Designing of High Comfort, Reliable and Economical Driver

description

Transcript of Designing of High Comfort, Reliable and Economical Driver

-

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

142

Designing of High Comfort, Reliable and Economical Driver

Car Seat Rakesh Singh

1, S.L. Ahirwar

2, Sunil Kumar Tiwari

3

1PG Scholar,

2Assistant Professor,

3Assistant Professor, Department of Mechanical Engineering, Oriental institute of Science

and Technology, Bhopal, India

Abstract To design and develop a comfortable drivers

seat, cheaper in cost and adds value to the customer is an

important issue in an automotive industry. It is tough to

design such a driver car seat. However, taking account all

these things many researchers have put effort to design and

developed a driver car seat considering various aspects (e.g.

Biomechanical, materials, vibration absorption, safety etc.)

which provides more comfortable value to driver with safety

and operational durability, but still having a chance to do

improvement in design and material to get an ideal designed

driver car seat. This work aims to design and develop

optimum driver car seat which is ergonomically satisfied have

less weight and cheaper in cost. The modelling of a new driver

car seat is done on AUTODESK INVENTOR software. In a

new design, driver car seat lever system is replaced by a press

button mechanism and an automatic seat adjusting lock

system used to restrict the movement. The nylon material is

used to fabricate the seat and simulation is done by using

Autodesk Inventor software.

KeywordsAutomobile, Autodesk Inventor, Frame,

Optimization, Seat Design.

I. INTRODUCTION

Many car manufacturers putting effort to be competitive

in the global market and to capture more market they are

offering variety of new product to customers satisfying their

requirements. This is important to frequently release new

products. To preserve focus from the market, marketing of

new products will be easier and most importantly ability to

manipulate the market and strengthen images gives high

values to company. Thus, the key issue is how to

economically develop various new products and which is

likely to be manufactured in shorter lead time [1]. In

product development the well known fact that corrects

decisions as early as possible have great importance, both

for success from a cost-effective and economical and the

perspective of how well the product will fulfill its overall

basic technical requirements.

In automobile while designing a component or part or

subassembly manufactures mainly focus on weight

reduction, safety, shorter lead time, cheaper in cost and

have high specific strength.

The major automobile manufacturers have studied the

safety of the occupants during a wide range of impact

conditions [13]. The large majority of the impact conditions

researched were frontal impacts, due to the large number of

injuries occurred during a frontal collision. Although safety

devices such as seat belts and air bags have reduced the

number and severity of injuries during an impact, there has

been an increase in the number of injuries sustained during

a rear impact. This rise in injuries has led automobile

manufacturers to redesign and increase the strength of their

seat structures. Numerical Analysis has become the widely

chosen method for design and optimization due to the time

and expense involved in the production and testing of a

prototype seat structure. Although Numerical Analysis has

been the preferred method of analyzing a seat structure, the

construction and analysis of a nonlinear numerical model

require a significant number of man hours to produce

reliable results due to the structures nonlinear behavior [1, 4, 15]. A general trend in the design process is to reduce

the total engineering development costs and time-to-market

of a product by using computer aided-engineering

technologies. In this context, car manufacturers use Digital

Mock-Ups together with Digital Human Models (DHMs) to

assess the ergonomics of their product during the early

phases of its design. Integrating DHMs in the early design

process allows the improvement of product and workplace

ergonomic design through virtual simulation of physical

interaction between target customers/workers and the

designed system [6].

The Ergonomics is the study of the interaction between

people and machines and the factors that affect the

interaction. Its purpose is to improve the performance of

systems by improving human machine interaction. This can

be done by designing-in a better interface.Consumer expectation for automobile seat comfort continues to rise.

With this said, it is evident that the current automobile seat

comfort development process, which is only sporadically

successful, needs to change. Safety and seating comfort are

two factors that seat and car manufacturers use to

distinguish their products from that of their competitors.

-

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

143

It is well established that the mechanical properties and

shape of the seat influence the head and torso movements

in impact conditions, especially in rear and side impact.

