CW India Sep 2015 - Feature Precast

-

Upload

laxman-wadhwani -

Category

Documents

-

view

48 -

download

2

Transcript of CW India Sep 2015 - Feature Precast

/ConstructionWorldmagazine/CWmagazine

www.ConstructionWorld.in

` 200

CW ARCHITECT AND BUILDER AWARDS

www.ConstructionWorld.in

CO N T E N TS

52

86

100

106

98

110

80

Cover StoryCWAB 2015 – A DECADE OF

EXCELLENCE Created a decade ago to salute the visionary architects and builders who traverse the lines of possibility and render form and function to the structures we inhabit, the CW Architect & Builder Awards (CWAB) enjoyed a memorable 10-year journey this year.

FeaturesROAD EQUIPMENTWith the focus shifting to concrete roads and road recycling, how should construction companies gear up?

PRECAST & PRECAST TECHNOLOGY Precast technology is poised to make inroads in the Indian building construction sector to the advantage of developers and occupants.

Equipment AppsPUMP IT UPLong-distance concrete pumping is a challenge often encountered in the construction of high-rise structures, buildings and vertical or angular shafts in hydropower projects as well as for concrete lining of small diameter tunnels for various applications. A practical solution to overcome this challenge is presented.

Civic sense “WE HAVE AN INDUSTRY-FRIENDLY DEVELOPMENT PLAN AND E-GOVERNANCE SETUP COMING UP.”

- Praveen Gedam, Municipal Commissioner, Nashik Municipal Corporation, on the corporation’s developments and upcoming projects.

On Contract“INDIA IS BOUND TO ATTRACT BUSINESS FROM DEVELOPED NATIONS IN TIMES TO COME.”- Anil Kumar Singh, Managing Director, APCO Infratech Pvt Ltd, elaborates on the company’s offerings, strategies and challenges faced.

Special Project CHENNAI EXPRESSThe newest launched metro in the country, the Chennai Metro is a boon to commuters.

1

86

52

8 Construction World September 2015

80

CO N T E N TS

94

112

128

116

118

120

127

MaterialSMALL, STRONG AND RESISTANT Hundred times smaller than cement, condensed silica fume is known to be durable and highly resistant to elevated temperatures, making its appropriate use a breakthrough technology in smart buildings.

Focus TALENT SEARCH

Following the success of the recently held Turner International New Hire Conference in India, experienced senior offi cial from various parts of Turner offi ces share more on the company’s activities.

Legal ZoneA TAXING ISSUEJairaj Purandare, Chairman, JMP Advisors Pvt Ltd, sheds more light on the recently notifi ed Income Computation and Disclosure Standard III.

Guest Article SMART CITIES: WHY AND HOW? Gurjot Bhatia, Managing Director-Project Management India, CBRE South Asia Pvt Ltd, sees smart cities as the long-term solution to urban development woes.

Event ReportsSMART BUILDINGS SUMMIT 2015The event last month, with 12 Speakers and fi ve high-powered sessions, took off successfully. NATIONAL CONCLAVE ON SMART TECHNOLOGIESThe conclave, held on August 22-23, 2015, in Hyderabad, brought together international experts on technologies and smart cities along with urban development offi cials from across India.

PROMISING CITIES SEMINAR, THANEAfter a successful fi rst Promising Cities Seminar in Ahmedabad, Smart Cities Council India kicked off its second seminar in Thane last month.

www.ConstructionWorld.in

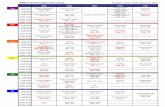

IN THIS ISSUE12 Index

16 Desk

18 Letters

20 News & Events

22 Project Update

32 Power Update

36 Transport Update

46 Cement Update

48 Equipment Update

152 Executive Profi les

161 Diary

162 Tenders

164 Product Parade

166 Contracts Awarded

168 Building Material

Prices

172 Advertisers’ Index

174 Newsmakers

In the October issue, Look out for!Features: • Safety & Automation • Crushing & Screening Equipment

• Airports • Tiles & Floorings

120

10 Construction World September 2015

148

140144

CW PROPERTY TODAY...131

Cover Story

CITIES IN THE MAKING

With established metros reaching saturation point, Tier-II and Tier-III cities could hold the promise of a better quality of life. CW gives you a realty check.

Special Project-Green SUSTAINING BY

RECYCLING Divyasree Omega C, a building hosting giant IT offi ces in Madhapur, Hyderbabad, recently received a Gold rating from the IGBC.

Guest ArticleMAKE IT MEGA

Niranjan Hiranandani, Managing Director, Hiranandani Communities, argues that the new development plan for Mumbai should be a vision document with a holistic view.

