Design of Well Foundation - IJSER · the river water, the foundation of transmission line tower at...

Transcript of Design of Well Foundation - IJSER · the river water, the foundation of transmission line tower at...

Abstract: Due to exposure to potential scouring action of

the river water, the foundation of transmission line tower at

location no. 456 of Unnao-Bareilly transmission line is

proposed to be provided in the form of a well. Detailed

design procedure has been carried out also SAP modeling

has been made to check the hoop stresses on the steining,

Key words: Well Foundation, Well Steining, SAP Modeling.

INTRODUCTION

Due to exposure to potential scouring action of the river

water the foundation of transmission line tower at location

no. 456 of Unnao-Bareilly transmission line is proposed to

be provided in the form of a well.

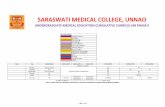

DETAILS OF TOWER

A schematic cross section of the stream together with the

location is available. The details of the proposed tower and

the hydraulic and geotechnical data at the site of the

proposed tower are given below.

Tower

type

Base

width at

top of

pedestal

(mm)

Max.

compression Max. uplift Lateral load

N.C.

(kN)

B.W.C

(kN)

N.C.

(kN)

B.W.C

(kN)

N.C.

(kN)

B.W.C

(kN)

A5+25 23000 776 1066 529 1639 36.5 89.85

Fig. 1: Schematic cross- section of stream at location of

tower No.456

HYDRAULIC DATA

Maximum flood discharge = 1680 cumecs

Maximum stream velocity = 1.94 m/s

R.L. of H.F.L. = 149.4 m

R.L. of river bank = 150.0 m

R.L. of river bed = 142.5 m

Silt factor = 0.83

SOIL CHARRACTERISTICS

Poorly graded fine to medium sand (SP) upto 32m

from G.L.

Average corrected SPT ‘N’ value = 10

Angle of friction = 32°

The legs of the tower are placed on the pedestal having

height 2.5 m having cross- section decreasing from 600x600

at bottom to 400x600 at top.

WELL CONFIGURATION

Single well with outrigger arms supporting the tower legs.

PROPORTIONING OF FOUNDATION

The foundation shall be taken adequately below the

minimum scour depth. The normal depth of scour is

estimated using Lacey’s formula as:

d = 0.473 1

3Q

f

= 6.79 m

where,

d = normal depth of scour

Q = design discharge in cumecs, and

f = 0.68 Lacey’s silt factor.

IRC: 78- 2000 recommends that scour depth calculations for

foundations may be made for a discharge larger than the

design discharge. Accordingly, 20 % increase in design

discharge has been assumed in scour depth calculations.

Since tower is to be located in straight reach of river, the

maximum scour depth dmax is given by,

dmax = 1.27d = 8.62 m

DIMENSIONING OF THE WELL FOUNDATION

From the scour considerations minimum grip length for

the well foundation = 0.33 x max. scour depth

= 2.84 m ≈ 3 m

However provide a grip length of 9 m as a conservative

measure.

R.L. of base of well w.r.t. HFL = 149.4 -9 -8.62 m

= 131.78 m

Height of well w.r.t. NGL = 150 – 131.78 m

= 18.22 m

Design of Well Foundation Thool Kushal P., Pawar Sachin L., Shirsath Abhishek D., Thombre Kiran B.

1Assistant Prof., Deptt of Civil Engg., Vishwaniketan’s iMEET, India, [email protected] 2Assistant Prof., Deptt of Civil Engg., Vishwaniketan’s iMEET, India, [email protected]

3M.E. Persuing (Const. Management, Deptt of Civil Engg., PVPIT Bavdhan, India, [email protected] 4Assistant Prof., Deptt of Civil Engg., Vishwaniketan’s iMEET, India, [email protected]

ffiliation, Country, Email 2Affiliation, Country, Email 3Affiliation, Country, Email

International Journal of Scientific & Engineering Research Volume 9, Issue 5, May-2018 ISSN 2229-5518

458

IJSER © 2018 http://www.ijser.org

IJSER

Thickness of well Steining

As per IRC 78- 2000 ( Cl. 708.2.3 )

t = Kd l = 1.152 m

t = Thickness of well steining

K = Constant = 0.03 m

d = External diameter of well = 9 m

l = Depth of well w.r.t. N.G.L. = 18.22 m

1.5 – 1.5 Provide t = 1.5 m for sufficient sinking effect.

