in its temporary use, e.g. for the duration of a building project. When considering the short usage period of the machines, maintenance work or even repairs during the utilisation are, at best, an annoying activity. Hence, robustness, long maintenance intervals and high cost-effectiveness, both regarding the purchase costs as well as the consump-tion, constitute the key success factors in the leasing business. In addition, it is also desirable to ensure the highest pos-sible resale value of the machines. This is the expectation the customers place in DEUTZ engines – and it is fulfilled in an exemplary way.

Lowest maintenance and operating costs

In principle, the delivery of DEUTZ en-gines for machines in the leasing busi-ness is nothing new. Quite the contrary, they have already proven their worth for a long time, as Gregorio Fernandez ex-plains, who is responsible for Material Handling Customers at DEUTZ in the position of Segment Head, and who co-initiated the DEUTZ Rental Power brand: "In the course of the past 25 years, the DEUTZ engines have proven their qual-ities in the business field of construction and hoisting machine leasing more than one million times." New, on the other hand, is the fact that, in the past two years and in addition to the known TCD-2011 series, DEUTZ has launched two additional engine series on the market that satisfy the needs of customers in the leasing business to a particular ex-tent: TCD 2.9 and TCD 3.6.

DEUTZ engines give a competitive edge that no other engine manu-facturer is able to pro-

vide so easily: Their maintenance costs are the lowest on the entire market. Decisive for this, among others, are the very long service intervals. With motor oil and with fuel filters, the change inter-val is up to 1,000 operating hours. In most cases, this exceeds the annual operating time of typical rental ma-chines, so that it is sufficient to send the machines to one annual mainte-nance check-up in the workshop. Other functions are completely maintenance-free. This applies for the complete valve train, which means that, thanks to the hydraulic lifters, the customers need have no concerns throughout the en-gine's entire service life. To attain the highest possible operating time, also with belt drive, DEUTZ offers a robust Poly-V drive with automatic tensioner pulley for all new engines, so that the regular checking of the belt tension can be omitted. Since compact machines can also be deployed in an indoor environ-ment, TCD 2.9 and TCD 3.6 have a closed crankcase breathing system.

It goes without saying that the new DEUTZ engines have consistently been developed in accordance with the most stringent exhaust emission standards worldwide. The engines smaller than 56 kW have an own oxidation catalyst from the DVERT technology construction kit. This catalyst ("DOC only") pursues the motto of "fit and forget": It requires no

Under the new description of "Rental Power", DEUTZ AG markets engines for construction and hoisting machines that find their first market in the leasing business. Ex-tremely economical and low maintenance requirements are trump in this business segment, where every oper-ating hour that is lost costs a great deal of money. When looking at the engine, this is clearly a case for DEUTZ.

SAFETY & QUALITYSAFETY & QUALITY

DEUTZ Rental Power – Minimising service costsEngines for construction machines in the leasing business

"In the last 25 years DEUTZ engines have proven their qualities in the business field of construction and lifting devices more than

one million times."Gregorio Fernandez, Head of Segment Field of Material-Handling Customers

< 56 kW

DOC only

Fit & Forget Solution

26 DEUTZINSIDE 3 I 2014 27

TEAM & CHANCENSAFETY & QUALITY

special sensor technology, is very easy to install and absolutely maintenance-free. For the majority of the markets and applications, quite simply, DOC only is the best solution. For the limited number of markets that - by defining the number of particles allowed - do de facto pre-scribe a closed particular filter, it goes without saying that a diesel particulate filter (DPF) is available for the charge-cooled variants of the TCD 2.9/TCD 3.6. Higher than 56 kW, the TCD 3.6 is additionally equipped with a SCR system, which is required for harsh con-struction machines operations. All this ensures that DEUTZ engines can be deployed worldwide, and that they are future-proof. Because, thanks to these features, they satisfy all known - also fu-ture - emission requirements for mobile work machines worldwide.

