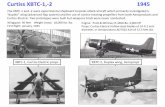

CURTISS WRIGHT Flow Control Company Target Rock · 2012-12-17 · 1.4 Certification of Received -...

Transcript of CURTISS WRIGHT Flow Control Company Target Rock · 2012-12-17 · 1.4 Certification of Received -...

Target Rock1966 E. Broadhollow RoadE. Farmingdale, NY 11735

Phone: 631.293.3800

CURTISS Fax. 631.293.6144- WRIGHT) Flow Control Company

Target Rock

November 19, 2012

U.S. Nuclear Regulatory CommissionAttn: Document Control DeskWashington, DC 20555-0001

Cc: Chief, Electrical Vendor Branch,Division of Construction Inspection and Operational Programs,Office of New Reactors

Subject: Reply to a Notice of ViolationReference: Nuclear Regulatory Commission Inspection Report NO. 99900060/2012-201

Enclosed please find the Curtiss-Wright Flow Control Company, Target Rock Divisionreply to a Nonconformances 99900060/2012-201-01, -02 and -03. These responses aredocumented on the enclosed Target Rock (TR) internal Corrective Action Report No.'s12-063-NON A, -NON B and -NON C respectively.

Please contact me if you have any questions or require any additional information.

Sincerely,

John DeBonisTR Quality Assurance Managerj [email protected] 396-4429

Enclosures:TR Corrective Action Report CAR 12-063 NON ATR Corrective Action Report CAR 12-063 NON BTR Corrective Action Report CAR 12-063 NON CTR Problem Report 071TR Problem Report 073

CWFCC-TARGET ROCK DIVISION CAR NO.: 12-063 NON ACORRECTIVE ACTION REQUEST NRC Nonconformance 99900060/2012-201-01

To: B. Maher, A Dimeo Project / Part / Serial No.: / Terminal Block

(responsible organization, dept. or individual) 205674-2Cc:

Response Due Date: 11/22/12Originator / Date: J. DeBonis 10/23/12

Reviewed by: W. Brunet 10/23/12

Description of the Nonconformance

The Nuclear Regulatory Commission (NRC) issued a Notice of Nonconformance (NON) to TR on 10/23/12. TheNON included the following nonconformance which was identified by the NRC inspection conducted at TR from9/10/12 to 9/14/12.

Criterion III, "Design Control," of Appendix B, "Quality Assurance Criteria for Nuclear Power Plants and FuelReprocessing Plants," to Title 10 of the Code of Federal Regulations (10 CFR) Part 50, "Domestic Licensing ofProduction and Utilization Facilities", states, in part, "Measures shall be also established for the selection and reviewfor suitability of application of materials, parts, equipment, and processes that are essential to the safety-relatedfunctions of the structures systems, and components,".

Contrary to the above, as of September 14, 2012, TR failed to perform a review for suitability of application ofmaterials and processes essential to the safety-related functions of the structures, systems and components as part ofcommercial grade dedication (CGD) of terminal block part number (P/N) 205674-2. Specifically, TR failed to requireverification of critical characteristics of acceptance that were identified during the technical evaluation of acommercially purchased terminal block. Electrical performance characteristics such as voltage rating, amperage rating,and dielectric rating, identified as design basis performance characteristics critical for safe operation of a solenoidvalve, were not identified on the Critical Characteristics Attribute Verification (CCAV) form or verified by the qualitycontrol inspector during receipt inspection.

This issue has been identified as Nonconformance 99900060/2012-201-01.

Immediate Action Taken to Correct the Identified Nonconformance

Extent of condition review was initiated and Problem Report PR 071 was generated............................................................................................................................................

Root Cause of the Identified Nonconformance[The reason for the noncompliance]

For Terminal Block p/n 205674-2, the method 2 dedication requirement and the attributes for electrical performancecharacteristics such as voltage rating, amperage rating, and dielectric rating, was identified on a Critical CharacteristicsAttribute Verification (CCAV) addendum page which is a separate page to the base CCAV sheet, see attachment 1.However, the format used in the current CCAV process consists of an index, a CCAV sheet and a separatelyscanned addendum to identify performance characteristics requiring verification by Method 2 commercial gradesurvey. This format did not provide the necessary visibility required to the implementing departments, i.e.: QA, QCand Purchasing and the scheduling / performance of the intended survey was missed.

Note: This CAR addresses the CCAV sheet format which caused the electrical performance characteristicverifications to be missed. PR 071 evaluates the affect on product............................................................................................................................................

Root Cause Corrective Action[The corrective steps that have been taken and the results achieved; the corrective steps that will be taken to avoidnoncompliances; and the date when corrective actions will be completed.]

QMP1014 Form 1 Rev. CPage 1

4-,CWFCC-TARGET ROCK DIVISION CAR NO.: 12-063 NON ACORRECTIVE ACTION REQUEST NRC Nonconformance 99900060/2012-201-01

All CCAV sheets have been reviewed for proper Dedication Method 2 assignments and for performance of requiredcommercial grade surveys. The CCAV sheet for Terminal Block p/n 205674-2 has been revised, see attachment 2.All other CCAV sheets will also be revised to provide clear verification methods and responsibilities for the actionsrequired. The separately scanned addendum process will be discontinued and Method 2 dedication requirementvisibility will be improved by incorporating the requirement directly into the base CCAV sheet.

Based on the review of CCAV sheets, the Approved Supplier List (ASL) has been updated to identify the suppliersrequiring a CG survey. There are no current purchase orders in place for the terminal block (P/N) 205674-2. Theapproval status for the supplier of this part has been changed to unapproved in the ASL with a special condition notedthat a commercial grade survey to verify electrical performance characteristics is required in conjunction with the nextpurchase. This temporary unapproved status in the ASL creates a system lock out which prevents the PurchasingDepartment from inadvertently placing purchase orders with this supplier.

Upon completion of the remaining CCAV revisions, training will be conducted.

The corrective actions to revise all CCAV sheets (approximately 300) and training will be completed by 6/30/13............................................................................................................................................

Other Hardware / Product Affected[Extent of condition]

Problem Report Required Yes _X_ No _

All CCAV sheets have been reviewed for proper Method 2 assignments and for performance of required commercialgrade surveys. This review identified that the CCAV sheet for pressure actuated switch P/N 200372-1 incorrectlyspecified dedication method 1 only instead of methods 1 and 2. This condition is addressed on CAR 12-063 NON C(Ref Nonconformance 99900060/2012-201-03). No other items were identified that did not have the propercommercial grade surveys performed. Therefore, although all CCAV sheets will be revised, no other hardware isconsidered affected. Also reference Problem Reports PR 071 for evaluation of affect on product.

Response Provided by:Date

QA Manager Approval: (1111A-r ////2.--/" Date

QMP1014 Form I Rev. CPage 2

TR NOMENCLATURE: TERMINAL BLOCKTR SPECIFICATION: 205674, 205675, 205676SUPPLIERS PART NO: PER DRAWINGSAFETY FUNCTION: ELECTRICAL CONNECTIONS

64k /-063 /o4I41t~tn4244 ~f p&Ioi5

"'6aseSCcr V4/'k~t

------- ----------------------------------------------------------------------------------------------------CRITICAL CHARACTERISTICS AfIRIEUTE VERIFICATION *

- ------------------------------------ --- --- --- --- --- ----- - -. - --- -- -- ---------- -- - - -------------------------- - - - --- -- -- -----

PRODUCT IDENT CHARACTERISTICSSUPPLIERDISTRIBUTORCERTIFICATE OF COMPLIANCEMARKING ON ITEM

PHYSICAL ATTRIBUTESMATERIAL COLORMATERIAL (DIALLYL PHTHALATE,GDI-30F PER MIL-M- 14)CONFIGURATIONTERMINAL IDENTIFICATIONTERMINAL SCREWSDIMENSION BOVERALL WIDTHVISUAL

PERFORMANCE CHARACTERISTICS

REOSYESYESYESYES

YESYES

YESA/R

YESYESYESYES

N/A

RE0UIEMENTMARATHON SPECIAL PRODUCTSBEYOND COMPONENTS LLC **

RECEIVED - PER DWG.PER DWG REQ'TS - 100% INSPECT

GREYMATERIAL ANALYSIS BY INFRAREDSPECTROSCOPY OR EQUIVALENT ***PER SHEET 2 OR 3MARKING PER DWGNON-MAGNETICPER SHEET 2 OR 3PER SHEET 2 OR 3SEE BELOW ****

I I

* REF TRP 5041 PARA 9 FOR INSPECTION ME iHODOLOGY UNLESS OTHERWISE SPECIFIED,

** DISTRI3UTER SHALL USE ORIGINAL SUPPLIER PACr•GI3 AND IT SHALL BE INTACT.

*** SAMPLES TESTED FOR MATERIALS ANALYSIS SHALL HAVE NICKEL PLATING REMOVED FROMTERMINAL SCREWS AND PLATES TO VERIFY BRASS MATERIAL.

**** LINEAR INDICATIONS ON END SURFACE POSITIONS OF THE TERMINAL BLOCK WHICH DO NOT

EXTEND ACROSS THE FUL THICKNESS ARE ACCEPTABLE.

REVISIONS/APPROVAL I TARGET ROCK CORPORATION

E: ADDED BEYOND COMPONENTS AS CRITICAL CHARACTERISTICS/AUTHORIZED DISTRIBUTOR I ATTRIBUTE VERIFICATION4.,,- A' ?U/iz 7/00

y" c~•~ 9 3/z-r/0 - CCAV # 205674, 205675, 205676

... :'/o SHEET I OF 3 REV: E

K.:\Eng\WP\CCAV\'205674-205676.wpd

4h /21-0463 AJOIV,

DESIGN BASED CRITICAL CHARACTERISTICS Lt,. 4c4,

ITEM DESCRIPTION OR NOMENCLATUREt TERMIKAL BLOCK

SAFETY RELATED FUNCTIONs PROVIDE MEANS OF ELECTRICAL INTERCONNECTIONINSULATED FROM GROUND AND FROM ADJACENTTERMINAL POINTS.

APPLICATION, GENERIC _X

ENVIRONMENT: HARSH _X

SPECIFIC

MODERATE

DESIGN BASED CRITICAL CHARACTERISTICS I VERIFIED BY------------------------------------------------------------------------

PERFORMANCE (VOLT.& CURRENT RATING) I COMMERCIAL GRADE SURVEY PLUStCONFIGURATION & DIMENSIONS I INSPECTINSULATION MATERIAL I MARKING & MATERIALS ANAL.

