Designing Supply Chain Analysis Tool Using SCOR …scss.sk/dvd_kega_037_stu_4_2012/2013/VÝSTUPY Z...

Transcript of Designing Supply Chain Analysis Tool Using SCOR …scss.sk/dvd_kega_037_stu_4_2012/2013/VÝSTUPY Z...

Designing Supply Chain Analysis Tool Using SCOR Model (Case Study in Palm Oil Refinery)

F. Lestari1, @, K. Ismail2, A. B. Abdul Hamid3, @, W. Sutopo4

1PhD Student on Faculty of Management, Universiti Teknologi Malaysia, Malaysia @Scholarship Grantee of Amanah Pelalawan Foundation

2Faculty of Management, Universiti Teknologi Malaysia, Malaysia 3Faculty of Management, Universiti Teknologi Malaysia, Malaysia

@Visiting Professor at Mitrans 4Department of Industrial Engineering, Sebelas Maret University, Indonesia

(E-mail address: [email protected]; [email protected]; [email protected]; [email protected])

Abstract - Business strategies of palm oil supply chain include linkages between plantation as suppliers, milling, refining and customer. Case study on palm oil refinery shows the distribution of product from supplier to customer has a pattern that can be standardized into operational procedures within business processes. This paper aims to present the implementation methodology of SCOR Model based case study on palm oil refineries using the software Process wizard. The methodology can facilitate the blending of business objective, strategy, process and technology in the supply chain. The result shows SCOR templates is very useful tool for the design of a supply chain configuration and also provide the ability to improve the system through best practice projects. It is necessary to note that the software Process wizard can be used as a tool for analyzing configuration operations of the supply chain.

Keywords - Palm oil, Process wizard, refinery, SCOR,

supply chain

I. INTRODUCTION Business strategies of palm oil supply chain include

linkages between the plantation as suppliers, milling, refining and customer which it illustrates the relationship between business entities into a chain [1]. Palm oil industries have a complex business chain. The business processes of palm oil are initiated from plantation, and then processed by the processing industries as refinery, distributed to industry of product developers who produce diverse products until the end users as customers.

In the refinery processes, there is a batch-process of processing crude palm oil into intermediate goods or finished goods. Many industries utilize the processing of palm oil refineries. Then, the result of this processing will be distributed to the customer at local market industries which producing finished goods of palm oil products and the international market using the port center as shipping services. Distribution of crude palm oil to be processed in the refinery industry requires handling the storage in the form materials of liquid or oil. The product of refinery processes not only in the form of liquid, but also can be a solid such as specialty fats thus requiring storage strategy in logistic arrangements and the distribution of finished goods. Products in the form of solid and liquid have

different handling in terms of the distribution to the customer [2]. Therefore, it needs an analysis tool that can support integration within the supply chain. Designing of supply chain practices in the palm oil industry will emphasize on integration. According to van donk et al., [3] uncertainties and complex operational characteristics increase of the need for integration.

There is a methodology that can facilitate the blending of business objective, strategy, process and technology in the supply chain. The tool is SCOR model which it seeks to develop the business processes of an interconnected flow material between business networking [4]. In addition, this model can also describe the mapping between the business process areas based on their stakeholders. The advantage of this model, users can design business chain and to develop strategies and improve on technology within a business process.

The software Process wizard is a software that can build a business strategy using the SCOR methodology to design a model within a supply chain. This paper aims to present the implementation of the SCOR Model based case study on palm oil refineries using the software Process wizard. This application is expected to give impact in the form one of the analytical tools to re-engineering supply chains with the implement of SCOR.

II. SUPPLY CHAIN

Strategic Supply Chain Management (SCM) is one of the strategies used to win the market. This strategy aims to minimize production costs with minimal resources to achieve more profit and customer satisfaction at the right time in the right place and the right amount [5]. In addition, SCM is an integration of the organization and activities through cooperative organization relationship, effective business process, and high levels of information sharing to create high performing value systems that provide member organizations a sustainable competitive advantage [6]. However, research found that these strategies were used for different constructs for different country. In fact, the manager has different perceptions and cultures on how to arrange a strategy for its organization [7]. Previous studies have shown that different industry may also have a different effect on SCM practices [8] [9].

978-1-4799-0986-5/13/$31.00 ©2013 IEEE

To solve these problems, the decision maker should find fitting on these approaches and models based on respective business processes.

Relationship among entities within SCM is exchanging of material flows, and financial information. This exchange occurs from upstream to downstream by providing some benefit to the product. Application of SCM covers with production and large geographic-scale distribution of a diversified set of goods. They are like horticultural, meat, fishery, dairy, bakery, beverages and other products are proposing logistic and safety challenges which require an implementation of the technology [10].

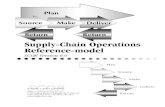

III. SCOR MODEL

Supply chain operational reference (SCOR) is the product which is developed by Supply Chain Council. SCOR model is a tool for mapping, benchmarking and configuration operations of supply chain [11]. This model is divided into three parts: performance metric, process building block and best practice. In this paper, SCOR model will be implemented by using software which adoption SCOR model version 8.0. The software provides modules to build a process model into supply chain which it is called Process wizard. Furthermore, glossaries in this terminology can be used for all business process.

