Degradation of ZnO based surge arresters under field conditions

Transcript of Degradation of ZnO based surge arresters under field conditions

Degradation of ZnO based surge arresters under field co n d it i o n s

A.l\rl.Plata M.A.Ponce J .NI. Rios F.de la Rosa V.NI.Castafio

Indexing terms: Surge arrester, Lightning, Field degradation

1 -

Abstract: An experimental study of the degradation of ZnO based lightning arresters is presented. The study included X-ray, SEM and electrical characterisation of commercial samples, first as received and then after they have been subjected to either an artificial degradatron or field degradation. The results show that changes in the specific local composition are clearly associated with the degraded samples, indicating the possible mechanisms for this phenomenon, in terms of segregation of some species during the degradation and also in terms of some of the particular microstructures observed in the laboratory and in the field degraded specimens, which indicates the pertinence of field experiments for exploring the span of the working life of these devices. - I

1 Introduction

In the past two decades, ZnO varistors have attracted a great deal of attention owing to their nonohmic cur- rem-voltage behaviour [ 1-71, which allow to fabricate lightning arresters, multiple-stage varistors and other important technological devices. Those studies included the influence of the preparation procedure [I-41, the role: of microstructure [5, 61 and some very interesting interfacial phenomena [7] apparently related to their unique nonlinear behaviour. One very important issue in these materials, however, is that of the degradation mechanisms during the working life of the devices. Since varistor materials are subjected normally to elec- trical, thermal, mechanical and chemical stresses, it is relevant to understand the parameters that can affect their performance and useful life. Some pioneering works [8-14] have analysed the degradation caused by DC and AC biasing and indicate, as a feasiblle mecha- nism for the experimental observations, a deformation

0 IE:E, 1996 IEE Proceedings online no. 19960484 Paper first received 31st July 1995 and in revised form 22nd March 1996 A.M. Plata, M.A. Ponce, J.M. Rios and F. de la Rosa are with the Insti tuto de Investigaciones Electricas, Interior Intemado Palmira, Apairtado Postal 475, Codigo Postal 62000, Cuemavaca, Mor., Mexico V.M. Castafio is with the Instituto de Fisica, UNAM, Apartado Postal 20-3154, Mexico, DF 01000, Mexico

in the Schottky barriers due to ion migrations. Most of the information available today on degradation of ZnO based varistors and surge arresters was gathered through accelerated life test studies [S, 15, 161, in which electrical stresses are applied in the laboratory under different conditions. Analysis of the performance of the materials, ranging from power dissipation to thermally stimulated currents, have been published [9-181. Never- theless, to our knowledge, there exists very scarce evi- dence of the degradation phenomena ocurring in ZnO lightning arresters (or varistors) during in-field opera- tion conditions, that is, under the real circumstances of very strong, extremely fast current peaks, to which a surge arrester is subjected during its useful life, in spite of some reports on laboratory studies in this regard [19-231. Accordingly, in this article we report our find- ings of the degradation mechanisms of ZnO based arresters subjected to actual lightning conditions in the field. The similarities and differences with previous and current laboratory tests will also be discussed.

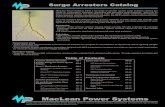

Fig. 1 Schematical diagram o j the commercial lightning arrested employed 1, alloy EP (ethylene propylene) rubber housing; 2, terminal, 3, stainless sleel cover; 4, metal oxide varistors; 5 , contact disc; 6, epoxy-fibreglass wrap; 7, stainless steel terminal stud; 8, thermal safety breaker; 9, insulating base

2 Experimental

2. I Lightning arresters Commercial lightning arresters for power distribution lines were utilised for the study. Fig. 1 shows schemati-

291 IEE Proc.-Sci. Meas. Technol., Vol. 143, No. 5, September I996

cally the structure of the arrester, by a cross-section view. As can be observed, the device is formed by two varistors (parts numbered 4 in the Figure) designed to stand 5kV each. This is a typical arrangement for nearly all commercially available arresters with slight differences in the details of the design, depending on the specific brand.

2.2 Degradation procedure The arresters were subjected to one of the following degradation procedures. (i) Induced in the laboratory, at controlled conditions of thermal shocks for 20 cycles. In each cycle, the sam- ples were kept for 1 hour at 373K and then for 2 hours at 274K. To evaluate the moisture intake of the speci- mens, the tan (6) factor (loss factor) was measured in laboratory controlled conditions with a relative humid- ity of less than 10%. The standard procedure for testing the arrester is to subject the device to this thermal cycling while a voltage between 10 to 20% above the nominal working voltage is kept. In this case, the volt- age was 12kV. (ii) In real field conditions. The arresters were con- nected to a power line for several weeks. During this period, they received a lightning stroke. A study of the lightnings in the area where the arresters were tested, indicate that, in 50% of the events, the current of the lightning is of around 30kA, with a duration of 1 . 2 ~ on average.

