Department of Physics The Islamia University of Bahawalpur …prr.hec.gov.pk › jspui › bitstream...

Transcript of Department of Physics The Islamia University of Bahawalpur …prr.hec.gov.pk › jspui › bitstream...

1

CHARACTERIZATION OF DEEP LEVEL DEFECTS IN

N-TYPE ZINC OXIDE LAYERS GROWN BY

HYDROTHERMAL TECHNIQUE

A dissertation submitted in partial fulfillment of the requirement for the degree

of Doctor of Philosophy

in Physics

By

HADIA NOOR

Department of Physics

The Islamia University of Bahawalpur Pakistan

2012

2

Abstract

Zinc oxide (ZnO) is a promising wide-bandgap semiconductor due to its favorable

properties for a variety of demanding device applications such as UV light

emitters/detectors, high-power and high-temperature devices. The presence of defects

in the material can considerably change the electrical properties of the

semiconductors. However, recently it has been found that the terminated face of the

material significantly alter the characteristics of such devices. The defects in ZnO

have been studied in last decades, but no clear consensus has been made. This

dissertation investigates the electrical properties of defects in ZnO grown by

hydrothermal and molecular beam epitaxy techniques using deep level transient

spectroscopy (DLTS). Among the growth techniques available to grow the thin film,

the hydrothermal is one of the most cheap and user friendly technique. DLTS

provides a sensitive method for identifying defects and for determining their

parameters. The main findings are as follow:

A. Several circular Schottky contacts (1mm diameter) with Pd metal on the Zn-

face and O-face on n-type ZnO grown by hydrothermal and Ohmic contact of

nickel-gold on the backside were deposited by e-beam technique. The as-

obtained samples were labeled as group A and B samples, respectively. The

present literature on n-type ZnO has highlighted a defect, labeled as E3

irrespective of growth technique, which is also studied thoroughly in this

research project. The respective summary of each group A and B of samples

is explained below:

DLTS has been carried out on the group A samples to study deep level

defects. Its result showed two electron trap level E1 having activation

energy Ec-0.22 ±0.02 eV and E2 with activation energy Ec-0.49 ±0.05

3

eV. E1 level has time-delayed transformation of shallow donor defects

zincinterstitial and vacancyoxygen (Zni-VO) complex. It is observed through

X-ray differaction that the preferred direction of ZnO growth is along

(1010) plane i.e. VO-Zni complex, assuming that under favourable

condition (Zni-VO) complex is transformed into a zinc antisite (ZnO).

Consequently, the trap concentration increases with decreasing free

carrier concentration. Hence, the ZnO is correlated to E1 level

demonstrating the increase in concentration.

Several renowned research groups have revealed different points

defects in bulk ZnO like naming oxygen vacancy, zinc interstitial,

and/or zinc antisite. These defects having activation energy (free

carrier concentration) in the range of 0.32–0.22 eV (1014

-1017

cm-3

)

below conduction band. The results of group A and B samples also

showed activation energy (free carrier concentration) as observed by

other renowned research groups. This result is due to activation energy

of the level while it is not conceivable by with Vincent et al.,[ J. Appl.

Phys. 50 (1979) 5484]. They believed that data should be carefully

interpreted obtaining by capacitance transient measurement of diodes

having carrier concentration greater than 1015

cm-3

. Thus the influence

of background free-carrier concentration, ND induced field on the

emission rate signatures of an electron point defect in ZnO Schottky

devices has been studied by using deep level transient spectroscopy.

Many theoretical models were tested on the experimental data to

understand the mechanism. Our findings were supported by Poole-

Frenkel model based on Coulomb potential. It is revealed by

4

investigation that Zn related charged impurities were found to be

responsible for electron trap. Results were also tested through

qualitative measurements like current-voltage and capacitance-voltage

measurements.

B. Several Schottky contacts of 1mm diameter with silver were prepared on ZnO

grown by molecular beam epitaxy. These samples were labeled as group C

samples, DLTS measurements revealed a hole trap exhibiting metastability

effect in the emission rates of trap with storage time. We determined that hole

trap transfers from one configuration to other with storage time. As a result the

activation energy of the acceptor level varied in the range of 0.31 eV to 0.49

eV above the valance band at different measurement time. Impurities cannot

be removed in the growth procedure. SIMS results showed the presence of

nitrogen. During the growth process nitrogen occupies O site and produces

Zn-N complex. But Zn-N bond is not stable because of its large bonding

energy and consequently results into metastable nature of the defect. All

experimental findings and available literature support the conclusion that the

observed hole trap arise from Zn-N complex.

C. The ZnO nanorods were grown on glass substrate coated with different metal

(Ni, Al, Ag and Au) by aqueous chemical growth. These samples were labeled

as D, E, F and G, respectively. The structural properties of ZnO nanorods were

investigated by X-Ray diffraction (XRD) and scanning electron microscopy

(SEM). The intensity of ZnO (0 0 2) diffraction peak in X-ray diffraction

pattern is maximum of sample D because of nucleation of Ni metal coated on

substrate. SEM measurements strongly support our observation that thin layer

Ni metal increases the growth of nanorods.

5

Declaration

I, Ms. Hadia Noor, PhD student in the subject of Physics session (2007 – 2012)

hereby declare that the material produced in this dissertation titled “Characterization

of deep level defects in n- type zinc oxide layers grown by hydrothermal technique” is

my own work and has not been submitted in as a whole or in part for any degree at

this or any other university.

Hadia Noor

6

Certificate

It is certified that the work presented in this dissertation entitled “Characterization of

deep level defects in n-type zinc oxide layers grown by hydrothermal technique” by

Hadia Noor under my supervision at the Department of Physics, The Islamia

University of Bahawalpur, Pakistan.

Supervisor

Prof. Dr. M. Asghar Hashmi

Chairman

Prof. Dr. Sh. Aftab Ahmad

Department of Physics

7

8

Acknowledgement

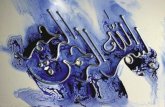

All praises and thanks to Almighty ALLAH, the most Beneficent and the

Merciful, The Creator of The Universe, Who enabled me to complete my research

work successfully. I would like to send my humble salutation to the Holy Prophet

Hazrat Muhammad (peace be upon him), Who is a source of guidance and knowledge

for humanity.

Now when I just finished this dissertation, all the memories of the past years

are flashing back in my mind. Many people who helped me slowly came into my

memory one by one, even though my gratitude is beyond words.

First of all, I am cordially thankful to the most inspiring character in this

research i.e my supervisor Prof. Dr. Muhammad Asghar Hashmi, whose

encouragement, guidance and support from the initial to the final level enabled me to

surpass all the obstacles in the completion of this research work. Without his great co-

operation I would not be able to complete my research work.

I am extremely appreciative and thankful to Prof. Magnus Willander, ITN,

Linköping University, Norrköping Campus, Norrköping Sweden, for his great co-

operation, excellent guidance and providing me full access to the research laboratories

at ITN, Linköping University during my six months stay in Sweden. My gratitude and

obligations are due to Prof. Dr. Omer Nur, Dr. Peter Kalson, and Dr. Q. Wahab for

helping me during research work. I appreciate the cooperation of Ms. Sadia Faraz in

co-authoring the related articles. In addition, I would like to thank my lab fellows Dr.

Adnan Ali and Dr. M. Imran Arshad for their cooperation during all these years. I am

very grateful to Higher Education Commission for providing me financial support for

completing my Ph.D studies.

9

Last but not the least I wish to express my nice feelings towards my loving

and sweet family and friends. Words cannot describe my immense feelings of

appreciation for them. Special thanks for their prayers, encouragement and

unforgettable sacrifices with patience throughout my life and Ph.D studies.

