Demolition of Structure Using Implosion Technology

-

Upload

sreerag-dileep -

Category

Documents

-

view

70 -

download

2

Transcript of Demolition of Structure Using Implosion Technology

PROJECT REPORT

ON

DEMOLISION OF STRUCTURES USING IMPLOSION TECHNOLOGY

SESSION NO 514 INTEGRATED COURSE IRICEN PUNE

GUIDED BY: SRI. A.K.RAI

(PROFESSOR - WORKS) IRICEN PUNE

PRESENTED BY

A. K. ARYA, ADEN (S/E) / PL A.K.SHARMA, ADEN (S) / BRC

ARVIND KUMAR, Mgr / IRCON N.K.SHARMA, ADEN (G) / BKN

INDEX Sl. Description Page no. 1. Introduction 1

2. Methodology 1 – 3

3. Demolition of structure using implosion

Technology: A case study 3 – 8

4. Explosive details 9 – 13

5. Conclusion 13

ACKNOWLEDGEMENT

We are very much grateful to SHRI SHIV KUMAR

Director/IRICEN, SHRI A. K. RAI, Course Director

and Professor Works for their valuable guidance and

consistent encouragement in preparing the project. Finally, we thanks to all faculty members and IRICEN staff for offering

their valuable assistance and providing a conducive atmosphere to compile

these reports in presentable form.

DEMOLITION OF STRUCTURE USING

IMPLOSION TECHNOLOGY 1.0 Introduction

An implosion is an event where something collapses inward, because the

external atmospheric pressure is greater than the internal pressure. For

example, if you pumped the air out of a glass tube, it might implode. When a

building is surrounded by other buildings, it may be necessary to "implode"

the building, that is, make it collapse down into its footprint. You can

demolish a stone wall with a sledgehammer, and it's fairly easy to level a five-

story building using excavators and wrecking balls. But when you need to

bring down a massive structure, say a 20-story skyscraper you have to haul

out the big guns. Explosive demolition is the preferred method for safely and

efficiently demolishing larger structures.

The basic idea of explosive demolition is quite simple: If you remove the

support structure of a building at a certain point, the section of the building

above that point will fall down on the part of the building below that point. If

this upper section is heavy enough, it will collide with the lower part with

sufficient force to cause significant damage. The explosives are just the

trigger for the demolition. It's gravity that brings the building down.

Demolition blasters load explosives on several different levels of the building

so that the building structure falls down on itself at multiple points. When

everything is planned and executed correctly, the total damage of the

explosives and falling building material is sufficient to collapse the structure

entirely, so clean-up crews are left with only a pile of rubble.

2.0 Methodology

In order to demolish a building safely, blasters must map out each element of

the implosion ahead of time. The first step is to examine architectural

blueprints of the building, if they can be located, to determine how the

building is put together. Next, the blaster crew tours the building (several

times), jotting down notes about the support structure on each floor. Once

they have gathered all the raw data they need, the blasters hammer out a plan

of attack. Drawing from past experiences with similar buildings, they decide

what explosives to use, where to position them in the building and how to time

their detonations. In some cases, the blasters may develop 3 – D computer

model of the structure so they can test out their plan ahead of time in a virtual

world.

The main challenge in bringing a building down is controlling which way it

falls. Ideally, a blasting crew will be able to tumble the building over on one

side, into a parking lot or other open area. This sort of blast is the easiest to

execute, and it is generally the safest way to go. Tipping a building over is

something like felling a tree. To topple the building to the north, the blasters

detonate explosives on the north side of the building first, in the same way you

would chop into a tree from the north side if you wanted it to fall in that

direction. Blasters may also secure steel cables to support columns in the

building, so that they are pulled a certain way as they crumble.

Sometimes, though, a building is surrounded by structures that must be

preserved. In this case, the blasters proceed with a true implosion,

demolishing the building so that it collapses straight down into its own

footprint (the total area at the base of the building). This feat requires such

skill that only a handful of demolition companies in the world will attempt it.