2.3 Characterisation techniques The ZnO varistors forming the arresters were analysed as received and after the degradations procedure (either induced artificially or in-field). Scanning electron microscopy (SEM) and compositional analysis were performed in a JEOL 6400 microscope at 20keV, X-ray diffractometry of thin sections was measured in a Sie- mens D-5000 machine, equipped with a Cu source. I against V curves (DC) were obtained for each case, along with an evaluation of the corresponding loss fac- tor, tan 6, by a Schering bridge for AC signals.

16221 2.5975

el

Fig. 2 As-received

X-ray dflructogrurn of lightning urrestei

3 Results and discussion

3.1 X-ray analysis X-ray diffractometry of the arresters as received, after artificial degradation and after a lightning stroke (in- field testing) is presented in Figs. 2-4, respectively. From analysis of the peaks present, it can be concluded that the as-received sample shows a ZnO matrix with CO, Mn and Ni inclusions, as expected. Also, the Zn7Sb2OI2 spinel structure was detected along with same mixture of phases of the type P-Bi,O, and 6-

292

Bi203, which have been reported during the sintering treatments of the specimens [7, 81. Crystallographically, Bi203 presents three possible structures, namely the so- called a, p and 6 phases which differ from each other in the crystallographic group, as will be discussed in what follows. Thermodynamically, those three possible phases appear under different heating conditions. The samples degraded in the laboratory and in the field pre- sented basically the same phases as the original, but a shift of the peaks in the diffractogram is observed. The shift is towards greater lattice parameters, indicating a distortion of the structure. As has been reported [5-71, the microstructure of ZnO based varistors is rather complicated [18, 191, consisting not simply of ZnO grains separated by a thin intergranular phase, but it is suspected that part of the reason for the nonlinear con- ductance lies in the compositional segregations at the interfaces 17, 18, 241. Thus, experimental evidence has been offered on the segregation characteristics of ZnO varistors. However, very little information was availa- ble on the lattice distortions of the ZnO matrix and on the other phases present in these materials [6]. No reports to our knowledge deal with the microstructural changes after degradation of these varistors. The p- Bi,03 phase has a tetragonal structure, whereas the 6- Bi203 presents an fcc crystallographic structure [25].

1 I

Fig. 3 After laboratory degradation

X-ray d$pactogrum of lightning urreste7

16371 2 5902

Fig.4 X-ray diffructogrum ojlightning urrestm After in-field degradation.

A comparison between the as-received samples and the degraded ones, in terms of the above X-ray diffracto- grams, suggests that the degradation induces changes in the Bi203/Zn0 grain boundaries, producing a swelling of the lattice due to the dissolution of the relatively big Bi3+ ions caused by the energy transfer to the material during the degradation process. Thus, under normal working conditions (without extreme currents, heat or

IEE Ptoc -Sei Meus Technol, Vol 143, No 5 September 1996

mechanical stresses) the segregation and diffusion of atoms in the varistors, would induce changes between the fi-Bi,O, and the 8-Bi203 structures at the Bi203/ ZnO interfaces that require relatively little energy of activation for the corresponding tetragonal and fcc structures to be geometrically related. Moreover, it is known that the fl phase is metastable at room tempera- ture [25, 261. These tetragonal-to-fcc changes have been also observed and studied theoretically and experimen- tally in other systems [27]. From the diffractograms, Figs. 2, 3 and 4, it can be seen that the artificially degraded sample shows a-Bi203 and 6-Bi203 phases in different proportions as compared to the original speci- mens. For example, the diffractogram of the as- received sample (Fig. 2) contains peaks at 0.33359, 0.32064 and 0.30153nm, corresponding to the a, (3 and 6 plhases of Bi203, respectively. Those reflections are not found in Figs. 3 or 4, which correspond to the lab- oratory and field degraded specimens. The spinel phase shows no changes in the three diffractograms (peaks at 0.213 and 0.174nm), indicating that the Zn matrix suf- fers basically no effect. The in-field-degraded sample shows neither or 6 phases but a-Bi203, which has a monoclinic crystallographic structure [25]. This indi- cates a more severe change from a tetragonal or cubic structure to a less ordered system, which is observed in a salmple subjected to a more demanding degradation process. Thus, in addition to the associated composi- tional changes, which will be discussed below, the present results indicate a clear distortion of the crystal- line lattice parameters of some of the phases present in the material. These changes in symmetry would change the Schottky barrier. These findings are supported by the SEM micrographs from a series of samples which were analysed for each set of specimens.