Always the right engine

Apart from their high power density, another common element of the en-gine series is low fuel consumption as well as a powerful torque delivery that secures a quick response at all times. The newly developed TCD 2.9/TCD 3.6 are water-cooled four-cylinder series engines with common rail high-pressure fuel injection, externally cooled exhaust gas recirculation and electronic engine control (EMR 4), with an intelligent con-nection to the drive management. Both series are available with turbocharging and with and without intercooling. In addition to this, the 2.9 is also avail-able as a naturally aspirated engine. Common to both series is high engine power with very low consumption and emission values. For deployment in less stringently regulated export markets, so-called emission-downgrade variants are available. Here, the after treatment

This year, the country's best production mechanic in NRW once again comes from Cologne. After a DEUTZ apprentice was already honoured as the country's best in the profession of "production mechanic" one year previously, an apprentice from the DEUTZ training centre in Cologne once again succeeded at beating his competitors, thanks to his outstanding performance. For this he could take home the coveted prize that was awarded by the Chamber of Industry and Commerce in Dortmund.

As DEUTZ AG attained the best over-all training performance country-wide in 2014, when considering all vocational companies in the training field of "pro-duction mechanic", the company thus ranks among the "Best of North Rhine-Westphalia". In recognition of its out-standing performance and exceptional commitment in the dual study course, the Chamber of Industry and Commerce in Dortmund honoured the DEUTZ training centre in Cologne with a certificate in Oc-tober 2014.

"It is a high praise for us to have been honoured as the country's best training company in this year again. We consider the award by Chamber of Industry and Commerce as a sign of recognition for our continual very good training activities, which is additionally reflected in individual prizes honouring outstanding perform-ances," says Dr Margarete Haase, board member of DEUTZ AG.

Two apprentices of the DEUTZ training centre also received a special award in honour of their performance from the

of exhaust gases can be omitted and, by means of a special tuning, the en-gines can also be operated with fuels containing a higher sulphur content than permitted in Europe.

Most of the times, rental machines are sold on the used-machine market after four to five years. Many of these machines are then exported outside of Europe or the USA. For this, and as an additional service, DEUTZ offers its cus-tomers a downgrade from Tier IV, re-spectively Tier-4 engines, to the exhaust gas level of Tier IIIA. In so doing, apart from the obligatory exchange of the engine model plate and the installation of a new dataset by DEUTZ service, the exhaust after-treatment system is also modified. This ensures that DEUTZ en-gines also operate reliably in the used-machine segment in distant regions.

As a tried-and-tested basic series among the DEUTZ construction ma-

Chamber of Industry and Commerce in Cologne. For their exceptionally good per-formance, the DEUTZ apprentices who learnt the profession of industrial and manufacturing mechanic, were honoured with the "The Best" certificate. Therefore, the training centre can rejoice at numerous awards in this year, which can be consid-ered a reflection of its exceptional commit-ment in dual study courses. Because, for the fourth consecutive time, the Cologne-based company was honoured for its out-standing performance in initial occupation-al training by the Chamber of Industry and Commerce in Cologne within the context of the "Honouring the Best 2014" award.

What is more, the company was also short-listed regarding the award for "Train-er of the Year": On the basis of an online voting ballot, the DEUTZ vocational trainer Mark Flake could secure 700 Facebook "likes" based on films regarding the five finalists in their working environments, and as such succeeded at winning the audience prize. Since 2009, Mark Flake has supervised more than 100 appren-tices in the professions of "manufacturing

chines engines, the TCD 2011 series has proven its worth with a great variety of different construction forms and ap-plication solutions. They are available with two, three or four cylinders, inte-grated cooling, whereat the liquid cooler is compactly fitted into the engine, or external cooling. With the four-cylinder version, apart from the standard version with oil cooling, the options of water cooling, turbocharging and intercooling are also available. Together, the com-pact DEUTZ engines of the TCD 2011, TCD 2.9 and TCD 3.6 series cover the complete power range between 23 kW and 100 kW. This makes them flexible for the deployment in work machines of varying sizes and with numerous differ-ent tasks. A broad range of engine and application varieties that have consis-tently been aligned to the needs of the leasing business – this has succeeded at winning broad acceptance for the compact DEUTZ engines in the rental business.

and industrial mechanics" and "specialist for metal technology" at DEUTZ AG. To date, four persons have been honoured as the best by the Chamber of Industry and Commerce in Cologne. Mark Flake is a member in four Chamber of Industry and Commerce examination committees and defends the interests of people with learning disabilities.