Blasters approach each project a little differently, but the basic idea is to think

of the building as a collection of separate towers. The blasters set the

explosives so that each "tower" falls toward the center of the building, in

roughly the same way that they would set the explosives to topple a single

structure to the side. When the explosives are detonated in the right order, the

toppling towers crash against each other, and all of the rubble collects at the

center of the building. Another option is to detonate the columns at the center

of the building before the other columns so that the building's sides fall inward

According to Brent Blanchard, an implosion expert with the demolition-

consulting firm Protec documentation services virtually every building in the

world is unique. And for any given building, there are any number of ways a

blasting crew might bring it down. Blanchard notes the demolition of the

Hayes Homes, a 10-building housing project in Newark, New Jersey, which

was demolished in three separate phases over the course of three years. "A

different blasting firm performed each phase," Blanchard says, "and although

all of the buildings were identical, each blaster chose a slightly different type

of explosive and loaded varying numbers of support columns. They even

brought the buildings down in different mathematical sequences, with varying

amounts of time factored in between each building's collapse."

Generally speaking, blasters will explode the major support columns on the

lower floors first and then a few upper stories. In a 20-story building, for

example, the blasters might blow the columns on the first and second floor, as

well as the 12th and 15th floors. In most cases, blowing the support structures

on the lower floors is sufficient for collapsing the building, but loading columns

on upper floors helps break the building material into smaller pieces as it falls.

This makes for easier clean-up following the blast.

Once the blasters have figured out how to set up an implosion, it's time to

prepare the building. In the next section, we'll find out what's involved in pre-

detonation prepping and see how blasters rig the explosives for a precisely

timed demolition.

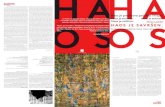

3.0 Demolition of structure using Implosion Technology: A case study

Introduction An structure which is made by any material is to be demolished after it’s

designed age is completed in order to reutilised the valuable land. Demolition

was also necessary to remove danger of falling. In western railway, Mumbai

division, there was a G+3 storied building numbered as 25/T. It was built in

1924, constructed by BB & CI railway as a first cement concrete residential

structure in Mumbai. It was having 80 Nos. (4×20) type I Quarter with total

land area about 430 Sq. m. The total height was 13.20 m. above rail level.

The structure completed its designed life and existing condition of building

was so deteriorated that there was no option but to demolition the same for

safety of running trains and adjoining residents.

Options for Demolition (Conventional Methods) As usual there are two methods for demolition. One by manually and other by

mechanical means such as using JCB, Poclains, etc. While planning for the

method to be adopted a lot of discussion was held and it was concluded that

neither of above method is suitable due to existing constraints around chawl

No. 25/T. These were as under.

1. There were four running lines just adjoining to structure in east side, the

face of building was just 4.55m away from track centre.

2. There was a OHE Mast containing portal for five numbers OHE live

conductors at a distance of 5.80 m. from face of building towards north side.

3. There was stone masonry boundary wall at a distance of 2.80 m. from

face of building.

4. In addition to above as described railway’s assets, there was a 40 storied

structure about 100 m. away from building to be demolished and one diamond

factory exists in the east side having exterior glazed building.

Due to above said constraints, manual method was not suitable as it

was going to take more time and structure was very near to running track

which requires continuous track protection / traffic block. Which would have

resulted longer disruptions to running traffic .The mechanical method was not

suitable, as there was no space to bring heavy machineries near the structure

and to work at a height of 13.50 m.

In the context of this project it is advisable and worthy to note that railway

context, this method of demolishing would be proved very suitable and useful,

most of railway assets i.e. building / structure located nearby running track

and in metro cities congested area which already passed their designed life.

Also in the view of Golden Quadrilateral and Freight corridors projects lots of

structures will be dismantled during execution of these projects.

Demolition by Implosion

When all above-mentioned methods of demolition was not found suitable, the

idea of demolition by using implosion technology came to mind as it is being

utilizes worldwide. Though it was not tried over Indian Railway till date.’

Implosion’ is a word which derived from word ‘Implode’ which means, make a

building collapse down on its footprint. The basic idea of implosion is quite

simple, If we remove the support of structure of a building at a certain point,

the structure of a building above that point will collapse. If the upper section is

heavy enough, it will collapse on the lower part of the structure with force to

cause significant damage. The explosives are used in these methods are

such that the whole structure should fall towards its center of its gravity by just

triggering off the explosive in designed manner for demolishing the structures.

