€D Udrumipindiaservices.gov.in/GI_DOC/169/169 - GI - Enclosing...consists of weak babul lir...

Transcript of €D Udrumipindiaservices.gov.in/GI_DOC/169/169 - GI - Enclosing...consists of weak babul lir...

N0-70t

To,Assistant RegistrarGergraphical Indjcation ReqistrationPettion OfficeGunidy Industrial EstateGST Road, Chennai

HEAD OFF : 8OMP,qY LIFE BIOG., 5TH FL00R,45, VEER MRllllAN ROAD, MUMBAI - 400 Ofi A UU7157 I 4186 FAX : (022)283 5881 Email [email protected]

€DUdrum

SAI{T ROHIDN LEATHER II'IDUSTRIE$ & CHARII|AKAR CORPOMTIOI'|LTD.

(A GOVT. OF MAHAMSHTRA UNDERI]

Sub : Regarding application for the

NG)

Date:2913t2010

rma in part A of the

aKar Developmentpany Act 1956 As

of this companyare manufacturing

to the Charmakarn in the region of

legal protection to aDKAR Corporation

ce statement

btr,

ueographtcal indtcation act 1999.

_ Sant Rohidas Leather Industries & (Corporation Ltd., is registered company unCei tneper the memorandum of this Corporation, the main ois, overall development of Charmakar Communities.the Leather goods and providing financiat essisirUornunrttes. To protect the traditronal rights of theKolhapur, Solapur. Sangli and Satara anj, proviOeo- tfreKornapur product. We are applying joinfly with the

& Ci:r.;;..-, . 45, V. 1

(Leather Industry Development Corpofttion oi Xarnatat a DKAR).

We are enclosing the main application historicalmap, evidence with photograph.

rs Sincerely

I ': '--i ir:lr.:rric:;. ..- it Col-.r! :

i ;,i:.- li , :'.1. : rl

CH I {', r,:41.

ADplication for tbe registration of a Geograplit:t I-t9Y::T^r'r"r!-"-- Regisier for goods falling in-different classes'

(Section 11(3)' RuIe 23(5)

+l*Y::l,,::::"^'J"-,Tl;"i',"Hlil1T,i13lrui:H'ff i

Part A of the

Register ofthe

Sao--t Rohidas Leather Ind

DeveloPment CorPorationNarne of the APPlicant

BombayTtE Btdg'. 5u floor, 4

Mumbai-4OO 001.

Ph. 22047 | 57 /220441 86 Fax :

stries DeveloPment

Corporation of

i Kalnataka LeatherCorporatio n Ltd , (LID

2. Leather Industries

Maharashtra (LIDCO

Li-st of Association ofOrganization/AuthoritY

using babulbark and

uppers and heel are

tanned leather'

tanned leather around

shape memory on

insole and uPPer and

taken from bag tanned

lhapuri chaPPals made

Nippani, where

fixed over uPPer

or goat skin tanned bY

Ethnic Product

Bag tanned leather,

myrobalan fruits.

All parts of chaPPal -from bag tanned

Degee of tannage of45%.

Chappal to exhibit

wetting/soaking in

Stitching of outer so

heel with leather

leather for most ofthein almost all Places,pasting is Presently fo

Decorative woven

bands are from Head

tanners in the sam-KotnaPuri Footwear)'in Kamataka - Dharwad,

covering a total area of

, Sangli, KolhaPur

irea of about 41,615

area that will have to be

Maharashtra is about

f-Onapuri ChaPPal

GeograPhical Area : Dlstrl{

Bels-aum, Bagalkot and Bij

about 34,812 Sq.Kms'

Districts in Maharashtra -and Satara - covering a

Sq.Kms.Thus, the total geograPhical

covered both in KamatatG

76,427.1 Sq.I{ms.

ft-ameof theGeograPhicallndication (and Particulars)

Proof of orisin The origin of KolhaPuri chaPl

12th Century rule of King BijjaPrime Minister Viswaguru B

who wanted to create a cast€

stigma associated with Chat

Vishwa Guru Basavanna, (Kannada) by Jagadguru MKalyana Mission, Bangalc

Basaveswara sought an aPPoi

chamar by name HaralalYa.and his family involved inBasaveswara was greatlY irrHaralayya's house. As a token

for Basaveswara , HaralaYYausing vegetable tanned skin al

from his thigh and as well a

thighs and presented to basar

The Viswaguru Shri Basaves

chappal, but kept it on his he

Footwear, as it was PartlY maHaralayyas. He retumed theWhile taking back the footwezthe Aasthan, by name MadlHaralayya and wore the footeit, he developed paralysis a