ENVIRONMENTAL INTEGRITY (MATERIAL)INTERFACE DIMENSIONSSUPPLIER AND PART NUMBER

I MATERIALS ANAL1 INSPECT1 REVIEW C OF CI

DEDICATION METHODS: METHOD 1, SPECIAL TESTS & INSPECTIONSMETHOD 2, COMMERCIAL GRADE SURVEY

------------------------------------------------------------------------

REVISIONS I APPROVAL I TARGET ROCK CORPORATION--------------------------------------- +----------------------------------------------------

AuREVISED CONTENT I PREP: JGS 1 DESIGN BASED CRITICAL3GS 1/25/93 1 DATE. //j/92 I CHARACTERISTICS

1 I APP: + -------------------------------I DATE: 2/_/13 I CCAV#: 205674 thru 205676

1 ADDENDUM 11 SHEET 1 of 1 REV: A

-----------------------------------------------------------------------TERMINAL BLOCKS 205674 THRU 205676

TR DESCRIPTION: TERMINAL BLOCK TR PART NUMBER: 205674, 205675, 205676

SAFETY FUNCTION: PROVIDE MEANS OF ELECTRICAL INTERCONNECTION INSULATED FROM GROUND ANDFROM ADJACENT TERMINAL POINTSSUPPLIERS PART NO: PER DRAWING APPLICATION: GENERIC X SPECIFIC__

ENVIRONMENT: HARSH X MODERATESAMPLE PER QMP 1010: YES X NO: (100% INSPECTION)

,,?, 12,-063I METHOD OF METHOD 1 -page 1 5X d CAOV/fI DEDICATION: t ANDz w,1 METHOD 2 - page 2

A. CRITICAL CHARACTERSTICS

METHOD 1 ATTRIBUTE VERIFICATION

CC# CRITICAL REQUIREMENT VERIFY BY COMPLETED BYCHARACTERSTIC (SIGN & DATE OR CERT #)

I PRODUCT IDENTIFICATION1.1 Manufacturer Marathon Special Products QC Inspection1.2 Distributor Beyond Components LLC QC Inspection1.3 Marking Per Drawing QC Inspection1.4 Certification of Received - per Drawing. QA Cert Review

Compliance ,,__II PHYSICAL ATTRIBUTES _

11.1 Material Color Grey QC Inspection11.2 Material Diallyl Phthalate, GDI-30F per QA Independent

MIL-M-14 Analysis11.3 Terminal Marking per Drawing. QC Inspection

Identification

11.4 Terminal Screws Brass (remove plating off one piece) QC Alloy IDand Plate Material (Alloy identification by Niton XRF or

equivalent)11.5 Dimension B Per Attached Sheet QC Inspection11.6 Overall Width Per Attached Sheet QC Inspection11.7 Visual Linear Indications on end surface QC Inspection

positions of the terminal block whichdo not extend across the full thicknessare acceptable.

III PERFORMANCE CHARACTERSTICSII1.1 None N/A N/A - N/A

REVISIONS CCAV # 205674, 205675, 205676F: Changed to new format

SHEET 1 OF 5 REV: F

4

TR DESCRIPTION: TERMINAL BLOCK TR PART NUMBER: 205674, 205675, 205676

METHOD 2 ATTRIBUTE VERIFICATION

CC# CRITICAL REQUIREMENT VERIFY BY COMPLETED BY:CHARACTERSTIC (TR AUDIT #)

I PRODUCT IDENTIFICATION

1.1 TR PART # 205674-1 THRU 16 QA/ENG205675-1 THRU 16 Commercial205676-1 THRU 16 Grade Survey

II __ _PHYSICAL ATTRIBUTES11.1 None N/A N/A N/AIII PERFORMANCE CHARACTERSTICS

111.1 Voltage and Current Per Attached Sheet. QA/ENGRating Commercial

Grade SurveyL

6A k / 2 - (--) (.- .3IVO AfA

Ak -ý& -37-6- 622-

B. DEDICATION REVIEW AND APPROVAL

Dedication of the above commercial grade items(s) will provide reasonable assurance that the item meets theapplicable specifications for the intended use.

Enginee/ring Preparer Date6-jI

. .J I

Quality Assurance Review Date

Engineering Approval Date

REVISIONS CCAV # 205674, 205675, 205676F: Changed to new format

SHEET 2 OF 5 REV: F

4

CWFCC-TARGET ROCK DIVISION CAR NO.: 12-063 NON BCORRECTIVE ACTION REQUEST NRC Nonconformance 99900060/2012-201-02

To: B. Maher, A Dimeo Project / Part / Serial No.: / Terminal Block

(responsible organization, dept. or individual) 205674-2Cc:

Response Due Date: 11/20/12Originator / Date: J. DeBonis 10/23/12

Reviewed by: W. Brunet 10/23/12

Description of the Nonconformance

The Nuclear Regulatory Commission (NRC) issued a Notice of Nonconformance (NON) to TR on 10/23/12. TheNON included the following nonconformance which was identified by the NRC inspection conducted at TR from9/10/12 to 9/14/12.

Criterion VII, "Control of Purchased Material, Equipment, and Services" of Appendix B to 10CFR Part 50, states inpart, "Measures shall be established to assure that purchased material, equipment, and services, whether purchaseddirectly or through contractors and subcontractors, conform to the procurement documents. These measures shallinclude provisions, as appropriate, for source evaluation and selection, objective evidence of quality furnished by thecontractor or subcontractor, inspection at the contractor or subcontractor source, and examination of products upondelivery."

Section 9.0, "Inspection (Dedication of CG items by method 1)," of Target Rock Report No. 5041 (TRP-5041),"Dedication requirements for Commercial grade Items," Revision S, dated August 23, 2012, states in part, that forplated or coated parts, when an unplated sample is not provided, per paragraph 4.1.2, remove plating/coating from oneitem per lot to enable alloy identification.

Contrary to the above, as of September 14, 2012, TR failed to adequately verify that commercial items received fromits suppliers conformed to the applicable specification requirements and failed to validate required criticalcharacteristics of acceptance during CGD receipt inspection and testing of terminal block P/N 205674-2. Specifically,TR did not perform the necessary inspection to verify that the material for the terminal screws and plate met thematerial acceptance criteria in accordance with the requirements of TRP-5041 and as specified in the terminal blockCCAV form No. 205674, 205675, and 205676.

This issue has been identified as Nonconformance 99900060/2012-201-02.

Immediate Action Taken to Correct the Identified Nonconformance

The screw and plate material was verified by XRF alloy ID to be brass as required by the Critical CharacteristicAttribute Verification (CCAV) sheet. Additionally two other lots of the same part were retrieved from stock andtested with satisfactory results. Problem Report PR 071 was generated............................................................................................................................................

Root Cause of the Identified Nonconformance[The reason for the noncompliance]

The CCAV sheet was not sufficiently clear that the requirement for the metallic material verification was to beaccomplished at TR by XRF alloy ID. See attachment 1 for the subject CCAV sheet which imposed the metallicmaterial verification requirement by reference to a note and three asterisks at the non metallic material attribute lineand not at the terminal screw attribute line. The QC inspector incorrectly assumed the non metallic materialverification performed by an independent lab also included the analysis of the metallic screw and plate material andtherefore did not perform an alloy ID test during CGD receipt inspection.

Note: This CAR addresses the CCAV sheet format which caused the material verification to be missed. PR 071evaluates the affect on product............................................................................................................................................

QMP1014 Form 1 Rev. CPage 1

4

CWFCC-TARGET ROCK DIVISION CAR NO.: 12-063 NON BCORRECTIVE ACTION REQUEST NRC Nonconformance 99900060/2012-201-02

Root Cause Corrective Action[The corrective steps that have been taken and the results achieved; the corrective steps that will be taken to avoidnoncompliances; and the date when corrective actions will be completed.]

This CCAV sheet has been revised to more clearly identify the methods and responsible departments for verificationof each of the critical attributes listed, see attachment 2. Additionally, all CCAV sheets will be revised to provideclear verification methods and responsibilities for the actions required as well as a column to clearly documentcompletion of each verification action.

Upon completion of the CCAV revisions training will be conducted.

The corrective actions to revise all CCAV sheets (approximately 300) and training will be completed by 6/30/13.

Other Hardware / Product Affected[Extent of condition]

Problem Report Required Yes _X_ No _

Two other lots of the same part were retrieved from stock. QC verified the metallic screw and plate material by theXRF alloy ID method and determined each part tested was in accordance with CCAV sheet material requirements.Additionally, Engineering and QA reviewed the index of all other CG parts for other electrical parts with similarmetallic material verification requirements and provided QC a list of four additional part numbers for follow upinspections. QC verified the metallic materials on each of these parts by the XRF alloy ID method and determinedthe material for each part tested was in accordance with CCAV sheet requirements. Therefore, although all CCAVsheets will be revised, no other hardware is considered affected. Also reference Problem Report PR 071 forevaluation of affect on product.

Response Provided by:

QA Manager Approval:

,,- lh/hzDate

Date/

QMP1014 Form 1 Rev. CPage 2

4

TR NOMENCLATURE: TERMINAL BLOCKTR SPECIFICATION: 205674, 205675, 205676SUPPLIERS PART NO: PER DRAWTNGSAFETY FUNCTION: ELECTRICAL CONNECTIONS

21~i 1- 6 63 WA/t'IBl A

------------------------------------------------------------------- -------------------------------------CRITICAL CHARACTERISTICS ATTRIBUTE VERIFICATION *

--------------------------- ---------------------.----.--------------------

.PRODUCT IDENT CHARACTERISTICSSUPPLIERDISTRIBUTORCERTIFICATE OF COMPLIANCEMARKING ON ITEM

PHYSICAL ATTRIBUTESMATERIAL COLORMATERIAL (DIALLYL PHTHALATE,GDI-30F PER MIL-M-14)CONFIGURATIONTERMINAL IDENTIFICATIONTERMINAL SCREWSDIMENSION BOVERALL WIDTHVISUAL

PERFORMANCE CHARACTERISTICS

YESYESYESYES

YESYES

YES

A/RYESYESYESYES

N/A

REQUIrmEMENTMARATHON SPECIAL PRODUCTSBEYOND COMPONENTS LLC **RECEIVED - PER DWG.PER DWG REQ'TS - 100% INSPECT

GREYMATERIAL ANALYSIS BY INFRAREDSPECTROSCOPY OR EQUIVALENT *PER SHEET 2 OR 3MARKING PER DWGNON-MAGNETICPER SHEET 2 OR 3PER SHEET 2 OR 3SEE BELOW ****

-------------------------- L------L ------------------- ~----.-------------------

* REF TRP 5041 PARA 9 FOR INSPECTION METHODOLOGY UNLESS OTHERWISE SPECIFIED.

** DISTRIBUTER SHALL USE ORIGINAL SUPPLIER PACKAGING AND IT SHALL BE INTACT.

*** SAMPLES TESTED FOR MATERIALS ANALYSIS SHALL HAVE NICKEL PLATING REMOVED FROMTERMINAL SCREWS AND PLATES TO VERIFY BRASS MATERIAL.

**** LINEAR INDICATIONS ON END SURFACE POSITIONS OF THE TERMINAL BLOCK WHICH DO NOTEXTEND ACROSS THE FUL THICKNESS ARE ACCEPTABLE.