The true meaning of implosion of structure is to fall on its footprints, but in

some cases structures are given desired direction of fall during demolition in

order to protect some important existing structures.

The advantages of implosion technology method over conventional methods are as under. 1.It is less expensive. 2.There are no ground vibrations 3.ThisMethod is quickest. 4. Suitable for multi-storeyed structures / high piers, cabins, distressed piers etc.

Important Aspect of Implosion Technology

Following are important aspects of Implosion

Analysis of Existing structure & locating weak points

The approximate strength of left on R.C.C / PSC member worked out by

taking the core of concrete, In order to decide quantity /location of explosive to

be provided. In our case the structure was very much dilapidated and unsafe,

there was no need to carry out such tests as weakening of strength of

structure was done by making the vertical columns from adjoining partition

wall, which were of RCC

Drilling of holes for placement of explosive The holes were drilled of about 25 mm to 30 mm dia and about 20 to 30 cm

deep depending upon quantity of explosive energy is required to break a

particular support. In this case the building was planned to bring down on

its footprint. We provided 20 holes of 25mm dia & 30 cm in depth central

column .It was reduced to 4 holes of 25mm dia & 20cm deep (4x1) at

columns away from centre

Holes drilled in columns for placement Quantity of Explosive The quantity of explosive to be placed depends upon the size of column and

extent up to which it is to be destroyed. Depending on above requirements we

placed 250 gm of explosive in central 24 columns. & 125 gm in outer 16

columns, because it was desired to destroy the central column completely. No

outer column was weakened so that the building collapsed towards its centre

from both side.

Type of explosive & Detonators

There are two types of explosive commonly used for implosion RDX & gelatin.

In this case we used brand name ‘Power Gel ‘ explosive, which is, ammonium

nitrate based explosive which expand at very high speed and applies at a very

high pressure of about 600 T/sq inch. The electronic detonators were used to

ignite the explosive.

PLACEMENT OF EXPLOSIVES – CROSS SECTIONAL VIEW

Test Blast

Before carrying out the actual blasting;

We done a test blast, in ordered to ascertain the efficiency of explosive &

detonators and also to develop a level of confidence as this was a specialized

work and executed 1st time on in Indian railway.

BEFORE AFTER

Wrapping of holes

The wrapping of holes is done to ensure that due to explosion of charges the

debris does not fly in air. For this purpose, the holes were covered with gunny

bags and iron net after placement of explosive and detonators.

Ground floor

Ballasting

Ballasting of Charges / Explosives work are carried out in a controlled manner

such that there will be a time gap of 1/100 second between two successive

blasts. The trigger of charges is done in such a control manner so that the

noise pollution and air pollution should be minimum. The central column is first

triggered and then blast proceed towards outside to produce three way action

and hence results the fall of existing structure on its footprint.

Falling of structure

Once central support/column will be destroyed and adjoining columns will be

weakened, due to its gravity the entire mass will come down on its footprints.

In this case after blasting within few seconds the entire structure of (g+3)

storied came down on its footprint without damaging any adjoining asset.

4.0 Explosive

Explosive, substance that undergoes decomposition or combustion with great

rapidity, evolving much heat and producing a large volume of gas. The

reaction products fill a much greater volume than that occupied by the original

material and exert an enormous pressure, which can be used for blasting and

for propelling.

Classification of Explosives

Chemical explosives can be classified as low or high explosives. Low (or

deflagrating) explosives are used primarily for propelling; they are mixtures of

readily combustible substances (e.g., gunpowder) that when set off (by

ignition) undergo rapid combustion. High (or detonating) explosives (e.g.,

TNT) are used mainly for shattering; they are unstable molecules that can

undergo explosive decomposition without any external source of oxygen and

in which the chemical reaction produces rapid shock waves. Important

explosives include trinitrotoluene (TNT), dynamite, nitrocellulose, nitroglycerin,

and picric acid. Cyclonite (RDX) was an important explosive in World War II.

Ammonium nitrate is of major importance in blasting.