Fig. !5 SEM micrograph

Microstructure of us-received specimen

Zn

$ ) k B i Sb SbSb Mn CO Ni

Microstructure oj us-received .specimen Zn A

Fig. 16 Microanalysis of ZnO matrix

3.2 Microstructure observations The microstructure of the as-received specimens shows (Fig. 5 ) a ZnO matrix with traces within the grains (Fig. 6) of C, Ni, Mg, Sb, CO and Mn, which are expected according to the standard preparation tech- nology for these materials. The average grain size ranges between 10 to 1 2 ~ . The microanalysis of these specimens showed a Bi-rich zone between the grains (Fig. 7). This zone was identified to be Bi203 with Sb, Mn, Ni and Zn inclusions. The average width of this zone is of the order of 3pt-n. It must also be noted that, in general, the as-received samples presented a homoge- neous structure with very low porosity, indicating an adequate sintering procedure during the fabrication. Finally, for this type of specimen, a spinel phase was found in both the ZnO matrix and the interfacial zone (Figs. 8 and 9).

BI

Zn I u u Mn co Ni

Fig. 7 Microanalysis of Bi-enriched intergranular phase

Microstructure of us-received specimen

(m

Fig. 8 M$rostructure of as-received specimen Microanalysis o f spinel phase, within the Bi-enriched phase

Fig. 9 Microanalysis of the spinel phase within the Zn matrix

Microstructure of us-received specimen

The laboratory degraded specimens showed a ZnO matrix with bigger average grain size (between 15 to 20 pm) indicating a thermal process during degradation (Figs. 10 and 11). Also, much more porosity appears all over the sample, which indicates some segregation and volume changes of the different phases due to crys- tallographic changes, as was suggested earlier when analysing the X-ray diffraction results. Note that, now, the Bi-rich intergranular phase (Fig. 12) has less Bi concentration, indicating a Bi segregation (also observed by the X-ray diffraction analysis). In this respect, it has been reported [28-301 that a change in the composition at the interfaces, produces changes in the density states. In particular, the Bi203 content along the grain boundaries [28] has an influence on the

293 IEE 1’roc:Sci. Mens. Techno/., Vol. 143, No. 5, September 1996

height of the Schottky barrier [30]. The spinel phase in the Zn matrix (Fig. 13) is also present in this case but the impurities contained there have different propor- tions compared with the as-received specimens.

Fig. 14 SEM micrograph

Microstructure of in;field degraded specimen

Fig. 10 SEM micrograph

Microstructure of' laboratory degraded specimen

IL" / I

Fig. 1 1 Microanalysis of ZnO matrix

Microstructure of laboratory degraded specimen

Zn

1 1 Zn

Fig. 12 Micyostructure of laboratory degraded specimen Microanalysis or Bi-enriched intergranular phase

Zn

Fig. 13 Microstructure of laboratory degraded specimen , Microanalysis of spinel phase

294

Zn

Fig. 15 Microanalysis of ZnO matrix

+ficrostructure of in-field degraded specimen

r Sb Sb 11 Bi Sb

Fig. 16 Micvostructure of in-field degraded specimen Microanalysis of Bi-enriched intergranular phase

On the other hand, the in-field degraded specimens showed a ZnO matrix with a much bigger grain size (from 20 up to 200pn), which indicates a more severe thermal regime during degradation (Fig. 14). The O2 concentratiom is lower than in the two previous cases (Fig. 15), indicating a change in chemical composition which could be related to the existence now of more C. This could come from atmospheric pollution, intro- duced after the arrester was destroyed by the lighting and exposed, still very hot, to the atmosphere, or from the polymeric components of the arrester design (see Fig. 1). The original Bi-rich intergranular phase (Fig. 16) has now very little Bi and a great Zn content with low 02, suggesting segregation of both elements and the possible formation of new phases that, due to their low amount, are beyond the X-ray diffraction detectability limit (of the order of 5% in weight). The