Sincerly

Hadia Noor

10

Contents

Abstract 2

Declaration 5

Certificate 6

Acknowledgement 8

List of Publications 13

List of Figures 14

List of Tables 18

CHAPTER 1 19

INTRODUCTION 20

1.1 Semiconductor Materials 20

1.1.1 Wide Bandgap Semiconductor Materials 23

1.2 Motivation 25

1.3 Dissertation Outline 29

CHAPTER 2 31

PROPERTIES OF ZnO 32

2.1 Crystal Structure 32

2.2 Point Defects 37

2.2.1 Types of Point Defects 37

2.2.2 Point Defects in ZnO 38

2.3 Contacts to Zinc Oxide 44

2.3.1 Schottky Contact to ZnO 44

2.3.2 Ohmic Contacts to ZnO 46

CHAPTER 3 49

GROWTH TECHNIQUES 50

3.1 Hydrothermal technique 50

3.1.1 Experimental Setup of Hydrothermal Method 50

3.1.2 Hydrothermal Synthesis of Zinc Oxide 51

3.2 Molecular Beam Epitaxy 54

3.3 Aqueous Chemical Growth 56

CHAPTER 4 59

CHARACTERIZATION TECHNIQUES 60

4.1 Current-Voltage Measurements (I-V) 60

11

4.2 Capacitance-Voltage Measurements (C-V) 63

4.3 Deep Level Transient Spectroscopy (DLTS) 64

4.3.1 Carrier Kinetics in Semiconductors with Deep Level- Shockley-Read-Hall

Theory 65

4.3.2 Basic Principle of DLTS 66

4.3.3 Measurement of Defect Parameters by DLTS 71

4.4 X-Ray Diffraction (XRD) 75

4.4.1 Hexagonal System 76

CHAPTER 5 79

EXPERIMENTAL DETAILS 80

5.1 Group A and B Samples 80

5.2 Group C Samples 81

5.3 Samples D, E, F and G 82

5.3.1 Preparation of Seed Solution 82

5.3.2 Pretreatment of Substrate 82

5.3.3 Chemical Bath Deposition Growth 83

CHAPTER 6 84

RESULTS AND DISCUSSION 85

Section- I 85

6.1 Current-Voltage Measurements 85

6.2 Capacitance-Voltage Measurements 88

6.3 Deep Level Transient Spectroscopy Measurements 93

6.4 X-Ray Diffraction 96

6.5 Trap Identification 99

6.5.1 Electron Level E1 99

6.5.2 Electron Level E2 103

Section- II 104

6.6 Current-Voltage Measurements 104

6.7 Capacitance-Voltage Measurements 106

6.8 Deep Level Transient Spectroscopy Measurements 110

6.9 Trap Identification 113

6.9.1 Electron Level E1 113

6.9.2 Electron Level E2 119

12

Section- III 120

6.10 Hall Measurement 120

6.11 SIMS Measurement 122

6.12 Current-Voltage Measurement 123

6.13 Capacitance-voltage Measurement 124

6.14 Deep Level Transient Spectroscopy Measurements 125

6.15 Trap Identification 127

Section- IV 130

6.16 XRD Measurements 130

6.17 SEM Measurements 133

CHAPTER 7 136

CONCLUSIONS AND FUTURE PLAN 137

7.1 Group A Samples 137

7.2 Group B Samples 137

7.3 Group C Samples 138

7.4 Samples D, E, F, & G 139

7.5 Future Plan 139

REFERENCES 140

13

List of Publications

1. Influence of background concentration induced field on the emission

ratesignatures of an electron trap in zinc oxide Schottky devices. Hadia Noor, P.

Klasan, S. M. Faraz, O. Nur, Q.Wahab, M. Asghar, and M. Willander, J. Appl.

Phys. 107 (2010) 103717.

2. Time-delayed transformation of defects in zinc oxide layers grown along

the zinc-face using a hydrothermal technique. Hadia Noor, P. Klasan, O. Nur,

Q.Wahab, M. Asghar, and M. Willander, J.Appl. Phys.105 (2009) 123510.

3. Modeling and simulations of Pd/n-ZnO Schottky diode and its comparison with

measurements. S. Faraz, Hadia Noor, M.Asghar, M. Willander, Q. Wahab,

Advanced Materials Research. 79-82 (2009) 1317-1320.

4. Post-annealing modification in structural properties of ZnO thin films on p-type Si

substrate deposited by evaporation. M. Asghar, Hadia Noor, M.S. Awan, S.

Naseem and M.-A Hasan, Mater. Sci. in Semicond Processing, 11 (2008) 30-35.

5. Characterization of ZnO Thin Film Deposited by RF Operated Thermal

Evaporation. M. Asghar, I. Hussain, Hadia Noor, M. S. Awan and M.-A. Hasan,

Proceeding IEEE Regional Symposium on Microelectronics, Penang, Malaysia

(2007) 160.

6. Growth and Characterization of Single Crystalline Cubic SiC on porous Si using

low pressure chemical vapour deposition technique. M. Asghar, Payam Shoghi,

Hadia Noor, and M.-A. Hasan, NAM Proceedings (2007) 59.

14

List of Figures

Figure 1.1 The block diagram of semiconductor by conductivity. 21

Figure 1.2 The block diagram of semiconductor by structure. 21

Figure 1.3 The block diagram of semiconductor by composition. 22

Figure 1.4 The block diagram of semiconductor by bandgap. 23

Figure 2.1 Unit cell of ZnO and neighbouring atoms, viewing direction approx

parallel to c. Small spheres: O-2

, big spheres: Zn+2

. 33

Figure 2.2 Temperature dependence of PL spectrum for Zn-polar face and O-

polar face in the temperature range of 10 K– 300K. 36

Figure 2.3 Schematic representation of defects in semiconductors. 38

Figure 2.4 Electron energy diagram in equilibrium (1) and in the presence of an

electric field (2) showing field-enhanced electron emission: (a)

Poole-Frenkel emission, (b) phonon-assisted tunneling. 43

Figure 2.5 Metal-semiconductor contacts according to the simple Schottky

model . 44

Figure 2.6 Energy band diagrams for Ohmic contact. 46

Figure 3.1 Schematic drawing of a hydrothermal growth system. 53

Figure 3.2 The diagram of MBE system [36] 56

Figure 2.3 The chemicals for growth solution of ZnO. 57

Figure 3.4 The stirring of growth solution for ZnO. 58

Figure 3.5 Growth solution container placed in oven. 58

Figure 4.1 Band diagram of the intimate contact between metal and

semiconductor (n-type) for a rectifying junction. 60

Figure 4.2 Electron energy band diagram for a semiconductor with deep a level

trap. 65

Figure 4.3 The metal-semiconductor contact and the depletion layer . 66

Figure 4.4 The schematic illustration of a majority injection pulse sequence and

energy band bending. (a) bias time, (b) capacitance-time, (c) and (d)

the energy band bending during the pulse and after pulse. 67

Figure 4.5 XRD measurement of the Zn. 77

Figure 5.1 ZnO wafer grown by hydrothermal. 80

Figure 5.2 ZnO samples grown by MBE. 81

15

Figure 6.1 I-V characteristics of the Pd-Schottky contact on the Zn face of the

ZnO. 86

Figure 6.2 I-V characteristics of the Pd-Schottky contact on the Zn face of the

ZnO at 120 K. 87

Figure 6.3 I-V characteristics of the Pd-Schottky contact on the Zn face of the

ZnO at 340 K. 87

Figure 6.4 Plot between Ideality factor and 1000/T indicates the To- effect for

the Zn face Pd/ZnO Schottky diode. 88

Figure 6.5 C-V measurements of the Pd-Schottky contact on the Zn face of the

ZnO. 89

Figure 6.6 Graph between applied bias and inverse squared capacitance. 90

Figure 6.7 Depth profile of free carrier concentration of Pd/ZnO. 90

Figure 6.8 C-V measurements of the Zn face of the ZnO at different

temperatures. 91

Figure 6.9 Depth profile of free carrier concentration of Zn-face ZnO at

different temperatures. 91

Figure 6.10 DLTS spectrum displaying two electron deep level defects below

conduction band of ZnO. 94

Figure 6.11 The DLTS spectrum of levels E1 in ZnO. 94

Figure 6.12 The Arrhenius plot of levels E1 and E2 in ZnO. 95

Figure 6.13 Trap concentrations of levels E1 in Zn-face ZnO 95

Figure 6.14 Typical XRD pattern of the Zn-face ZnO layer exhibiting the Zni-VO

complex as the preferential direction of growth. Peaks other than

ZnO are seen because the XRD measurements were performed on

Pd\ZnO–Zn\Au–Cr mounted on an alumina substrate by silver paste. 97

Figure 6.15 C-V measurements indicate decrease in amplitude. 100

Figure 6.16 DLTS measurements indicate increase in amplitude. 101

Figure 6.17 Demonstration of time-delayed transformation phenomenon of

defects in ZnO layer. 101

Figure 6.18 Representative I-V measurements of group B samples. 105

Figure 6.19 Representative C-V measurements of group B samples. 105

Figure 6.20 Schottky behavior of the sample B is demonstrated in 1/C2-V, filled

squares represent the experimental data and the line corresponds to

16

the theoretical fit of the data, extrapolated to x-axis yield built-in

potential. 107

Figure 6.21 The uniform spatial distribution of the free-carriers in the as-

deposited ZnO material. 107

Figure 6.22 C-V measurements of the O face of the ZnO at different temperature. 109

Figure 6.23 Depth profile of free carrier concentration of O-face ZnO at different

temperatures. 109

Figure 6.24 Representative DLTS scans of group A and B samples to show the

variation in peak position of E1 level even measured under same

measuring setup. 111

Figure 6.25 The DLTS spectra measured at different frequencies for Arrhenius

plot of levels E1 in sample B. 112

Figure 6.26 The Arrhenius plot of levels E1 in samples A and B. 112

Figure 6.27 Depth profile of trap concentration of levels E1 in O-face ZnO. 113

Figure 6.28 Influence of background concentration ND on activation energy of E1

level. Data 1 and 2 are ours and rest of the data is taken from Refs.