"That we are once again honoured for our work by the Chamber of Industry and Commerce in Cologne fills us with pride, because, by means of this, the commit-ment of our trainees and that of the train-ers is recognised in equal measure. For us it is important to provide young adults with a well-founded start in their professional careers, because this is the only way to train qualified employees for the future," says Frank Opitz, head of the DEUTZ training centre in Cologne.

DEUTZ AG has already conducted voca-tional initial trainings since 1919. Career entrants can apply for six different training occupations at DEUTZ: Apart from the training occupations of specialist for metal technology, electronics technician, me-chatronics engineer, cutting machine op-erator and industry mechanic, the young adults can also select the training occupa-tion of warehouse logistics. What is more, by regularly participating in the action day "Girls Day", the company intensifies its ef-fort to spur enthusiasm for technical and business-related education among girls. Already for numerous years, DEUTZ has also been involved in the annual initiative "Erlebnis Maschinenbau", Experience Me-chanical Engineering, which has the pur-pose of providing young people with first impressions of the work offered to em-

ployees at a mechanical engineering company. In addition, DEUTZ also conducts vocational training for other compa-nies: presently, about ten external companies send their career entrants to the Cologne engine producer to be trained there, secure in the knowledge that they can rely on the quality of the DEUTZ training centre.

< 56 kW

DOC only

Fit & Forget Solution

TEAM & CHANCES

27

DEUTZ trains „The Best“

TEAM & CHANCES

28 DEUTZINSIDE 3 I 2014

TEAM & CHANCES

Haase, management board member for Finances, Human Resources and In-vestor Relations, emphasised in her wel-coming speech. The responsible trainers also extended a warm welcome to the young adults and presented themselves not only as contact persons regarding training contents, but also encouraged them to approach them in the event of any concerns or problems.

Traditionally, the first two days of the ap-prentices' training is in keeping with the motto of "Introduction Days". Here, in the DEUTZ Technikum, the apprentices are given an introduction into the working life at DEUTZ by the DEUTZ trainers and the apprentices of the second learning year. They get to know the company by means of presentations and guided tours, find out more about the company's history and corporate structure, and also have the possibility of establishing first net-working contacts for their professional future at DEUTZ by means of intensive cooperation with the other apprentices, for instance in the form of group projects,

such as Logo-Bau (Logo Construction).This "networking" of the young career entrants is further strengthened about four weeks later, by the so-called "com-petence week". The competence week takes the new apprentices to a university of cooperative education in Neu-Lister-nohl, where, thanks to intensive cooper-ation with social education specialists, the personal skills and requirements for the working life are trained, developed and promoted. This includes reliability and ad-herence to schedules, but also a sense of responsibility, to recognise that every in-dividual activity is part of a process chain that can only function with good and relia-ble cooperation.

Acquiring competences for the profession

Therefore, within the context of the com-petence week, group and team tasks are also a fixed element of the appren-tices' timetable. Here, accompanied by their instructors and trainers, the DEUTZ apprentices are afforded the opportunity

of acquiring competences for their pro-fession, under expert guidance and in a playful way. The competence week offers the instructors the chance of get-ting to know the apprentices better, for instance also with regard to their social competence and behaviour during con-flicts, when criticism is expressed. This week also incorporates exercises that prepare the apprentices for the formal requirements of the examinations. This includes, among others, presentation techniques, communication training and skills pertaining to speaking freely.

Young people also commenced their apprenticeships at the three other Ger-man DEUTZ AG locations on the 1st of September 2014. Here, in the Ulm plant, four industrial mechanics and an indus-trial clerk are currently being trained, in Übersee/Bavaria, two apprentices have started learning the vocation of indus-try mechanics as of this year, and at the Herschbach location, two young adults have commenced the training as a cut-ting machine operator.

29

For the new DEUTZ apprentices, the first official working day at DEUTZ AG started on the 1st of September 2014, and as such also a new stage of life. Matching the 150-year anniversary of the company, the 20 Cologne-based apprentices were welcomed by the DEUTZ board member

Dr Margarete Haase in a festive ceremo-ny in the DEUTZ-own "Technikum" en-gine museum in Cologne. "I am delight-ed that you have decided to complete your training at DEUTZ AG, because it is important to have the young adults perceive us as an attractive employer.