REVISIONS/APPROVAL 1 TARGET ROCK CORPORATION------------------------------------------------------------------

E: ADDED BEYOND COMPONENTS AS I CRITICAL CHARACTERISTICS/AUTHORIZED DISTRIBUTOR I ATTRI13UTE VERIFICATION

-------- ------- -3/z--------------- --------------------~ ~ /2-/cY( ICCAV # 205674, 205675, 205676

------ jSHEET I OF 3 REV: E

K:\Eng\WPFCCAV\205674-205676.wpd

TR DESCRIPTION: TERMINAL BLOCK _ TR PART NUMBER: 205674, 205675, 205676

SAFETY FUNCTION: PROVIDE MEANS OF ELECTRICAL INTERCONNECTION INSULATED FROM GROUND ANDFROM ADJACENT TERMINAL POINTSSUPPLIERS PART NO: PER DRAWING APPLICATION: GENERIC_X_ SPECIFIC

ENVIRONMENT: HARSH X MODERATESAMPLE PER QMP 1010: YES X NO: (100% INSPECTION)

\

METHOD OF METHOD 1 -page 1

DEDICATION: ANDI I METHOD 2 - page 2

S6,49 12-Ob -A/OA/2

9c4 -tA. CRITICAL CHARACTERSTICS

METHOD 1 ATTRIBUTE VERIFICATION

CC# CRITICAL REQUIREMENT VERIFY BY COMPLETED BYCHARACTERSTIC (SIGN & DATE OR CERT #)

I PRODUCT IDENTIFICATION1.1 Manufacturer Marathon Special Products QC Inspection1.2 Distributor Beyond Components LLC QC Inspection1.3 Marking Per Drawing QC Inspection1.4 Certification of Received - per Drawing. QA Cert Review

Compliance

II PHYSICAL ATTRIBUTES11.1 Material Color Grey QC Inspection11.2 Material Diallyl Phthalate, GDI-30F per QA Independent

MIL-M-14 Analysis11.3 Terminal Marking per Drawing. QC Inspection

Identification

11.4 Terminal Screws Brass (remove plating off one piece) QC Alloy IDand Plate Material (Alloy identification by Niton XRF or

equivalent)

11.5 Dimension B Per Attached Sheet QC Inspection11.6 Overall Width Per Attached Sheet QC Inspection11.7 Visual Linear Indications on end surface QC Inspection

positions of the terminal block whichdo not extend across the full thicknessare acceptable.

III PERFORMANCE CHARACTERSTICS111.1 None N/A N/A N/A

REVISIONS CCAV # 205674, 205675, 205676F: Changed to new format

SHEET 1 OF 5 REV: F

TR DESCRIPTION: TERMINAL BLOCK I TR PART NUMBER: 205674, 205675, 205676

METHOD 2 ATTRIBUTE VERIFICATION

CC# CRITICAL REQUIREMENT VERIFY BY COMPLETED BY:CHARACTERSTIC (TR AUDIT #)

I PRODUCT IDENTIFICATION1.1 TR PART # 205674-1 THRU 16 QA/ENG

205675-1 THRU 16 Commercial205676-1 THRU 16 Grade Survey

II PHYSICAL ATTRIBUTES11.1 None N/A IN/A N/AIII PERFORMANCE CHARACTERSTICS111.1 Voltage and Current Per Attached Sheet. QA/ENG

Rating CommercialGrade Survey

ýK 2- -ýb' 363 -0/jjý

/1,49/u/5ge 2

2- _2

B. DEDICATION REVIEW AND APPROVAL

Dedication of the above commercial grade items(s) will provide reasonable assurance that the item meets theapplicable specifications for the intended use,

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 2-

Engineering Preparer DateI ,2 ¢ 1 •-•,

Qualit'/Assurance Review Date

Engineering Approval Date

REVISIONS CCAV # 205674, 205675, 205676F: Changed to new format

SHEET 2 OF 5 REV: F

CWFCC-TARGET ROCK DIVISION CAR NO.: 12-063 NON CCORRECTIVE ACTION REQUEST NRC Nonconformance 99900060/2012-201-03

To: B. Maher, A Dimeo Project / Part / Serial No.: / Terminal Block

(responsible organization, dept. or individual) 205674-2, Pressure Switch 200372-1Cc:

Response Due Date: 11/20/12Originator / Date: J. DeBonis 10/23/12

Reviewed by: W. Brunet 10/23/12

Description of the Nonconformance

The Nuclear Regulatory Commission (NRC) issued a Notice of Nonconformance (NON) to TR on 10/23/12. TheNON included the following nonconformance which was identified by the NRC inspection conducted at TR from9/10/12 to 9/14/12.

Criterion VII, "Control of Purchased Material, Equipment, and Services," of Appendix B to 10 CFR Part 50, states inpart, "Measures shall be established to assure that purchased material, equipment, and services, whether purchaseddirectly or through contractors and subcontractors, conform to the procurement documents. These measures shallinclude provisions, as appropriate, for source evaluation and selection, objective evidence of quality furnished by thecontractor or subcontractor, inspection at the contractor or subcontractor source, and examination of products upondelivery.'

Section 7.3.200 "Supplier Evaluation and Selection," of the Target Rock QMP-1023, "Energy Products NuclearQuality Assurance Manual, Edition 9," Revision 1, dated March 16, 2012, states in part, that before the award of acontract, TR shall evaluate a supplier's capability to provide items and services in accordance with the requirements ofthe procurement documents.

Contrary to the above, as of September 14, 2012, TR failed to adequately verify that commercial items received fromits suppliers conformed to the applicable specification requirements and failed to validate required criticalcharacteristics of acceptance during CGD receipt inspection and testing of terminal block P/N 205674 and pressureactuated switch P/N 200372. Specifically, TR relied on a commercial supplier-issued certificate of conformance as thesole method to verify critical characteristics of acceptance without conducting a commercial-grade survey, sourceverification, or other surveillance of the supplier, to verify that the supplier's quality program was capable ofappropriate control of required critical characteristics.

This issue has been identified as Nonconformance 99900060/2012-201-03.

Immediate Action Taken to Correct the Identified Nonconformance

For the terminal block, TR P/N 205674, an extent of condition review was initiated and Problem Report PR 071 wasgenerated as discussed in CAR 12-063 NON A.

For the pressure switch, TR P/N 200372-1, the immediate action taken was to verify all of the critical characteristicsfor all pressure switches that were in TR stock. This included the critical characteristics identified both as part ofMethod 1 dedication (receipt inspection) and Method 2 dedication (supplier survey). All critical characteristics wereconfirmed to meet the technical requirements.

Root Cause of the Identified Nonconformance[The reason for the noncompliance]

For the terminal block, TR P/N 205674-2, the scheduling and performance of a commercial grade survey wasintended but was missed for the reasons discussed in CAR 12-063 NON A.

For the pressure switch, TR P/N 200372-1, TR Engineering currently uses two forms for dedication of CommercialGrade Items, see attachment 1. The first is the CCAV Sheet (Method 1 Dedication). This form documents the

QMP1014 Form I Rev. CPage 1

CWFCC-TARGET ROCK DIVISION CAR NO.: 12-063 NON CCORRECTIVE ACTION REQUEST NRC Nonconformance 99900060/2012-201-03

safety function, critical characteristics and the attribute verification requirements for the parts at receipt inspection.The second form is the CCAV Sheet Addenda (Method 2 Dedication). This form documents the safety function,critical characteristics and the attribute verification requirements for the parts during a commercial grade survey.For reasons unknown to TR at this time, the CCAV Sheet Addenda mistakenly states that the dedication method isMethod 1 only. However, this contradicts the reasoning to have the addenda to CCAV sheet. Since the addendastates the pressure switch is dedicated at receipt inspection, there has never been a Commercial Grade Surveyperformed on the pressure switch supplier. Regardless, having two forms to identify the critical characteristicsseems to have caused confusion with inspection and verification activities.

Note: This CAR addresses the CCAV sheet format which caused the electrical performance characteristicverifications to be missed. PR 071 and PR 073 evaluate the affect on product...........................................................................................................................................

Root Cause Corrective Action[The corrective steps that have been taken and the results achieved; the corrective steps that will be taken to avoidnoncompliances; and the date when corrective actions will be completed.]

The corrective actions for the terminal block, TR P/N 205674-2 and the pressure switch, TR P/N 200372-1 arerelated. TR Engineering has redesigned the CCAV form, listing all critical characteristics, requirements and whowill verify each characteristic. In addition, in the case of Method 2 dedication, the requirements of the CCAVaddenda will be incorporated into the CCAV sheet, thereby eliminating the need for the separate CCAV addenda.The form will clearly identify the method(s) of dedication. The Revised CCAV sheet for the pressure switch isattached and is also shown as an example of the format to be used for all others, see attachment 2.

Based on the review of CCAV sheets, the Approved Supplier List (ASL) has been updated to identify the suppliersrequiring a CG survey. There are no current purchase orders in place for the terminal block (P/N) 205674-2 or forthe pressure actuated switch P/N 200372-1. The approval status for the supplier of these parts has been changed tounapproved in the ASL with a special condition noted that a commercial grade survey to verify electrical performancecharacteristics is required in conjunction with the next purchase. This temporary unapproved status in the ASL creates asystem lock out which prevents the Purchasing Department from inadvertently placing purchase orders with thesesuppliers.

Upon completion of the CCAV revisions training will be conducted.

The corrective actions to revise all CCAV sheets (approximately 300) and training will be completed by 6/30/13.

Other Hardware / Product Affected Problem Report Required Yes _X_ No__[Extent of condition]

All CCAV sheets have been reviewed for proper Method 2 assignments and for performance of required commercialgrade surveys. No other items were identified as having similar noncompliances. Therefore, although all CCAVsheets will be revised, no other hardware is considered affected. Also reference Problem Reports PR 071 and PR073 for evaluation of affect on product.

Response Provided by: /- -.&/•r u//iLDate

QA Manager Approval: /-• /// /( /J--Date

QMP1014 Form 1 Rev. CPage 2

TR NOMENCLATURE:TR SPECIFICATION:SUPPLIERS PART NO:'SAFETY FUNCTION:

SWITCH, PRESSURE ACTUATEDTR DRAWINGMODEL NO. 608GC851PRESSURE INDICATION

6AZ2-~3 godA1

"•: "'a, ''C..CAV •-hta m~t I f _ o2

CRITICAL CHARACTERISTICS ATTRIBUTE VERIFICATION *__

PRODUCT IDENT CHARACTERISTICS

SUPPLIER

MARKING ON SWITCH

CERTIFICATE OF COMPLIANCE

PHYSICAL ATTRIBUTES

DIMENSIONS & CONFIGURATIONPRESSURE PORT

CONFIGURATIONTHREAD

ELECTRICAL RECEPTACLECONFIGURATION

THREADSHELL MATERIAL (300 SERIES SS)SEAL (HERMETIC)

INTERNAL CONFIGURATIONSWITCH P/NSWITCHWIRE INSULATION (SILICONE), POTTING

PERFORMANCE CHARACTERISTICSINSULATION RESISTANCE (500 VDC EACHCONTACT TO CASE)FUNCTIONAL

HYDROSTATIC TEST

YEST

YES

YES

YES

YES

YESYES

YES

YESYESYES

NOTEREFYESYES

NOTEYESYES

YES

REQUIREMENT

CUSTOM CONTROL SENSORS INC.

PER DWG. REQUIREMENTS (MODEL NO.NOTED ABOVE)

PER DWG.