[14]. Today, in the industrialized world, sitting is the most

common working posture and perhaps the most frequent

leisure posture. It is well-recognized that constrained sitting

postures can lead to discomfort and health disorders (e.g.,

back pain, neckshoulder complaints, etc.) causing a major cost to the society through missed work and reduce worked

effectiveness productivity consequently [10]. The different

postural angles describing the driving posture are given in

table I.

Table I

Postural Angles Describing The Driving Posture [7]

Au

thor

An

gle

(deg

rees

)

Tru

nk

flex

ion

Kn

ee

flex

ion

An

kle

pla

nt.

Fle

x.

Sh

ou

lder

flex

ion

Elb

ow

flex

ion

Wri

st

flex

ion

Rebiffe Min 95 94 90 10 80 70

Max 120 135 110 45 120 190

Winser-

Rebiffe

Mln 85 100 85 15 80 -

Max 100 120 95 35 90 -

Wiss Min 87 95 90 35 80 -

Max 103 135 110 45 120 -

Babbs Min 95 95 90 10 80 -

Max 120 135 110 45 120 -

Au

thor

An

gle

(deg

rees

)

Tru

nk

flex

ion

Kn

ee

flex

ion

An

kle

pla

nt.

Fle

x.

Sh

ou

lder

flex

ion

Elb

ow

flex

ion

Wri

st

flex

ion

Re Min 97 115 96 42 95 -

Max 103 120 104 48 115 -

Mesturino

Min 95 115 98 46 100 -

Max 97 119 100 47 104 -

Dreyfuss Min 95 110 90 0 80 -

Max 100 120 100 35 165 -

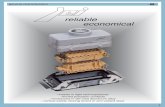

II. DESIGNING OF DRIVER CAR SEAT

A. Old Car Driver Seat

In an old model of car driver seat, the seat movement is

controlled by lever system. The liver system design is

complex. The old car driver seat is shown in figure 1.

Figure 1 An Old Passenger Car Seat Model[21]

Apart from this old passenger car seat produce jerk when

the driver applied brake. The excessive jerk causes

discomfort to driver. The driver move forward when brake

applied but seat remains in his own position and time when

driver again take place his original position he suffered

from shock and jerk as shown in figure 2. In figure 2 red

dotted lines indicates the initial condition of seat and blue

dotted line indicates the driver position. When driver

applied break the driver move forward and reach in new

position which shown by line and again when driver reach

original position, he suffered from shock and jerk which is

shown by a red spot. This uncomfortness is reducing by

design and optimization of the driver seat.

-

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

144

Figure 2 Shock Impact While Applying Brakes

B. Design Of New Driver Seat

New car seat model which is described in figure 4 is

designed by considering the suitable postural angles from

table 1. The new car seat model postural angles in

maximum and minimum position are shown in figure 3. All

these postural angles are fulfilling the all ergonomically

condition. In a new design, driver car seat lever system is

replaced by a press button mechanism and an automatic

seat adjusting lock system used to restrict the movement.

Figure 3 Posture Angle Of New Driver Seat

The seat model has been established from three bodies,

i.e., seat cushion, seat back and head restraint. These bodies

have been connected to each other by three joints: one for

the connection between seat cushion and its surroundings,

one for the connection between seat cushion and seat back,

and one for the connection between seat back and head

restraint. These joints allow adjustment in the seat back

angle and head restraint angle, but, in addition, re present

the stiffness of the connections between seat cushionseat back and seat backhead restraint. The joint choice for the connection between seat cushion and its surroundings

depends on the application of the seat model and, therefore,

in this paper it has been arbitrarily set to a translational

joint. The seat back and seat cushion have been connected

to each other by a revolute joint to allow rotations around

the y-axis. A similar connection is implemented between

the seat back and the head restraint. In this seat model the

height of the head rest cannot be adapted. For seats that

have an adaptive head restraint, this aspect can be included

in the model by the definition of an extra-translational

joint.