IEE Proc.-Sci. Meas. Technol., Vol. 143, No. 5, September 1996

spinel phase (Fig. 17) also shows a slight change in chemical composition, even considering the uncertainty associated with this microanalysis technique, with a lower O2 content. Therefore, apparently in the chemical structure of the degraded samples, there exist some changes due to the high voltage. These changes are detected through an increase in the average grain size, due perhaps to some diffusion within adjacent grains, an increase in porosity and a decrease in the concentra- tion of the Bi-enriched phase. This phase is known to be closely related to the nonlinear character of these materials and therefore the observed compositional changes would have a direct influence on the electrical performance. It is also possible that the Bi content could decrease owing to very high temperatures locally, especially for the in-field degraded samples. Since the melting point of Bi203 is 1090K, the ZnO-matrix could have endured the heating, whereas the Bi oxide might have evaporated during the degradation. Another feasi- ble explanation of the observed changes in the Bi con- centration [12] would be that the Bi oxide could have become metallic Bi, with which the chemical composi- tion and properties of the whole material could have changed, producing a more conducting material. More- over. it has been found [29, 301 that the volatilisation of some liquid-phase sintered materials, such as Bi203, also has an effect on the nonlinear behaviour of ZnO varistors.

obtaining a perpendicular cut, indicating also the direc- tionality of the out-of-equilibrium regime within the degraded specimen.

Fig. 18 Dendritic structures

Microstructure of in-field degraded specimen

Izn

Fig. 17 Microanalysis of spinel phase

Microstructure of in-jield degraded specimen

As for the possible influence of the observed grain size 'changes on the properties of the varistors, recent micromodels, based on the assumption that a ZnO varistor could be regarded as a set of micro ZnO varis- tors connected in series and parallel [31], depending on the grain size, have indicated that a change in either average grain size or grain size distribution has a direct influlence on the a parameter of the varistor.

Al:so, besides the compositional changes reported, some of the microstructure formation of the in-field specimens is not observed in either the as-received or the laboratory degraded specimens. In particular, den- dritic structures are commonly observed (Fig. 18). These dendrites have not been reported before in these ZnO based materials, either the as-prepared or the degraded ones, and indicate the extreme conditions to which the material has been subjected, for dendrites are known to be related to severe out-of-equilibrium states and also to the presence of specific impurities which lead to the formation of these structures. In the: present case, the compositional mapping of the dlendrites showed the presence of ZnO. Note that, whereals all the SEN[ micrographs shown so far were obtained through cross-section cuts, the dendrites were observed when

IEE P,poc.-Sci. Meas. Technol., Vol. 143, No. 5, September 1996

current,mA Fig.19 degraded samples (' *)

I against V curves for as-received samples (+) and in$eld

3.3 Electrical characterisation Consider the relationship between microstructure and composition with electrical performance. Fig. 19 shows the I against V plots (DC) of the as-received and in- field-degraded specimens. The as-received samples show the expected highly nonlinear behaviour with a big slope in the curve. As mentioned, the low-current region has a different slope for the different sets of samples analysed. Since it is known that this region has both capacitive and resistivity contributions [32], due to the impedance of the ZnO grain boundaries, the observed changes are in agreement with the microstruc- tural changes (especially grain size and structure) dis- cussed earlier. The intermediate nonlinear region, characterised by a slope a = d(ln I ) / d(ln V), also presents changes between the as-received and the

295

degraded material. In general, the greater the value of a, the better the material. The plots obtained in this work show lower U values as the material degrades The figures obtained for a from our measurement are 50.11 and 1.34 for the as-received and the degraded specimens, respectively, obtained from the V and I val- ues of the intermediate nonlinear region in each case (Fig. 19).

As was suggested by the microanalysis results, there is a difference between the thermal histories of degraded and nondegraded samples, which is con- firmed now by the a differences, since it is known that a decreases with temperature of application [l]. Also, it has been found that the value of a is determined by the differential impedance between the grain boundary and the grain [32]. According to the SEM and X-ray dif- fraction results of this present work, the different segre- gation regimes of laboratory degraded and in-field degraded materials, should also be reflected in the a values, which is indeed the case. Moreover, the tan 6 plots of Fig. 20 are an indication of the performance of the materials. The as-received samples have a low loss factor even for higher voltages, whereas the laboratory degraded specimens have a very strong dependence of the loss factor on voltage. This could also have been influenced by the moisture intake in the laboratory, despite the low relative humidity. It must be clarified that the attempts to measure tan 6 for the in-field degraded samples failed because the apparatus went out of range immediately, indicating a very poor mate- rial in terms of electrical performance. Also, there are considerable probabilities that the material could have absorbed a considerable amount of water during the lightning. Another possibility for explaining this behav- iour is that the Schering bridge is limited when used with ZnO in the high conduction regime.