PER DWG.7/16- 20

3 MALE CONTACTS LABELED A, B, C;SILVER METALLIC COLOR5/8 -24ALLOY IDENT.FUSED GLASS BEADS SURROUNDINGEACH CONTACTONE PER LOTMICROSWITCH I I SX22-TPOTTED WITHIN HOUSINGMATERIAL ANALYSIS

100% TEST100 MEGOHMS MINIMUMACTUATION AT 25 TO 40 PSIGINCR. PRESS; DEACTUATIONBEFORE 15 PSIG WITH DECREASINGPRESSUREHYDRO TEST PRESSURE SIDE OF SWITCHTO 2375 ± 50 PSIG FOR 10 MIN

* REFERENCE TRP 5041, PARAGRAPH 9, FOR INSPECTION METHODOLOGY UNLESS OTHERWISESPECIFIED.

- - - ------------- --------.--------------------------- - .--------------------

REVISIONS/APPROVAL TARGET ROCK CORPORATION

CAD~DEDHYDRO REQUIREMENT CRITICAL CHARACTERISTICS/ ATTRIBUTE

/? •/sbi VERIFICATIONCCAV # 200372-1

__" 1 SHEET 1 OF 1 REV: C

.4

/CAvi, 06O 3 /JO/ / C-

DESIGN BASED CRITICAL CHARACTERISTICS

ITEM DESCRIPTION OR NOMENCLATURE: PRESSURE SWITCH

SAFETY RELATED FUNCTION: Indicates oocurrance of leakage inbellows pilot actuator

APPLICATION: GENERIC SPECIFIC _X (three stage pressurerelief valve)

ENVIRONMENT: HARSH _X MODERATE

DESIGN BASED CRITICAL CHARACTERISTICS VERIFIED BY

SUPPLIER AND PART NUMBERENVIRONMENTAL INTEGRITY

WIRE INSULATIONHERMETIC CONNECTORPOTTING

VOLTAGE & CURRENT RATING

. PRESSURE SET POINTS *CONFIGURATION & DIMENSIONS

--------------------------------

INSPECT MARKING & C OF CDISASSEMBLE & MATERIALS ANAL

DISASSEMBLE & INSPECT SWITCH,INSULATION RESISTANCE TESTTRC TESTINSPECT

DEDICATION METHODS: METHOD I ISPECIAL TESTS AND INSPECTIONS

REMARKS: * Exact set pressure points not critical to detectleakage

----------------------------------- - -- - -----------------

REVISIONS : APPROVAL : TARGET ROCK CORPORATION--------------------------------- ---------------------------------------A:ADDED VERIFICATION AND + PREP: JGS 1 DESIGN BASED CRITICAL

METHODS. IGS 9/8/92 : DATE:4/29 I CHARACTERISTICSe //- :APP: SK j

DATE:4/3/92 CCAV#: 200372-1ADDENDUM ISHEET 1 of I REV: A

--------------------------------- --------------------------------------PRESSURE SWITCH, 200372-1

TR DESCRIPTION: PRESSURE ACTUATED SWITCH TR PART NUMBER: 200372-1

SAFETY FUNCTION: PRESSURE INDICATION. INDICATION OF LEAKAGE IN BELLOWS PILOT ACTUATOR.SUPPLIERS PART NO: 608GC851 APPLICATION: GENERIC SPECIFIC _x

(three stage pressure relief valve)ENVIRONMENT: HARSH X MODERATE

SAMPLE PER QMP 1010: YES X NO: (100% INSPECTION)

f / 063-METHOD OF METHOD 1 - page 1, 2 12- /O 3

DEDICATION: AND

METHOD 2- page 3

A. CRITICAL CHARACTERSTICS

METHOD 1 ATTRIBUTE VERIFICATION

CC# CRITICAL REQUIREMENT VERIFY BY COMPLETED BYCHARACTERSTIC (SIGN & DATE OR CERT #)

I _PRODUCT IDENTIFICATION

1.1 Manufacturer Custom Control Sensors Inc. QC Inspection1.2 Mfr. Part Number 608GC851 QC Inspection1.3 Certification of Received - per DWG. QA Cert Review

Compliance

1.4 Markings PER DWG. REQUIREMENTS QC Inspection11 PHYSICAL ATTRIBUTES11.1 Dimensions & Per Drawing QC Inspection

Configuration11.2 Pressure Port Per Drawing QC Inspection

Configuration11.3 Pressure Port 7/16-20 UNJF-3A QC Inspection

Thread

11.4 Electrical 3 male contacts labeled A, B, C; silver QC InspectionReceptacle metallic color.Configuration

11.5 Electrical 5/8-24 UNEF QC InspectionReceptacle Thread

11.6 Electrical 300 Series SS (Alloy identification by QC Alloy IDReceptacle Shell Niton XRF or equivalent)Material

11.7 Electrical Fused glass beads surrounding each QC InspectionReceptacle Seal contact.(Hermetic)

REVISIONS CCAV # 200372-1D: Changed to new format

SHEET 1 OF 3 REV: D

-pJ

TR DESCRIPTION: PRESSURE ACTUATED SWITCH I TR PART NUMBER: 200372-1

11.8 Internal Configuration

11.8.1 Switch P/N Microswitch 11SX22-T QA Independent

Analysis11.8.2 Switch Installation Potted Within Housing QA Independent

Analysis11.8.3 Wire Insulation Silicone QA Independent

AnalysisIII PERFORMANCE CHARACTERISTICS111.1 Insulation 100 MQ minimum. Electronics Lab

Resistance (500 VDC each contact to case) Test 100% of Lot

64jW 12-o, A A/CA ~Oa-• it2

REVISIONS CCAV # 200372-1D: Changed to new format

SHEET 2 OF 3 REV: D

I TR DESCRIPTION: PRESSURE ACTUATED SWITCH FTR PART NUMBER: 200372-1

Z -0 -JOAJ C-

44 2 32 e 5/"METHOD 2 ATTRIBUTE VERIFICATION

CC# CRITICAL REQUIREMENT VERIFY BY COMPLETED BY:CHARACTERSTIC (TR AUDIT #)

I PRODUCT IDENTIFICATION

1.1 TR PART # 200372-1 QA/ENG11.2 Supplier Custom Control Sensors Inc. Commercial11.3 Supplier P/N 608GC851 Grade SurveyII PHYSICAL ATTRIBUTES11.1 None N/A N/A N/AIII PERFORMANCE CHARACTERSTICS111.1 Voltage & Current 120 VAC & 2 AMPS QA/ENG

Rating CommercialGrade Survey

111.2 Functional Actuation at 25 to 40 psig increasing QA/ENGpressure. Deactivation before 15 psig Commercialwith decreasing pressure. Grade Survey

111.3 Hydrostatic Test Hydro test pressure side of switch to QA/ENG2375 ± 50 psig for 10 minutes. Commercial

I Grade Survey

B. DEDICATION REVIEW AND APPROVAL

Dedication of the above commercial grade items(s) will provide reasonable assurance that the item meets theapplicable specifications for the intended use.

//-/q - / -2- q* 4,

Engineering Preparer Date

0 a 6 /,ý //A-Z11Quality Assurance Review Date

Engineering Approval Date

REVISIONS CCAV # 200372-1D: Changed to new format

SHEET 3 OF 3 REV: D

. CURTISS WRIGHT'FLOW- CON TROL TARGETROCK- DIVISIoN

-. ,.',.t."~,-PROBLEM REPORT -071 ,~:..

DATE: 9/12/12 REPORTED BY: Target Rock

FIELD PROBLEM: INTERNAL PROBLEM: X

1. PROBLEM DESCRIPTION: (Include source, item identify, customer, project number and adetailed description of the condition/s)

In accordance with Target Rock Commercial Grade Dedication Program, critical characteristics forcommercial grade items and the method of attribute verification are designated on Target Rock's CCAV(Critical Characteristics Attribute Verification) Sheet. The critical characteristics of the component aredetermined by Target Rock Engineering based on the component's safety function. During auditsurveillance activities at Target Rock, receipt inspection of terminal board, TR Part No. 205674-2, wasperformed on September 11, 2012. Per the applicable CCAV Sheet (CCAV Sheet No. 205674, 205675 and205676), several component characteristics require verification. One such characteristic requiringverification is sample testing of the terminal screws and terminal plate brass material. The materialverification analysis of the brass screws and plates was requested during the audit surveillance. TargetRock was unable to provide material test analysis for these components. Target Rock had not performedthe material analysis required by the CCAV sheet.

Review of previous inspection results determined Target Rock had not performed this material analysis onearlier orders.

NOTE: Decision basis for reporting problems, See QMP 1014.

Page 1 of 5

CURTISS WRIGHT FLOW CONTROL TARGET ROCKDIVISION

PROBLEM REPORT PR-O7t:1

lI. EVALUATION OF PROBLEM:

Quality Engineering/Engineering Review

__ Correctable within specification requirements.

x Not correctable within specification requirements (Nonconformance)

Problem Solution or Evaluation of Nonconformance Status(Provide Details)

The terminal board (TR Part No. 205674-2, vendor part no. 37TB02F-72098) is a purchased item from anapproved Target Rock supplier. The terminal board is certified, by the supplier, to meet the requirements ofMIL-T-55164/1 and Target Rock Drawing, 205674, requirements.

The terminal board consists of two brass components, the screws and the mounting plate. Both the screwsand plate are nickel plated, providing additional protection against corrosion. The primary function of thescrews is to provide secured fastening of the wiring connections lugs to the terminal board's plate. Thebrass plate provides the necessary current path/flow between the terminal board connections. This currentflow path is necessary to connect plant wiring to the valve solenoid.

This terminal board's electrical rating is 300 volts and current rating is 15 amps. This high poweredterminal board was selected by Target Rock due to its high performance, greatly exceeding Target Rock'smaximum voltage requirement of 140 volts and maximum amperage requirement of 3.9 amps. The voltagecapability of the terminal board is more than double the required voltage for solenoid operation. Thecarrent carrying capability is nearly four times greater than the required amperage needed for the largest(worst case) solenoid that TR manufactures.

The terminal board was originally qualified under TR part no. 102995-1. This part no. identifies an 8-terminal block made of Diallyl Phthalate material with a closed back and brass terminal plates and screws.The terminal block was part of Equipment Qualification Type Testing for a I" solenoid valve. TRP 3996 isthe type test report generated for the qualification. TR Part no. 204674-2 is made from identical materialsbut is a 2-terminal block. TR evaluated the changes as part of Technical Evaluation of Replacement Item(TERI)-010.

Page 2 of 5

CURTISS WRIGHT.' FLOW CONTROL -TARGET ROCK DIVISION,

!.,J~.. PROBLEM REPORT PR-07tK. 2..:.