A. Performance metrics

Performance metrics serve to measure the performance

of a business process using the standard metrics available. This measurement is a tool for benchmarking between our company and competitors. In addition, this metric is also known as key performance indicators. The performance is divided into two types of elements: performance attributes and performance indicators.

B. Process Modeling

Process model serves to configuration operations of

the supply chain structure and improvement activities in the supply chain. The model defines the process into three levels. Level 1 is process definitions and describes the scope and level configuration of the supply chain. This level contains five different processes such as Plan, Source, Make, Deliver and Return.

Level 2 is process type level which positioning of business process in the supply chain determines the supply chain strategy. This level contains 26 level 2 in different processes. In Plan level, the model is distinguished among Plan supply chain (P1), Plan source (P2), Plan make (P3), Plan deliver (P4) and Plan return. In the Source level, the model is distinguished among Source stocked product (S1), Source make to order product (S2), and Source engineering to order product (S3). In Make level, the model is distinguished among Make to stock (M1), Make to order (M2), and engineering to order (M3). In Deliver level, the model is distinguished among Deliver stocked

product (D1), Deliver make to order product (D2), Deliver engineering to order product (D3), and Deliver retail product (D4). Then, in Return level, the model is distinguished among Source return defective product (SR1), Source return MRO product (SR2), Source return excess product (SR3), Deliver return defective product (DR1), Deliver return MRO product (DR2), Deliver return excess product (DR3).

Level 3 is process category which contains 185 level 3 processes. This level is a breakdown of the sub process of level 2. It shows same procedures to other companies whether they want to configuration operation in the supply chain. For the instance, in process Source stocked product can be generated in Schedule product deliver (S1.1), receive the product (S1.2), verify product (S1.3), transfer product (S1.4), and authorize supplier payment (S1.5).

C. Best Practice

Best practice is a way to improve and configure a set

of supply chain processes. Improvement can be done through automation, technology, special skill which applied in the process and unique method for distributing. The software Process wizard provides a module to do best practice based on process at the level 2. The module of improvement consists of type best practice, definition, status level of maturity and level of importance.

D. SCOR Template in Process wizard

Template in Process wizard consists of several modules. In this case study, it will use three modules: Balanced scorecard, Geographic diagram and Thread diagram. Balance Scorecard is used to generate performance metrics which user can pick up materials from the master database. Configuration operations of the supply chain can be built with the drag icon from the toolbox as representative in the business process. Furthermore, a map that describes geographic area is available in this module. All of this can be created using the Geographic diagram module. Thread diagram serves to build a block diagram of SCOR model. This module show interconnected flow material between operations of the supply chain.

IV. CASE STUDY

This paper tries to provide an analysis tools to design palm oil refinery within a supply chain structure. Designing of palm oil refinery supply chain is done with an adoption SCOR model which using software Process wizard. The structure of supply chain involves processing of milling, refinery and penetration of the market.

A. Palm Oil Refinery

A case study was conducted from refinery process in Johor Bahru, Malaysia. This process produces oil and

Proceedings of the 2013 IEEE IEEM

specialty fats to be shipped to the customer. Raw materials for the production process are obtained from the milling industry. Furthermore, the finished products will be sent to the local industry, using tank trucks and also shipped through the port center uses the shipping services. This distribution uses Third-party Logistics (3PL) service delivery where online booking is done through established contracts. Fig. 1 is a business process that occurs on the palm oil refinery. For the detailed information, the red line means service by 3PL and the black line means cover of their own business. Furthermore, process model between entities supply chain multiple link concurrently in palm oil refinery can be seen in fig. 2.

Fig. 1. Business processes palm oil refinery

B. Adoption SCOR model

Benchmarking is done by selecting performance

metrics from the master database of software Process wizard then the data entered source of the data in annual reports. In this case, the performance attributes divided into external and internal. External facing includes supply chain attributes of reliability, responsiveness, and flexibility. While the Internal faces include supply chain attributes of cost and asset management. It can be seen in fig. 3. Each attribute has different performance metrics depend on its performance attributes used. In the instance, attribute reliability has a metric as Perfect order fulfillment. Value this metric can be achieved with [Total perfect orders] / [Total number of orders] x 100%.

This software provides a tool to develop the supply chain based on the work area as well as its association with other industries. Refinery process which is located in

the state of Johor Bahru will be shown through the southern part of the Malaysian map which is bonded directly to Singapore. Fig. 4 shows that this project was done on a Geographic diagram module which the icon of industries can be dragged from the toolbox on this software. In addition, movements of material flow from suppliers to manufacturing and to the customer shown through the direction of arrow. Each entity will display the process type on level 2 based on the SCOR Model methodology.