Internal diameter of well = 9 – 1.5 – 1.5

= 6 m > 2 m

as per IRC 78 : 2000 hence OK

The thickness of well cap is taken as = 1.5 m

Thickness of top plug = 0.6 m

(Because we are using well cap)

Height of well Curb = 0.5 x internal diameter of well

= 0.5 x 6

= 3.0 m

As per IRC 78:2000 projection ≥ 75 mm.

Take 100 mm projection.

Size of ISA cutting edge = 150 x 150 x 18 mm.

= 6 m > 2 m

as per IRC 78 : 2000 hence OK

After using AutoCAD for drawing well the length of

outrigger for supporting the pedestal is coming out to be =

12073.47 mm.

Taking,

= 5

= 5

d= 2414.69 mm Take D = 2700 mm.

The outriggers is being tapered from 1 m to 2.7 m.

Thus, the well details are:

The proportioned well dimensions are shown in fig. 2 and 3

Fig. 2: Plan of well foundation (all dimensions are in mm)

Fig. 3: Sectional elevation of well foundation at section X-X

(all dimensions are in mm)

ESTIMATION OF WELL CAPACITY

1. Uplift capacity

The safe uplift capacity, Qsafe, may be calculated as the

submerged weight of the well, conservatively ignoring the

effect of side friction. Thus,

Qsafe = + (4 x .5 x (1+2.7) x 12.08

x 0.6 x (25-10))

= 9728.138 kN > 1639 kN, O.K.

Hence the well is safe in uplift.

2. Axial compression load capacity

The effect of skin friction is conservatively ignored and the

axial load capacity is taken as the base resistance with a

factor of safety of 3. The base resistance, Qsafe, is calculated

as

Qbsafe =

Total height of well = 18.22 m

Grip length = 09.00 m

External diameter of well = 09.00 m

Internal diameter of well = 06.00 m

Thickness of well steining = 01.50 m

Length of outrigger = 12.08 m

Max. depth of outrigger = 02.70 m

Width of outrigger = 00.60 m

International Journal of Scientific & Engineering Research Volume 9, Issue 5, May-2018 ISSN 2229-5518

459

IJSER © 2018 http://www.ijser.org

IJSER

Where,

v = Effective overburden pressure at base

Nq = Bearing capacity factor

Ap = Area of base of well

F.O.S. = Factor of safety

For soil at base of well, φ = 32°, hence Nq = 24.36

Qbsafe = (9 x 10) x (24.36 – 1) x ( )

= 44582.9696 kN > 4264 KN

Hence OK.

3. Lateral load capacity

The lateral load acting on the well consists of two

components :

Design lateral load corresponding to B.W.C. = 359.4 kN.

Lateral load due to water current force corresponding to

H.F.L. acting on curved surface area of the well. Intensity of

water current pressure at HFL = 0.52KV2

Where,

V = Velocity of the current at the point where the pressure

intensity is being calculated, in meters per second.

K = a constant having a value of 0.66 for circular piers.

P = 0.52 x 0.66 x ( x 1.94)2

= 2.58 kN/m2

Water current (lateral) force = 0.5 x 8.62 x 2.58 x 9

= 100.07 kN

Total lateral force = 359.4 + 100.07

= 459.47 kN

Ka = 0.31 and Kp = 3.25, for φ = 32°.

Let the total lateral is acting at a height ‘h’ above base of

well.

459.47 x h = (100.07 x 14.74) + 359.4(18.22+2.5)

h = 19.42 m.

Elevation of resultant lateral load = 19.42 m.

Safe lateral capacity, Hsafe, may be computed as,

Hsafe = 10.5 ( )( 2 )

. . .

p a eK K D D d

F O S

Where,

D1 = 23 9 6

3

2

Dh h D h

h = Height of resultant lateral load

above base

= 19.42 m

D = Grip length = 9 m

Kp = 3.25 For ф = 32°

Ka = 0.31

γ = Submerged unit weight of soil = 10 kN/m3

F.O.S. = Factor of safety, = 3.0

de = External dia. Of well = 9 m

D1 = 54.17 and 4.09 ( we have to select lower value )

Hsafe = 0.5 10 (2.94)(9 8.18) 9

2

x x x

= 488.187 > 459.57 O.K.