Target Rock has performed an analysis "Effect of Alternate Conductor Material for Terminal Board,205674-2" (see Attachment 1) to determine the effect material has on the solenoid coil operation. Thematerials considered for the analysis is brass, silver, and stainless steel. Stainless steel is considered to bethe worst case material and bounds all commercially available materials. The attached analysis considers

the solenoid valve's "pull-in" and "drop-out" voltage. The "pull-in" voltage is the minimum voltagerequired for the solenoid to lift the pilot disc. The "drop-out" voltage is the maximum voltage required forthe solenoid to shut the pilot disc. Target Rock requires "pull-in" and "drop-out" tests is included on valveassembly travelers and is performed on every valve assembly. Typical "pull-in" voltage for a Target Rocksolenoid operated valve is 50 to 60 volts. Once the pilot disc has lifted, system process fluid aids in themain disc lift, continuing to bring the valve to the full open position. The "pull-in" voltage is considerablylower than the minimum voltage (90 volts) provided by the plant. Target Rock requires the end user to

provide a minimum of 90 volts to the solenoid. Therefore, assuming the higher limit of pull in voltage (60volts) and the supplied minimum voltage (90 volts), a 50% margin exists. The attached analysis details theeffect resistivity of different materials has on the voltage drop across the terminal plate. Excessive voltagedrop (below the required minimum for "pull-in") across the plate is not desired. The analysis hasdetermined the worst case scenario, 300 series stainless terminal plate with a 36 ohm coil operating at 140volts, can experience a decrease of 0.04 volts. Thus, the 50% margin, or additional 30 volts supplied by theend user is more than adequate to support the needed voltage for pilot lift. The Attachment 1 analysisconfirms any of the three materials considered more than adequately performs the required function.Therefore the actual terminal plate and terminal screw material does not need to be considered a criticalcharacteristic for TR valve applications.

A review of Target Rock inventory determined two lots of the 20567-2 terminal boards from previousorders were still in Target Rock stock. Target Rock has pulled one terminal board from each order (TargetRock Cert No.'s 00-1818 and 11-2258) and has performed the material verification on the screws andplates. See Attachment 2 for revised certs based on material verification performed. Material for both itemswere identified, via Alloy I.D., and found to be in conformance with the CCAV Sheet requirement. Bothcomponents were verified to be made of brass. These two separate batches of terminal boards span over a

length of approximately' eleven (11) years. In addition to these two batches (from inventory), Target Rockhas performed the required material verification analysis on the most current batch of terminal boards. Thisbatch of terminal boards was receipt inspected by Target Rock on September 11, 2012. The materialverification testing was performed in accordance with the CCAV sheet requirements and both the screwand plate material was verified to be made of brass. See Attachment 2, Cert no. 12-2280, for inspection andtest results.

Lastly, as previously stated, TR requires the terminal blocks to be in accordance with the requirements ofMIL-T-55164/1. In accordance with MIL-T-55164, the supplier (Marathon Special Products) is required tomaintain material control and to perform material analysis of the terminal plates and screws. Attachment 3demonstrates compliance with these requirements (both terminal plates and screws are manufactured frombrass). While TR cannot explicitly use the supplier's tests and inspections for the verification of terminalplate and screw material, this provides reasonable assurance that the terminal plate and screw material iscorrect per TR drawing requirements.

Quality Assurance Manager Date Engineering Manager Date

Page 3 of 5

I

,ýCURTISS W.RIGHTTFLOW CONTROL-TARGET .ROCK*DI.VISION-":

... ~~~PRO BLEM-REPORT P-01, .

III. DETERMINATION OF NONCONFORMANCE STATUS

1. Product Nonconformance Issue NCR

2. System Deficiency X Issue CAR

CAR 12-063A and CAR 12-063B issued

Quality Assurance Manager Date Engineering Manager Date

Page 4 of 5

CURTISS WRIGHT FLOW CONTROL TARGET ROCK DIVISION

:PROBLEM REPORT: IR-7IV. EVALUATION OF POTENTIAL 10 CFR PART 21 REPORTABILITY

(Refer to QMP 1014)

_ Potentially Reportable

x Not Reportable (Include Reason)

By analysis, Target Rock has shown the brass material specified for the terminal screws and plate is notcritical for any Target Rock valve to operate. Target Rock valves operate with a minimum voltage, wellbelow the voltage supplied by the end user. In addition, the voltage drop across the terminal blockregardless of terminal plate material is insignificant. Given this margin, a change in material has no impacton valve operation.

TR will continue to require brass material for the terminal plate and screw material on its CCAV sheet aswell as nickel plating.

/ 0/a -~//i 6Z~0~,fl&r 10)261)2-Quality Assurance Manager Date Engineering Manager Date

Page 5 of 5

Attachment 1 toProblem Report 071

Effect of Metallic Conductor Material other than Brass used forTarget Rock PN 205674-x (Vendor PN 37TB0-x)

Overview:

The TR CCAV sheet, "TERMINAL BLOCK" includes TR PN 205674-x. The specificationdrawing for PN 205674-x defines the screw material as "Brass per QQ-W-321, Nickel plated per QQ-N-290" and the Terminal Plate as "Brass per QQ-N-613, Nickel plated per QQ-N-290".

The CCAV sheet requires that both the Terminal Screws and the Terminal Plates be tested on asampling basis for materials analysis to verify Brass material for both screws and terminal plate.

By calculation Target Rock has determined that the use of a non-brass metallic material for eitherwould not affect valve operation due to the very low material resistivity of a wide range of metals.

Analysis:

The major impact a non-brass material would have on terminal board performance would be toincrease resistance of the terminal plate resulting in a higher voltage loss across the terminal blockeffectively reducing the voltage to the TR solenoid coil. The major function of the brass screws is tosecure the connecting wires to the terminal plate which is then the primary conductor of current across theTerminal Block connection.

If the voltage to the coil was reduced below the TR Pull-[N and Drop-OUT voltage of the coilthen terminal block material could have an effect on TR SOV operation. TR solenoid coils are specifiedto work with plant voltages between 90 - i40VDC. The solenoid coils are conservatively designed suchthat PULL IN and DROP OUT voltages of any given TR SOV are 40-50% less than the 90VDCminimum coil voltage requirement.

If it can be shown that the voltage drop across the terminal block for metallic materials other thanbrass are much less than 40-50% derating for 90V operation the terminal plate material will not affect TRSOV operation.

For any given material, resistance (R) is a function of the resistivity of the material (p), the lengthof the material (L), and it's cross sectional area (CSA) and is defined as:

R pLCSA

Where: R = Resistance (Ohms)p = Resistivity of the material (Ohms*m)L Length of material (m)CSA = Cross-sectional area of material (M

2) or (width x height of material)

Page 1 of 2

Attachment I toProblem Report 071

A range of resistivity values for metal conductors ranging from Silver to Stainless Steel 316 isgiven in Table 1. Given the solenoid coil current and the resistance of the terminal block, the voltagedrop across the terminal block can be calculated.

The following table computes coil current at 90VDC and 140VDC for the range of TR solenoidcoil resistances (220ohms to 36ohms) and multiplies that DC current times the computed values ofterminal plate resistance for a range of metallic materials from silver to SS316. It is shown fromcalculations below that the worst case voltage drop for the worst case coil (36ohms) and the worst casemetallic material (SS316) is only 4 millivolts (.004V). Therefore, material resistivity values 2.5 timesgiven in Table I would only have a voltage drop of 0.01V - well below any voltage drop that wouldaffect valve function.

Table I

Terminal Plate Dimensions

Inch Meters

Plate Length = 0.317 0.00805

Plate Height= 0.030 0.00076

Plate Width = 0.290 0.00737

Metal Resistivty/Resistance

Metal I / Terminal Plate

Solenoid Coil Current (A)Resistance Voltage (VDC)

(ohms) 90 -140

220 0.41 0.64155 0.58 0.9036 2.50 3.89

Voltage Drop across Terminal PlateF--- 22oohm 1 15S ohm I 36ohm

Iohms/meter 1 Resistance (ohms) II

Metall Min I Max I Min I Max I Min I MaxSilverBrass

SS316

0.0000000160 0.0000229523 Silver 0.0000094 0.0=00146 0.0000133 0.0000207 0.0000574 0.00008930.0000006300 0.0009037469 Brass 0.0003697 0.0005751 0.0005248 0.0008163 0.0022594 0.00351460.0000007200 0.0010328537 SS 316 0.0004225 0.0006573 0.0005997 0.0009329 0.0025821 0.0040167

The length, height and width of the 37TB0 terminal plate are taken from the CCAV sheet.

Resistivity values are obtained from Electronics Engineers Handbook, 2nd Edition

Page 2 of 2

to Problem Report 071Pg I of 6

... . ......... .. ... ... ,, . 0:.:,

D F m •ce 1 - .. ' - , . . . .

.. ' C ..............- . ...... .. . .... . .. . .. . .L . , B,$t" . i Y L ,

Non r"'bbe%

/ •.. i , j, ri-

. . . .. . . . ...... . . .. . .. .

.. , -. ' . .- -.. .'

- - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - -t ' --- - - - -- - - - -

• " d -.. _ _0 50 ......... . ............... s .. .... ...... ..

C a i k s. . .. .. . .. . . . . . . . . . . . . ..... .11 . .

": :•": ': :/ tI - fll:" n-/i -- "

" " . ......"..... ?'

.1- fe 0,; S r-. IA

. l" ei t o .- .... " ... ".- :. .... '... ... . . ..... .. "

I R eport .-.-...

..... i•i:...-'....-.......!,-.:: • '::"::' ... ..' .. .. -. .. ... ..... .. .. ':":: : " . ...... C o i m r C d w':. qy::.Al , • t ;az ,, .,-.. .......

,.:W1 70 of ,eec a lo m Dinpss .;v•n. of- Aro.a ... c m.:w . . . . .:

-CaP , is.. 1; t M e 1 ...............K ,.. .. : '

~0-

.. .. , . . .. .• - . . . . .. -. ; :::'" :i::;': :.'....:....". .... ..-. . : . . .

,ttacnment Zto Problem Report 071

Pg 2 of 6WOT# "#

TARGET ROCK/EESFINAL ACCEPTANCE INSPECTION REPORT

PARTNAME Tepz.m,4L 6coa..j DWG NO./PART NO. ;V S- 6',.. -X REV r'-

PROJECT- r-jo SOURCE/MO 3 5'--4r

QUANTITY ACCEPTED 'eo

MAT. CERT. HEAT LOT S/N INSPECTED

DETAILSCheck ACC box when item Is verified. Check N/A box when item Is not applicable.

ACC N/A - ACC N/A

Eý" 21 VISUAL HARDNESSALLOY ID -a-, THREAD SYSTEM 21

• MARKING l]ill THREAD SYSTEM 22TT El

INSPECTIONCheck ACC box when item is verified. Check N/A box when item is not applicable.

ACC N/A ACC N/AJiM I INSPECTION TO DRAWING 2+C] I M&I PROCEDURE NO. -/P REV 0'

_]ET 100% MAJOR .[] 1100% CRITICAL [?to I SAMPLE TRIP 5087: SAMPLE SIZE Zo__o DRAWING NOTES ADDRESSED ___100% INSPECTION

RECORDED DIMENSIONS PURCHASE ORDER REVIEW

ATTRIBUTES INSPECTED _] I " OPERATION SHEET REVIEW_] CC' A.'1d E I[ E OTHER

NDT REPORT HEAT REPORT *_^__/7r _ WELD REPORT

NDT REPORT M/ - OTHER PROCESS _ _ __-

COMMENTS:

INSPECTED BY: DATE: /'9i//

REVIEWED BY: DATE: 167t

ANI REVIEW: DATE:

"THE RECORDING OF FALSE, FICTITIOUS, OR FRAUDULENT STATEMENTS OR ENTRIES ON THISDOCUMENT MAY BE PUNISHED AS A FELONY UNDER FEDERAL STATUTES."

