DEMONSTRATIVE SAFETY ASSESSMENT OF LNG STORAGE …

Transcript of DEMONSTRATIVE SAFETY ASSESSMENT OF LNG STORAGE …

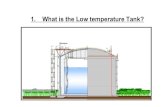

6.7–1

DEMONSTRATIVE SAFETY ASSESSMENT OF LNG STORAGEFACILITY EARTHQUAKE RESISTANCE, ANDREINFORCEMENT OF CRISIS MANAGEMENT

AT LNG RECEIVING TERMINALS

GESTION DES RISQUES SUR LE SITE DU TERMINALMETHANIER ET EVALUATION DE LA RESISTANCE AU

SEISME DES RESERVOIRS DE GNL

Takanori MizunoYoshiaki WadanoNorihito Terada

Takuji TsunomuraThe Kansai Electric Power Co., Inc., Japan

Kunio MikiEiichiro Fukui

Osaka Gas Co., Ltd., Japan

ABSTRACT

On January 17, 1995, a powerful earthquake with a seismic intensity of Magnitude7.2 (Southern Hyogo Earthquake) shook the southern region of Hyogo Prefecture, locatedin west-central Japan. The quake inflicted serious damage on the residents and propertiesof the region, resulting in many number of deaths and destroyed structures. AlthoughKansai Electric Power Co., Inc. and Osaka Gas Co., Ltd., suppliers of electricity and gasin this region, also suffered damages to their distribution facilities and gas piping in theurbanized areas of the region, the LNG receiving terminals did not suffer much damagesand could continue their operation. Nevertheless, based on the lessons learned from thedisaster, the two companies have improved their crisis management measures inpreparation for such disasters. Also, Kansai Electric Power conducted evaluations of theearthquake resistance of the LNG tanks and the results of an experiment to verify theearthquake resistance of a 1/8 scale model tank. The results of this experiment arereported here.

6.7–2

RESUME

Le 17 janvier 1995, un grand séisme de magnitude 7,2 (appelé couramment “le grandtremblement de terre de Kobé”) s’est déclaré dans le sud du département de Hyogo, qui aconnu ainsi de nombreuses pertes en vies humaines et de graves dégâts matériels.Fournisseurs respectivement d’électricité et de gaz dans la zone sinistré, Kansai ElectricPower Co., Inc. et Osaka Gas Co., Ltd., ont vu également endommager leurs réseaux dedistribution. Par contre, ne subissant aucune conséquence grave, leurs terminauxméthaniers ont pu continuer à fonctionner. En se fondant sur les leçons qu’elles ont tiréesde ce grand séisme, les deux entreprises ont renforcé leur système de gestion des risquesafin de se prémunir contre les cas d’important désastre. En outre, Kansai Electric Power aprocédé à une évaluation de la résistance au séisme des réservoirs de GNL ainsi qu’à unessai de démonstration sur une maquette à l’échelle de 1/8ème.

6.7–3

DEMONSTRATIVE SAFETY ASSESSMENT OF LNG STORAGEFACILITY EARTHQUAKE RESISTANCE, ANDREINFORCEMENT OF CRISIS MANAGEMENT

AT LNG RECEIVING TERMINALS

1. INTRODUCTION

Kansai Electric Power Co., Inc. supplies electricity to the Kansai region in west-central Japan (an area of about 30,000 km2 and with a population of about 22 million); itscustomers total approximately 12 million households.

The sources of its power generation are nuclear, fossil-fired, and hydro plants. Ofthese, the ratio of electric power generation by fossil-fired power is 44% (about 60 billionkwh).

About 50% of the total fuel used in fossil-fired power plants is LNG (annuallyconsumed LNG: 5 million tons). Also, a new power plant is scheduled for completion inWakayama in 2004, with its own LNG receiving terminal. LNG constitutes an importantelement of Kansai Electric Power’s business.

In providing city gas to 6 million households in the Kansai region, Osaka Gas Co.Inc. annually processes some 5.4 million tons of LNG (LNG comprises 95% of the rawmaterial for city gas) at its Himeji and Senboku LNG receiving terminals.