Hearing the incidence,Basaveshwara advised Madhrof Harala'yya and also bathe i

make the footwear. He re1

Lavanyavathi, daughter ofHaralayya's house and sough

back home with a pot ofmanufacture and gave it to herthat processing liquid, he fr

ailment. Then he realized theHaralayya and as a gesture ofdaughter in mariage to Shee

Thus, Basaveswara achievedcasteless society and in tunlingayat faith and worshipping

al can be traced back toof Bidar district and hisrsavanna (Basaveswara)

ess society and removerar community. (Ref :

n Vemacular languagerte Mahadevi, Vishwar€, 1980). As such

ltment for lunch with aTraditionally Harala;yabotwear manufacturing.rressed by his visit toof appreciation and lovenade a pair of footweard a part of his own skin; his wife Kalyanamm'seswara (Photograph 1).

rwara did not wear therd, saying it is a Divinee from their own skin offootwear to Haralayya.

r, a Brahmin Assistant inuvarash grabbed it fromear. As soon as he wornrd became bed ridden.the Jagadguru Shrivarsh to seek the pardon

r the liquids he used torsed to do so, ThenMadhuvarsh went to: his pardon and cameiquid used in footwearlather. After bathing withlly recovered from hisgreatness and divinity ofgratitude, he offered hisLavanth, Harlayya's son.

ris objective of creatingthe chamar tumed to

tingu.

Further, the chamars consic

period as a glorious chaPter i

their lives to lingaYat faithworship. it is with that sPirit,

made excellent varieties ofcreative work in footwear Prccentury was the beginning c

Chamars using bag tanned letKolhapuri. However, the nar

prefixed to it was onlY frorCentury. (See Picture).

There is also some recorded intanning, probably bag tanningShahu (1874-1922) was resP

units from Bindu Chowkoutskirts of the town. About 2!

vogue during this period (18!of Kolhapur, By J.H.Pathan, funpublished article).

In the undivided Bombay Stal

the Kolhapuri chappals were P

leathers by chamars of Maha

the select districts relerred urthis application. The name ofexistence as chappals made

enabled others in other distrkState to make similar type of (

leather. Hence, the name Kobeing used by all the chamarsfrom where they are produce(

the reorganization of States, z

of the districts have formed p

tanners and chamars continmethods ofproduction in their

In another report, it was n(Saudagar) in the late 1920s

design of chappal, which wasflaps (which gave it the name

with an ear). It also had a dec

to Bombay and was noticed b1

footwear trader. They ordered

of Kanwalis and sold them irdemand for Kanwalis had pror

teach the skills to others.fromCalcutta where thesepopular. It was reported thi

ered that 12* centuryr their lives to dedicate

and consider work as

the chamar communitybotwear and used theirJuction. Hence, the 12s

I footwear made by the

lher and it looked likere Kolhapauri that was

. the beginning of 20'n

brmation on the status ofin Kolhapur. Chatrapati:nsible to shift tanningo Yallomareal, in thetanning centrtes were in

5) (Ref.Leather Industry.R.Mane Co[[ege, Kagal,

: (before 1947), most of:oduced from bag tanned:ashtra and Karnataka inder Geographical area inKolhapuri has come intoLnd traded in Kolhapur,ts of undivided Bombayhappals from bag tannedhapuri was used and isirrespective of the placein Bombay State. After

fter Independence, somert of Kamataka and theLe to follow the same

espective places.

entioned that a familyleveloped an indigenoushinner and had two sides

"Kanwali" or a chappalrrative upper. It was sentJ.J. and Sons, prominent20 pairs of new designsBombay. The increased

rpted Saudagar family tofhe JJ sons got orderbotwear became moret the name "Kolhapuri

chappals" was given to thel

competitors the fact that the (

Athani. Later, of course, t

Kolhapur also started manufacl

Hence, the kolhapuri chaPPal ir

exclusively from bag tanned ler

(Ref : Footwear industries in AIndustrial Development Bank c

Report prepared by Mahz

Technical Consultancy Organil

The consolidated map showiKarnataka and Maharashtra I

process and Kolhapuri Chappaare found is enclosed at the en

r to conceal from thehappals originated fiomther centres includingrring these footwear.

an ethnic product, made

Iher.

haniflndiarashtra Industrial and

ation Ltd., 1988.)

rg all the 8 districts intates where bag taningmanufacturing activities

t.