19, 33, and 34. 115

Figure 6.29 The ND-induced field effect on the thermal energy data of the level.

Data 1 and 2 are ours and rest of the data is taken from Refs. 19, 33,

and 34. 116

Figure 6.30 Qualitative evidence of the Poole–Frenkel mechanism on the ND-

induced variation in emission rate signatures of E1 level. 117

Figure 6.31 Theoretical fitting of the ND-induced field emission rates (filled

circles) obeying Poole–Frenkel mechanism associated with Coulomb

potential (curve C), while square well potential (r = 4.8 nm) is not

consistent (curve S). 118

Figure 6.32 Representative temperature dependent Hall measurements of group

C samples. The upper part, middle part, and lower part of Figure

display mobility, carrier concentrations and resistivity, respectively. 121

Figure 6.33 SIMS depth profiles of O, Zn and N elements in group C samples. 122

Figure 6.34 Representative I-V measurements of group C samples. 123

Figure 6.35 Schottky behavior of group C sample is demonstrated in A2/C

2-V,

filled squares represent the experimental data and the line

corresponds to the theoretical fit of the data. 124

17

Figure 6.36 Depth profile of free carriers of group C sample. 125

Figure 6.37 Representative DLTS spectrum displaying one hole trap of group C

samples. 126

Figure 6.38 Typical DLTS spectra of levels H measured at different frequencies

of group C samples. 126

Figure 6.39 The Arrhenius plot of hole level in group C samples. 127

Figure 6.40 Metastability behavior of hole trap H with respect to time. 129

Figure 6.41 The Arrhenius plot of hole level in group C samples with passage of

time. 129

Figure 6.42 XRD patterns of four samples (D, E, F, & G). 131

Figure 6.43 SEM image of sample D grown by ACG. 134

Figure 6.44 SEM image of sample D grown by ACG. 134

Figure 6.45 SEM image of sample E grown by ACG. 135

Figure 6.46 SEM image of sample E grown by ACG. 135

18

List of Tables

Table 1.1 III-V compound semiconductors 20

Table 1.2 II-VI compound semiconductors 22

Table 1.3 Electrical parameters such as activation energy capture cross section

and defect concentration of different defects in ZnO. 26

Table 2.1 Physical properties of Zinc oxide 34

Table 2.2 2θ, intensity, and Miller indices of peaks of Zn-polar face and O-polar

face samples calculated from XRD measurements . 36

Table 3.1 The growth conditions optimized by Sakagami for zinc oxide crystals. 52

Table 4.1 Calculated miller indices (hkl) of hexagonal system when l = 0. 77

Table 4.2 Calculated miller indices (hkl) of hexagonal system 78

Table 6.1 Electrical parameters of Zn face ZnO calculated from C-V

measurements. 91

Table 6.2 Details of electrical parameters such as activation energy, capture

cross section measured via indirect and direct methods and trap

concentration of defects observed in the DLTS spectrum of Zn-face

ZnO. 96

Table 6.3 2θ, intensity, Miller indices, and sources of peaks measured from

XRD data in ZnO layers listed. 98

Table 6.4 Electrical parameters of O face ZnO calculated from C-V

measurements 108

Table 6.5 2θ, intensityand Miller indices from XRD data of sample D, E, F

and G. 132

19

CHAPTER 1

20

1 INTRODUCTION

This chapter presents an introduction about the importance of wide bandgap

semiconductor materials in the development of electronics industry. Among the wide

bandgap materials special focus is given to zinc oxide because of its potential

applications. A brief comparison of zinc oxide attractive properties with other wide

bandgap materials is given. Motivation and dissertation outline are also presented.

1.1 Semiconductor Materials

The importance of electronic industry cannot be denied in the progress of

world. Semiconductors are one of the basic and major materials of this industry.

Semiconductors can be classified in various ways. Four significant ways are given

below:

Conductivity

Structure

Composition

Bandgap

The block diagrams of semiconductor classification by foresaid ways are shown

in Figures 1.1, 1.2, 1.3 and 1.4.

Table 1.1 III-V compound semiconductors [1]

Group III A Group V A

N P As Sb

B BN BP BAs BSb

Al AlN AlP AlAs AlSb

Ga GaN GaP GaAs GaSb

21

In InN InP InAs InSb

Figure 1.1 The block diagram of semiconductor by conductivity.

Figure 1.2 The block diagram of semiconductor by structure.

22

Figure 1.3 The block diagram of semiconductor by composition.

III-V and II-VI compound semiconductors are formed by the combination of

elements of respective group in Periodic Table. These III-V and II-VI compound

semiconductors are listed in Tables 1.1 and 1.2, respectively. SiC, SiGe and GeSn are

the examples of IV-IV compound semiconductors.

Table 1.2 II-VI compound semiconductors [1]

Group II B Group VI A

O S Se Te

Zn ZnO ZnS ZnSe ZnTe

Cd CdO CdS CdSe CdTe

Hg HgO HgS HgSe HgTe

23

Figure 1.4 The block diagram of semiconductor by bandgap.

Bandgaps are direct and in-direct for various compound semiconductors.

1.1.1 Wide Bandgap Semiconductor Materials

Wide bandgap semiconductors like GaN, ZnO and SiC got significant

attention due to their importance in optoelectronics and microelectronic devices. Wide

bandgap semiconductors are related to the emission/absorption wavelength of optical

devices. Light emitting diodes, laser diodes, photodiodes, photoconductive sensors,

electro-modulation devices are the examples of optical devices. Among the wide

bandgap semiconductors there is an increased interest in ZnO because of the

following advantages over other wide bandgap materials;

ZnO is a low cost material as compared to other wide bandgap materials such

as SiC and GaN.

Quality films of ZnO can be grown by a number of cost effective methods like

aqueous chemical growth method and hydrothermal growth technique etc.,

whereas quality GaN and SiC film growth require comparatively much

expensive techniques.

Semiconductor: Bandgap

Narrow bandgap

(0.1-1.5 eV)

Moderate bandgap

(1.5-3.0 eV)

wide bandgap

(3.0-6.0 eV)

24

ZnO is more suitable material for wet chemical etching which is most

essential in the device design and fabrication [2].

ZnO is an attractive material with high luminescence efficiency as compared

to GaN and SiC [3].

The growth of large single crystals of ZnO is possible on the other hand which

is still an issue for GaN and SiC.

It is easy to make nanostructures from ZnO which emit light and sense charge

transfer efficiently [4].

ZnO is a fascinating material due to piezoelectric properties and potential uses

in electronics [5], optoelectronics [6], energy conversion [7], and biosensors

[8].

It has great tolerance for radiation [9,10].

A brief preview of ZnO applications is presented in the following: zinc oxide

(ZnO) is a II-VI direct wide bandgap (3.37 eV) semiconductor with a large exciton

binding energy (60 meV). This material is famous for its photonic and electronic

applications such as UV light emitters/detectors and as high-power and high-

temperature devices [3,11]. ZnO nanostructures have significant device applications

for example surface acoustic wave filters [12], photodetectors [13], photonic crystals

[14], light emitting diodes [15], gas sensors [16], photodiodes [17], optical modulator

waveguides [18], varistors [19], solar cells [20, 21] and nanowire, nanolasers,

biosensors and field emission devices [22]. It has superior physical parameters for

electronic applications including a high breakdown electric field strength, high

thermal conductivity, high electron saturation velocity and high radiation tolerance. In

addition to its valuable optoelectronic properties, it is a candidate for the fabrication

of a dilute magnetic semiconductor with a Curie temperature higher than room

25

temperature [23]. Piezoelectric properties of the material are being explored for

fabrication of various pressure transducers, acoustic- and opto-acoustic devices [24].

Because of these characteristics, ZnO is now considered to be in the line of traditional

semiconductors such as Si and GaAs, and it is also compatible with wide-bandgap

semiconductors such as SiC and GaN [25].

1.2 Motivation

The electronic device applications as meantioned in previous section are

linked with the in house defects chemistry and thereafter, electronic structure of the

material. Defects have detrimental effects on the working of the devices, they are

known to degrade the lifetime and efficiency of the devices. However sometimes

defects are blessings, for example, several research groups [26-31] have suggested

that oxygen vacancies (defects) are the source of green luminescence in ZnO.