REAL ESTATE UPDATE

PROPERTY RATES

132

150

Photo courtesy: ATS Infrastructure Ltd

16 Construction World September 2015

/CWmagazine

EDITO

R’S

DES

K

Group Managing EditorFalguni [email protected]

Sr. Assistant EditorShriyal [email protected]

Managing DirectorPratap Padode

DGM - SalesSoumo [email protected]

National Sales ManagerSandip Chalke [email protected]

[email protected]: 022-2419 3000/6526 7838.

Published by: ASAPP Media Pvt Ltd, A-303,Navbharat Estates, Zakaria Bunder Road, Sewri (West), Mumbai-400 015. Tel: 022-2419 3000.Fax: 022-2417 5734.

Branch Offi cesDelhi: Tel: 011-4656 1818.Bengaluru: Tel: 080-4095 3423/4095 9611.Pune: Tel: 020-2605 2987/6602 5990.Chennai: Tel: 044-4299 1234.Kolkata: Tel: 033-6450 0465/6456 0011.Ahmedabad: Tel: 079-2646 4890/2656 0872.Vadodara: Mobile: 098242 64071/70434 94071.

Representative Offi ces• Austria, Switzerland & GermanyGunter Schneider - [email protected]

All rights reserved. While all efforts are made to ensure that the information published is correct, Construction World holds no responsibility for any unlikely errors that might occur.

Printed and Published by Tarun Pal on behalf ASAPP Media Pvt Ltd, printed at Indigo Press (India) Pvt Ltd, Plot No 1C/716, Off Dadoji Konddeo Cross Road, Between Sussex and Retiwala Ind. Estate, Byculla (East), Mumbai-400 027 and Published from A-303, Navbharat Estates, Zakaria Bunder Road, Sewri (West), Mumbai-400 015. Editor : Pratap Vijay Padode.

CONSTRUCTION WORLD is a member of INS. Subject to Mumbai jurisdiction only.

The information on products and projects on offer is being provided for the reference of readers. However, readers are cautioned to make inquiries and take their decisions on purchase or investment after consulting experts on the subject. CONSTRUCTION WORLD holds no responsibility for any decision taken by readers on the basis of information provided herein.

To subscribe to the digital edition of CW India log on to:www.ConstructionWorld.in/Magzter

/ConstructionWorldmagazine

/CWmagazine

Construction Worldwww.ConstructionWorld.in

www.ConstructionWorld.in EDITOR’S DESK

Follow me on twitter @PratapPadode

he global gloom turned into panic as the Chinese stock markets tumbled 8.5 per cent on August 24, paving way for speculation that China has lost its stem and is heading for a major slowdown. Its manufacturing index is at a 77-month low and its auto, cement and steel industry growth has

turned negative. The Indian stock markets too, caught the cold, as the Chinese markets sneezed. Luckily, it turned out to be a minor ailment and the markets began recovering their losses. The progress of the monsoon, movement of the rupee against the dollar, crude oil prices and auto sales numbers will be key factors determining the trend on the bourses.

Realising that private capital is shy considering a gloomy economic picture, the government has taken upon itself to provide the triggers. It has already spent nearly a quarter of plan funds in the first three months of the fiscal year, the highest pace of spending since 2008-09. The Finance Ministry has already directed ministries and departments to go full speed ahead on budgeted expenditure in line with government thinking. The minister said capital expenditure increased by about 17.8 per cent in the first quarter as the government looks to target 8 per cent growth this year. Public spending has indeed outstripped private investment.

India needs to seize the moment to emerge as a manufacturing hub as China slows. The current outlook just in, indicates a marginally positive report: GDP growth for the first quarter of the current financial year grew at 7 per cent versus 6.7 per cent in the previous year. Manufacturing growth slowed down to 7.2 per cent versus 8.4 per cent. Agricultural growth also slowed down to 1.9 per cent versus 2.6 per cent. However, foreign direct investments are up 30 per cent from a year earlier. Collections of indirect taxes indicate that there are green shoots of recovery. In the words of the finance minister, this has created an “enabling situation, wherein we are in a position to spend more. The government will spend Rs 70,000 crore, raised from additional revenue mobilisation measures, towards infrastructure.” Public spending is yet to reach the markets through tenders that get converted into orders for building materials and equipment. Mr FM, we are waiting for the green shoots to grow beyond the roots!