4. Stability check of outriggers

Clear span of cantilever (lo) = 12.07 m.

Dav. =

= 1.85 m or 1850 mm

dav = 1775 mm b = 600 mm

a) 25b = 15000 mm

b) = 20281.69 mm

Take smaller value between (a) and (b) = 15000 mm

lo < 15000 mm O.K.

DESIGN OF WELL COMPONENTS

1. Design of outriggers

Due to the large moments coming on the critical section a

no. of trials have to be done because of the change in the

value of effective depth after the placement of the bars in the

cross section. Final calculations has been shown here.

Leff = lo + (1.5/2)

= 12.07+ .75

= 12.82 m

Load (P) = 1085 kN

Taking

Overall depth ( D ) = 2700 mm

Effective depth ( d ) = 2500 mm

Effective cover (d’) = 200 mm

Grade of concrete = M25

Grade of steel = Fe415

Self-weight of beam

Volume of RCC = 0.5 (2.7+1) x 12.82 x 0.6

= 14.2302 m3

Weight of beam = 25 x 14.2302 m3

= 355.755 kN

Factored Moment

Mu = 1.5 x (1085 x 12.48 + 355.755 x 6.41)

= 23732 kNm

= 23732 x 106 Nmm.

=

= 0.4848

Mu, lim = .362 ( )(1- (0.416 x )) x fckbd2

= 13134.375 x 106 Nmm

Since Mu > Mu, lim section is to be designed as doubly

reinforced.

Pt,lim = 41.61 ( fck/fy)( = 1.2 %

ΔAst = = 12761.84 mm2

Ast,req. = 12761.84 + Ast,lim

= 30567.44 mm2

Provide 28 nos of 36ф bars and 6 nos. of 22ф bars.

Ast,prov. = 30781.32 > 30567.44 mm2

Calculation of new d

30781.32 d = 71735808.84 + 6 x (π/4) x 222 x 2337

d = 2504 mm ≈ 2500 mm . OK

International Journal of Scientific & Engineering Research Volume 9, Issue 5, May-2018 ISSN 2229-5518

460

IJSER © 2018 http://www.ijser.org

IJSER

d’ = 196 mm

Calculation of Asc

ΔAst, prov. = 30781.32- 17805.6

= 12975.72 mm2

Asc,req. =

fsc =

=353.308 N/mm2

Asc,req. = 13693. 165 mm2

Provide 14 nos. 36ф bars

Asc,prov. = 14250.26428 mm2 > 13693.165 mm

2 O.K.

Pc =14250.264/(600 x 2504) x 100

=.9485

Pt = 2.05

Pc* =

= 0.8969

Pc > Pc* (hence beam is under reinforced ) O.K.

2. Side face reinforcement

Side face reinforcement has to be provided because depth of

the beam is more than 750 mm.

Minimum area = 0.001 x 600 x 2700

= 1620 mm 2

At a spacing not exceeding 300mm.

Provide 8 nos. of 12ф bar at each face at equal spaces.

3. Design of shear reinforcement.

Shear at critical section

V = 0.5 x 3.7 x 12.07 x 25 x 0.6 +1085 kN

=1419.94 kN

Vu = 1.5V = 2129.94 kN

Mu = 1.5 ((334.94 x ) + (1085 x 11.73))

= 22122.61 kNm.

tanβ = = .141

( β = angle of sloping surface with the horizontal )

τv =

= 0.588 N/mm2

100 = x 100

= 2.05

From table 19 of IS 456:2000

τc = 0.826 N/mm2

τc > τv, Hence section is safe in shear, and minimum shear

reinforcement should be provided.

Minimum reinforcement should be provided as per the

following formula.

