Denim

-

Upload

mazadul-hasan -

Category

Engineering

-

view

614 -

download

3

description

Transcript of Denim

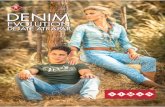

DENIM

Name : MAZADUL HASAN SHESHIRID: 2010000400008Batch: 13th Batch (Session 2009-2013)Department: Wet Processing Technology Email: [email protected]: www. Textilelab.blogspot.com Southeast UniversityDepartment of Textile Engineering

PREPARED BY ©right

Introduction :

Denim is a rugged cotton twill textile, in which the weft passes under two or more warp threads. Denim is the most popular pieces of clothing in the world. In 1969 a writer for American Fabrics magazine declared, "Denim is one of the world's oldest fabrics, yet it remains eternally young.“

Denim was invented in California by Levi Strauss in the 1850s. Denim is designed most of the famous USA brand and 400 pieces thousand per month. Now a day’s 415 million pieces of jeans/ Denim sold every year in USA alone and worldwide in denim market is worth amount of 40 billion dollars.

Introduction :Denim's popularity was also on the rise. It was

stronger and more expensive. Denim was made of one colored thread and one white thread. The countries over 20 denim plants, installed during the last five to six years, have the capacity to produce 20 million gauge fabrics per month.

Denims are hard wearing, high density fabric with a higher mass per unit area. At least 225 pair of denim jeans can be made from one bale of cotton. Denim is made from 48% of the world's cotton. Denim fabric was unique in its connection with one color - blue.

Types of Denim :

Stretch denim Slub denim Printed Denim

Bull Denim Ring Denim Poly-Denim

Types of Denim Stretch denim: Elastomeric yarn is used in weft.Poly-Denim: Polyester yarn is used in weft.Ring Denim: 7,9,12 count of yarn is used.Bull Denim : A heavy weight denim weave (14oz.

Plus)Printed Denim : That has been printed with a

pattern-a batik, stripe or floral.Slub denim: Slub yarn is used in warp or weft or in

both(Cross Hatch Denim).

Manufacturing Process:

Spinning:The initial processes of denim manufacturing consist of the regular activities of opening and mixing or blending of cotton fibers. Carding is done to remove any foreign materials and the short fibers.

Drawing process produces a single, uniform sliver from a number of carded slivers.

Yarn is then spun through Open-End Spinning or Ring Spinning.

Quality criteria:Minimum staple length – 2.7 cmProportion of short fibers(<less then 12 mm

long) :under 40%Micronaire value – 4.0 to 4.5Twist Factor – 4.5 to 5.0(for warp), 4.2(for

weft)Count range: Warp 50-90 tex & weft 75-120

tex. low yarn hairinessYarn strength & uniformity.

Warp Preparation - Dyeing and Sizing Processes:Warp yarns are indigo dyed and sized with the help of some methods:Indigo Rope dyeing: There are some stages in indigo rope dyeing. They are: 1.Ball warping. 2.Dyeing. 3. drying. 4.Rebeaming. 5.beaming. 6.Sizing

Indigo sheet dyeing: Threads from several back beams are combined to form a warp sheet and dyed then sized on the same machine

Indigo loop dyeing: The yarn is dyed in a single bath instead of several. The desired depth of colour is attained by passing the yarn through the vat several times then sized on the same machine.

Size recipe for 100 liters of liquor:-8.00 Kg modified starch.-4.00 kg acrylate size.-0.2 kg textile wax.-Size concentration: 8%-Size temperature 850C.-Squeezing pressure: approx.15 KN.-Size pickup: 9% - 10%

Weaving & DesizingThe weaving process interlaces the warp, which are the length-wise indigo dyed yarn and the filling, which are white in color. Airjet, Rapier, or a Projectile weaving m/c used.

Weight range: (6 oz/yd2) to (14 oz/ yd2)

Finishing

The final woven fabric, wound on a cloth roll.The woven Denim Fabrics then goes through

various finishing processes, such as singeing, washing, brushing, drying.

Denim Fabric TreatmentsThere are many fabric treatments, and each treatment gives the denim a

unique and fashionable look:

Stone-washed: In traditional washing process, volcanic rocks or pumice stones are added to the garments during washing

Laser technology: It is a computer controlled process for denim fading

Spray techniques: This technique is based on spraying the chemicals or pigments to get different effect

Sandblasted: Denim is sprayed with sand or chemicals during the wash process to create a worn-out appearance.

Denim bleaching: In this process, a strong oxidative bleaching agent such as sodium hypochlorite or KMnO4 is added during the washing

Vintage/Dirty: Dirty denim is usually created with brown filler yarns.

Diversification of DenimBy using Slub/fancy Yarn.By changing EPI & PPI.By using different count.Spandex(Lycra) can be used.By applying different wash effect. (Stone,

Enzyme, Blech)By applying different mechanical effect.

(Rubbing, brushing)

Prospect of Denim in Bangladesh:

Bangladesh Export of Denim Jeans to EU: Bangladesh is a major exporter of denim jeans

to EU. Being low priced and with special and indefinite duty free and quota free access under ‘Everything but arms’ initiative to EU, Bangladesh continues to dominate the EU denim import business. Currently, it has about 19% share of the denim jeans import market in EU 27 countries. Let’s have a look at the figures of imports of denim from Bangladesh for the last 10 years.

Prospect of Denim in Bangladesh

Table: Imports of denim from Bangladesh for the last 10 years

Different denim factory in Bangladesh:

Sinha Denim Ltd.Ha-Meem Denim Mills Ltd. BEXIMCORoyal Denim:Zulekha Denims LtdSiatexBIG X ENTERPRISES AND ASSOCIATE BONAMI FASHIONToptex Design Ltd.Trendz Group etc

Some denim products by Bangladesh:

Common Defects of Denim Sewing in BANGLADESH:1. STITCHES – NEEDLE CUTBROKENTING

Where the thread is being broken where one seam crosses another seam (ex: bartacks on top of waistband stitching, seat seam on top of riser seam) resulting in stitch failure.

Where the thread is broken during stone-washing, sand blasting, hand sanding, etc. Broken stitches must be repaired by restitching over the top of the stitch-line.

2. Broken Stitch – Abrasion:

Common Defects of Denim Sewing in BANGLADESH:

3. Broken Stitches: Chemical Degradation:

4. Unraveling Seams:

Where thread is being compromised by the chemicals used during laundering resulting in loss or change of color and seam failure.

where either the stitch has been broken or a skipped stitch has occurred. This will cause seam failure unless the seam is Re-stitched.

Common Defects of Denim Sewing in BANGLADESH:

5. Ropy Hem:

Where hem is not laying flat and is skewed in ROPY HEM appearance.

6. Ragged – Inconsistent Edge:

Where the edge of the seam is either extremely "ragged" or "rolls" inside the stitch

Common Defects of Denim Sewing in BANGLADESH:7. Wavy Seams on Stretch Denim:

Where the seam does not lay flat and is wavy due to the fabric stretching as it was sewn or during subsequent laundering and handling operation.

8. Twisted Legs: Where the side seam twists around to the front of the pant and distorts the appearance of the jeans.

End use:Men’s shirtBottom wearCritical cargoHI-FASHION DENIM JeansWrinkle Free fabric Laser finishDress PantsCapri pantsdenim skirtsHatsJacketsOverallsShirtsBooties & shoes

ShortsSofa coversBean bag chairsDirector-style chairsLampshadesCollege BagsTravel BagsCar Seat CoversDenim CurtainsDenim Body SuitDenim Face Mask etc