We have already been training young adults since 1919, with the goal of thus providing them with a sound foundation for their professional future. In so doing, we invest both in their and in our future, because the apprentices of today are the junior staff of tomorrow," Dr Margarete

Take-off for the vocational training

The DEUTZ apprentices of the anniversary year!

PEOPLE & MARKETS

30 DEUTZINSIDE 3 I 2014

PEOPLE & MARKETS

31

Cast iron and forged steel – this is what DEUTZ engines are made of. Yet who would have though the assembly plant in Cologne-Porz also processes a great deal of wood? Yes, it even has a real carpentry. Working there are em-ployees from Stute, the DEUTZ partner in logistics matters.

Maximal process-efficiency is trump in a state-of-the-art engine plant such as is found at the DEUTZ headquarters in Co-logne-Porz. And these efficient process-es do not end once the engine has been completed. Because, being a product made by an exceptionally export-strong manufacturer, depending on the circum-stances, the DEUTZ engine might still have a long trip ahead of it, to the USA, China or India, meaning that it must still be prepared, i.e. packed. When Claus Rausch, Head of Transport, Packaging Management & Customs at DEUTZ re-ports on this, a certain degree of pride

From the first sketch of an engine on paper, right up to its deployment in a cus-tomer machine, the development of a diesel engine passes through numerous steps. Following the construction and procurement, the first construction of an early prototype follows. The controlling software, which regulates the behaviour of the engine, must already depict the fundamental functions. First data regard-ing injection, load change and the after treatment of exhaust gases must already have been provided. Only then does the engine perform its first running tests on a test bench.

This is the start of an extensive phase of tests, where the engine is precisely aligned to the customers' specific needs and requirements. This alignment work is referred to as calibration.

In the test field of research and develop-ment of DEUTZ AG, functional testing, endurance testing and the calibration of engines is performed. The data thus acquired is then analysed and prepared, supported by complex calculation and simulation programmes. The approach allows about 40,000 different data valu-es to be acquired, which are needed in the field of engine controlling. Hence

can be noted: "Our one-piece-flow-sys-tem for packaging has proven itself to be exceptionally good in the two years since its introduction. Without the loss of time – and most importantly: without the need to stock a large amount of packaging mate-rial in the plant, which would involve high costs and require a great deal of space – we get every single one of the 200,000 engines that roll of the production belts in 2014 on their way." Briefly stated, one-piece-flow means: The wooden trans-port frames for every engine are built at the same time as the final manufacturing phase of the engine - and precisely for this

DEUTZ engines are optimised to the customer application.

The acid test of an engine then ensues in the customer vehicle. The goal is to carry out supplementing tests under real-life conditions, especially with a view to the exhaust gas quality in the corresponding device. The measurement data required for this is established with highly compact and transportable measurement devices, and this technology has only been avail-able since this decade. Like their cabinet-sized brothers, these measure the exhaust gas components and particles at the test benches. These devices are referred to as Portable Emission Measurement Systems, abbreviated to PEMS.

A measurement campaign in the field is very elaborate and requires good plan-ning. The measurement devices must be maintained and prepared in the laboratory of the development. So that the additional electricity requirement of a PEMS does not have an influence on the test, the electricity is generated from external power units and not "taken" from the customer's vehicle. What is more, gases are also carried along. These, e.g. serve the purpose of control-ling the PEMS devices prior to and after deployment in the field. An additional point

one engine. There is no frame production that is kept on stock.

The wooden frames are built by about 30 employees of Stute Logistics in three shifts, directly on the company premises of DEUTZ AG. In the carpentry situated there they process hundreds of metres of squared timer every day, as well as thou-sands of nails or staples. And, as already mentioned, this is possible without much warehousing. The about 20 building com-ponents for every frame - also by Stute – are pre-picked and delivered to the car-pentry. There are 75 different parts. These are used to manufacture 60 different vari-eties of wooden frames. Hence, similar to the DEUTZ engines, the frame production follows a modular design. And this ensues just-in-time. From the moment the DEUTZ production calls off the wooden frame from the service provider Stute, it still has two hours at its disposal for construction. When the time comes for packaging, the engine and its wooden transport sub-structure are ready, to the point. According to the customers' requirement, the outer packaging of the frame is completed as a wooden frame or with cardboard. For deliveries within Europe, where the effort for return transport is manageable, multi-way frames made of steel are increasingly being deployed, instead of the wooden frame. What is more, their processing is also in the hands of the logistics pros at Stute, who ensure that the engine safely reaches its final destination, in line with the DEUTZ customers' wishes.

that should also not be underestimated is the positioning of the measurement de-vices on the customer vehicle. Here the team is challenged to find the ideal solution. Engineers and technicians must reconcile security, handling and, most of the time, very restricted space conditions.