Therefore, an understanding of defects in the materials is essential for improving the

material quality and device performance. The defect chemistry and electronic

structure of the material have been the subjects of recent theoretical and experimental

studies. To understand the true nature and cause of defects in ZnO, it is important to

review the previous history of the defects in the material. A comprehensive study of

defects in ZnO grown by various techniques reported in the literature is prepared in

the form of a Table 1.3.

26

Table 1.3 Electrical parameters such as activation energy capture cross section and

defect concentration of different defects in ZnO.

Defect

identificati-

on

Defect

activation

energy

(eV)

Capture cross

section

(cm2)

Defect

concentration

(cm-3

)

Growth

technique

Research

group

Oxygen

vacancy

0.1 (1.2±0.5)×10-13

(14±2) ×1014

Seeded chemical

vapor transport

Wenckstern

et al. [11] 0.11 (1.2±0.5)×10

-13 (14±2) ×10

14

Pulsed-laser

deposition

0.12 (1.3±0.5)×10-13

(14±2) ×1014

Pressurized melt

growth

0.22 5×10-13

-

Hydrothermal

Grown

Vines et al.

[32]

0.27

1.6×10-16

for Pd-

SBD

1.2×10-16

for Au-

SBD

(4-5)×1014

Vapor-phase

grown

Fang et al.

[33]

0.27 0.3×10-14

2.1×1012

Hydrothermal

grown

Simpson et

al. [34]

0.29 1.5×10-15

1016

Pressurized melt

growth Auret et al.

[35] 0.29 - 10

14

Seeded chemical

vapor transport

0.29 2.8×10-14

5.1×1012

Hydrothermal

grown

Simpson et

al. [34]

0.3

-

-

Hydrothermal

grown

Kuriyama et

al. [36]

0.3 4×10-16

1 ×1015

Pressurized melt

growth

Ling et al.

[37]

Conted….

27

Conted….

Defect

identificati-

on

Defect

activation

energy

(eV)

Capture

cross

section

(cm2)

Defect

concentration

(cm-3

)

Growth

technique

Research

group

Oxygen

vacancy

0.31 5×10-13

-

Hydrothermal

grown

Vines et al.

[38]

0.32 2.5×10-14

8.3×1012

Hydrothermal

grown

Simpson et

al. [34]

0.53 4×10-15

1×1015

Vapor

transport

process

Hofmann

et.al [39]

0.57 1.5×10-16

-

Hydrothermal

grown

Vines et al.

[32]

Zinc

interstitial

0.1 - - Solid state

method

Chattopadh-

yay et al.

[40]

0.27

1.6×10-16

for Pd-

SBD

1.2×10-16

for Au-

SBD

(4-5)×1014

Vapor-phase

grown

Fang et al.

[33]

0.32 -

1014

to 1016

Pulsed-laser

deposition

Frenzel et.

al [41]

Zinc antisite

0.22 8.22×10

-

17

110×1014

Hydrothermal

technique

Noor et. al

[42]

28

Defect

identificati

-on

Defect

activatio

n energy

(eV)

Capture

cross

section

(cm2)

Defect

concentratio

n

(cm-3

)

Growth

technique

Research

group

Intrinsic

Defect

0.29 (6.2±0.7)

×10-16

(62±7)×10

14

Pulsed-laser

deposition

Wenckster

n

et al. [11]

0.3 (2±0.4)×10

-

16

(80±4)×1014

Pressurized

melt growth

0.3 (6.2±0.7)×10

-16

(2.2±0.4)×101

4

Seeded

chemical

vapor

transport

Zn-related

defect

0.26 11.16×10-17

-

Hydrotherma

l

technique

Noor et. al

[43]

0.31 1×10-15

1.2×10

14

Vapor-phase

Frank et al.

[44] -ve U-

centre 0.54 2×10

-13

from 1015

to

1017

Donor like

defect

0.01

-

-

Pulsed laser

injection

Seghier et

al.

[45]

0.03 - 1017

Seeded

chemical

vapor

transport Wenckster

n

et al. [11] 0.05 - 5×1016

Pressurized

melt growth

0.07 - 5.7×1016

Pulsed-laser

deposition

Surface

related

defect

0.49

3.4×10-14

for

Pd-SBD

3.5×10-15

for

Au-SBD

- Vapor-phase

grown

Fang et al.

[33]

0.49 1.18×10-14

2.01×1014

Hydrotherma

l

technique

Noor et. al

[42]

H diffusion

in ZnO

0.17 &

0.37

-

-

Dc

magnetron

sputtering

Nickel [46]

29

However, the following few of the unclear results listed in Table 1.3 are given to

justify the present work:

The fluctuating activation energy of so called oxygen vacancy ( Vo) defects

varies from 0.1eV to 0.75eV [32-39] but the defects parameters should be same like

fingerprints. Similarly, defect parameters like capture cross section and defect

concentration of oxygen vacancy also vary from one to other. The defect parameters

(activation energy and trap concentration) of zinc interstitial are not clear [33, 40, 41].

In the same way activation energy and trap concentration of donor like defect are not

the same [11,45]. Identification of an electron defect level having activation energy

0.3 eV is not clear [36-38]. In addition, a number of controversial interpretations of

defects are discussed in the recent literature [47-54].

This ambiguous knowledge about defect parameters and their origin motivated us

for this study. For getting better quality, good performance, high efficiency and long

working lifetime of ZnO-based devices, it is necessary to carry out a comprehensive

study of defects in ZnO.

1.3 Dissertation Outline

This dissertation is organized into seven chapters. Chapter 1 covers motivation

and dissertation outline about the current research. Chapter 2 highlights the details of

material (ZnO) such as crystal structure, physical properties and contacts to n-type

ZnO. Chapter 3 explains the growth techniques such as hydrothermal method,

molecular beam epitaxy and aqueous chemical growth. Chapter 4 presents various

characterization techniques such as current-voltage (I-V), capacitance-voltage (C-V),

deep level transient spectroscopy (DLTS) and x-ray diffraction (XRD) used for

characterization of defects in semiconductors. Chapter 5 explains the experimental

30

details of growth techniques such as hydrothermal method, molecular beam epitaxy,

and aqueous chemical growth. Chapter 6 explains the experimental results and

discussions of current experiments. Chapter 7 describes the conclusions and future

plan.

31

CHAPTER 2

32

PROPERTIES OF ZnO

This chapter briefly explains crystal structure of ZnO. A detail review about the

different defects in ZnO is provided. Furthermore, the influence of electric field on

deep level defects is enlightened which is helpful to identify the defects. The progress

of Schottky and Ohmic contacts to ZnO are also described because quality of ZnO

based devices depends upon better quality contacts (Ohmic and Schottky).

2.1 Crystal Structure

The crystal structure of ZnO is hexagonal (Wurtzite) as shown in Figure 2.1.

The space group of this hexagonal lattice is a P63mc. ZnO is a polar material. The

values of some physical properties of ZnO are listed in Table 2.1. The lattice

parameters of ZnO are a = 3.25 Ao and c = 3.18 A

o. There is a strong ionic bond ZnO

due to the large difference in the values of electronegativity (oxygen = 3.44 and Zinc

= 1.65) [1]. ZnO is characterized by two connecting sub lattices of Zn+2

and O.-2

Each Zn ion is surrounded by tetrahedra of O ions and each O ion is surrounded by

tetrahedra of Zn ions. This tetrahedral coordination provides the polar symmetry

along the hexagonal axis. In an ideal Wurtzite crystal, the ratio of lattice parameters

c/a and the u (it is the parameter by which each atom is displaced with respect to the

next along the c-axis) are correlated by the relationship as

8

3

a

uc (2.1)

33

ZnO Unit Cell

Figure 2.1 Unit cell of ZnO and neighbouring atoms, viewing direction approx

parallel to c. Small spheres: O-2

, big spheres: Zn+2

[2].

b a

34

Table 2.1 Physical properties of Zinc oxide [3]

Property Values

Chemical formula

ZnO

Lattice parameters at 300 K

a0

c0

3.24 Ao

5.20 Ao

Density

5.606 gcm-3

Stable phase at 300 K

Wurtzite

Melting point

1975 oC

Boiling point

2360 oC

Linear expansion coefficient

a0 = 6.5×10-6 o

C-1

c0 = 3.0×10-6 o

C-1

Energy bandgap

3.4 eV, direct

Static dielectric constant

8.5

Refractive index

2.008, 2.029

Exciton binding energy

60 meV

Electron effective mass

0.28 mo

Hole effective mass

0.59 mo

Bulk Young’s modulus

111.2 ± 4.7 GPa

Bulk hardness

5.0 ± 0.1 GPa

Electron Hall mobility at 300 K

200 cm2 (Vs)

-1

Hole Hall mobility at 300 K

5-50 cm2 (Vs)

-1

35

The conditions for an ideal crystal are

3

8

a

cand

8

3u (2.2)

ZnO crystals deviate from this ideal arrangement by variation of both of these

values. This deviation occurs in the lattice because tetrahedral distances are roughly

constant. For Wurtzite ZnO, experimentally calculated values of u and c/a were in the

range u=0.3817–0.3856 and c/a=1.593–1.6035 [4 – 6].