The powerful earthquake that struck southern Hyogo in 1995 inflicted seriousdamages on the distribution facilities in the urbanized areas of Kansai Electric Power andOsaka Gas, which are responsible for two essentials for daily life: electricity and gas.

The LNG receiving terminals of the two companies, about 30 km away from theepicenter, did not suffer serious damage. Nevertheless, based on the lessons learned fromthis disaster, the companies have improved their crisis management measures. Thisarticle reports on their efforts.

Also Kansai Electric Power conducted evaluations of the earthquake resistance of itsLNG tanks because of an active fault that exists near the site for the planned WakayamaLNG receiving terminal (about 2 km away and 70 km in the total length). Also, it carriedout experiments in which shaking movements were applied to a 1/8 scale model of anabove ground LNG tank with a storage capacity of 140 thousand kl, to test the tank’ssafety against huge seismic tremors.

2. DAMAGE CAUSED BY THE SOUTHERN HYOGO EARTHQUAKE,AND THE CURRENT STATE OF THE COUNTERMEASURES

(1) Scale of the Earthquake

At 5:46 a.m. on January 17, 1995, a powerful earthquake with an observed seismic in-tensity of Magnitude. 7.2 and maximum acceleration of 0.8 G shook the southern Hyogo

6.7–4

region. This was the first time in the history of Japan that an earthquake had its epicenternear metropolitan areas.

As a result of this proximity, it inflicted serious damage, causing approximately 6,000deaths; 40,000 injuries, and 240 thousand totally or partially destroyed houses.

Fig.1 LNG receiving terminal and active fault in Kansai area

(2) Extents of the Damage

a. Damage to electric power equipment. In the Southeastern part of Hyogo prefecturewhere the most powerful seismic waves struck (hereinafter referred to as the “hard hitarea”), some 2.6 million customers within a radius of about 30 km, including the northernpart of Osaka Prefecture and Awaji-shima island, experienced a blackout immediatelyafter the quake. However, an emergency transmission of electricity to about one millioncustomers was completed within 2 hours, and to all the customers in the areas in 6 days.

Wakayama

Active Fault2km

Himeji

SenbokuEpicenter

hard hit area

70km

Osaka Pref.

Wakayama Pref.

Awaji Island

Hyogo Pref.

Active fault

hard hit area

LNG receiving terminalHimeji(which includes Kansai Electric Powerand Osaka Gas terminal)

Senboku (which includes terminal 1 and 2)

Wakayama(which is planed by KansaiElectric Power)

6.7–5

Ten Fossil-fired power plants suffered damage to their power generation equipment;among these, three plants near the severely affected areas saw subsidences resulting fromliquefaction.

Particularly, at the Higashi-nada gas turbine power station, although its principalequipment such as the gas turbine and stacks were not damaged, powerful seismicmovements and liquefaction caused cracks in on-site roads and damage to the foundationpiles supporting the oil tank.(D=19.3m, H=15.2m), as shown in Fig.2

Seven power stations relatively distant from the epicenter suffered only minordamages, e.g., the deformation of boiler anti-vibration facility.

At the Himeji LNG receiving terminal, about 50 km from the hard hit area, seismicforce acceleration registered less than 0.2 G, and there was no noteworthy damage.

Fig.2 Exposed Higashi-nada oil tank foundation piles

b. Damage to gas equipment. Although the high-pressure (equal to or over1MPa)trunk lines, about 500 km in total length, experienced seismic forces of up to 0.4 Gacceleration in some places, it suffered virtually no damage. However, the medium orlow pressure gas lines within a 20 km radius from the hard hit area suffered variousdamages.

Damage to the medium pressure (between 1MPa and 0.1MPa)gas lines occurred atonly to 106 points; most were slight gas leaks caused by loosened dresser joints. At 14points, older pipes with no penetrating weld joints, installed under older specifications formedium pressure gas, cracked due to various causes such as sand boil or, location at theboundary of different kinds of soil, etc.

Low pressure gas lines were damaged at 21,647 points, most involving screw joints ingas supply pipe to individual households. These damages were caused by cracks or gapscreated in the streets by tremors or by liquefaction.