Applications of Explosives (Detonators and Dynamite) In the last section, we saw how blasters plan out a building implosion. Once

they have a clear idea of how the structure should fall, it's time to prepare the

building. The first step in preparation, which often begins before the blasters

have actually surveyed the site, is to clear any debris out of the building. Next,

construction crews, or, more accurately, destruction crews, begin taking out

non-load-bearing walls within the building. This makes for a cleaner break at

each floor: If these walls were left intact, they would stiffen the building,

hindering its collapse. Destruction crews may also weaken the supporting

columns with sledgehammers or steel-cutters, so that they give way more

easily.

Next, blasters can start loading the columns with explosives. Blasters use

different explosives for different materials, and determine the amount of

explosives needed based on the thickness of the material. For concrete

columns, blasters use traditional dynamite or a similar explosive material.

Dynamite is just absorbent stuffing soaked in a highly combustible chemical or

mixture of chemicals. When the chemical is ignited, it burns quickly, producing

a large volume of hot gas in a short amount of time. This gas expands rapidly,

applying immense outward pressure (up to 600 tons per square inch) on

whatever is around it. Blasters cram this explosive material into narrow

boreholes drilled in the concrete columns. When the explosives are ignited,

the sudden outward pressure sends a powerful shock wave busting through

the column at supersonic speed, shattering the concrete into tiny chunks.

Demolishing steel columns is a bit more difficult, as the dense material is

much stronger. For buildings with a steel support structure, blasters typically

use the specialized explosive material cyclotrimethylene trinitramine, called

RDX for short. RDX-based explosive compounds expand at a very high rate of

speed, up to 27,000 feet per second (8,230 meters per second). Instead of

disintegrating the entire column, the concentrated, high-velocity pressure

slices right through the steel, splitting it in half. Additionally, blasters may

ignite dynamite on one side of the column to push it over in a particular

direction.

To ignite both RDX and dynamite, you must apply a severe shock. In building

demolition, blasters accomplish this with a blasting cap, a small amount of

explosive material (called the primer charge) connected to some sort of fuse.

The traditional fuse design is a long cord with explosive material inside. When

you ignite one end of the cord, the explosive material inside it burns at a

steady pace, and the flame travels down the cord to the detonator on the

other end. When it reaches this point, it sets off the primary charge.

�

These days, blasters often use an electrical detonator instead of a traditional

fuse. An electrical detonator fuse, called a lead line, is just a long length of

electrical wire. At the detonator end, the wire is surrounded by a layer of

explosive material. This detonator is attached directly to the primer charge

affixed to the main explosives. When you send current through the wire (by

hooking it up to a battery, for example), electrical resistance causes the wire

to heat up. This heat ignites the flammable substance on the detonator end,

which in turn sets off the primer charge, which triggers the main explosives.

�

To control the explosion sequence, blasters configure the blast caps with

simple delay mechanisms, sections of slow-burning material positioned

between the fuse and the primer charge. By using a longer or shorter length of

delay material, the blasters can adjust how long it takes each explosive to go

off. The length of the fuse itself is also a factor, since it will take much longer

for the charge to move down a longer fuse than a shorter one. Using these

timing devices, the blasters precisely dictate the order of the explosions.

Blasters determine how much explosive material to use based largely on their

own experience and the information provided by the architects and engineers

who originally built the building. But most of the time, they won't rely on this

data alone. To make sure they don't overload or under-load the support

structure, the blasters perform a test blast on a few of the columns, which they

wrap in a shield for safety. The blasters try out varying degrees of explosive

material, and based on the effectiveness of each explosion, they determine

the minimum explosive charge needed to demolish the columns. By using

only the necessary amount of explosive material, the blasters minimize flying

debris, reducing the likelihood of damaging nearby structures.

To further reduce flying debris, blasters may wrap chain-link fencing and

geotextile fabric around each column. The fence keeps the large chunks of

concrete from flying out, and the fabric catches most of the smaller bits.

Blasters may also wrap fabric around the outside of each floor that is rigged

with explosives. This acts as an extra net to contain any exploding concrete

that tears through the material around each individual column. Structures

surrounding the building may also be covered to protect them from flying

debris and the pressure of the explosions.

When everything is set up, it's time to get the show underway. In the next

section, we'll find out what final steps the blasters must take to prepare for the

implosion, and we'll look at the implosion itself. We'll also find out what can go

wrong in explosive demolition and see how blasters evaluate the project once

the smoke has cleared.