TROC FORM 2A-6/09

to Problem Report 071Pg 3 of 6

WOT _•#.. ...

TARGET ROCK/EESFINAL ACCEPTANCE INSPECTION REPORT

PART NAME"-• • jJ NA.. DWG NO./PART NO. 2 0 •Co 7 L -- Z REV FPROJECT c - I a3 I< 0O - SOURCE/MO ZM37 "AJt-1

QUANTITY ACCEPTED

MAT, CERT. HEAT LOT S/N INSPECTED

DETAILSCheck ACC box when Item Is verified. Check N/A box when Item Is not appicable.

ACC N/A ACC N/AFe VISUAL El HARDNESS[ I ALLOY ID S.-reCL - P. . __ THREAD SYSTEM 21C] I MARKING jt]-f• THREAD SYSTEM 22

INSPECTIONCheck ACC box when Item Is verified. Check N/A box when Item Is not applicable.

ACC N/A ACC N/A ,INSPECTION TO DRAWING 1D M&l PROCEDURE NO. REV100% MAJOR E] 100% CRITICAL _ SAMPLE TRP 5087: SAMPLE SIZE

[- DRAWING NOTES ADDRESSED [r 100% INSPECTIONRECORDED DIMENSIONS E" PURCHASE ORDER REVIEWATTRIBUTES INSPECTED E[I OPERATION SHEET REVIEW

o, _rE-l El' OTHER

* NDT REPORT _ __ __HEAT REPORT /4/9- WELD REPORT _ _ __NDT REPORT OTHER PROCESS _ _____

COMMENTS:

nwp PAIL-r scR.APCLI7 owT Icag jA~t.4AM~-L 4jjArfjV/X *tExrtA&-

INSPECTED BY: I _.,_ DATE:

REVIEWED BY: / I __DE:_i,/__-_ _-,_-_,

ANI REVIEW: DATE:

"THE RECO DING OF FALSE, FICTITIOUS, OR FRAUDULENT STATEMENTS OR ENTRIES ON THIS

DOCUMENT MAY BE PUNISHED AS A FELONY UNDER FEDERAL STATUTES:"

TRQC FORM 2A-6/V9

to problen Report 071pg 4 of 6 INSPECTION ATTRIBUTE SEET

Part Number: .2 C_ 7 L-. 2 Rev: jSketch Number: Rev.

Page___ of I

S: a 1 \Project,.C / (.-Z hc"Q-MO/PO: -7 V &4=1WOT:

SIN:

Lot Qty:- Acc: e :4 ReIj:

Sample Proc: ' 3 " 7 Sample Qty: ,.5.C.

NCR: --

Inspected by: ^Dete 1 /'/

Feature Fearurel Dim Ace. Rei. [Wt. enrsGg## Qttr .-QtY.

A *I I29- I/ I (, ,

V .. -2 , 16fcea

,.. ______-___,__ 1Cf - ____ -__ __- iCu)..'/- _ 1 - , . ,(

k__ -7 -F0: -66 1-e WL2 _

M~~C 0-y iehi *0 T-m7-- C p

si_ k__ _ _ _ _ _ _ Go_ _ __ _ _ NJ S

V.A!Q 7 c4- * F- 5 ~ ~ ' jQ- - ------ 4 ')~

I - 0 ___________________________________________________ __________Q _______0___ _____1____ _____________1__________________________

THE .RECORDING OF FALSE, FICTITIOUS OR FRAUDULENT STATEMENTS MAY BE PUNISHED UNDERFEDERAL, STATUTES

TR Form: 2A Rev: OCT 2007

Attacnment zto Problem Report 071

Pg 5 of 6-,,

@

TR NOMENCLATURE: TERMINAL BLOCKTR SPECIFICATION: 205674, 205675, 205676SUPPLIERS PART NO: PER DRAWINGSAFETY FUNCTION: ELECTRICAL CONNECTIONS

ADi

CRITICAL CHARACTERISTICS AT1TRIBUTE VERIFICATION *

.PRODUCT IDENT CHARACTERISTICS MD, REQUIRESUPPLIER YS MARATHON SPECIAL PRODUCTSDISTRIBUTOR YES BEYOND COMPONENTS LLC **CERTIFICATE OF COMPLIANCE YES -PIECEIVED - PER DWG.MARKING ON ITEM YES ER DWG REQ'TS - 100% INSPECT

PHYSICAL ATTRIBUTES /4GMATERIAL COLOR G REYMATERIAL (DIALLYL PHTHALATE, I ATERIAL ANALYSIS BY INFRAREDGDI-30F PER MIL-M-14) SPECTROSCOPY OR EQUIVALENT *CONFIGURATION YES(/ PER SHEET2 OR3TERMINAL IDENTIFICATION A/R MARKING PER DWGTERMINAL SCREWS 1 YESC, NON-MAGNETICD5IMENSION B I YES PER SHEET 2 OR 3OVERALL WIDTH PER SHEET 2 OR 3VISUAL SEE BELOW ****

PERFORMANCE CHARACTERISTICS I N/A II. II I

* REF TRP 5041 PARA 9 FOR INSPECTION METHODOLOGY UNLESS OTHERWISE SPECIFIED.

** DISTRIBUTER SHALL USE ORIGINAL SUPPLIER PACKAGING AND IT SHALL BE INTACT.

* SAMPLES TESTED FOR MATERIALS ANALYSIS SHALL HAVE NICKEL PLATING REMOVED FROMTERMINAL SCREWS AND PLATES TO VERIFY BRASS MATERIAL.

****LINEAR INDICATIONS ON END SURFACE POSITIONS OF THE TERMINAL BLOCK WHICH DO NOTEXTEND ACROSS THE FUL THICKNESS ARE ACCEPTABLE.

REVISIONS/APPROVAL I TARGET ROCK CORPORATION------------------------------------E: ADDED BEYOND COMPONENTS AS [ CRITICAL CHARACTERISTICS/AUTHORIZED DISTRIBUTOR I ATRIBUTE VERIFICATION

,----- - -- - ----V#20567--20566----- ------------* d. m~r~h ICCAV # 205674, 205675, 205676

1 SIMET I OF 3 REV: E -

41 .--------------- - --- ---------- - - -------- ---------------------

K:AEng\WRCCAV'205674-205676.wpd

,ttacnment 2to Problem Report 071

Pg 6 of 6

iCUR TISS

-)Flow Control CompanyTarget Rock

(TEL) 631-293-3800 (FAX) 631-293-3714

TO:BEYOND COMPONENTS LLC65 N PLAINS IND RDWALLINGFORD,CT 06492United StatesATTN: CHRIS PUGLIESE

PURCHASE ORDERPO # - REV 37845 - 0

PO DATE 11-JUN-12PAGE 1 of 10

CSHIP TO:1966 E Broadhollow RoadFarmlngdale,NY .11735

BILL TO:1966 E Broadhollow RoadPO BOX 379Famiingdale,NY 11735

Early delivery Is acceptable.

rU CONFIRRMATION-O0 NOT DUPUCATE

[X] CERTIFICATIONS REQUIRED

L] TAXABLE

"X] NON-TAXABLE RESALE # 11-1640651

Purchase Ordernumber MUSTappear on ALL

correspondence,invoices,

certfllcations.packing slips andon every shipping

container.

VENDOR # P00943

SHIP VIA UPS

F.O.B. Origin I Collect

TERMS 1/10 Net 30

DELIVERY DATE ORDER PLACED WITH BUYERSEE LINE CHRIS PUGLIESE J Grisales - 631-396-4548

Ln ITEM NUMBER PROJECT DELIVERY QTY UOM PRICE AMOUNT# ITEM DESCICOMMENTS/MESSAGES DATE USD$ USD$

1 205674-2.REV.E C-10SK03 12-SEP-12 100 Each 31.8900 3,189.00TERM BD,M1 00/M610/3WITEM SPEC Une Total 100 3,189.00DRAWING 205674MATERIAL SEE DRAWING NOTESSPECIFICATION SEE DRAWING NOTESPRS I PRS08-28.REV.B

REQ NOs: 54688ITEM CLASS: CG

GL CODE: 00-15110

BUYER SIGNATURE PURCHASING AGENT CONTINUED

ACKNOWLEDGMENT AND AMENDMENTSIREVISIONS: A duly signed acknowledgment of this CONTRACT CHANGES AND AMENDMENTS/REVISIONS:purchase order is to be forwarded to Curtiss-Wright Flow Control Corporation, Target Rock, within All changes to this contract must be requested In writing and10 days of receipt of this order. Acknowledgement of this order constitutes acceptance of all terms will be authorized by formal Purchase Order amendment only.and conditions.

VENDOR

ATTACHMENT 3PROBLEM REPORT 071PAGE 1 OF 10

M.TWL RB9Q~MCS.S0LV fl:l. 4 b4Ci

i '•!• -:W&A•;t16=Lm o9.4•Utke;';

ww,,v gse11tUO rtWWeIOttflS.UI, @

*-~

Perftctiom e crS w & Rtvuc

Waaf,6*.0 T .-USX:

MMRI SO. 41 &79%~03customer 0wdt 0 9ttGý

fr

IfV(4 • •

Product. .14' Of, CDA.260 Brass Wi49 Ii8,Hard aZdoilHemNumbev- 14020i26O= t i14Country of OrIsim PE.RU

lnf'• ASTIM B I34,-. .

Ft, 0.0044.a0,0070•:8I;Pv', O.O000,ý O.OO7it.

Zmv Rontinds.*'w

rensil sq.. au • 63.90 ksk

Mis certifies that the mrateriai shipped apinst the, above customer purchas orde~r numibr cc

the requirements as spc-ified ow thszcustommrt order.

iii-1t9-12

aforms to

E4-,ND OF CERTIFICATION

ATTACHMENT 3PROBLEM REPORT 071PAGE 2 OF 10

UniMetal3urflcPFnhshlng'LLc

T homaltow,.CT 0P38•• , Is

Phone-800) 2,342,l0 Fvz(860) 2$3-858f, wwUniMetasifl' '•o

TOW4 LIN% RO.:. WoLCOmT. T05711A_

SURA",U FA , F•tS IN-

I.SIt 1?

PERFECTIONl SCREWP 0. BOX 1 1022WATERBURY. CT08703Phonet (203) 879-4l461;Fir, (203) 87956824'

Ind-

Certlffcate otComoBancC fiT i. . . ."l. .. -o!... . .:f

We herebyvcertIfy that all. artlicle (Urniished liv the quantities stated. as called for, have beinspected andltestedand'ar irr conformancewith al applicabledrawiing.. specificationtrequirements 0t:the said purchaseordei;,-:; :-

- !* 'k :' t --- -1A-863gF' . .-

278.00 .•s. Sp1ca N/Pt.ATE'.0002,PEROQ-N.290A;CLASS 1.GRAOE 8.ATOTECH SUPER DRAW

LU8& WAX &4.-54 WMaterilslu BRASS-I,,PLO.i 51,A7Lot44961-.PContainers Shloaed 5 PANS

270.00 Lb*

/-)/ *1

Pir BRIAN THOMPSON I QUALITY ASSURANCEiENG!-4- ý !ý 303."1 1 1 '.' I

ATTACHMENT 3PROBLEM REPORT 071PAGE 3 OF 10

I&J- P09ECISM4 ZIYELUT1 V4C.