At the Senboku LNG-receiving terminal, about 30 km from the hard hit area, therewas no damage to major equipment. The plant continued operation after the earthquake.However, in some places on the plant site, such as the sports ground and open spaceswhere no soil improvements had been made, some liquefaction took place, and someutility equipment such as covered local meter boxes were damaged slightly

6.7–6

Fig.3 Liquefaction at the sports ground Fig.4 Crack of terminal road

c. Damage to LPG terminal.[1] In the LPG terminal of the other company locatednear the hard hit area, liquefaction caused by the earthquake resulted in subsidence overmost of the plant site. As shown in Fig.5, the flange of the root valve in the send out line,connected to a 37 m inner diameter and 37 m high LPG storage tank (20 thousand toncapacity double metal-shell cylindrical tank, with flat base) was deformed by thesubsidence, and LP gas leaked.

The LPG storage tank itself was not damaged, and liquefaction did not take place inits foundations because it was supported by piles (1 m diameter and 27 m long) reachingbearing strata. However, the grounds surrounded by liquid-containing embankments thatwere not improved sank by 60 cm at the maximum. (Fig.6, Fig.7)

The foundations of the racks supporting the piping were different from the onesupporting the tanks. Because of this, subsidences brought about by liquefaction causedthe foundations supporting the piping to lose any load-bearing capacity. Its weighttherefore bore directly on the flange of the root valve, leading to the gas leak.

Incidentally, secondary disaster was avoided through various disaster preventionactivities carried out immediately after the earthquake.

Fig.5 Outline of the LPG leak

Leak

Send out line

LPG storagetank

Emergencyshutoff valve root valve

6.7–7

Fig.6 Liquefaction at the LPG tank ground

Fig.7 Sand boil (diametor:1m) inside dike

(3) Lessons Learned from the Earthquake

Since the tanks and piping connected to them were built on different foundations inthe LPG terminal of the other company located in the severely affected areas, subsidencesin the foundations supporting the piping were brought about by the load on the root valveflange, leading to LPG leakage.

6.7–8

On the other hand, in addition, some measures to make LNG receiving terminalresistant to liquefaction have been implemented in Japan. For example, grounds on whichthe principal facilities of terminal are standing have been improved, piles reachingsupporting strata have been established, and the root valve in piping attached to a tankmust now be supported by the same foundation as the tank.

Since most of the LPG receiving terminal were about 30 km away from hard hit areaby the Southern Hyogo Earthquake, they did not suffer major damages, and initialresponses to it and other activities were carried out in an orderly manner, in accordancewith the current disaster manual.

However, the earthquake resistance of the LNG tanks were evaluated at the nationallevel in the wake of the earthquake. Then, energy companies studied crisis managementbased on the evaluation. These circumstances are explained in the following:

a. Evaluation result of the earthquake resistance of the LNG tanks at the nationallevel. LNG tank earthquake resistance design complied with national laws andregulations. The results of earthquake resistance evaluation by a national examinationcommittee confirmed that the currently implemented standards for earthquake resistanceare sufficient to prevent the toppling of LNG tanks or gas leaks and serious casualties,even in a powerful earthquake.

b. Managerial countermeasures. Kansai Electric Power and Osaka Gas reaffirmed theneed to improve their crisis management measures against large-scale disasters, such asthe one caused by the earthquake, and have been advancing studies on these measures.Such measures are being implemented independently at each corporation. If evaluated asa whole, they can be classified into the following four categories.(Table.1)

6.7–9

Table.1 Measures for Earthquake

Item Problems Solution Measures� Establishment of

initial responses• Virtual impossibility of

immediate response to anearthquake because of toomuch equipment to bechecked

• Drawing up of an equipment-checking manual in whichproper priorities are estab-lished

� Improvement ofcommunicationsystem

• Difficulty in communicatingwith other equipment-checking personnel

• Delayed arrival of employeesat their work place in anemergency situation on aholiday or at night

• Delayed dispatch of servicepersonnel, material, andequipment to affected bases

• Increased number of portableshort-range transceivers andimage transfer equipment

• Mobilization of personnel incharge of initial responsesand introduction of holdingpattern for emergency

• Establishment of procedureto dispatch service personnel,material, and equipment