Auto Desk Inventor software is used to create the model of car seat.

The seat lever system is replaced by a press button mechanism.

Figure 4 New Model Of Passenger Car Seat

-

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

145

Figure 5 New Car Seat Model With Press Button

III. MATERIALS SELECTION

The material selected for automotive component should

reduce weight of vehicle which results reduction in fuel

consumption and green house gases. The material must

provide safety to the passenger from crashworthiness and

penetration resistance. The crashworthiness energy

absorption is a key property for structural components or

complete structures materials of automobile. Lower noise is

strongly demanded as well parts must be able to withstand

service conditions from extreme winter cold to high

temperatures. The selected part material can be easily

recycled thus it may result cost saving and protection from

environmental hazards. Apart from these High strength,

stiffness, toughness, impact resistance, fatigue resistance,

chemical resistance and low friction and good appearance

quality is required in material. For selecting the most

optimum material for the seat cushion, seat frame and

spring, the functional requirements and limitations for each

of the component were specified and through manual and

software analysis, the most optimum material was

identified. For the seat cushion material, elasticity as well

as stiffness is required to provide comfort. Also, the

material must not be too heavy, with reasonable service life

duration and cost. Most importantly it must provide support

for a stable posture. The most optimum material identified

by CES is Medium density flexible polymer foam. For

the seat frame, the material must have sufficient durability

to withstand the weight of a human.

The material must have a suitable hardness and at a

reasonable price. The material identified by CES is

Annealed Carbon Steel AISI 1025.

Table II

Required Part Properties In Driver Car Seat

S.N. Component Materials Properties Author

1. Cushion Nylon Elasticity

Stiffness

D.A.

Wahab

2. Frame Annealed

Carbon

Steel AISI

1025

Durability

Hardness

D.A.

Wahab

3. Spring Mild steel Elasticity

Stiffness

D.A.

Wahab

It is not a constraint to select a single material for all

parts of passenger cars driver seat. According to the contact pressure distribution in different parts at various

angles of drivers seat, materials can be selected. In proposed drivers seat model, by the calculation of contact pressure in different parts we achieved a point to select a

high strength and low alloy steel and mild steel for all

bottom attachment seat parts. Polyaryletherketone and

nylon composites (Nylon, molybdenum disulphide) is

selected for upper part, bottom side, support part, mid part,

bottom side support part, back support of the seat.

Table III

Comparsion Of Various Material Properties

Properties

Materials

Steel Peek, resin

Acetyl resin

Nylon composite

Mass density (g/cm3)

7.85 1.32 1.42 1.13

Yield strength

(Mpa)

207 99.97 68.21 82.75

Ultimate tensile strength (Mpa)

345 210 67.52 82.68

Youngs modulus (Gpa)

210 1.1 3.585 2.93

Poissons ratio (ul)

0.3 0.42 0.35 0.35

Shear modulus (Gpa) 80.76 0.387324 1.32778 1.08519

Expansi-on coefficient (ul/c)

.000012 0.0000468 0.000085 0.0000558

Thermal

conductivity

W/ ( m K )

56 0.25 0.24 0.24

Specific heat

J/ ( kg c )

460 1339.84 1465.45 1339.84

-

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

146

IV. SIMULATION & RESULTS

A. Simulation Of New Driver Car Seat

Auto Desk Inventor software is selected for part

simulation. The calculation of various properties of

materials is done by Auto Desk Inventor design software.

The properties which are taken as inputs for a multi-body

seat model in Auto Desk Inventor are given below.

For mass of head rest, seat back and seat cushion are,

o Moments of inertia of head rest, seat back and seat cushion.

o Location of the centre of gravity of the head rest, seat cushion and seat back.

o The lumped framefoam stiffnesss (loading and unloading) of the different parts in the seat cushion,

seat back and head restraint.

o The lumped damping properties of the frame and foam.

o The joint properties (loading and unloading). o Friction coefficient of the seat cushion and seat back.