Thomastobd.Ct, 0&757"

Fax ta V 20-671

e* --6.

I~

I

CERT FICATE

Date: 1i20:2

Comptrny '*famoi -,tarathon

'his-is to certitf that part number 9201841.

Rev. D has been tested and complies with all of the applic le

riquirfmlents and specifications. as stated in your purchase ord{ ,,

I turchase Order * 469(7-0(

Quantity: 5(),000

l.0t Number: ,I L-2059

C,_ n 0 I111 : _________

Litre: o. A. 1Xlchni n

ATTACHMENT 3PROBLEM REPORT 071PAGE 4 OF 10

F, Fina I spc tioon, Shet'

Custom*" Marathon Piot 9 9201841• Quantlty, 50.0 0

Part N81m1 J'tV,4ttat R. 0- Lot ... JL-2059 . P.O. 10 46907 .•06 -

Sampling Pi • ',,.. Sample Size a 6,,-

Specification. . , Metho4. Reaults -

,,22{iI *.M '23• Mtronmr;: .2278- .22841-

.312 *.K}115 Cw~mpt r, ,,.3125--.3128.

, ,.162l') ±.'I.i' 'mitainutr .1206- .1231

. I! 3! *.'.i'.i ,,, Cot~r~u ll~r .1121 -. 1153

-0 ....1 t.002J comparator .0905R - .091 R

122.1 ItIs.)i.I. ' Ih:,1.s I..X 47 Accept

±__ _. k, 1• _ _i_•llX .17 Accept.

.*iC., -.u,•l P'oitii Mkrl'iir r .0269 - .0283

• * • *I.• I' -. )1 .s : ,t sr~atlr .1701 - .1706

M *.•.• , lr 2183-2188

Comments:

i~lspector • 't Oate: 8/9/12nspector 'p Date: 8/9/12

ATTACHMENT 3PROBLEM REPORT 071PAGE 5 OF 10

CRTIiICATO REPORTu bi

3TS)II'trELO. R11SOUT1HtRiL0, NP•::

,MI14F SO "

C2172

PRO" .1.4? 1SCRWMIOM• .. ORC.N@

Sonr, aEP oWy.L0W BRpA$ WTRLO' "& S 4. W

ASTM B341111631M.08 PIN CUULRQ00B1?. ug 14=a~ -~I CTRG

Lai. 14M, CwrSl 13C•I4•I

TS10.31.42AlhI

I COIL NUMBERt A6•1656 x

COMPV.. .01I .1

PROPERTIES,ficckg.el F 743).Tonsil SV. (k*-, 52.1.raet SUr (kal) Q-2 OvFSar.- - 20 O0-6ioigatioa (%)in 2 kwr.O* 51:3 |

Grain Size in mm': .025" _ _.

Th-x6'~jThi~Mo" /

(c//311A ~

7CUST9C :rýa3PO :- -,.

t.GS. SHIPPED:-.. ..

'N.

WE IHEREIBY CERTIFY that these test results were obtained from samples takes from coil(s ) whi

produced for the purchase order stated l.These samples have been subjected to tilb tests called for bI

the cusmnter and/or AST.1 speciflcation(s).

rhis product was maaufacturedj In compliance with oU applicable givernment and lafkryacorlstrilIu

restrtcted. toxic. and htuardous materials and complies to the Restricdoo of H)amrdous Substances

Dlirecdve (RolUS) .ZO0 S95IEC and the Consumer Product Safety [tupruoemeatu of Zof00L

.\urubls Bluffalo, Inc. product .1aterisl Safety Uane Sheeut (MISDS) provides conipeaeut loormaiad

for all hazardous materials in, confortiance with the OSHA lfazard Cummunicatlon Standard (291

9101).1201i.1

cb were

is on

a:FRt

1'icnicome Vepartincut

, :,3:•'U~ftja'O 14-. :-J). '30X 96•1 i3LFFALO NY I4,;F¢¢h~~i¢.141 4eatmu

ATTACHMENT 3PROBLEM REPORT 071

PAGE 6 OF 10

p I.

FOR .103. . ,. WORKORDER4-:

COPPER ANI1BRAS$SaALS

COPP E9JCOPP~1 ElALLOYS`,,

C1820(t C I97I}O C 19400 C2I100! NC22000SE 4[ C260201 C26800

C2720Q C27406 (C28UW0 C3300( C33:104. C3320U C335011 C34U14 (C34200

C35000 C3530) :C3560G C360013 C36020•C36501k C3700Y €C37701k C38000

C40500C4tlOO C4250uJ C4350(1 C44300'CC44401 ;C44504iC46201kC46400

C48200 C485041 CS050I (CSlOO• JCSI 0('E5 194t34 C52l0Q C5Z4OQi C53400

C6100J. C6t4 6 S00:C651 C661 00•C 6670(k- 67.50. QC6760 Cý681t0%C C68"700

INIIALING L•iwit-AMOU.Nr!.OF. COPVEf FIE$ M Y. CACK.SIE, TALFUM It FEVER WIT.1

SV*. 1PT03WLREPEATED E.XIO.SLRE 3,V(.ý'?AV CAlt.E, TIIUCKLVI.N( OF u'S~ e

.AND3 sKI.+,rEETnHAn hI Rl t DISCOLORATIIO.TARGET ORU%.X IS 1r J.JUL't Hl LUNG,!

.EKEATED 111; IGEXOSURE CA.N ALS,-.\A VFECT, THI LIVE IL:

TII is pRODucTALSO 'CONTAINS LlLD.0VERXLOSVRlLTO I.LD 13Y r4IJAL%'r1ON MAY C

SEIZE ItESiCbOMlA AND DEt\Uri LEADIL\3 BEEN IDCNITIFIEDYAS P~rJNXrAL HUMAN CARCI

IF COIrEDWITI' OIL.MAtY CAUSE SKIN I1U1ITATION/DEIlNL'rlTi $ 13T CONTACT. WELDIN

LIS'lEID•A.•A, POIOl ILE CARitiNOGE•NIC:TO HUMANSk

READ) T11E COPPEiRCOPPRit A LLOY!SNI£ATR IA.L s.jJEf DTASi EEfSD ON FIL. WI'

-IIPLOY El BE•¥OREAVORKING,\¥THrfIUS.MT.TlUAL.

" If proerssing or rwycling produces partlcultateuse exhaust vtnttlaltims or tither contnils hdesignud te pr

ti waorkturs. Examples~ot such altlritIl include in•iting, elddinglirindl, abrusive smsiIag,saadIngi and f,

,ctivilF.whticI unlindew tfie surface. of thils nisterlal cuip geuieratu alrhurne parliculate.Ulse apprepriate NI

;pprvue* r•spiratnry protection (Pg.uaPr0a for I[nda.with• tlntitatiaile it tesutinigrequlred)if e.posutrus

pernilsible limits.iThe Occupatlonal Safety and I leatl Admlinistration (OSHIL) h %at* mendatory Ilulits o occupiftont

* CoppOer In solidtbrns ltl nsCoutained hsliblihed products presents ie. specitl [|eallb risk.

• Sold ror muiuflUaclurbill purposes omnly.ThIs protidsa tcam be ren'ledu:1ontinct your sales represenmtatlve,

The Occutpuunonai Sorely nian HeIeall, %drlnlhtsiraiomn require eumpioyers to prolde Itraining li tile propui

imrtumhtal.

C345004C38500C46500*ý0440$-..'109.40•,

LC.LIKE':

*OGEY•FVI:3E lis

*ii.\'OU1A

•utl exposurv

ilsi.iig.Aniy

cccii tite

I ex poiures.

usu u thUls

.f

I:.tr a tIiithnta I i nit Irtrtiititi. cn il 'i r% rito Io C up)ur a mitl BLra.i S.aWits.212.1 f \West Llevei .\ iIi IQle d. Sit U I .id. NIt

li3.!.•.~etuh~~hng- 13-2.%.3-6601. ior % sit our N•ehI site i., ilb .coilpt:.ri 1tttlhSAratss.v tit

I JL \1)1-1)t k IH I I. \lkjj N ).jNst ED 1111101. !11114

ATTACHMENT 3PROBLEM REPORT 071

PAGE 7 OF 10

UniMetal SurftCe P*tnhNng %L-L . '15 Sast- Wsturbury Road~Naugalucl C? o877Phlone•(2O3) 2124244 Pa:(203) 7214!48? "

www.%Unlmet~l.acon1 ,

JJ PRECISION=t 1EWATER3URV RO iTHCMASTOW,&CT 08787,

Cert

1=o90614200 (VS.ON." I '117092S'

mq

ShipOate 0./071.1 Z:,rL

JJ PRECISIOI,-116 WATERBURY RO

THOMASTON CT 08787Phonei (860)% 2-8241L.,Fas.860)x,2834729.• ` ý

Iffdat.Of CbmpliancI I I Ill I I I I I ml - im

We hereby.certif that all articles flrnished rir thequantitlies statei as, called for,. haw

inspected and- tested and are irv conformanc With alk applicable drawings, specificatk

requirements of the said purchase ordert.

beer:in and..

Qty Recived;~ Part Nm & Descotlom- a________ 12t madfe4

87500:1: JA 4.Q& BRASS. S OU BLE EYELET 8750G

141 Lbs:, Specs. COPPERti.00002S00015, NICKEL.0C03-.0004 141 Lbs,

Mit.Spe=l QQ-Nf4290Q ' I

P 0., 2221(TJob * 2215040 PS. 1443104.Lot A. NORTH,.

Contaiwers: 2 PANS.-

The above ordor has been. procesed to.

Bright nickel plate .00031.0004 thick per QQ-N-290, Class I over copper plate .00002W.0110150 thick

'NVe certify that the information supplied Is a true copy of our record and wilt be retained in our fites for a

peario of not less than eleven years..

Avu

ATTACHMENT 3PROBLEM REPORT 071PAGE 8 OF 10

Part Submission Warrant (PSWF

i:v" ' i* 37T840T8 Con9201841."

*W~4UlW*5Wfad !*10* U:.. PtaT

SUPPLIER INFORMATION'

JJ.. Precislio

tact (3-33yI pinP lOhi• 321419201110.

4690M0W'I I

I a- I

II

Oat *ý 716 Gl ý .n

0

'-a.~8 ~ju~A!!oct0 M3PFMgo0W-u 4____n_________i

116 Watosbur, Rct.$t, Q'| t a•, ýQ. • -

h:.m.•uac'r dow0787 USA

M.0-3.w. Postalt < ,4 Ccow"

AU' HORtZEQ CUSTOMER REPRESENTATIVE IREQUESTOR),

3ryan McCracke:

rO*.aL,0sIDI5 Nwo,'0

Al Rebnnsn,%"C~ntacii-

880-2234273Phwr Numb" .

7118120121. ______

Am• I

REQUIRED PPAP COMPLETION DATE1. I

RI!ASON FOR SUBMISSION (Check at least one)

.. ;,* :~'.., 't' •.ion ,cs)

... .-., ,: :~'•fu imnwt or addiationmal

.t.'of C:§stf;,aN..

