Delcrete

-

Upload

jose-luis-jarpa -

Category

Education

-

view

515 -

download

1

description

Transcript of Delcrete

General

Delcrete™ m Elastomeric Concrete is a pour-in-place, free-flowing, two-part polyurethane-based elastomeric concrete. Delcrete™ m has been compounded to bond to a variety of surfaces including steel and concrete. Following are the design features of the industry’s premier elastomeric concrete:

Mixing/Components

Part A - 1500 ML ClearPart B - 3000 ML Black

www.dsbrown.com

The D.S. Brown Company

Product Datasheet

Delcrete™ mD.S. Brown Co.

Founded in 1890 and based in North

Baltimore, Ohio, USA, The D.S. Brown

Company is a worldwide designer, man-

ufacturer and supplier of engineered

products for the highway and bridge

construction markets.

D.S. Brown is fully integrated, perform-

ing and controlling all requirements of

a project internally:

• Research and Development

• Engineering Design/CAD Detailing

• Load Testing

• Rubber Compounding, Mixing,

Extruding and Molding

• Custom Steel Fabrication and

Machining

PROTECT YOUR INVESTMENT

HEADQUARTERS

300 East Cherry

North Baltimore, Ohio 45872

CONTACT

Phone (419) 257-3561

Fax (419) 257-2200

www.dsbrown.com

© 2008 D.S. Brown - All rights reserved.

DSB ML-Delcrete m - Datasheet-01

• Polyurethane chemistry • Non-brittle over extreme temperature ranges • Permanent, long-term repair solution • Resistant to nearly all chemicals • One hour cure time

One 48 lb bag of aggregate. One batch is equal to 3.5 mixed gallons. 12 batches per unit is equal to 42 mixed gallons. 42 gallons is equal to 5.6 cubic feet per unit.

DELCRETE BINDER & AGGREGATE

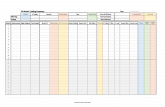

TEST TEST METHOD SPECIFICATION

Original Properties (after conditioning at 100 F [37 C]

for 7 days)

Tensile Strength, psi (MPa) Note 1 600 (4.14) Min.

Elongation, % Note 1 25 Min.

Hardness, Durometer D ASTM D2240 50 Shore D Max.

Compressive PropertiesCompressive Stress, psi (MPa) 5%

Deflection ASTM D695, Note 2 800 (5.52) Min.

Resilience, % - 5% Deflection Note 3 70 Min.

Impact Properties Ball Drop, ft.-lb. (Joule) @-20 F (-29C) Note 4 >10 (13.56) (no cracks)

Adhesion PropertiesDry Bond Strength to Concrete, psi (kN/m) Note 5 (Dry) 350 (61.30) Min.Wet Bond Strength to Concrete, psi (kN/m) Note 5 250 (43.78) Min.

Gel Time Tex-614-J 5-30 Minutes

DELCRETE BINDER ONLY

TEST TEST METHOD SPECIFICATION

Original Properties (after conditioning at 100 F [37 C]

for 7 days)

Tensile Strength, psi (MPa) ASTM D638 1,500 (10.34) Min.

Tensile Stress, 100% psi (MPa) ASTM D638 500 (3.45) Min.

Elongation, % ASTM D638 150 Min.

Hardness, Durometer A ASTM D2240 92 +/-3 A

Tensile Properties, After Oven Aging (7 days @ 158 F [70

C])

Tensile Strength, psi (MPa) ASTM D573 (D638) 1,500 (10.34) Min.

Tensile Stress, psi (MPa) ASTM D573 (D638) 500 (3.45) Min.

Elongation, % ASTM D573 (D638) 150 Min.

Hardness, Durometer A ASTM D573 (D2240) 92 +/-3 A

Physical Properties

Delcrete™ m meets or exceeds the following properties:

Delcrete™ m

The D.S. Brown Company

Product Datasheet