In the last couple of sections, we looked at everything blasters do to prepare a

building for implosion. In addition to these measures, the blasters must

prepare the people in the area for the blast, assuring local authorities and

neighbouring businesses that the demolition won't seriously damage nearby

structures. The best way blasters can calm down anxious authorities is by

demonstrating the firm's success with previous implosions.

c uses portable field seismographs to measure ground vibrations and air-

blasts during an implosion. Brent Blanchard, an operations manager for the

company, says that they also inspect surrounding structures prior to the

implosion, so that they can help assess any damage claims following the

blast. Additionally, Protec's staffs videotape the blast from multiple angles so

that there is a record of what actually happened. Using data collected from

previous blasts, the company's engineers can predict ahead of time what level

of vibration a particular implosion may cause.

Once the structure has been pre-weakened and all the explosives have been

loaded, it's time to make the final preparations. Blasters perform a last check

of the explosives, and make sure the building and the area surrounding it are

completely clear. Surprisingly, implosion enthusiasts sometimes try to sneak

past barriers for a closer view of the blast, despite the obvious risks. With the

level of destruction involved, it is imperative that all spectators be a good

distance away. Blasters calculate this safety perimeter based on the size of

the building and the amount of explosives used.

On occasion, blasters have misjudged the range of flying debris, and

onlookers have been seriously injured. Blasters might also overestimate the

amount of explosive power needed to break up the structure, and so produce

a more powerful blast than is necessary. If they underestimate what explosive

power is needed, or some of the explosives fail to ignite, the structure may not

be completely demolished. In this case, the demolition crew brings in

excavators and wrecking balls to finish the job. All of these mishaps are

extremely rare in the demolition industry. Safety is a blaster's number-one

concern, and, for the most part, they can predict very well what will happen in

an implosion.

Once the area is clear, the blasters retreat to the detonator controls and begin

the countdown. The blasters may sound a siren at the 10-minute, five-minute

and one-minute mark, to let everyone know when the building will be coming

down. If they are using an electrical detonator, the blasters have a detonator

controller with two buttons, one labelled "charge" and one labelled "fire."

Toward the end of the countdown, a blaster presses and holds the "charge"

button until an indicator light comes on. This builds up the intense electrical

charge needed to activate the detonators (this is similar to charging a camera

flash to build the necessary electrical energy to illuminate a scene). After the

detonator-control machine is charged, and the countdown is completed, the

blaster presses the "fire" button (while still holding down the charge button),

releasing the charge into the wires so it can set off the blasting caps.

Typically, the actual implosion only takes a few seconds. To many onlookers,

the speed of destruction is the most incredible aspect of an implosion. How

can a building that took months and months to build, and stood up to the

elements for a hundred years or more, collapse into a pile of rubble as if it

were a sand castle?

Following the blast, a cloud of dust billows out around the wreckage,

enveloping nearby spectators. This cloud can be a nuisance to anyone living

near the blast site, but blasters point out that it is actually less intrusive than

the dust kicked up by non-explosive demolition. When workers take down

buildings using sledgehammers and wrecking balls, the demolition process

may take weeks or months. In this time, a significant amount of dust is being

kicked up into the air every day. When the building is levelled in one moment,

on the other hand, all the dust is concentrated in one cloud, which lingers for a

relatively short period of time. Nearby residents with allergies can leave the

area for that one-day and avoid the dust entirely.

After the cloud has cleared, the blasters survey the scene and review the

tapes to see if everything went according to plan. At this stage, it is crucial to

confirm that all of the explosives were detonated and to remove any

explosives that did not go off. If a demolition consulting crew was on hand, the

blasters review their vibration and air blast data as well. Most of the time,

experienced blasters bring buildings down exactly as planned. Damage to

nearby structures, even ones immediately adjacent to the blast site, is usually

limited to a few broken windows. And if something doesn't work out quite right,

the blasters log it in their mental catalogue and make sure it doesn't happen

on the next job. In this way, job-by-job, the science and art of implosion

continues to evolve.

5.0 Conclusion

It is concluded that this methodology of demolishing building / structure will

prove very useful, economical and quickest in contest of future planned

project in Indian railway i.e. quadrilateral project and freight corridor project,

as during these projects lot of buildings/structures will fall in the alignment of

new lines located nearby existing running lines.