1**',r q k than -,o

12012•To

PPAP Document Number 'r112t.ufl.1ER

C3 Change t O wgl iatrsMalon of NtaueIl

2 OPange,1 PsOa Pfa cGM.a

JPantg Ptoduced at AedironU Locmt-7 plea ~se lW14'

REQUESTED SUBMISSION LEVEL (Chock one)

v. q,.jI •'artrat n%;y •.ivd ta daoigqssae, appearance itonis, art &.Varaace Approval qOrtrn) su,•jmtt•d t2 Cuttcm4f'.

.2 Wir;is. -oj'd".At uaaples andid ited~skiusniong data subwnlted to cu"Tw~.v

3',..,2. 3. •aramtan it:h prOducJt sAs a wilq d cOfrlIeto su;plrtinlg date suubmtted ti custWofr.o DEFAULT

c.c: I • V.'trant and cittv ie.muireents as dofinod OV 4ustomwt (%"e attached SPE(CIA. P•SrRUCTrONO)

(it 3 • ;aratiat w.tI1 hJ." ingJes and ccmw4gote supp¢ojrting data ra'vewed at W iza•'i mMikufVi.rl"9 IVI•at`oa.

SIUBMIS41ON LEVEL

SUPPLIER ACKNOWLEDGEMENT AND ACCEPTANCE

. y "•,,ieW And UtlrlarS'llad 01% A00vo rSouli• aaIGAI: (ý-6d-(ýC 7-Is-I?

!S;qnslute ol aiusjlciett jujppfior ,~rtesitetve

"." '... t t'1 / ;2t ."i•; v'. *-•..uO ti'rn *.I rS U S S IO R E U J 9t a p w n iC -t e a ~ o l ta m l

-DE CLARATION.. :.--":.-..• : -... t ...:: S.;, .- -•y 1.1 . t d' leutqelentativ of ctuPr3 s m3oI, an , ýi•.'ee¶ 3.t;,1CUIt C.S.l i jtOmlOf d 3%%V' ;$ '11.2 .r3.-*y'i

.i~':I:~ ~.l 5r:;i-: ';'a' ~'~;~ar ~ tuii.J .I~ no~L~rt~u~t ~ 'r o iritA'2t~~tf.*'1G'SI.e :i1 I# 8.

". '. " " ". :..2"."$.;t'. ,

.- n... ~3art '~

- .1 inuId., Aaaa.nnrs NA

~:e~ ~I I 312012* ~ ~80-2a3.~T29

la

S I-. - .. . 3~ ' 60-2113-8243

Assufance Nlaný of,

-(ISP USE ONLY

................... . .~ .*, .J ,*~* ~*,-*. (.1

AATTACHMENT 3PROBLEM REPORT 071PAGE 9 OF 10

PART ' 1 "" 40T1"C4 "t"4*

ENGINIUERING CAMS 1GB CUWZNtTWrNA-1 OF IhSPEC71014 FACIITYr

J 1 J Pttor j E. ot

DIMENSIONI SP. '"'CATION. T.--12 OT! z- EASURVM ft?- jEASURIEN " tNOT-1

11 Sm'CFICATIONW. UW!ATS: 0ATW7 TESTED R IESULTS (DATA~l GAOS.TY'IP - Oi Olt,

.1.53v t.0025 .5535l' •5.. 7117112 t 55? rmX-c• om -r.

2 2230, t.00253, .2233*' .2285 .717112 1 .2275 i8" MIcromet er

3 .3'2:'.-i1 1.3105-'.3138 7112 .3111 I Compartatt - :

4 .002S ,119W-.1245- 7117112 1 .1220- Comparator X;

.' .9•"* ;002 C91Rj .0R' :7/17/12 ! .- "0925R- Comnarator X •

113-0. - t.002S .01105, .115S "717/12 - t "____.1 ___ ______ t_____K 11902 O2 -119' - , A8 Ci',

.11,12ZI. 119". 7/17/12 1 c12.tI7M712 1_ GagoPinw -

a 0213 " .0&5 .023', 033. 7117112 1 , .029& 1_ Pin Micrometr x

0¶ 1503 :±010- 14 .140lL' 7117112 1 isil,- __ fillefromgtev X _

I 213& 05 * . 2032;- .2344 7117412 1 .218V21281 ___________-

.173-,. !Gsi.o•3. .170 .178- 7/17112 1 .1753, Comnpaator X

'- ' a - - *-a-..a-pa.aIa.a-t_ _ _ _

* .Ii 1. a. . a:a - -

___________ a a I________

____ ___ ____ ___ __ a - -a _ ____ ___ ___ __ _ _ _ _ _ _- -

T!ar3Ket saten•ents of conformance are unacceotab:.3 for 3ny 1est reuilts.

CC Insoecicr.,~~1,,*

// ///'-~-':

6IaPIUILLFCI

;.. jr)i

t...

(~j i ~

(0-i 1 '-

4-. I&

*.-. *~-,.*~-w -~

* -9-'.-

- ~I... I *1

1~* *1'~

j I

f I ~ ~ '~"'-'

A

~.I7.,.-'I

t AI'tC:.

a-- .-*•"Z

1I-

-.

] • • "- U-•.]I " L•2 'r.€.• I)•;Z - J .. ?'L• :' -.'".

, .- l - r. .. ,.

A" .i0 ¶I -

• I•L,-•" •.. .: :•'_ I'tý IA I".- i

0f

Lzf £.4AL

!

• io

1 A.. ,

- 1 ..~L .41 I -

=e .4ý

2

&:~i.. A"~ II, F

f.,','~ '.4* . ~ -

~.lp,,6 -Q ~ 74.4-..

QAT~REC~X~D

p; .~aj.,j, r~-4 *~-'~~1' r ~ 4WrC7i~i~Li -.- ~-.. ~

-

~ ,"~ i(E.4 A1 *QO~ .4 ~ __

* *. .

a e- V~-----.--.. _________________ ___________

- -.- -. C. *~4-.*~.~* ~ I*tSI~I- I wt-.r~.&.g -- I.E. I.)

- I "6

,r-,,• ...n .6 . ,.

- -. . ~.* "~ )45•''s ... ,h • "-

• -'•l' ,:d.•:: fC. t A'7. 1 • ,'-.,; - ,nI',, . ;*| .. •"~

4i T.[ ________ ,

'C-0 "0 >> X--I

. r-- 0C m .->

-rn~mOZ

-10;o

CURTISSWRIGHT FLO.WCONTROL TARGET ROCK, DIVISION

*~ RBEM REPORT .* *.

DATE: 11/1/12 REPORTED BY: Target Rock

FIELD PROBLEM: INTERNAL PROBLEM: X

I. PROBLEM DESCRIPTION: (Include source, item identify, customer, project number and adetailed description of the condition/s)

Reference PR-071 for terminal board

In accordance with Target Rock Commercial Grade Dedication Program, critical characteristics forcommercial grade items and the method of attribute verification are designated on Target Rock's CCAV(Critical Characteristics Attribute Verification) Sheet. The critical characteristics of the component aredetermined by Target Rock Engineering based on the component's safety function. During auditsurveillance activities at Target Rock, receipt inspection of pressure switch, TR Part No. 200372-1, wasperformed on September 11, 2012. Per the applicable CCAV Sheet Addendum (Method 2 dedication),several performance characteristics require verification. One such characteristic requiring verification issample testing of the lead wire material between the potted switch and pins. However, the CCAV SheetAddendum listed the applicable dedication method as Method 1 only. It was therefore assumed that therequirements of the CCAV Sheet Addendum was not being performed. In addition, TR could not provideany evidence of a supplier survey. The material verification analysis of the lead wire was requested duringthe audit surveillance. Target Rock was unable to provide material test analysis for these componentsduring the audit.

NOTE: Decision basis for reporting problems, See QMP 1014.

Page 1 of 5

L

CuRTISSWRIGHTT FLOW CONTROL, TARGET ROCK DIVISION,

PROBLEMý REPORT PR-073

II. EVALUATION OF PROBLEM:

Quality Engineering/Engineering Review

__ Correctable within specification requirements.

x Not correctable within specification requirements (Nonconformance)

Problem Solution or Evaluation of Nonconformance Status(Provide Details)

The pressure switch (TR Part No. 200372-1, supplier part number and model number 608GC851) ispurchased from a single approved Target Rock supplier (Custom Control Sensors, Inc). The pressureswitch has been obtained from the same supplier since the inception of the drawing (1972). In addition, thesupplier part number is unique to the TR part number.

The pressure switch consists of a standard switch element, single throw double pole (STDP) manufacturedby Honeywell (1 ISX22-T). The switch element is wired to external pins and potted inside a stainless steelcase. The pressure side of the switch is connected to external threads and the electrical side of the switchhas a standard connector to mate to the three pins. The primary function of the pressure switch is to satisfythe ASME Code requirement that "means shall be provided to reveal failure of the pressure sensingelement, such as a bellows". The TR 3-stage safety relief valve employs a machined bellows as theprimary sensing element and thus this pressure switch is installed in the sealed chamber surrounding thebellows to detect leakage past the bellows.

The pressure switch had been procured for many years to the TR drawing, without Commercial GradeDedication. However, with the commencement of Commercial Grade Dedication, TR generated the CCAVSheet (Method 1 Receipt Inspection) and the CCAV Sheet Addendum (Method 2, Commercial GradeSurvey), in accordance with the Commercial Grade Dedication Program. This supplemented the drawingwith critical characteristics that were required to be verified. For reasons that cannot be verified, theCCAV Sheet Addenda for this part states the dedication method to be in accordance with Method 1 only.Therefore there has never been a Commercial Grade Survey (Method 2) performed at the supplier'sfacility.

While the supplier is not subject to IOCFR50 or lOCFR21, the supplier is certified to AS9100 and IS09001and is frequently audited to confirm compliance with AS9100 and IS09001. In addition, the supplier hasconfirmed that the assembly and test process for this pressure switch has not changed since 1975. TR hadperformed a qualification test for GE in 1975 with this revision of the pressure switch. Therefore thispressure switch has been qualified to the GE requirements and has remained unchanged since that test. TRhas obtained a representative traveler from the supplier. The traveler provides objective evidence that eachpressure switch undergoes a proof pressure test, functional testing and a dielectric test. A copy of thesupplier traveler is given in Attachment 1.

Page 2 of 5

CURTISS WRIGHT FLOW CONTROL TARGET ROCK DIVISION

PROBLEM REPORT PR-073

All of the critical characteristics that are listed on both the CCAV sheet and CCAV Sheet Addendum wereverified on 6 pressure switches that TR had in Finished Goods Inventory. All 6 pressure switches met allrequirements. The 6 switches were from four different lots. In addition, S/N 435 was destructively testedfor complete material analysis.

S/N TR Cert Number Additional Tests Performed @ TR421 None Assigned Burn test, Functional test, Dielectric test429 04-0424 Burn test, Functional test, Dielectric test432 05-2452 Burn test, Functional test, Dielectric test435 05-2452 Burn test, Functional test, Dielectric test, Materials analysis438 05-2452 Burn test, Functional test, Dielectric test445 05-3108 Burn test, Functional test, Dielectric test