� Risk evaluationof disaster andutility equipment

• Evaluation of optimumcapacity of emergency powergenerators

• Danger of interrupting LPGsupply for adjustment of citygas heat generation

• Damaged piping to enclosedlocal meter boxes, due to dis-placement caused byliquefaction

• Improvement of emergencypower generators

• Consideration of doubletracked LPG procurementsystem

• Use of flexible pipes for en-closed local meter boxes

� Establishment ofcrisis manage-ment activities

• Deficient responses in emer-gency and disaster situationsat the LNG receiving terminal

• Development of trainingcourses for shift chiefs, to im-prove their crisis managementcapabilities

The following describes, as an example, activities carried out by Osaka Gas for crisismanagement, the development of a training course for shift chiefs that is designed to im-prove crisis management capabilities.

m Background of Development Efforts

Company employees living in the disaster-stricken Osaka-Kobe region were surveyedas to their states of mind and behavior at the time of initial response to the disaster. Tosummarize some representative answers:

• I postponed decision making and judgment regarding unsure matters, and soon itwas too late to do anything about them.

• I was obsessed with the task at hand and made light of higher objectives and timelimits.

• I concentrated on my work too much to send out or take in information.

6.7–10

Such states of mind and behavior are not seen in normal circumstances; and this reaf-firmed the importance of operational managers being capable of responding to the initialsituation in an emergency. It was therefore decided to develop emergency training differ-ent from conventional technical training, or learning of rules, and aimed at improvingmental preparation and behavior characteristics.

A shift chief, responsible for the operational management of a manufacturing plant, ispositioned between the “insider team” and the “outsider team,” as shown in Fig. 8. In anemergency, a variety of events are taking place at the same time, and this chief is requiredto make decisions promptly, with scarce information. Therefore, the abilities a shift chiefmust improve, called training points from the aspect of human factors, are categorized inthe list shown in Fig. 9.

Activity element Training points Requiredabilities

Understanding thesituation

1. Information gatheringand evaluation

2. Target setting

Makingjudgments

3. Schedule setting

4. Assigningresponsibilities

5. Sharing information

Control

6. Managing the“consciousness mode”

7. Securing alternatives

Managing thesituation

Risk management8. Assuming worst-case

scenarios

9. Reporting prospectsand situationNetworking

10. Asking cooperationetc.

Rallying relatedparties

Fig. 8 Required activities of chiefs Fig. 9 Training points for chiefsin an emergency

m Development of simulation training

To have trainees master the training points described above effectively,improvements were made on the existing techniques of computer simulation training,developed primarily to teach operational procedures in dealing individually with variousproblems, such as blackout, tripped equipment, gas or LNG leak, fire, computermalfunction, etc. likely to be encountered at an LNG receiving terminal. As a result, anew training course was developed that had the following features:

• Situations in which the problems described above take place simultaneously; noavailable information from the field; inquiring outsiders, etc., were assumed.

• Simulation training in a realistic environment similar to an actual control room.• Training in which trainees had no knowledge of the scenario.• Emphasis on simulation training in human relationships such as information gather-

ing, assignment of responsibilities, and reporting.

Peopleinside or

outside thecompany

Target settingfor tasks and

schedules

Informationdispatch

Informationgathering and

judgment

Thinking outalternatives

Members

(Outsideworld)

(Chief’s activities) (Inside world)

6.7–11

Actual training was conducted in a simulated operation management room in the Edu-cation and Training Center. Participants in the training and staff members of the centerassumed the roles of captains, operators, patrolling personnel, and outside parties, andacted on the supposition that various kinds of accidents were occurring. Instructorsguided cast members as to how they should behave according to the response behavior ofa trainee chief, using a multimedia training system so that training points could be moreeasily grasped. The behavior of the trainee chief was video-taped. Watching the tapes,and through discussions with the instructors, the chief became aware of the trainingpoints on his/her own, and tried to improve in abilities related to the points, and masterthe skills to cope with various emergencies.