Method of Production The ethnic Kolhapuri chap

exsclusively made from bag I

Hence, for Kolhapuri chappal,pre-requisite.The methods of production thstages - (1) manufacture of bi

manufacture of Kolhapuri chap

l. Production of bag lanne2 to ll) : The traditioadopted by Artisans inwhere bag tanned (vegetaethnically called Kolhapu

(D(4.,

is described below :

Raw materials :

Buffalo hides - Green/w25-30 kg. each. Cow hidtcow are also used.

Lime (staked)

Vegetable tanning matelArabica) and myrobalan nr

Miscelleneous : Sisal fibrand hand tools for unhairirscrubbing.Soaking : The raw hides, :

wash the hides thoroughllto clean the surfaces frommaterial is of wet salted tday in water, handling c

soaking is completed, inrehydration, take out, drair

(b)(cl

(d)

(2)

ral is completely and

lnned vegetable leather.

bag tanned leather is the

:refore shall include twog tanned leather and (2)pal.

I leather (Photographsral/orthodox process as

the Geogaphical areas

rle) leather and chappals,i chappals are produced

salted/ weighing aboutcalf skins of buff and

ials : Babulbark (Acaciats (Terminalia Chebula).e for stitching into bagsg, fleshing, beaming and

I they are of green hides,in 2-3 changes of waterlirt and blood. Ifthe raw,pe, soak the hides for Ince or twice. After thelicated by softness andthe water.

(3). Liming : Put the hides

rectangular 4'x6'x5' Pit an

once a day and keeP the h

days. On the 7' daY,

strengthened by adding ab,

per hide. The hides are Pabout 10 daYs, each daY

once.Now the hides become 1

stock is taken out, unhai:

and then fleshed with a fle

water, scudded to remove l

surface. Wash thoroughlYNow cut the hides into si

spinal line.

n old lime liquor, in a

I handle it by hauling up

.de in the same pit for 6

he old lime liquor is,ut 10 lbs. of slaked limeLt in this lime liquor forrandling and hauling up

lump and swollen. Theed with unhairing knife;hing knife, washed withhort hair and to clean thein 2-3 changes of water.les by cutting along the

(4) Deliming : The sides ar

well to remove lime fronovernight in water, the sidr

its thickness. The stock istanning.

r put in water, trampledthe sides. After leaving

s get delimed upto 2/3 ofnow ready for vegetable

(s) Vegetable tanning : Itcolouring and suspensic

consists of weak babul lir

branches crushed myrobalThe sides are put in this I

out, wrung and put in s<

another two days. The sk

both grain and flesh side

still untanned.

After this, the sides are tedrained by keeping on bar

into a bag, using strong si

on the neck portion. Themixture of babul bark anc

(10 : 7) upto l/3'd of its hover wooden logs, inmeasuring about 7' x 5' xare poured into the bag thneck portion. Tanning tak

of tan liquor by osmoticspacs in the skin. The liquput back into the bag ez

quantity is collected. Thcondition for two days , aI2/3'd of its height. The bag

opened on the butt porti(neck portion is closed.direction, the bag is susl

involves two stages -r. The colouring bathuor, made from bark ofm and soaking in water.quor for two days. Takeoond colouring bath forns now get coloured on

leaving central portion

ken out, wrung, water isrboo poles, then stitchedal fibre, leaving openingbag is filled up with acrushed myrobalan nuts:ight and then suspended

o a pit (rectangular)2' . Water and tan liquor"ough the opening in the:s placed by penetrationrressure into the interiorrr collected into the pit is:h time when sufficient: bags are kept in thiser which a knot is tied atis taken out, the mouth isn and the mouth on thelhus, reversing the bagended over the pit. Tan

liquor is poured into the 1

for two days.