The thread diagram module will generate process models from the Geographic diagram module. The results showed that process models are distinguished based on the business process of entities in the supply chain structure. Fig. 5 shows the definition of process in every industry. The process model of refinery process shows its business strategy in running process industries. For the instance, the refinery stored stock materials from suppliers in storage, produced products in the production system based on a push strategy and stored the final product at the warehouse. Plan level shows all the overall planning process is done in the form of a Plan supply chain. Furthermore, in the preparation of the return strategy, the source that reject will return to the supplier. Then, if the customer is not satisfied with a product of this industry, they will repatriate the product to replacing with a product that has been agreed.

Best practice module performed on each process type at level 2 which wants to be improved. Fig. 6 shows best practice of process type of Stock Delivery of product (D1) on Internet orders. The user can declare status is going on at this time and determine the level of importance to be improved. Each Best practice module can be recommended for proposed projects that will be improved.

V. CONCLUSION

The palm oil refinery has business networking that associated with suppliers and customers. Distribution of product from the supplier to the customer has a pattern that can be standardized into operational procedures within business processes. This paper has successfully to show designing supply chain at a case study using software Process wizard which adopted methodology in the SCOR model. The result of this paper shows SCOR templates is very useful tool for the design of a supply chain configuration and also provide the ability to improve system through Best practice module. Therefore, the Process wizard is software that can be used as a tool for analyzing configuration operations of the supply chain.

Improvements through Best practice module recommend projects which would be carried out. Further studies proposed to rank the priority project that wants to improve. Furthermore, improvement strategy of business process directed towards dynamic supply chain analysis tool on discrete event simulation. It aims to improve the supply chain system which featuring multiple scenarios of business process to achieve optimal results.

Proceedings of the 2013 IEEE IEEM

ACKNOWLEDGMENT

The authors thank to the Amanah Pelalawan Foundation for Ph.D Degree Scholarship Program that fund this research.

REFERENCES

[1] S. Z. Omain, A. B. Abdul Hamid, A. R. Abdul Rahim, and N. Md

Salleh, “Supply chain management practices in Malaysia palm oil industry,” in The 11th Asia Pacific Industrial Engineering and Management Systems Conference, 2010.

[2] K. Yu and J. Cadeaux, “Alternative forms of fit in distribution flexibility strategies,” International Journal of Operations & Production Management, vol. 32, no. 10, pp. 1199–1227, 2012.

[3] D. P. Van Donk, R. Akkerman, and T. Van Der Vaart, “Opportunities and realities of supply chain integration: the case of food manufacturers,” British Food Journal, vol. 110, no. 2, pp. 218–235, 2008.

[4] P. Bolstorff and R. Rosenbaum, Supply chain excellence�: a handbook for dramatic improvement using the SCOR model, 3rd Editio. Amacom, 2007.

[5] H. Li and K. Womer, “Modeling the supply chain configuration problem with resource constraints,” International Journal of Project Management, vol. 26, no. 6, pp. 646–654, Augustus. 2008.

[6] P. Trkman, K. McCormack, M. P. V. de Oliveira, and M. B. Ladeira, “The impact of business analytics on supply chain performance,” Decision Support Systems, vol. 49, no. 3, pp. 318–327, Jun. 2010.

[7] W. S. Chow, C. N. Madu, C.H. Kuei, M. H. Lu, C. Lin, and H. Tseng, "Supply chain management in the US and Taiwan: an empirical study." Journal Omega, vol. 36. no.5, pp.665-679 2008.

[8] D. Mollenkopf and G. P. Dapiran, “World-class logistics: Australia and New Zealand,” International Journal of Physical Distribution & Logistics Management, vol. 35, no. 1, pp. 63–74, 2005.

[9] S. Jharkharia and R. Shankar, “Supply chain management: some sectoral dissimilarities in the Indian manufacturing industry,” Supply Chain Management: An International Journal, vol. 11, no. 4, pp. 345–352, 2006.

[10] C. Costa, F. Antonucci, F. Pallottino, J. Aguzzi, D. Sarriá, and P. Menesatti, “A Review on agri-food supply chain traceability by means of RFID technology,” Food and Bioprocess Technology, vol. 6, no. 2, pp. 353–366, 2012.

[11] SCC, “Supply chain operations reference (SCOR) Model Version 8.0 Overview,” 2006.

Fig. 2. Supply chain in palm oil refinery

Fig. 3. Balanced scorecard module

Proceedings of the 2013 IEEE IEEM

Fig. 4. Geographic diagram module

Fig. 5. Thread diagram module

Fig. 6. Best practice module

Proceedings of the 2013 IEEE IEEM

![Service Performance Assessment and Governance - …scss.sk/dvd_kega_037_stu_4_2012/2013/VÝSTUPY Z VLASTNEJ VEDE… · implementation of PIs, such as: ECOGRAI, IPMS and DPMS [2],](https://static.fdocuments.us/doc/165x107/5b98c64509d3f2b16c8c734f/service-performance-assessment-and-governance-scssskdvdkega037stu420122013vystupy.jpg)