0 I / I , l I I 0 2 4 6 8 10 12 14 16 18 20

R M S voltage, kV Fig.20 tory degraded samples (U)

Tan 6 against Vplots for received specimens (+) and labora-

Also, some studies on the effect of impulse currents on the microstructure and electrical properties of ZnO

296

varistors [20] indicate that the degradation is associated with the formation of cracks, which could be developed from highly localised conduction paths during the application of the current pulses. In this regard, the observed dentritic microstructure mentioned above could be also related to the formation of those paths even for single pulses, due to segregation and the for- mation of microcracks on each of the multiple branches of the tree-like dentritic structure.

4 Conclusions

Extensive microstructural, compositional and electrical behaviour studies have been carried out on commercial ZnO based varistor devices. The results show clear dif- ferences in all the above parameters not only between the as-received and the degraded specimens but also demonstrate the specific degradation procedure to be very important, for the laboratory induced degradation yields different results as compared to the in-field tested materials. In general, the differences are both qualitative and quantitative since the mechanisms detected are not necessarily the same for both cases. In particular, Bi ions seem to play a key role in the behav- iour of these materials, leading to changes in crystallo- graphic structures of its associated oxides. A geometrical model of the feasible mechanisms based in the results presented in this work is currently being pre- pared and will be reported separately.

5 References

1 MATSUOKA, M.: ‘Nonohmic properties of zinc oxide ceramics’, Jpn. J. Appl. Phys., 1971, 10, pp. 136-746

2 EDA, K.: ‘Zinc oxide varistors’, IEEE Electr. Ins. Mag., 1989, 5, pp. 28-30, 32-33, 36-41

3 WONG, J.: ‘Sintering and varistor characteristics of ZnO-Bi,O, ceramics’, J. Appl. Phys., 1980, 51, (8), pp. 4453

4 WONG, J., and MORRIS, W.G.: ‘Relation of properties of microstructure in the metal oxide varistor’, Am. Ceramic Soc. Bull., 1974, 52, (8 ) , pp. 631

5 OLSSON, E., FALK, L.K.L., DUNLOP, G.L., and OSTER- LUND, R.: ‘The microstructure of ZnO varistors material’, J. Mater. Sei., 1985, 20, pp. 40914098

6 KANAI, H., IMAI, M., and TAKAHASHI, T.: ‘A high-resolu- tion transmission electron microscope study of a zinc oxide varis- tor’, J. Mater. Sei., 1985, 20, pp. 3957-3966

7 KINGERY, W.D., VANDER SANDE, J.B., and MITAMURA, T.: ‘A scanning transmission electron microscopy investigation of grain boundary segregation in a ZnO-Biz03 varistor’, J. Am. Ceramic Soc., 1979, 62, ( 3 4 , pp. 221 PHILIPP, H.R., and LEVINSON, L.M.: ‘ZnO varistors for pro- tection against nuclear electromagnetic pulse’, Adv. Ceramics, 1984, 7, p. 1 SATO, K., and TAKADA, Y.: ‘A mechanism of degradation in leakage currents through ZnO varistors’, J. Appl. Phys., 1982, 53, p. 8819

10 EDA, K., IGA, A., and MATSUOKA, M.: ‘Degradation mecha- nism of the non-ohmic zinc oxide ceramics’, J. Appl. Phys., 1980, 51, pp. 2678-2684

11 HAYASHI, M., HABA, M., HIRANO, S., OKAMOTO, M., and WATANABE, M.: ‘Degradation mechanism of zinc oxide varistor under DC vias’, J. Appl. Phys., 1982, 53, pp. 5154-5762

12 EDA, K.: ‘Destruction mechanism of ZnO varistors due to high currents’, J. Appl. Phys., 1984, 56, (lo), p. 2948

13 SHIRLEY, C.G., and PAULSON, W.M.: ‘The pulse-degradation characteristic of ZnO varistors’, J. Appl. Phys., 1979, SO, (9), p. 5182

14 IGA, A., MATSUOKA, M., and MASUYAMA, M.: ‘Effect of heat-treatment of current creep phenomena in non-ohmic ZnO ceramics’, J. Appl. Phys., 1976, 15, pp. 1847-1848