What’s more, the Ministry of Urban Development recently released the list of 98 nominated cities, with two cities yet to apply. Over the next three years, these 100 cities will take part in a competition to receive funds from the Centre on the path to becoming ‘smart cities’. The announcement of these 100 cities – covering 24 capitals, 64 small and medium category cities and at least one city in every state and union territory – has been rolled out under a time-bound plan. Although the impact of this mission will be felt in 2016-17, it is addressing a compelling need to fortify our cities, which are crumbling under the pressure of migration. The return on this investment is high as cities generate 60 per cent of the GDP and take only 0.6 per cent of the GDP. This will lead to opportunities in water management, waste management, mobility management, power-efficient equipment, solar power generation systems, security management, HVAC management, and so on.

The 10th CW Architect & Builder (CWAB) awards were celebrated on August 21, in pomp and splendour with India’s best architects and builders celebrating their glory by walking the ramp and striking a victory pose. A room full of winners has an energy that can send spirits soaring and this is precisely what is needed for our infrastructure industry, which is spending more time and effort with bankers than on sites building assets. In order to get the infrastructure story back on track, while we may have new investors like Canadian realty investor Brookfield, which snapped up Gammon Infra’s road assets, arbitration and dispute resolution should be made into a fast-track programme to secure a better future.

Shoot beyond the roots

T

100 Construction World September 2015

FEATURE Precast & Precast Technology

recast technology has been a fi xture of Indian infrastructure for decades now. So much so that precast segments have become the default choice in urban

infrastructure projects, particularly for elevated metro rails, expressways and grade separators.

“What’s changed in the past fi ve years or so is that several construction companies and real estate developers have started constructing precast concrete buildings, and the Indian Government has launched several precast housing projects,” says Bob van Gils, Director, Van Boxsel Engineering Pvt Ltd, a structural engineering fi rm providing consultancy services in the fi elds of structural analysis and design and detailing of precast buildings. “Acceptance is gradually growing for precast sections in building construction,” agrees P Surya Prakash, President, Pre-Engineered Structures Society of India.

Next, Van Gils expects Indian developers to use precast for high-end residential buildings, especially with the use of precast sandwich panels with excellent fi nishing. In fact, Van Boxsel Engineering is kick-starting this trend. It is behind BCC Infrastructures’ Bharat City project in Ghaziabad and Sobha’s

Sobha Dream Acres project in Bengaluru. “Both are large-scale residential developments with a combined fl oor area of over 10 million sq ft,” he adds.

So, who is adopting precast?“Delhi and Bengaluru are leading the

residential precast building trend,” says Laxman Wadhwani, General Manager, Peiko, a provider of joints and connections for precast members.

“In Delhi, Supertech, Jindal Realty,

Amrapali and BCC Infrastructures are some developers engaged in precast construction. BG Shirke has bagged a Delhi Development Authority affordable housing scheme project entailing the construction of 120,000 fl ats,” observes Wadhwani. “Brigade Group and KEF Holdings are active in Bengaluru. Omkar Developers has opted for precast technology in Mumbai. Shapoorji Pallonji and L&T are leading precast construction companies.”

Speedy constructionWhat’s driving the precast

construction trend?“Continuing labour shortages and the

poor delivery of conventional solutions are driving demand for precast segments for infrastructure projects,” says Surya Prakash.

Developers gain better control over their projects by going the precast way, according to Van Gils. “Shortage of construction workers and challenges in completing building projects with the conventional technology are the main reasons for developers to explore new building technologies,” he adds. “Precast construction makes it possible to work with a relatively small construction team and achieve high speed and get excellent quality output.”

“Precast construction can cut construction time by half vis-à-vis conventional construction, as long as the moulds are manufactured in good time and the elements kept ready on site for erection,” says Rajendra Varma, Director, Omkar Realtors & Developers, which has made use of precast construction for Pragati Towers, a high-rise residential project in Bhoiwada, Mumbai.

“Precast construction can save 60 per cent of construction time,” opines Dr Anil Kumar Sharma, Chairman & Managing Director, Amrapali

• Demand drivers: Labour shortage and poor delivery of con-ventional solutions are driving demand for precast segments.• Precast potential: To grow tenfold in the coming decade.• It can save 60% of construction time.• Suitable for all types of construction – high rise, low rise, villas, parking lots, commer-cial construction, etc.

QUICK BYTESPCASTING SUCCESSPrecast technology is poised to make inroads in the Indian building construction sector to the advantage of developers and occupants.

Construction companies and real estate developers have started constructing precast concrete buildings and the

government has launched several precast housing projects.

Phot

o co

urte

sy:

VM

E P

reca

st

September 2015 Construction World 101

www.ConstructionWorld.in

Group. Amrapali has adopted precast technology for Amrapali Dream Valley and Amrapali Verona Heights in Greater Noida (West). “Precast technology speed ups construction because we cast all the structural units in our factory while we work on the foundation,” he explains. “We transport precast units to site using fl at bed trailers or (A) frame. We erect the units on site with the help of mobile cranes or tower cranes, causing minimal site disruption.”