By this time , the middle Pc

tanned. At this stage, the kand myrob are allowed tothe balance l/3 portion ofkept in this position for hthe entire side gets tanned

tanned in 3 steps. Aftertaken out, cut open to makon a bamboo pole, beame

with water thoroughlY. Tlsun on the flesh side for o

are still damp, they are pul

for 1 or 2 days. Then takermake them ready for sellin

The whole production frcabout 30-32 days. The yielraw weight.

at frequent intervals

lion ofthe bag also gets

rot is removed, the barklip into the butt portion,the bag and the bag isro days, by which time,Thus, the entire side is

this process, the bag is

: the side flat and placed

l, scrubbed and washed

e sides are dried in there day. When the sides

back into the tanning pitout and dried in order to

m raw to tanning takesI varies from 40-45Yo on

Other variations in methods a

The above method is the mr

followed by the tanners, produ<

chappals. However, some bagputting the soaked hides in freold lime liquor, keeping a total

Bag tanning was also practict(Jalandhar), West Bengal (Kolin the past. However, the prr

certain natural materials suchlimed fleshings, and Akandadeliming and bating and use of

Consumptionof processing t

weight 30 kg)

1. Lime2. Babul bark (crushed)3. Myrob nuts (crushed)

nd production

st widely used process

ing leather for Kolhapuritanners are straightaway;h lime liquor, instead ofiming period of l5 days.

d extensively in Punjabratta) and U.P. (Kanpur)cess differed in use ofrs Sajji Matti in liming,leaves fermentation forrabul bark alone.

raterials(w/s hide-Ave.

3-4 Kg. ihide8-10 Kg./side7-8 Kg./side

1.

Manufacture of Kolha;Kolhapuri Footwear -Photographs 12-27) :

Raw material : Bagleather. Bag tanned cov

cow calfare also used.

Pattern making : Thelgeneration to generatiolmakes his own patterl

measurements and then

inch in lenglh for each

cut in rubber sheets.

Grading : The pafterns

to I I for gents and gradr

Making Upper and bo

tanned vegetable buff ltwell as for uppers. Atleather soles are also mcalf leathers (bag tanmaking uppers.

The bag tanned leatherCut into outer sole at

sheets. The cut soles ar

While in damp corhammered heavily andleather even, flat and prpolished by rubbing witl

In the case of punch

desigls are punched wiside ofthe insole as wel

In case no punches a

applied in between bokeep them together teml

Meanwhile, toe ringprepared with leather 'l

and fixed over it a

leather piece.

uri Chappal (Ethnic.llustrated with

tanned vegetable buff/bag tanned buff calf or

e are handed over fiom. At times, the producerby taking actual foot

Srading by increasing 1/3

size. These pattems are

re available for grades 6s 5-9 for ladies.

:tom stock : Mostly bagather is used for soles as

times, bag tanned cowLde use of. Buff calf/cowred) are also used for

is ri/etted to ease cutting.Ld insole, using patteme exposed to sun dryinglition, the leather isrepeatedly to make the:ssed. The soles are thena porcelain cup/rod.

:d designs, the desiredh punchers on the grainas on upper straps.

e made, earthern soil istom sole and insole toorarily.

and instep band are

*en from belly portionolaited/woven/decorative

Also a toe loop/strapattached passing forwarpoint adjacent to toe rinlto anchor forepart of the

be two such toes looP

Now, the InsteP band irsole and insole and the

the toe. The heel Piecechappal is now stitchedfrom tail portion of theThe sole stitching is allin the middle of the sole

In the case of KaPshr

rubbed with a mixture o

oil to get shining and gl

types of Kapshe, 3 s

together and stitched. S

shiny and last longer (S

(woven in leather) isI from Instep band to aon the sole between toe

foot. At times, there can(see photograph 27).

enclosed between outertoe loop into a slot near

is also fixed. The wholevith a leather rope, taken;ame bag tanned leather.around the sole and also

(Kapsi), the insole is

I coconut and ground nutrssiness. In some special

rle pieces are attachedrch chappals are soft and:e photograph 26).