≥

Where,

Asv = total cross sectional area od stirrups effective in shear.

sv = stirrup spacing along the length of the member.

b = breadth of the beam ( = 600 mm)

fy = Characteristic strength of stirrup reinforcement in

N/mm2. ( 415 N/mm

2)

Provide 2-legged 10mm dia. Bars.

Asv = 157.08 mm2.

Putting the values in above formula we get

sv = 236.31 mm.

Give shear reinforcement at 230 m c/c.

4. Development length

Grade of Concrete = M25

Grade of steel = Fe415

The development length Ld is given by

Ld =

Where,

Ф = nominal diameter of the bar.

s = Stress in bar at the section considered at design load

= 0.87fy), and

τbd = Design bond stress ( = 1.4 for M25)

Ld =

Ld = 64.47 ф

For 36mm dia. bar, Ld = 2320.92 mm

For 22 mm dia. bar Ld = 1418.34 mm

5. Deflection

The total deflection shall be taken as the sum of short-term

deflection and the long term deflection.

Short term deflection

We have

b = 600 mm D = 2700 mm

fck = 25MPa fy = 415 MPa

W = 1085 kN l = 12830 mm.

M = 15821330000 Nmm.

Igr = = 9.84155 x 1011

fcr = 0.7 = 3.5 N/mm2

yt = D/2 = 1350 mm Mcr = = 2.6 x 109 Nmm

Ec = 5000 = 25000 N/mm2

Es = 2 x 105 N/ mm

2

m = 8

Let x be the depth of neutral axis, then taking moment of

transformed section about N.A.

We get,

x = 980.48 mm

Icr = + ( m – 1)Asc(x - d’)2 + mAst(d – x)

2

Icr = 8.355 x 1011

mm4

Ieff. =

Ieff = 7.49 x 1011

Since, Ieff < Icr, hence Ieff = 8.355 x 1011

mm4

Δshort term = = 36.56 mm

6. Deflection due to shrinkage

αcs = k3Ycsl2

here, k3 = 0.5

Ycs = k4 ,

k4 = 0.72 x

where

Pt = 2.05, Pc = 0.95

Putting the values we get

αcs = 5.06 mm

International Journal of Scientific & Engineering Research Volume 9, Issue 5, May-2018 ISSN 2229-5518

461

IJSER © 2018 http://www.ijser.org

IJSER

Deflection due to creep

Calculation of deflection due to creep is same as that of

short term deflection but with modified E given by

Ece = ; being the creep coefficient.

Ece = 9615.38

Δcreep = 57.73 mm

Δtotal = 36.56+5.06+57.73 = 99.355 mm

7. Design of well cap

Since no direct load is coming on well cap, minimum should

be provided.

i.e. 0.12% of gross sectional area

= x 1500 x 1000

= 1800 mm2

Provide 18 mm. diameter bar at 300 c/c on top and

bottom faces of the well cap at a clear cover of 75 mm.

Ast provided = 2035.75 > 1800 mm2

O.K.

8. Design of well steining

Lateral load acting on well = 359.4+ 100.07 kN

= 459.47 kN

Distance of lateral load from base of well = 19.42 m.

The resultant earth pressure force at depth ‘y’ below M.S.L.

is given by :

= 0.5 x γsub x (Kp-Ka) x y2 x De

Equating the lateral loads at depth y gives the location of

zero shear (and max. moment section).

459.47 = 0.5 x 10 x (3.25-.31) x y2 x 9

y = 1.86 m

weight of well steining of 1.86 m height

= x (92 - 6

2) x 1.86 x 25

= 1643.45 kN

Moment of lateral forces about section of zero shear

M = 459.47 x (18.22-9+1.86)

= 5090.93 kNm

Total axial load at section of zero shear

= Load from tower + Weight of pedestal + Weight of

outriggers + Weight of well cap + Weight of steining

= ( 4 x 1066) + (4 x 18.75) + (4 x 355.76) + ( x 92 x 25

x 1.5 ) + 1643.45

= 9791.14 kN = P

Area of cross section of steining = x (92 - 6

2) = 35.34 m

2

Ixx = Iyy = (94 – 6

4 ) = 258.44 m

4

y = = 4.5 m

The stresses in the steining

f1,2 = ±

putting the values we get.

f1,2 = 277.06 ± 88.64

f1 = .365 MPa < 8MPa

f2 = .188 MPa > 0

Both the stresses f1 and f2 are compressive and significantly

smaller than the allowable stresses for M-25 grade concrete.