The actual measuring performance then ensues during the standard working time of the corresponding tractor or con-struction machine by means of PEMS measurement technology, in all weather conditions. Here, dust and dirt, extreme temperatures, ice & snow as well as de-ployment in the mountains demonstrate whether the low engine emission values of the test bench still hold up in practice, because, at the end of the day, DEUTZ develops engines for a great variety of different usages, depending on the cus-tomers' individual needs.

By using PEMS technology in the field tests, the test engineers gain additional valuable data on the way toward devel-oping a high end diesel engine product. Therefore, in the meantime, the application of PEMS technology has become an inte-gral part of engine development at DEUTZ and another building block in the devel-opment of optimal customer applications.

Look who's tacking

The PEMS technologyThe carpenters from the Stute Logistics partner company in the Cologne- Porz DEUTZ plant

From the test bench to the tried-and-tested customer application

Herzlichen Gluckwunsch zum 150!

Wenn die Firma gut floriert!Mitarbeiter motiviert!Fleiss gebuhrend honoriert!viele Jahre existiert!deren Zahl sich zu 150 summiert!wird ihr gerne gratuliert!

In diesem Sinne auf weitere 150 Jahre!

Congratulations on the

occasion of 150th anni-

versary of DEUTZ. Wish

every success in the years

to come. DEUTZ have made it! The

most reliable engine ever.

Good luck to staff and

management of DEUTZ.

Congratulations DEUTZ for 150 years. We wish you many more successful years in the future!

Schon 150 Jahre sehr beachtlich

Wirklich: Das Geschäft, es macht sich

Vom Erfolg, wie jeder weiß

Fließt ja immer sehr viel Schweiß

Eifrig habt Ihr viel geschafft

Glück, Gesundheit und auch Kraft

Sollen weiter Euch begleiten

Wie sich ändern auch die Zeiten.

What a remarkable achievement for Otto & the DEUTZ Company.Inventors of the 4 stroke engine that is still used 150 years on…

Thanks to DEUTZ AG, Cologne has

an automobile history the likes of

which only very few other cities

have worldwide. Also the history of

aviation is hardly conceivable wit-

hout the combustion engine.

Therefore, also in the name of

the Cologne aviation, we wish you

a happy birthday on 150 years of

company history.

Congratulations to DEUTZ, the green tractor. Today, I am 61 years. With 8 or 9 years I helped my uncle repair DEUTZ tractors. I was fascinated by the technology and mechanics and because of this, I learnt the craft of mechanical engineering and subsequently studied it. The technology never let me go again. During my studies, I ran laboratory tests on the 70 kW truck turbine, which caused an infernal noise and was incredibly exciting, par-ticularly the high revs. Later on, I became interested in the development history and the obstacles. Once again, happy birthday!

I am the owner of an 11 series DEUTZ F1 M414 from 1939, it has been in family pos-session ever since then. I received it from my grandfather, via my father, as an heir-loom. Since then, I have come to apprecia-te the solid and durable construction of this tractor.

I would like to make use of this oppor-tunity to express my recognition for your long-standing company history and thank the employees of DEUTZ!

Wonderful company!

wonderful products.!

Congratulations on your 150th birthday.You have achieved an age others can only dream of. To another 150 years and the best engines on earth.

Greetings from Bavaria

Die Firma soll bluhen und gedeihen

Die Kunden sollen stehen in Reihen

Und alle Produkte hoch loben

Der Umsatz soll schießen nach oben

Sogar sollen die Konkurrenten

Noch kommen und Beifall Euch spenden.

Auf weitere 150 glorreiche Jahre!