Variations :

(i) In Nippani aret

process is follo'method practicethe stuck on prtheir sequence ir

places, but onlysoles and upperbands are alsolever, ear pi,

bgtween outer alIn some types, tinstep band.In all other pkleather thread isAt times, the ulstraps and theirtanned goat/she(vegetable tanne

(ii)

(iiD

('9

, now-a-days, stuck onred, instead of stitchingI for several decades. Inrcess, all operations and

the same as in all otherlatex is used to paste thebands to the sole. Upper'iveted in the side of a

ce (Leather) inserted

d insoles.rere can be toe band and

oes, only stitching withbllowed.per band and the wovenlining can be vegetablep skins or head leather[) (Photograph 20).

Uniqueness :

o Household productioltraditional practices and

r Completely and exclttanned vegetable leathel

o Eco-friendlyprocessingo Resistance to abrasion a

o Have shape memory evln water.

with centuries oldfully hand made.

sively made with bag

and production.

rd water absorption.:n when wet back/soaked

farmers - a fashion

action in wear foro Suitable for rugged use

foowvear with soft and

urbanites and elite.

o Low degree oftannage of

logy. Mumbai (under

otr, Govt. of

Leather TechnologYLeather Industries

of Kamataka

Inspection BodY :

. CLN.e Institute of Leather T

Dept. of Technical

Maharashtra).e Karnataka Institute of

(KILT), Bangalore (

product made bY

of Marathi sPeaking

for generations withhanded over from

in the GeograPhical

lgaum and some other

rataka and Maharashtra

around Rs.100

and leather, amounting

involving about I lakh

chappals).

Kolhapuri ChaPPal is

misused bY calling anY

tanned leather in

different from

ld on the same name in. It is distinct as it

bag tanned vegetable

of the geograPhical

It is not the shaPe of:e of leather used in the

chappal that determines

chappal. The chaPPals

rs growth, when theY

uniqu.n"r. and sPecialitY

chappals are _made in

rrlv in the toe band ano

Others :

1. The onlY authentic and

artisans of ethnic origiartisans in households

Region of KolhaPur,

districts in Parts of lStates.

2. Annual Production is

to about 10 million Pai

households (Tanning

3. The ethnic name ofextensivelY abused and

footwear made withthe shaPe of ethnic Ko

4. KolhaPuri ChaPPal is

other tYPes of chaPPals

different markets in the

is made entirelY

regions mentioned ab

fo-ot'*.u., but it is the

the ethnicity of Koare free from moul

are kept dry. Hence,

of this product.

5. The ethnic KolhaP

5. The ethnic KolhaPuriseveral designs, Particulinstep bands of the uPPt

several names as KaPsiand all of them are term(

The main markets are

Athni and other majorKolhapuri chapPals are

actual export ofethnic Pl

6. Sale price of ethnidepending on their stYlr

Rs.250 to Rs.2,000 per 1

sell only against mail (type of chappals. The e'

about 25% higher price t

7. Market : Prevailing Ptregion under consideratirange and are as below :

(i) Raw buff hides 9Green/of about 30 Kg. weight.

(ii) Selling price of bag 1

135/Kg.

(iii)Yield in bag tanning - 4

(iv)Purchase price of bag ta

by chamars - Rs.135-15

(v) Selling price of Ethtdepending on design, ra

Rs.l20-150/Pair, Rs.2000lPair for ordinarpunching design, popugeneral use chappal, t

pieces of sole for rugge

very special Kapsi withwith woven patterns an

respectively.

(vi)The price of raw goat sk

and the pit tannedRs.200/piece.

chappals are made inLrly in the toe band and

rs. These are known byKanwalis, Benta etc.

d as Kolhapuri chappals.

in Kolhapur, Nippani,cities in India. Part ofalso exported but the

oduct is not clear.

, Kolhapuri chappals,and design range fiom

air. Some manufacturersrders, particularly Kapsihnic product is priced at

ver non-ethnic products.

ces (April 2009) in thern are almost in the same

V.S.) - Rs.300-500/piece

rnned leather - Rs.125-

)-50% (6-7 Kg/side).

rned leather from dealers)/Kg.

ic Kolhapuri Chappal,rges from Rs.80-85/Pair,i50-400/Pair, Rs.750-

' chappals with onoyar variety of Kapsi forpecial chappals with 3

1 use in Kapsi style andheavily decorated upperI finished for glossiness,

n is around Rs.160/piece

3oat skin costs about

10

Gii Raw head skin of co'Rs.l0/piece and thatRs.16/piece. The Pitaround Rs.62lKg.