The stress distribution in various parts of car seat is

given in Figure 6.

Figure 6 Stress Distribution In Parts Of Car Seat.

The figure 7 shows the maximum and minimum

displacement of the seat due to factor of pressure force.

Maximum displacement occurs at the upper part of the seat

due to unsupported part of the seat.

Figure 7 Displacement In Car Seat Parts

This figure 8 describe in about the safety factor in

various zone.

Figurer 8 Factor Of Safety In Parts Of Car Seat

-

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

147

Figure 9 shows the pressure distribution in the various

parts of seat where human body comes in contact with seat.

Figurer 9 Contact Pressure Distribution In Car Seat

B. Results

With the help of simulation we found out various

properties and factors related to new car seat model. All

these properties and factors like stress, strain, factor of

safety, contact pressure and displacement of all the parts of

the car driver seat are shown in table IV.

Table IV

Simulation Results Of Car Driver Seat

Name Minimum Maximum

volume 6220160mm3

Mass 9.404 kg

Von mises

stress

0 MPa 65.7282MPa

1st principal

stress

-7.32789 MPa 54.8644MPa

3rd principal

stress

-57.8842MPa 4.54135MPa

Displaceme

nt

0 mm 35.6264mm

Safety factor 1.258 ul 15 ul

Stress XX -29.041 MPa 21.1085MPa

Stress XY -9.09781MPa 6.73652 MPa

Stress XZ -30.8444 MPa 34.1474MPa

Stress YY -37.0047MPa 20.1611 MPa

Stress YZ -17.5148MPa 20.547MPa

Stress ZZ -377234MPa 31.4927MPa

X

Displaceme

nt

-34.3753 mm 4.52457 mm

Y

Displaceme

nt

-4.98736mm 4.93369mm

z

Displaceme

nt

-9.86774mm 0.0533656mm

Equivalent

strain

0 ul 0.0201908 ul

1st principal

strain

-0.0000885242

ul

0.0190461 ul

3rd principal

strain

-0.0179094 ul 0.0000000308188 ul

Strain XX -0.00707345 ul 0.00858361 ul

Strain XY -0.00419182 ul 0.00310386 ul

Strain XZ -0.0142116 ul 0.0157334 ul

Strain YY -0.00917197 ul 0.00443044ul

Strain YZ -0.00806997 ul 0.00946703ul

Strain ZZ -0.00806997 ul 0.00778926ul

Contact

pressure

0 MPa 94.5498 MPa

Contact

pressure X

-52.7266 MPa 79.1514 MPa

Contact

pressure Y

-28.4631 MPa 24.8802 MPa

Contact

pressure Z

-38.3764 MPa 50.8811 MPa

-

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 10, October 2013)

148

V. CONCLUSION

This paper presents different tools and methods used for

optimization of structural properties of seats to reduce

shocks while applying brake and the future perspective of

making suitable changes in design to obtain better results.

It will also serve an important guidance to the users for the

selection of required cross-sectional properties at different

positions and the most important load-carrying structural

components of the car driver seat. The work presented in

this paper reports optimal design of the car driver seat,

taking into account various aspects (e.g. Biomechanical,

materials, vibration absorption, safety etc.) which provides

more comfortable value to driver with safety and

operational durability. Previously for adjustment of seat the

lever system was used. In our work the lever system will be

replaced by press button mechanism. Spring and plunger

damping system is used to reduce shock during brakes

applied by the driver. It will reduce unbalancing and help

the driver to auto adjust himself. The designing and

modeling and simulation of car driver seat are done on

AUTODESK INVENTOR software model under different

operating conditions. Apart from these, this paper result

saving of material in car driver seat currently this is 9.404

kg from previous one which was 17kg. The use of new

materials (Nylon and Polyether ether kiton) gives high

strength value with reduced weight and other desirable

properties at cheaper cost as required in car driver seat.