With regard to Training Point , “information gathering and evaluation,” for instance,training in the ability to gather information as quickly as possible, evaluate it, issueappropriate orders, and inform related parties is given in a simulated situation in which alarge-scale leak is occurring, with very little information available from the field aboutthe leak. With regard to Training Point , “assuming the worst-case scenario,” the abilityof a shift chief to respond to the worst situation during a blackout, in which no power canbe expected even from emergency power generators.

3. EVALUATION OF THE EARTHQUAKE RESISTANCE OF THE NEWWAKAYAMA LNG-RECEIVING TERMINAL

(1) Features of the Earthquake Resistance Design for Wakayama LNG ReceivingTerminal

Kansai Electric Power. is planning to build the Wakayama power station as a planthaving its own LNG receiving terminal (total storage capacity: 880 thousand kl, as shownin Table.2) and a total power output of 3.7 million kW, generated by combined-cyclepower generators using natural gas only (operation start up is slated for the year2004).(Fig.10)

Only about 2 km from the planned construction site, however, lies one of the largestactive faults in Japan. If seismic tremors were ever to originate there, they would be pow-erful ones.

Kansai Electric Power is planning to construct the Wakayama LNG receivingterminal, where safety against earthquake is a very important factor in the company, hasprepared the following safety measures.

1. The design assumes the strongest seismic tremors that can be anticipated fromgeological surveys of the site, and other researches.

2. To counter liquefaction, the grounds of building sites are to be improved inaccordance with the importance of individual buildings; particularly important in thisregard is the ground inside liquid-containing embankments, which requiresimprovement over the entire area. Furthermore, such important facilities as LNGtanks, liquid-containing embankments, and piping racks require steel piles reachingsupport strata 20 to 40 m underground to make them structurally resistant toanticipated seismic tremors.

6.7–12

3. Individual facilities are designed for earthquake resistance in accordance with theirimportance, with different seismic tremors anticipated for each. Facilities with highpriority, LNG tanks and disaster equipment in particular, must be designed so as toensure continuance of their security maintaining function.

4. To determine the earthquake resistance of LNG tanks, shaking experiments using a1/8 scale model tank of a 140 thousand kl tank were conducted.

Fig.10 Layout of Wakayama LNG receiving terminal

LNG tank (140,000 kl)

Vaporizers‚N

1087m

918m

LNG tank (80,000 kl)

BOG Compressors

LNG pumps

Power station

Wakayama

Osaka Pref.

Awaji Island

Wakayama Pref.

Active Fault2km

70km

6.7–13

Table.2 Description of Equipment for Wakayama LNG Receiving Terminal

Item SpecificationType Double metal-shell above-ground tank

LNG tank Capacity 4 units of 80,000 kilo liter ,9%Ni steel4 units of 140,000 kilo liter ,9%Ni steel

Type Submerged and centrifugalLNG primarypump Capacity 24 units of 130 t/h and 1.87MPa

Type Submerged and centrifugalLNG secondarypump Capacity 6 units of 100 t/h and 9.8 MPa

Type Open -rack typeLNG vaporizerCapacity 6 units of 100 t/h capacityType Reciprocating typeBOG compressorCapacity 3 units of 15 t/h

(2) Description of Shaking Test Equipment

The shaking experiment was carried out at the Tadotsu Engineering Laboratory of theNuclear Power Engineering Corporation, which is reputed for its experience in testing thesafety and reliability of important equipment and systems comprising the nation’s nuclearpower generation plants.

The shaking test device is equipped with a large, high capacity shaking table (seismictremor generation device), the largest in the world; the table is 15 m 15 m, has a maxi-mum load capacity of 1,000 tons and can generate vibrations in the horizontal andvertical directions simultaneously. This shaking table is shown in Fig. 11 and Table.3.

Fig.11 Large-scale high-performance shaking table facility

Vertical Actuator

Shaking Table

HorizontalActuator

6.7–14

Table 3 Large, High Capacity Shaking Table

Item CapacityMax. load 1,000 tTable size 15 m × 15 m

Excitation direction Horizontal, Vertical

Horizontal ± 200 mmMax.displacementVertical ± 100 mm

Horizontal max. 5 GMax. accelerationVertical max. 2.5 G

Max. shaking duration 20 sec

(3) Shaking Test with a Large Model

a. Input seismic vibrations. On the assumption that seismic tremors are generated inthe active fault (70 km in the total length) near the planned power generation plant, themagnitude would be 7.5, and the seismic force acceleration at the ground surface at theLNG tank would be approximately 0.4 G.