Several properties of ZnO such as piezoelectricity and spontaneous

polarization depend on its polarity. Based on termination scheme, the Wurtzite ZnO

has four types (i) polar type terminated at Zn-face along (0001) direction (ii) polar

type terminated at O-face along (0001) direction; (iii) non-polar type along (11 2 0)

direction (iv) non-polar along (1010) direction. The number of Zn and O atoms are

equal in both non-polar (11 2 0) and (1010) faces. Furthermore, the polar surfaces and

non-polar surface (1010) are stable, but the (11 2 0) face is less stable and generally

has a higher level of surface roughness than its counterparts. Each polar face has

unique chemical and physical properties like electronic structure of O-terminated face

is slightly different from Zn-terminated [7]. The optical properties, for example in

photoluminescence, the PL intensities of Zn-polar face are different from O-polar face

because of exciton-phonon coupling strengths, opposite band bending effects and

difference of the adsorbed molecules as shown in Figure 2.2 [8-10]. In the same

manner XRD intensities of Zn-polar face are different from O-polar face as exposed

in Table 2.2.

36

Figure 2.2 Temperature dependence of PL spectrum for Zn-polar face and O-polar

face in the temperature range of 10 K– 300K [10].

Table 2.2 2θ, intensity, and Miller indices of peaks of Zn-polar face and O-polar face

samples calculated from XRD measurements [11].

Peak# Zn-face O-face Identification

(Miller Indices)

2Θ

(degree)

Intensity 2Θ

(degree)

Intensit

y

P1 31.28 1097 31.04 1844 ZnO (1010)

P2 34.48 15744 34.48 812147 ZnO (0002)

P3 36.36 455 Missing ZnO(1011)

P4 38.08 1607 Missing Al(11 1), Ag(111)

P5 40.2 32603 40.2 13862 Zn(1010)

P6 44.76 880 44. 32 90 Ca(531)

P7 Missing 52.72 1334 Unidentify

P8 Missing 57.44 59 ZnO(11 2 0)

P9 64.4 990 64.6 246 Li(211)

P10 65.48 1362 Missing Al(220)

P11 72.64 2208 72.6 49633 ZnO (0004), Zn(11 2 0)

P12 73.72 8260 Missing Ca(331)

P13 77.56 382 Missing Mg(20 2 2)

P14 81.6 181 Missing Al(222), Ag(222)

P15 86.64 1466 86.92 473 Zn (20 2 1)

37

This difference of properties can be due to defects present in Zn and O-polar.

In the following section we describe the Physics of various defects reported in

literature.

2.2 Point Defects

Semiconductors usually have small crystallographic irregularities, also called

as point defects. Point defects are introduced during growth or in post- growth

methods for example annealing or ion implantation. Even if semiconductor materials

are free of point defects and unexpectedly pure, defects in small concentrations do

exist which have remarkable effect on properties of semiconductors. Defects are not

bad in all cases. However, sometimes they may appreciably enhance the performance

of devices instead of reducing it. The defects such as dislocation, edge dislocation and

others are not addressed because this dissertation is focused only on point defects

2.2.1 Types of Point Defects

There are many forms of crystal point defects. Defects involving only the host

atoms are called the intrinsic defects. Several types of defects are shown in Figure 2.3.

A defect wherein a host atom is missing from one of these sites is

known as a vacancy defect.

If an atom is located on a non-lattice site within the crystal, then it

is said to be an interstitial defect.

A defect in which one host atom is located on wrong site (one host

atom occupied the site of another atom), then it is called an antisite

defect.

38

Figure 2.3 Schematic representation of defects in semiconductors [12].

2.2.2 Point Defects in ZnO

There are two types of point defects in bulk ZnO which have been studied in

literature.

2.2.2.1 Intrinsic Defects

In case of ZnO, the oxygen vacancies (VO), zinc vacancies (VZn), oxygen

interstitials (Oi), zinc interstitials (Zni), oxygen antisites (OZn) and zinc antisites (ZnO)

are the intrinsic defects [13]. Similarly, complex defects are the combination of point

defects like VO-Zni in ZnO [14,15]. They are acting as free carrier concentration and

are responsible for n or p-type in bulk ZnO. The electric field induced by intrinsic

defects affects the properties of deep level defects present in bulk ZnO to be discussed

in section 2.2.2.3.

2.2.2.2 Extrinsic Defects

The defects involving the foreign atoms (impurities) are called the extrinsic

defects for example hydrogen interstitial (Hi) and hydrogen on oxygen sites (HO) in

ZnO [16, 17].

39

2.2.2.3 Influence of Electric Field on Deep Level Defects

The activation energy of traps can be lowered in strong electric fields. The

activation energy of traps is calculated from the emission rate. The emission rate of

carriers from trap is most significant parameter of defect. Each defect has a unique

emission rate. According to Martin et. al. [18] the origin and the carrier excitation

phenomenon of the defect are determined from the emission rate. The emission

rateen,p (the subscripts n and p stand for electron and holes carriers) of defect in terms

of mathematical equation is defined as:

kT

GNVge vcthpnpnpn exp.,,, (2.3)

where G ,png ,,

pn, , thV , vcN . , k, and T are the change in Gibb’s free energy at

constant temperature and pressure, degeneracy of deep states, capture cross-section,

the carrier’s average thermal velocity, the effective density of states, the Boltzmann

constant and absolute temperature, respectively. An internal electric field is produced

in depletion region due to the free carrier concentrations.The relation between internal

electric field and free carrier concentration is explained as what follows:

The electric-field is calculated by the following relation [19]:

Electric field = Qdep /εεo (2.4)

Qdep = god EqN 2 (2.5)

where Qdep, q, εo, ε, , Nd, and Eg are charges in the depletion region, electronic charge,

permittivity of free space, relative permittivity of the host crystal, free carrier

concentration and bandgap, respectively. The emission rate of defects is affected by

40

the electric field due to free carrier concentration. The electric field dependence of the

emission rate has to be taken into account, because neglecting this effect may lead to

serious misinterpretations in the determination of deep level parameters. On the other

hand, it can yield a lot of useful information on the nature of deep traps. Interaction of

fields with emission rate of defect has been explained by various models which helps

to identify the nature of defects. Some of famous models are the following:

(i) Poole-Frenkle [20]

(ii) Phonon-assisted tunneling [21, 22]

(iii) Pure tunneling [18]

Vincet et al. and Naz et al. [23, 24] proposed a simple model to distinguish

between phonon-assisted tunneling and Poole-Frenkle mechanisms, i.e to compare the

plots of ln(e) vs F2 and ln(e) vs F0.5, respectively. In the case of phonon-assisted

tunneling the plot of ln(e) vs F2 is expected to provide a good linear fit, while for

Poole-Frenkle the electric field should follow the ln(e) vs F0.5 linear variation.

2.2.2.3.1 The Poole-Frenkel

According to the Poole–Frenkel theory, when electric field is applied, the

electron band diagram is slanted and the barrier depth is reduced. The emission rate

due to the barrier lowering of the Poole-Frenkel effect is written as [20]:

kT

EEEvNe iic

nncn

exp (2.6)

It can be written as:

41

kT

FEeFe i

non

exp (2.7)

The various models like Coulomb potential, square well potential and dipole

potential have been suggested to fit Poole–Frenkel effect on the emission rates of the

carriers from defect level.The mathematical equations for emission rates at electric

field F to Coulomb potential and square well potential are given below [18,23]:

2

111

1

)0( 2

ee

Fe

n

n (2.8)

where kTqqF or // 2

1

2

11

2

1

)0(

e

e

Fe

n

n (2.9)

where kTqFr /

where F and r are the electric field and radius of potential well, respectively. All other

constants bear usual meanings.