REFERENCE

[1 ] A. Marek, K. Zek, D. Ziemiansk (2012), Optimal driver seat suspension for a hybrid model of sitting human body. Journal of Terramechanics, Vol. 49, pp. 255261.

[2 ] A. Siefert, S. Pankoke (2008), Virtual optimization of car passenger seats: Simulation of static and dynamic effects on drivers seating comfort. International Journal of Industrial Ergonomics, Vol. 38, pp. 410424.

[3 ] A.G. Thompson (1969), Optimum damping in a randomly excited non-linear suspension, Proceedings of the Institution of Mechanical Engineers, Vol. 184, pp. 169184.

[4 ] D. Karnopp (1989), Analytical results for optimum actively damped suspension sunder random excitation, ASME Journal of Vibration, Stress, and Reliability in Design, Vol. 111, pp. 278283.

[5 ] D. Wagner, M. O. Musculoskeletal (2010), Computational analysis of the influence of car-seat design/adjustments on long-distance driving fatigue. International Journal of Industrial Ergonomics, Vol. 40, pp. 345355.

[6 ] E. Chateauroux*, X. Wang (2010), Car egress analysis of younger and older drivers for motion simulation Applied Ergonomics, Vol.42, pp.169177.

[7 ] G.Andreoni, F. Beverina, G. C. Santambrogio1 (2006), The ergonomics of car driver seat. Ergonomia IJE&HF, Vol. 28, pp. 2, 113123.

[8 ] I. Raasch, Sizing in conceptual design at BMW, SeaWorld Congress, Detroit, USA, March 811, 2004.

[9 ] L. Lo, M. Fard, A. Subic, R. Jazar (2013), Structural dynamic characterization of a vehicle seat coupled with human occupant. Journal of Sound and Vibration, Vol. 332, pp. 11411152.

[10 ] M. Bouazara, M.J. Richard, S. Rakheja (2006), Safety and comfort analysis of a 3-Dvehicle model with optimal non-linear active seat

suspension. Journal of Terramechanics, Vol. 43, pp. 97118.

[11 ] M. Grujicic, B. Pandurangan, X. Xie, A.K. Gramopadhye M. Kolich (2008), Conceptual framework proposed to formalize the scientific investigation of automobile seat comfort. Applied Ergonomics, Vol. 39, pp. 1527.

[12 ] M.J. Griffin (1996), Handbook of Human Vibration, Elsevier Academic Press, London.

[13 ] Maciejewski (2012), Design of active seat suspensions control system. Journal of Sound and Vibration, Vol. 331, pp. 12911309.

[14 ] Martin G.R. Toward, Michael J. Griffin (2011), The transmission of vertical vibration through seats: Influence of the characteristics of

the human body. Journal of Sound and Vibration, Vol. 330, pp. 65266543.

[15 ] M.M. Verver et al (2005), Aspects of seat modelling for seating comfort analysis Applied Ergonomics, Vol. 36, pp.3342.

[16 ] O. Gundogdu (2007), Optimal seat and suspension design for a quarter car with driver model using genetic algorithms. International Journal of Industrial Ergonomics, Vol. 37, pp. 327332.

[17 ] S. Gupta, D. Das, W.C. Regli, D.S. Nau (1997), Automated manufacturability: a survey, Res. Eng. Des., Vol. 9, pp. 168190.

[18 ] S.-B. Choi, Y. - M. Han (2007), Vibration control of electro rheological seat suspension with human-body model using sliding

mode control, Journal of Sound and Vibration, Vol. 303, pp.391404.

[19 ] S.K. Kim, S.W. White, A.K. Bajaj, P. Davies (2003), Simplified models of the vibration of mannequins in car seats. Journal of Sound and Vibration, Vol. 264, pp. 4990.

[20 ] W. Sun, J. Li, Y. Zhao, H. Gao (2011), Vibration control for active seat suspension systems via dynamic output feedback with limited frequency characteristic Mechatronics, Vol. 21, pp. 250260.

[21 ] Honda City (www.hondacity.com), Accessed date 5th August, 2013)