To verify the design strength of an actual LNG tank, about 2 times the anticipatedintensity of the seismic tremors (seismic vibrations with 0.8 G horizontal acceleration fortesting design strength through shaking) were applied in the shaking test.

In addition, to test the limit strength of the tank, another experiment was carried outusing the seismic waves actually observed at the time of the Southern Hyogo Earthquake,since the tank’s responses to these were more intense.

b. Model tank for the shaking experiment and schedule. At the Wakayama LNGReceiving terminal, 140 thousand kl LNG tanks, among the largest in Japan, are to bebuilt above ground. Since shaking experiments were to be conducted using a largeshaking table (15 m × 15 m), an approximately 1/8 scale model of the 140 thousand klLNG tank (φ10 m × h. 6 m) was constructed, as shown in Fig.12.

The experiments were conducted during the 2-month period starting July, 1996.

Incidentally, the model tank used in the shaking experiment was smaller than a realone and water was used as its content, and to make the distortions generated in thesmaller model tank comparable to those that would be generated in an actual LNG tankby an earthquake, the acceleration had to be about 5 times that of an actual earthquakeand the shaking duration about one-sixth.

6.7–15

140 Thousand kl Tank Test Model NoteDimensions 78 m× 45 m h 10 m× 6 m h Size scaling factor: 7.8Fillingliquid

LNG (0.5 density) Water (1.0 density) Weight scaling factor:0.5

Material 9% Ni steel SM520B Elasticity ratio: 1.0Thicknessof shell

38.3 mm 6.0 mm Thickness ratio: 6.4

Fig.12 Outline of model tank

c. Results of the shaking test.

(a) Verification of design strength

Judging from the results of shaking experiments using seismic vibrationsapproximately twice the anticipated intensity, the theoretically anticipated valuescorrespond quite well with the actually measured values on the test model; no harmfuldeformations were observed.

When the side plate at the bottom of the model for a 140 thousand kl LNG tank wasanalyzed as to strength, the safety ratio, the ratio of its strength to the value of itspermissible stress, was calculated to be 1.3, proving that it was sufficiently safe.

(b) Verification of model limit strength

The seismic vibrations used in the experiments had the same wave forms as the vibra-tions actually observed at the time of the Southern Hyogo Earthquake, to which themodel responded to greater degrees. In the experiment, input accelerations, the directionsof shaking movements and time intervals were varied in a stepwise manner to increasethe response acceleration of the model tank.

As a result of applying shaking movements that were more intense than the energylevel of earthquake at which the national examination committee conducted itsevaluations, slight deformation in the side plates of the model tank was induced.

Model Tank

6m

Dike

10m

6.7–16

Judging from this results of the experiments, an actual LNG tank with a 140 klthousand capacity could be expected to resist a seismic force of approximately 1.8 G, interms of tank response acceleration.

It can, therefore, be assumed that an LNG tank designed in compliance with thenational standards for earthquake resistance will not suffer harmful deformation, and willbe sufficiently safe even in earthquakes more powerful than the Southern HyogoEarthquake.

In addition, shaking the test session was made public to emphasize the safety of LNGtanks, so that residents around the planned site of Wakayama LNG receiving terminalwill be able to reach a consensus as to the Plant’s construction.

4. CONCLUSION

This article describes some examples of the activities carried out at Kansai ElectricPower and Osaka Gas to evaluate LNG tanks resistance to large-scale earthquakes, and toimprove crisis management measures in the wake of the Southern Hyogo Earthquake.

Based on the lessons learned from the disaster, we two companies reconfirm theimportance of examining the safety of our LNG facilities, and continue in our efforts toprevent accidents, in the hope of maintaining and enhancing the superb safety record ofthe LNG industry.

REFERENCE CITED

[1] Committee for Investigation of Gas Leakage from LPG Storage Facility; InterimReport on LPG Storage Facility Gas Leakage Resulting from Southern HyogoEarthquake, April 1995.