2.2.2.3.2 Phonon-Assisted Tunneling

Phonon-assisted tunneling theory states that if the electron has coupling with

the suitable phonon, then electron will tunnel through the barrier because the emission

energy will be reduced. The field dependence emission rate of the carrier to

characterize the phonon-assisted tunneling mechanism is given below [24]:

2

2

exp0

cF

F

e

Fe (2.10)

42

where Fe and 0e are the emission rate at field F and the emission rate at zero

field. The characteristic field cF is calculated as:

3

2

2

*3

q

hmFc (2.11)

where *m , q and 2 are the carrier effective mass, charge of electron, and the tunneling

time. The tunneling time is calculated as:

122

Tk

h

B

( 2.12)

where h and 1 are the Planck’s constant and characteristic time constant of the order

of the inverse local impurity vibration frequency.

The electric field to enhance emission for Poole-Frenkle and Phonon-assisted

tunneling is in the range of 104-106 V/cm. The enhanced emission processes are

illustrated in Figure 2.4. The electric field in pure tunneling is in the range of ≥107

V/cm [20].

43

Figure 2.4 Electron energy diagram in equilibrium (1) and in the presence of an

electric field (2) showing field-enhanced electron emission: (a) Poole-Frenkel

emission, (b) phonon-assisted tunneling [25].

44

2.3 Contacts to Zinc Oxide

For quality devices, suitable metals should be used to make contacts to ZnO

thin films. Device performance depends not only on the materials quality but also on

the type of metals and its contact. There are two types of contacts that are fabricated

on ZnO, namely:

Schottky Contacts [1]

Ohmic Contacts [26]

2.3.1 Schottky Contact to ZnO

The Schottky model of the metal and n-type semiconductor is defined as [24]:

smB

(2.13)

where φm is work function of metal, defined as the potential difference between the

the vacuum level and the Fermi level EF and φB and χs are barrier height and electron

affinity of semiconductor. The electron affinity of semiconductor is defined as the

energy difference between the bottom of the conduction band EC and the vacuum

level at the semiconductor surface.

Figure 2.5 Metal-semiconductor contacts according to the simple Schottky model

[25].

EC EF EV

X S

EF

M

45

The parameters such as barrier height, series resistance, and ideality factor of

the diode are determined after the fabrication of Schottky contacts. The fabrication of

Schottky contacts is difficult due to following factors: (i) the surface states, (ii) the

contaminants, (iii) the defects in the surface layer, and the diffusion of the metal into

the semiconductor. It is fact that high-quality Schottky contacts are serious issue for

ZnO device applications. First time Mead [27] fabricated the Schottky contacts with

different metal on vacuum-cleaved n-type ZnO surfaces in 1965 but he did not

comprehensively study the thermal stability of the Schottky diodes fabricated on ZnO.

The metals such as Au, Ag, Pd, Pt, and Ti are used for Schottky - contact to n-

type ZnO [28-45]. Al has strong reaction with anions (O). Al is supposed to make the

most dissociated cations (Zn) in ZnO. This results in low barrier height and leakage

current. Simpson et al. [46] reported that the thermal stability of Ag Schottky contacts

was better than that of Au Schottky contacts. Some other reports [30,31] also show

that Au Schottky contacts have some serious problems at temperatures more than 340

K. I-Vcharacteristics of as-deposited Au and Ag Schottky contacts on n-type ZnO are

improved by exposure to the plasma at room temperature or cleaning with organic

solvent before the metal deposition [31,47]. Ohashi et al. [33] suggested that the value

of the barrier height was lower because of high donor density. The higher value of

ideality factors may be due to relatively high carrier concentration which leads to the

increase of tunneling current through the junction. Ip et al. [43] observed that the

Schottky barrier height of Pt contacts on P-doped n-type ZnO grown by plused laser

deposition decreased and ideality factor increased with increasing temperature. It is

clear from the literature that the ideality factor for the ZnO Schottky contacts is higher

than unity in the most of the cases. The higher value of ideality factor can be

explained by different phenomenon such as the prevalence of tunneling [48] the

46

presence of an interface layer, surface states [34] increased surface conductivity [47]

and/or the influence of deep recombination centers [31].

2.3.2 Ohmic Contacts to ZnO

Any contact having a linear and symmetric current-voltage relationship for

both positive and negative voltages is called Ohmic contact. An Ohmic contact obeys

Ohm’s law and is demonstrated in Figure 2.6. It is essential for carrying electrical

current into and out of the semiconductor, ideally with no contact resistance. The

contact resistance is one of the main problems for long-lifetime operation of optical

and electrical devices. The high contact resistance between the semiconductor and

metal affects the device performance because of thermal stress and/or contact failure

[49]. It is necessary to attain Ohmic contacts that have low contact resistance and

thermally stable for high-performance ZnO-based optical and electrical devices. This

can be attained by reducing the metal-semiconductor barrier height or increasing the

effective carrier concentration of the surface [50-52].

Figure 2.6 Energy band diagrams for Ohmic contact [53].

EC

EF

EV

qF

qB

Ei

Metal Semiconductor

47

Ohmic-contact metallization is essential for obtaining good electronic device

performance [50]. In case of wide-bandgap semiconductors like ZnO, low resistance

Ohmic contact can be attained by thermal annealing. But surface roughness and

structural degradation of the interface can be produced during the thermal annealing

process [54,55], resulting in poor device performance [56]. The non-alloyed Ohmic

contacts having low specific contact resistance arechosen in Ohmic-contact

technology especially for shallow junction and low voltage devices because they give

smooth metal semiconductor interfaces [52, 57, 58].

The metals such as Al, Au, In, InGa , Pt , Ti, and Ru are often used for

Ohmic-contact to n-type ZnO [59-63]. Some reports are following; Lee et al. [64]

have successfully fabricated low-resistance and non-alloyed Ohmic contacts to

epitaxially grown n-ZnO. Marlow et al. [65] deposited Ohmic-contacts to n-ZnO by

hydrogen plasma treatment by Ti/Au metallization schemes and observed the contact

resistivity decreased by Ar plasma-treated. They suggested that this decrease in

contact resistivity is due to the formation of shallow donor by ion bombardment. Kim

et al.[54] also reported that resistivity of annealed samples decrease two order of

magnitude as compared to the as deposited samples. They proposed that this reduction

in resistivity is caused by the combined effects of the increases in the carrier

concentration near the ZnO layer surface and the contact area. Kim et al. [63]

proposed that Ohmic contact of Ru to n-type ZnO is appropriate for high-temperature

ZnO based devices. The Ohmic-contacts of Pt were characterized as linear if it

deposited to n-ZnO after surface modification [50,66]. Sheng et al. [52] reported an

extensive study of Ohmic-contact to n-ZnO. They found the following results: (i) the

electron concentrations are increased and the specific contact resistivity is decreased

48

because of tunneling and (ii) the specific contact resistivity of heavily doped ZnO is

lowered than unintentionally doped ZnO.

49

CHAPTER 3

50

2 GROWTH TECHNIQUES

Zinc Oxide can be grown by various techniques such as, sol-gel chemistry, spray

pyrolysis, metal organic chemical vapor deposition (MOCVD), molecular beam

epitaxy (MBE), pulsed laser deposition (PLD), hydrothermal, reactive thermal

evaporation, and sputtering [1-7]. ZnO samples used in this study were grown by

hydrothermal technique, MBE and aqueous chemical methods. These three techniques

are hereby described in detail.

3.1 Hydrothermal Technique

Hydrothermal technique can be defined as a method of synthesis of crystals

under elevated pressure and temperature conditions in the presence of water. The term

hydrothermal usually refers to any heterogeneous reaction in the presence of aqueous

solvents under high pressure and temperature conditions to dissolve and recrystallize

(recover) materials that are relatively insoluble under ordinary conditions. Today, the

hydrothermal technique has gained a unique place in various branches of modern

science and technology like in fabrication of nanostructures. Hydrothermal method is

preferred one and economical because of its short reaction times and lower energy

requirements. It is very important for its technological efficiency in developing

bigger, pure, and dislocation-free single crystals.

3.1.1 Experimental Setup of Hydrothermal Method

In hydrothermal technique, the growth chamber is capable of containing

corrosive solvent at high temperature and pressure required for growth. The

temperature, pressure, and corrosion resistance of solvent are the important

parameters for selecting a suitable growth chamber. The nutrient is supplied to the

51

growth chamber along with solvent (i.e an aqueous solution of alkali). The

temperature gradient is applied at the opposite ends of the growth chamber. The

nutrient dissolves at the hotter end of chamber and seed crystal are introduced at

cooler end of chamber for additional growth. An ideal growth chamber for

hydrothermal should have the following characteristics

Inertness to acids, bases and oxidizing agents.

Easy to assemble and dissemble.

Sufficient length to obtain a desired temperature gradient.

Leak-proof with unlimited capabilities for the required temperature and

pressure.