Hence, the steining section is safe.

Reinforcement in well steining

Provide vertical steel = 0.12 % of gross sectional area =

11907 mm2

Provide vertical steel equally on both faces of steining.

Area of vertical steel on each face = 21206 mm2

Provide 48 Nos. of equally spaced 25ф bars on the inner

and outer faces of the steining. Keep the vertical bars

equally spaced.

Area of vertical steel provided = 23561.94 > 21206 mm2,

Hence O.K.

Provide hoop steel at 0.04 % of the volume per unit height

of steining.

Volume of hoop steel per ‘m’ height of steining.

x x ( 92 – 6

2 ) x 1.0

= .014137107 m3

= 141.37107 mm3

Volume of hoop steel required on each face

= 7068583.5 mm3

Total cross-sectional area of hoop bars required on each

face per meter height of steining.

= = 252.24 mm2

Provide 12ф hoops in the form of closed rings on both

the inner as well as the outer face of the well steining @

250 mm c/c.

Area provided = 452.39 mm 2 > 252.24 mm

2 O.K.

9. SAP Model of Steining

To check the hoop stresses on the steining, a modelling on

SAP has been done

As can be seen from the stress contours all the stresses are

within the permissible limits for M25. Hence steining is

safe.

10. Design of well curb

Provide normal steel at 72 kg/m3 in the well curb.

Vol. of concrete in well curb

= x 3 x 1.6 .159 2

2x

= 62.26 m3

Total weight of steel in well curb = 72 x 62.26

=4482.72 kg

Consider the following arrangement of steel in well curb.

International Journal of Scientific & Engineering Research Volume 9, Issue 5, May-2018 ISSN 2229-5518

462

IJSER © 2018 http://www.ijser.org

IJSER

(i) 40 nos. of 25ф hoops of average dia. = 7.25 m.

Weight provided = 3510.6491 kg.

(ii) 20 mm ф triangular at 280mm c/c.

Total no. of rings = 80

Average Length of one ring

= (1.6 – (2 x 0.075)) + (3 - (2 x 0.075 )) + (3.332 - 2.075)

= 5.557 m

weight of 80 stirrups.

= 80 x x 5.557 x 7850 = 1096.35 kg.

Total weight of steel provided in well curb

= 3510.65 + 1096.35 kg

= 4607 > 4482.72 kg

Hence O.K.

CONCLUSION

SAP modeling has been carried out to check the stress

contours for all the stresses are within the permissible limits

for M25 or not And it is found that all the stresses are in

permissible limit. Hence steining is safe.

References

1. IRC : 6-2000. Standard Specification and Code of

Practice for Road Bridges, Section II, Loads and

Stresses (Fourth Revision). The Indian Roads Congress,

New Delhi, 2000, 29 pp.

2. IRC : 78-2000. Standard Specification and Code of

Practice for Road Bridges, Section VII, Foundation and

Substructure (Second Revision). The Indian Roads

Congress, New Delhi, 2000, 97 pp.

3. IS Indian Standard. Code of Practice for Design and

Construction of Well Foundation. IS, Bureau of Indian

Standard, 1967, IS 3955 -1967.

4. IS Indian Standard. Plain and Reinforced Concrete- Code

of Practice. IS, Bureau of Indian Standard, 2000, IS 456:

2000.

5. Pillai, S Unnikrishna and Menon, Devdas. Reinforced

Concrete Design, 3rd

edn., McGraw-Hill, New Delhi,

2010.

6. Punmia B.C., Jain A.K. and Jain A.K. Soil Mechanics,

16th

edn., Laxmi Publications, New Delhi, 2005.

7. SP Special Publication. Handbook on Concrete

Reinforcement and detaiing. Bureau Of Indian

Standards, 1987, SP34: 1987

International Journal of Scientific & Engineering Research Volume 9, Issue 5, May-2018 ISSN 2229-5518

463

IJSER © 2018 http://www.ijser.org

IJSER