And M Karthik, Director, VME Precast Pvt Ltd, tells us, “Precast wall panels eliminate the need for plastering. Windows can be prefi xed, thus saving time. Electrical conduits can be inbuilt. Using precast beams and columns eliminates the time involved in shuttering and scaffolding.”

Advantage precastVME Precast set up an automated

precast factory in 2008, in partnership with Finnish companies Valkeakosken Betoni, an experienced manufacturer of precast elements, and Elematic, a leading supplier of precast concrete

machinery. Having successfully delivered numerous precast buildings to different clients, VME Precast established VME Realty, a company committed to precast construction.

“We want more people to benefi t from precast building construction. Fast delivery and structural longevity are some of its better known advantages. Precast can also help build more spacious interiors,” opines Karthik, and explains how: “Precast load bearing wall panels are typically 150 mm thick while partition wall panels are 100 mm thick; conventional brick walls are 200 mm thick. Using precast walls thus helps achieve more fl oor space. Also, using pre-stressed beams and hollow core slabs opens up large spans, meaning more inner unobstructed space for building occupants.”

Precast can additionally help lower the air-conditioning needs of a building by 30 per cent, according to Karthik, by the use of sandwich wall panels with insulation and fi lling cool ambient air in the holes of precast hollow core slabs.

The current trend is for developers to place orders

for project-specifi c precast sections.

Using precast eliminates the need for plastering

and time involved in shuttering

and scaffolding."- M Karthik, Director, VME PRECAST PVT LTD

We cast all the structural units in our factory while

we work on the foundation, speeding

up construction.” - Dr Anil Kumar Sharma, Chairman &

Managing Director, AMRAPALI GROUP.

Phot

o co

urte

sy:

VM

E P

reca

st

102 Construction World September 2015

Limited market = In-house supply

With just a few precast plants dotting the country, the market for precast products is yet to mature. The current trend is for developers to place orders for project-specifi c precast sections.

“Manufacturing of customised sections dominates the precast industry. However, precast as a concept, will only take off when the pre-engineered precast solutions market grows, as that will lower the cost of precast construction,” says Surya Prakash.

Greater availability of off-the-shelf building solutions in completely knocked down condition and conforming to standardised plans would pave the way for the construction of structures with factory-made fi nishes. “Now is the right time for more suppliers of general precast sections to enter the market,” says Surya Prakash. He has a suggestion for

suppliers eyeing a bigger market share: “With each state implementing part of the Centre’s plan to provide Housing for All by 2022, there is tremendous scope for precast component suppliers to start manufacturing sections conforming to the standardised plans of each state. This project alone envisages the construction of 12 crore housing units. Precast business has the potential to grow tenfold in the coming decade.”

With less than 1 per cent of residential building construction being precast, there’s plenty of scope for adoption to grow, agrees Wadhwani.

Some developers adopting the technology are relying on their own precast construction division. As an example, Amrapali has set up a precast factory at Kasna in Greater Noida with an installed capacity of 800,000 sq m for pre-stressed hollow core slabs and 800,000 cu m for wall panels and other Precast construction

can cut construction time by half vis-à-vis

conventional construction.” - Rajendra Varma, Director,

OMKAR REALTORS & DEVELOPERS

Cost comparison: Precast construction vs conventional construction

“Precast exceeds conventional commercial construction costs by 10 to 20 per cent and residential construction by 30 per cent,” says Dinesh Kumar, Technical Manager, Teemage Precast India.

“Precast construction is 15 to 20 per cent higher than conventional construction,” says M Karthik, Director, VME Precast Pvt Ltd.

“While precast costs about 10 per cent more than conventional construction upfront, it saves on indirect maintenance cost. Precast structures have a life of at least 50 years, and are earthquake and weather-resistant,” opines Dr Anil Kumar Sharma, Chairman & Managing Director, Amrapali Group.

“In the long term, precast construction costs the same as conventional construction for structures with many repetitive units,” says Rajendra Varma, Director, Omkar Realtors & Developers.

FEATURE Precast & Precast Technology www.ConstructionWorld.in

Manufacturing of customised sections dominates the precast industry.

Precast construction makes it possible to

achieve high speed and get good quality output."