Rugged enough to bear high pressure and temperature condition for long

duration, so that no machining or treatment is needed after each experimental

run.

3.1.2 Hydrothermal Synthesis of Zinc Oxide

The hydrothermal technique is the most suitable method for fabricating

isometric (having equal measurement) zinc oxide crystals of good quality [8-13]. In

this method, the aqueous solution of ZnO is heated at suitable temperature in

temperature gradient chamber where ZnO seed crystals are mounted. ZnO vapors are

condensed on the seed crystals and form ZnO wafer.These wafers can be separated

from seed crystals by stress pressure. The schematic diagram of the hydrothermal

growth chamber is shown in Figure 3.1. The hydrothermal apparatus consists of

furnaces, pressure gauge, autoclave, heaters and Pt crucibles. The furnaces and

autoclave are used to increase the temperature. The Pt crucible contains baffle, vessel

of seed crystals in upper part of crucible and vessel of solution in lower part of

52

crucible. The heaters F1 and F2 are used to control the temperature in such a way that

temperature of upper part is less than lower part of Pt crucible.

Hydrothermal growth process is described as following: initially some seed

crystals are hanged in the upper part of Pt crucible by a Pt wire. The sintered ZnO as

nutrient and aqueous solution of alkali (NaOH, KOH, LiOH) or chlorides of desired

molarity as solvent are mixed together to form the solution [14-18]. The solvent

breaks the intra molecular bonds of ZnO due to week Van de Waal forces. This

solution is put in lower part of Pt crucible. A Pt baffle is installed to separate seed

crystals from solution. The crucible is placed into an autoclave after closing it by

welding. The autoclave is then placed into a two-zone vertical furnace. When solution

temperature and pressure of autoclave are increased, water of aqueous solution

converted into steam and moved to upper part of crucible. Then steam returned backin

liquid form to lower part of crucible because of condensation of water molecules.

ZnO is attached to seed crystals in upper part of Pt crucible and seed crystals grow to

bulk. Only ZnO grow in upper part of crucible due to the presence of its mother seed.

Table 3.1 The growth conditions optimized by Sakagami for zinc oxide crystals [30].

Parameters

Values

Growth temperature

370–400 °C

Temperature difference

10–15 °C

Total pressure

700–1000 kg/cm

Partial pressure

10–30 kg/cm

Solvent KOH 3.0 M + LiOH 1.5 M

Oxidizer

H2O2 0.1 M–0.3 M

Nutrient ZnO sintered

Growth run

15–20 days/run

53

Figure 3.1 Schematic drawing of a hydrothermal growth system. F: furnaces (F1,F2),

T: thermocouples for control (T1,T2) and monitor (T3), P: pressure gauge, A:

autoclave, C: Pt crucible, S: seed crystals, N: nutrient, Baffle [19].

In the zinc oxide growth, the oxidation of the chamber material produces

hydrogen due to the presence of alkalis. The amount of hydrogen formed depends on

the temperature, the concentration of the alkali, and the duration of the experiment.

54

Several research groups have successfully grown ZnO nanostructures by

hydrothermal methods for biomaterials applications [20-28]. Sun et. al. [29] had

grown ZnO nanostructures by hydrothermal technique. They obtained the outstanding

variety of ZnO nanostructures having different and controllable morphologies by

varying growth parameters such as precursor chemicals, their concentrations and/or

the growth temperature. Sakagami [30] has grown zinc oxide crystals of high purity

by the hydrothermal method using platinum-lined chamber. The growth conditions

optimized by Sakagami are listed in Table 3.1.

3.2 Molecular Beam Epitaxy

Molecular beam Epitaxy is the most advance technique to grow atom by atom

layers of thin films. There is no substitute to the quality of materials grown by MBE,

however it does have some fundamental limits. An ultra high vacuum is required to

grow the material. Advantages of MBE are the following:

Excellent interface and surface morphology.

It is possible to control the thickness of epilayer precisely.

In-situ characterization techniques (RHEED).

High purity starting materials, easy chemistry.

Low growth temperature which reduces any undesirable thermally

activated processes such as diffusion.

The slow growth rate and high cost are disadvantages of MBE growth. Now

various scientists have successfully grown ZnO by MBE [31-34].

The substrate is placed on sample holder. It is heated to required temperature

and rotated continuously (if necessary) for better quality of growth homogeneity [35].

55

The ultra high vacuum (UHV) in the range of 10-6

to 10-4

mbar is needed for MBE

growth. The O2, CO2, H2O and N2 contamination on the growing surface can be

ignored after outgasing under UHV. The reduced rate down to nm/sec is achieved by

particular growth conditions. In this way precise growth of control thickness is

possible. Prior to growth, substrate is cleaned to avoid the effect of contamination on

the properties of substrate. The basic requirements for MBE growth are following, (i)

pure startng materials are to be used. (ii) Low background pressure in the evaporator

to decrease contamination; (iii) Uniform flux of effusion cell across the substrate. (iv)

The reaction chamber is evacuated to <10-8

mbar and the walls of the chamber cooled

with liquid nitrogen. The UHV is an important characteristic of MBE. The most

common diagnostic techniques to monitor the growth is reflected high-energy electron

diffraction (RHEED). Each monolayer growth can be seen in the intensity and pattern

of the RHEED signal. Thus growth can be controlled precisely at themonolayer

level.The diagram of MBE system is shown in Figure. 3.2.

56

(1) RHEED, (2) growth chamber, (3) baking heaters, (4) ion pump, (5) gate wall, (6)

mechanical pump, (7) preparation chamber, (8) fishing lever, (9) Viewing windows.

Figure 3.2 The diagram of MBE system [36]

3.3 Aqueous Chemical Growth

It is the easiest, cheap and time saving growth technique. A number of ZnO

nanostructures such as nanowires, nanorods and nanotubes have been grown by this

technique [37-40]. In this method, first of all, seed solution of required material is

prepared by the mixture of different chemicals of desired molarity under necessary

condition of temperature and stirring. The seed solution should be transparent. Then

few drops of the seed solution were placed on the substrate and rotated with help of

1 4 3

2

5

6 7 8

9

57

spin coater at desired speed. After this the growth solution is made by the mixture of

chemicals (HMT and Zinc nitrate hexahydrate for ZnO as shown in Figure 3.3) of

preferred molarity in deionized water at room temperature and stirred using magnetic

stirrer apparatus as illustrated in Figure 3.4. The substrate is put in the solution with

face downward towards the solution. Subsequently, solution container is placed into

the oven as shown in Fig.3.5 at temperature less than 100oC for some hours. Then

substrate is removed from the solution, cleaned with deionized water and dried at

room temperature and used for characterization.

Figure 2.3 The chemicals for growth solution of ZnO.

58

Figure 3.4 The stirring of growth solution for ZnO.

Figure 3.5 Growth solution container placed in oven.

59

CHAPTER 4

60

3 CHARACTERIZATION TECHNIQUES

Characterization techniques can generally be placed into two categories i.e. Electrical

and Optical. It is one of the most important steps to study the various properties of

semiconductor materials. This chapter describes the various characterization

techniques like current-voltage (I-V), capacitance-voltage (C-V), deep level transient

spectroscopy (DLTS), and X-ray diffraction (XRD). To perform the electrical

measurements, Schottky and Ohmic contacts are necessary, described in the previous

chapter.

4.1 Current-Voltage Measurements (I-V)

The current-voltage characteristic (I-V) provides the knowledge of

fundamental parameters about the performance of devices. Figure 4.1 shows the

intimate contact between the metal and the n-type semiconductor.

Figure 4.1 Band diagram of the intimate contact between metal and semiconductor (n-

type) for a rectifying junction [1].

61

When a voltage is applied to the metal contact, current flows through a

uniform metal-semiconductor interface. The movement of majority carriers across the

interface such as electrons in n-type material or holes in p-type material generates a

flow of current. Three main current mechanisms can occur, namely, (i) Thermionic

emission (TE), (ii) thermionic field emission (TFE), and (iii) Field emission (FE).

Thermionic emission is dominant for lightly doped semiconductors, for the

intermediate doped semiconductors, the current flows as a result of thermionic field

emission whereas field emission can dominate in heavily doped semiconductors [2].