15 MIZUNO, M., HAYASHI, M., and MITANT, K.: ‘Thermal sta- bility and life of gapless surge arrester’, IEEE Trans., 1981, PAS- S , pp. 266k2671

16 TOMINAGA, S., SHIBUYA, Y., FUJIWARA, Y., IMATAKI, M., and NITTA, T.: ‘Stability and long term degradation of metal oxide surge arrester’, IEEE Trans., 1980, PAS-4, pp. 1548- 1556

8

9

IEE Proc.-Sei. Meas. Technol, Vol. 143, No. 5 , September 1996

17

18

19

20

21

22

23

CHIANG, Y.M., KINGERY, W.D., and LEVINSON, L.M.: ‘Compositional changes adjacent to grain boundaries during elec- trical degradation of a ZnO varistor’, J. Appl. Phys., 1982, 53, (3), p. 1765 CLARKE, D.R.: ‘The microstructure location of intergranular metal-oxide phase in a zinc oxide varistor’, J. Appl. Phys., 1978, 49, pp. 2407-241 1 KOBAYASHI, M., MIZUNO, M., AIZAWA, T., IIAYASHI, M.. and MITANI. K.: ‘Develonment of ZnO nonlinear resistor and their applications to gapless surge arresters’, IEEE Trans.,

SARGENT. RA.. DARVENIZA. M.. and DUNLOP. G.L.: 1’378, PAS-97, pp. 1149-1 158

‘Effects of multinle imnulse corrents on the microstructure and I .

electrical properties of metal-oxide varistors’, IEEE Trans. Electr.

DARVENIZA, M., and MERCER, D.R.: ‘LaboratorIy studies of the effects of multipulse lightning currents on distribution surge arresters’, IEEE Trans., PD-8, pp. 1035-1044. MAJOR. R.W., WERNER, A.E., WILSON, C.B., and MOD-

h ~ . , 1992, 27, pp. 586-592

WE, FA.: ‘Polarization currents ‘in zinc oxide varistors from 77 to 450 K’, J. Appl. Phys., 1994, 76, pp. 7361-7371 B,ARGIGIA, A., DE NIGRIS, M., PIGINI, A., and SIRONI, A.: ‘Comparison of different test methods to assess the thermal suesses of metal oxide surge arrester under pollution conditions’, LEEE Trans., 1993, PD-8, pp. 146-155

24 GLOT, AB., HOGARTH, C.A., BULPETT, R., and REY- NOLDS, A.J.: ‘Characterization of the Zn0-SnO2-CoO-Bi203 ceramic material sintered at high temperature’, J. Mater. Sri. Lett., 1985, 4, pp. 963-966.

25 JCPDA X-Ray Diffraction Tables 26 CERVA, H., and RUSSWURM, W.: ‘Microstructure and crystal

structure of bismuth oxide phases in zinc oxide varistor ceramics’, J. Am. Ceramic Soc., 1988, 71, (7), pp. 522

27 CASTARO, V.M.: PhD thesis (physics), UNAM, Mexico City, 1985

28 BAI, S . , and TSENG, T.Y.: ‘Influence of sintering temperature on electrical properties of ZnO varistors’, J. Appl. Phys., 1993, 74,

29 SHIM, Y., and CORDARO, J.F.: ‘Admittance spectroscopy of polycrystalline ZnO-Bi,O, and ZnO-BaO systems’, J. An?. Ceramic Soc., 1988, 71, (3), pp. 184

30 BHUSHAN, B., KASHYAP, S.C., and CHOPRA, K.L.: ‘Electri- cal and dielectric behavior of a zinc oxide composite (varistors)’, J. Appl. Phys., 1981, 52, (4), p. 2932

31 WANG, L., WU, W., LI, X., and ZHANG, Y.: ‘Two different micromodels of zinc oxide varistors’, J. Appl. Phys., 1995, 77, pp. 5982-5986

32 GUPTA, T.K.: ‘Application of zinc oxide varistors’, J. Am. Ceramic Soc., 1990, 73, (7), pp. 1817

pp. 695-703

IEE Proc-Sri. Meas. Teclinol., Vol. 143, No. 5, Septemher 1996 291

![Energy Division LV and MV Metal-Oxide Surge Arresters · Overview of ZnO surge arresters offered by Tyco Electronics Energy Division Type Rating [kA] Line Application Continuous Page](https://static.fdocuments.us/doc/165x107/5f048d217e708231d40e87bb/energy-division-lv-and-mv-metal-oxide-surge-overview-of-zno-surge-arresters-offered.jpg)