- Bob van Gils, Director, VAN BOXSEL ENGINEERING PVT LTD

Acceptance is gradually growing for precast sections in building

construction.” - P Surya Prakash, President, PRE-ENGINEERED STRUCTURES

SOCIETY OF INDIA

Phot

o co

urte

sy:

Van

Box

sel E

ngin

eerin

g

Cadbury Choclate factory, Chittoor

L V Prasad Eye Hospital, Hyderabad

D.E.Shaw & Co, HyderabdIGATE, Hyderabad

Constructing PRECAST Buildings in every walk of human life• State of the art factory with European

production technology

• department having international experience

• Promoted by Indian-Israeli International joint venture

• Successfully completed many challenging precast projects

Commercial | Residential | Institutional | Industrial | Stadium

Precast turnkey solution from design to erection

Preca Solutions India Pvt Ltd. Plot #6, D. No.: 2-9/5/6, Venkatasai Gateway, Green Land Colony, Gachi Bowli. Hyderabad — 500032

Phone: +91 040 230 00664 Fax: +91 40 230 00669 Email: [email protected]

www.preca.in

WE

AR

E A

GRE

EN PRODUCT

Quality Costa aLabor

104 Construction World September 2015

structural members like columns, beams, staircases, T-beams, etc. What prompted Amrapali to take this route?

“We set up Asia’a largest precast factory to guarantee ourselves and our customers the adequate and timely supply of quality precast parts. Manufacturing in a strictly controlled environment ensures quality. Having our own factory also

accords us greater flexibility over the choice of surface finishes and colours, which means our architects and designers can create buildings of unique character,” explains Dr Sharma.

Precast myth: It limits designPrecast construction involves the

transportation of readymade sections to site. Some developers feel this could limit the design possibilities of buildings. “It doesn’t,” clarifies Dinesh Kumar, Technical Manager, Teemage Precast India, a company manufacturing precast walls, beams, columns, stairs and hollow core slabs for buildings. “We can transport sections of width 2.4 m to 3 m and length 12 m to 15 m (or height). Typically, this never imposes any limitation on design because most buildings fit this scheme,” he elaborates.

“Precast technology presents no limitations on the design or height of the structure. We have successfully implemented a precast fins based structure for Infosys in Chennai, and a 14 floor hotel building of 300,000 sq ft area, the Novotel Ibis Combo Hotel in Chennai,” says Karthik.

“Precast technology is suitable for all types of construction – high rise, low rise, villas, parking lots, commercial construction, etc.” adds Dr Sharma.

Overcoming precast challenges

A often cited drawback of precast construction is the high transportation cost of the sections. One way to overcome this challenge is to transport casting tables to the site instead of the sections. Industry experts say it makes

sense to reverse the method as such for projects of 100,000 sq ft and above.

To facilitate precast construction at sites located at a distance from casting factories, Weckenmann, a provider of precast machinery solutions, has recently launched Mobile Battery Moulds, compact casting units fitted in trailers.

“Mobile Battery Moulds are mobile factories that can be easily taken to any construction site. They are also easy to assemble and remove,” explains Ans Hariharasudhan, Business Development Consultant, Weckenmann Anlagentechnik.

Another typical drawback of precast construction is the compulsion to work with a crane at site.

A crane is used to elevate the building. Ideally, it helps to have a clear 5 to10 ft around the structure. If this isn’t feasible as in constrained city areas, experienced players start at the furthest periphery and work their way to the entrance.

As long as expertise is available, precast technology brings great advantages to developers and occupants of buildings.

Transportation of readymade sections to site

never imposes any limitation on design."- Dinesh Kumar, Technical Manager,

Teemage PrecasT IndIa

Mobile Battery Moulds are easy to assemble

and remove and can be easily taken to any construction site."

- Ans Hariharasudhan, Business Development Consultant, Weckenmann anlagenTechnIk

What does successful precast construction involve?

Ans Hariharasudhan, Business Development Consultant, Weckenmann Anlagentechnik, identifies the steps for successful precast construction:

• Identify the right precast system.• Identify the right connection types.• Optimise layouts for precast.• Create an economical design.• Buy suitable machines.• Find the right supplier.

www.ConstructionWorld.in Feature Precast & Precast Technology

Fast delivery and structural longevity of precast helps build more spacious interiors and achieve

more floor space.

To share your views on the Precast & Precast Technology market in India, write in at [email protected]

Delhi and Bengaluru are leading the residential

precast building trend.” - Laxman Wadhwani, General Manager, PeIko

- charu bahri

Phot

o co

urte

sy:

Van

Box

sel E

ngin

eerin

g

This article was featured in September 2015 CONSTRUCTION WORLD, India’s first B2B Construction magazine from the house of ASAPP Info Global Group.For more details on the magazine visit www.ConstructionWorld.in or mail: [email protected] for subscription and [email protected] to advertise.