The current-voltage technique involves a range of voltages, both positive and

negative, to the metal-semiconductor system and the measurement of the resulting

current [3]. When a reverse or negative voltage is applied, the energy levels of an n-

type semiconductor are lowered with respect to the metal Fermi level. The barrier for

electrons to traverse from the semiconductor to the metal is increased as a result of the

increased band bending, associated with the lowering of the Fermi level. In this

scenario, the electrons flow from the semiconductor to the metal is decreased. When

positive or forward voltage is applied, results in the Fermi level of the semiconductor

being raised compared to the metal. In this case, the barrier for electrons to traverse

from the metal to the semiconductor remains the same, but the barrier for electrons to

traverse from the semiconductor to the metal is reduced. Thus, equilibrium conditions

in the current flow are altered, and the flow of current from the metal to the n-type

semiconductor is greater than the opposing current. Therefore the metal-

semiconductor junction with positive voltage has a rectifying behavior. A large

current exists under forward bias than the reverse bias.

62

The ideality factor (n), barrier height (φB)I-V and saturation current (Is) are

measured by forward I-V measurements at given temperature. By plotting the

experimentally measured I-V data, as ln(I) vs V, the intercept of the linear fit will give

saturation current (Is) from which barrier height (φB)I-V could be extracted, (method is

described below) and the slope of the plot will give the value of ideality factor (n),

using following relations[1]:

1exp

nkT

qVII S (4.1)

kT

qTAAI

B

S

exp2* (4.2)

slopekT

qn

(4.3)

dV

Idslope

ln (4.4)

where A is Schottky contact area, A* is the Richardson constant, T is temperature in

Kelvin, k is the Boltzmann’s constant (k = 1.3810-23

J/K or 8.61710-5

eV/K) and q

is the electric charge. Deviation of n from the ideal range 1.01 <n < 1.1 may be

generated by a thick interface layer or substantial recombination in the depletion

region. A non-uniform interface will also produce an increase in n from 1.01- to

higher value [1]. The saturation current is calculated from the intercept of semilog

graph of I-V measurements at different temperatures. In this way we have the values

of saturation current at different temperatures. The slpoe of plot of log (Is/T2

) vs

1000/T gives the barrier height.

63

4.2 Capacitance-Voltage Measurements (C-V)

Capacitance-Voltage (C-V) method is based upon the voltage dependence of

the charge in the depletion region of the diode. The C-V method measures the

electrostatic properties of the Schottky barrier and is not affected by transport

processes such as tunneling and image force lowering.

The capacitance of Schottky diodedecreases asreverse bias increases.In

capacitances-voltage characteristics, capacitance for a Schottky diode is given by

following relation [4]:

VV

qNAC

bi

roD

2

(4.5)

where C, A, ε, q, ND, V, k and T are capacitances, area of contact, dielectric constant,

electric charge free carrier concentration, applied voltage, Boltzmann constant and

temperature, respectively. In C-V measurements, a plot of (A/C)2

vs V will give a

straight line. The slope and x-intercept of straight line are (2/ εqND) and 2Vbi/εqND

respectively.The Vbi (electrostatic potential at equilibrium in semiconductor) is called

built-in potential. The free carrier concentration ND is calculated from the slope using

the following relation:

slopeq

N D

2 (4.6)

The depth profile of free carrier concentration is also found from C-V

measurements by plotting the graph between free carrier concentration and depth. The

depth x is calculated by following relations:

64

dV

dCq

N D 2

2

(4.7)

C

Ax o

(4.8)

The barrier height, (φB) C-V can be calculated from:

VoVbivcB (4.9)

D

C

ON

NIn

q

kTV (4.10)

222

ekTmNC

(4.11)

where VO is the energy difference between the Fermi level and the bottom of the

conduction band, and NC

is the conduction band density of the states, m*

is the

effective mass of material. High densities of impurities or defects with deep energy

levels in the band gap make it difficult to measure the Schottky barrier height (SBH)

by C-V, since these defects change the space-charge region and hence the intercept

voltage. These deep level defects typically cause the SBH (C-V) to be greater than the

SBH (I-V).

4.3 Deep Level Transient Spectroscopy (DLTS)

Deep Level transient spectroscopy is one of the most versatile techniques to

detect impurities and defects in semiconductors. The level of detection, going down to

~1011

cm-3

by this method, is unmatched with other characterization techniques. The

DLTS technique also provides electrical parameters of the levels associated with

impurities or defects. By monitoring capacitance transients produced by pulsing the

65

semiconductor junction at different temperatures, a spectrum is generated which

exhibits a peak for each level. The height of the peak is proportional to trap density

and the position of the peak on the temperature axis leads to the determination of the

fundamental parameters governing thermal emission and capture (activation energy

and cross section).

4.3.1 Carrier Kinetics in Semiconductors with Deep Level- Shockley-

Read-Hall Theory

The carrier kinetics in extrinsic semiconductors can be explained by

Shockley-Read-Hall theory [2]. To support our results, we will describe this theory

qualitatively only. Consider ND, Pt, and Nt which denote the doping concentration, a

hole trap concentration and an electron trap concentration, respectively. Both the

electron and the hole traps are uniformly distributed throughout the semiconductor

with the trap activation energy of ET as shown in Figure. 4.2 Ec, Ev, cn, en,cp and ep

represent the energy of conduction band, energy of valence band, capture of electrons,

emission of electrons, capture of holes and emission of holes, respectively.

Figure 4.2 Electron energy band diagram for a semiconductor with deep a level trap

[2].

66

Figure 4.2 shows a recombination event (a) followed by (c) and a generation

event (b) followed by (d). The impurity is a G-R center and both the conduction and

valence bands take part in recombination and generation. A trap has only two charge

states, a filled state which is occupied by an electron, or an empty state which is

unoccupied. If the capture and emission of electrons are dominating, then the total

electron trap concentration can be expressed as

NT = nt + pt (4.12)

where nt is the concentration of the trapped electrons (occupied states), pt is the

concentration of unoccupied states. Similarly, if the capture and emission of holes are

dominant, then the total hole trap concentration is:

PT = nt + pt (4.13)

where nt and pt , are respectively the concentrations of trapped holes (occupied states)

and neutral traps (unoccupied traps).

4.3.2 Basic Principle of DLTS

In the following, we consider an n-type semiconductor containing only

electron traps. A depletion layer of width x will be formed as show in Figure 4.3.

Figure 4.3 The metal-semiconductor contact and the depletion layer [2].

x

Depletion region

V

67

When bias voltage V is imposed across the junction, the depletion layer

capacitance per unit area is given by:

VV

qNC

bi

roD

2

(4.14)

where Vbi is the built in potential and V is the bias voltage, positive for forward bias

and negative for reverse bias.

Figure 4.4 The schematic illustration of a majority injection pulse sequence and

energy band bending. (a) bias time, (b) capacitance-time, (c) and (d) the energy band

bending during the pulse and after pulse [2].

68

Assuming that a forward bias pulse ∆V is applied, then the capacitance prior to

the application of the forward bias pulse is:

VV

qNC

bi

roD

o

2

(4.15)

When a pulse ∆V<V is applied, electrons will move into the n-side and they will

fill the traps step by step. After a certain period of time, when the traps are filled then

the capacitance will increase.

VVV

nNqC

bi

tDo

2

(4.16)

When all traps are filled with electrons, nt= NT. At the moment when ∆V= 0 at t

= 0 as shown in Figure 4.4 (b), the capacitance C changes to:

VV

NNqtC

bi

tDo

20

(4.17)

After ∆V= 0, the trapped electrons are regularly re-emitted to the conduction

band as shown in Figure. 4.4 (d). This means that nt slowly reduces and finally nt, = 0,

then Eq. (4.17) becomes Eq. (4.15) and C returns to Co. The change of the capacitance

C with time after t = 0 is referred to as the capacitance transient, which can be written

as:

VV

tnNqtC

bi

tDo

2

(4.18)

Eq. (4.18) can be written as:

69

tnNK

VV

tC D

bi

22

1 (4.19)

where oqK 2 , is a constant, by defining S (t) = -dV/d (1/C2), we obtain

tt nnKSS 00 2 (4.20)

Suppose that nt(0) = NT and nt (∞) = 0, then from Eq. (4.20) we have

2

0

K

tStSN tt

T

(4.21)

Thus, from above Eq. (4.21) the deep-level impurity concentration can be

calculated by the DLTS measurements. The emissions of the trapped electrons from

traps change the capacitance with time. Since the capacitance transient reveals the

emission process of trapped electrons. The emission rate depends upon the following

factors: (i) trap activation energy ET; (ii) trap capture cross section σn;

(iii) temperature T. Hence these trap parameters can be calculated by capacitance

transient spectroscopy. The capacitance of a junction due to impurities with a single

level of activation energy can be written as:

eD

to

t

N

nCtC

exp

2

01 (4.22)

where nt (0) the concentration of trapped electrons at t = 0, ND is the doping

concentration which can be considered as the free electron concentration, τe is the

trapped electron emission time constant, which is given by:

70

2