Customer Story Leggett & Platt’s Enterprise Procurement System.

-

Upload

michael-chase -

Category

Documents

-

view

225 -

download

0

Transcript of Customer Story Leggett & Platt’s Enterprise Procurement System.

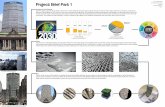

Customer StoryLeggett & Platt’sEnterprise Procurement System

Page 2

Business Profile

• 120 year old diversified manufacturer• Residential Furnishings

• Commercial Fixtures & Components

• Aluminum Products

• Industrial Materials

• Specialized Products

Page 3

Sample Products

Residential Furnishings

Commercial Fixtures & Components

Aluminum Products

Industrial

Materials

Specialized

Products

Page 4

Business Profile

• $5.5 Billion revenue

• 30 divisions

• 300 branches

• 33,000 employees

• Significant acquisition growth• 160 in last 10 years

• Very decentralized• Operations

• Culture

Page 5

Challenge with legacy environment

• Distributed transaction system• Inability to share information across branches

• Inconsistent reference data• Multiple vendor masters

• Non-standard UOM codes, terms codes, etc.

• Inability to get actual price paid• Paper-based system of record

• Manual matching of PO, Receipts, Invoices

• Undisciplined and inefficient business process• Distribution of 6 part PO forms

• Branch manager signs every PO and Invoice

Page 6

Program Mission & Objectives

Establish a disciplined purchasing process and implement a single technology solution to enable Leggett & Platt branches to achieve cost savings through leveraged Strategic Sourcing and elimination of non-value-added activities.

• Streamline and automate the business process

• Improve quality of procurement data

• Share purchasing information across the enterprise

• Increase Strategic Sourcing productivity

• Improve implementation of supply contracts

• Lower COGS – direct and indirect materials

Page 7

PeopleSoft Enterprise 8.8 Modules

• Strategic Sourcing

• eProcurement

• Purchasing

• Accounts Payable

• eSupplier Connection

• eSettlement

• EPM Supplier Rating System

Page 8

Implementation Challenges

• Integrations R Us

• Branch Setup• Business Units

• Vendor Locs

• Ship To

• Item Rationalization

• Subcontract POs

• Automotive Release Schedules

• Strategic Sourcing Distribution

• Query Strategy

Page 9

Rollout Strategy

• Roll out to branches by Division

• 1-2 branches scheduled per week, every week, except major holidays and quarter ends

• Implementation and Support staff• 8 – Implementation

• 5 – Administration and Support

• 9-week conversion project plan• Business process review – 2 weeks

• User role definition and setup – 3 weeks

• Data scrubbing and conversion – 3 weeks

• Training and go-live – 1 week

Page 10

Implementation progress

April 2006, approximately:

• 28 Branches converted

• 30,000 PO’s dispatched

• 120,000 invoices processed

• $200,000,000 paid to 3,600 suppliers

• 750+ users• 525 Requestors

• 130 Purchasing users• 70 actively creating PO’s

• 150 Accounts Payable users• 45 actively creating vouchers

Page 11

Results

• Purchasing data is available across the enterprise.

• Data accuracy has improved.• Actual paid price, by item, is easily captured and available.

• Consistent units of measure allow for aggregation of volume data.

• Vendor master is being rationalized.

• Business process has been streamlined.• Online workflow approvals

• Electronic PO dispatch

• Automated A/P 3-way match

Page 12

Next steps

• Take it to the bottom line• Leverage improved data

• Form commodity teams

• Strategic Sourcing events

• Organizational change• Consolidated procurement activities

• Accounts Payable shared services

• Supplier portal – PO collaboration and acknowledgement

• Electronic invoice settlement

Page 13

Lessons learned

• Organization• Project team dedication

• Transition to support model

• Off-shore development• Explicit detail in requirements documentation

• Extensive QA

• Testing• Discipline and dedication

• Increase complexity of test cases

• Change Management• More about business process than software

Questions?