(viii) The cost oftanning r

Lime : Rs.l0/Kg.Babul bark (crushed'

Myrobalan fruits (nu

Sisal fibre - Rs.3-4llWater - 200 liters/dtunit

(ix) Waste liquors are mi

required thrown out.

Hair and fleshings a:

covering with soil at

compost.Waste bark is used a

traders to sell it for r

The units are not registered Ioperate within their own resi,

process is eco-friendlY and nothe Environmental Board hal

Pollution Control regulations. (

registered and operate fromtanning and chappal making ar

and artisans.

The socio-economic status is l

the bag tanners and chappal prtwith undergraduate qualifi catio

The productivity is 5 hides prc

unit of family consisting of 3 m

Productivity :

1 Kg. of bag tanned leather 1

chappals depending on the des

expected to be 20 pairs per dayfootwear and the daily producpairs for woven and Kapsi typerson in a day.

z/calfcosts around)f buffalo at

anned head leather costs

raterials and utilities :

: Rs.12,Kg.;s) (Crushed) Rs.12lKg.iag (15 pieces of fibre)y for processing in I

rimal and when not

: dumped into pitsd converted into

; a fuel or taken byLce courts.

y Golt. agencies. They.ential premises. As theoxic chemicals are used,

exempted them underhappal units also are nottheir houses. As such,: confined to households

lirly protected. Some ofducers are well educatedLs like B.A. degree.

;essing per week by one

rle and I female artisans.

ives 1.5 to 2.5 pairs ofigns. The productivity isin case of pasted type ofivity varies from 3 to 6

le of footwear for each

1l

t)l

in 3rfi'ays - Individualpiece work and also

and run by one

basis, each labourer

is estimated at about4 persons and in case

is around Rs.15.000

workshop, hiring

around Rs.250-300 Per

eamings of bag tanners

000 per month per familY

l(at atalr Lcrthet lndustries 0evel

tlo. 176,Oblong Block 2nc F mr unrt! grrrldlng, J. C.

Sugalore - 560 002. Ptune : 222i81 26 tu : 08fr.2222

TRAM)

Sant Eohldas t la:lue|iec I er' a,m lkslDe:telopm Co;3tati3n l.tBombay e BlC.1, St,i :'

45, V Na man Road.

)v - 4AJ 001 .B

Photograph I : Harlayya presenting a pair offootwear (looks [ike Kolhapuri) to

Shri Basaveshwar. '

l3

Photograph 2 : Wet Salted BuffHide'

PhotograPh 3 : Removing ofFlesh from

Photograph No.4 : Colouring the Sides.

Photograph No.5 : Bundles of sisal fibers for usage m

lf

of taming bag.

,-,:-9

- -i9

Photogr4h No.6 : Tarnirfrg Bag Stitching with Sisal

Photograph $o.7 : Bag Tanning unit.

lo

Photogaph No.8 : Observing tannng

3'--

Photograph No.9 : Beaming Log.

;v\

Photogaph No.10 : Final Stages ofVeg. Tanning'

'r--{

Photograph No.l 1 : Tarned Leather in dried

l8

Photograpp No.12 : Pattems.

Photogrehl'{o.13 : Sole Cutting'

l9

Photograph No. 14 : Hammering the Sole.

Photograph No.15 : Prmctring Sole &

PhotographNO.16 : Potshing ofSole

Photograph No.1? : iUnstitched and Stitched

,1

PhotographNo.l8 : Stitched Soles'

Photograph No.l9 : Cutting the Leather Tlread from

Photogaph No.20 : Vegetable Tanned Head

Photograph No.21 : Woman Preparing Veni for

ZJ

Photogrqh No.22 : Veni Mderials for Upper

Photogaph No.23 : The couple sppcialised skills inKolhapuri Footwear , Kapsi'

Kapsi Variety of

iJr0's

Photogaph No.Z : Popular Variety ofllard Sole Kapsi

Photograph No.25 : Bottom Sole of lfupsi Vanety

Photograph No.26 : Fine quality of Kapsi Vanety

of Soles).

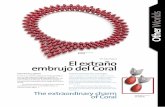

oThe ma*ed border withpink colour showsDistricts having bagtanning processingand Kolhapuri foolwearproducing artisans,locations

27