Cultivation of microalgae in shake flasks and laboratory...

Transcript of Cultivation of microalgae in shake flasks and laboratory...

Cultivation of microalgae

in shake flasks and

laboratory scale

photobioreactor

Authors of the presentation:

Bsc. Chem. Liene Kunga (Laboratory of Bioengineering, Institute of wood chemistry)

Dr.sc.eng. Juris Vanags (Biotehniskais Centrs, JSC)

Microalgae

• Microalgae are relatively easy to cultivate – they can grow using wastewater as well as clean water and can easy obtain nutrients.

• Using photosynthesis, microalgae can reproduce themselves and complete all growth stages in a short time.

• Microalgae are widely used in different industries – pharmaceutical, cosmetic, in those dealing with pollution prevention and especially biofuels.

• Because of the wide range of use, there is an active interest in microalgae large-scale cultivation.

2

1 http://www.infinitamenteverona.it/2014/wp-content/uploads/2014/02/cellule-alga-al-microscopio.jpg2 http://protist.i.hosei.ac.jp/pdb/images/chlorophyta/scenedesmus/maximus/sp_1.html3 http://www.microscopy-uk.org.uk/mag/indexmag.html?http://www.microscopy-

uk.org.uk/mag/wimsmall/green.html

12

3

Microalgae cultivation• Commonly algae biomass production requires sterile conditions with

well-defined external parameters.

• Microalgae biomass production is based on the simple scheme:

CO2 + H2O + nutrients + light energy → biomass + O2.1

• The simplest cultivation vessel is an illuminated flask that is placed on a shaker.

• More efficient cultivation systems - closed laboratory and pilot scalephotobioreactors .

• The latter can provide contaminant-free environment and make possible the control of culture pH, temperature, CO2 concentration in aeration gas, light intensity, and other culture variables, hence giving a wider range of relevant products.

31 MASOJÍDEK, J., et al. Mass cultivation of freshwater microalgae. Encyclopedia of ecology, 2008, 2226-2235.

Types of photobioreactors• Tubular reactor (TR)

– Vertical TR

– Horizontal TR

– Helical TR

– α-Shaped TR

Generally in the TR the microalgae culture is circulated in transparent tubes by a centrifugal pump, and passes intermittently through a degasser – i.e. an air-sparged vessel, where the accumulated oxygen is blown off.1

• Flat plate reactors (FPR)Vertically or horizontally oriented flat, transparent vessel in which mixing is carried out directly in the reactor via air sparging.1

• Stirred tank reactor STR)A vertical cylindrical tank, in which agitation is provided via an impeller or magnetic stirrer (in smaller units), every parameter can be controlled to a higher level than in other reactor types. Illumination can be provided internally/externally by artificial light.1

• Etc.

41 A. Catarina Guedes, F. Xavier Malcata. (2012). Bioreactors. Design, properties and applications. Antolli ,P.G., Liu, Z. (Eds).

New York: Nova Science Publishers, Inc.

Stirred-tank photobioreactor

• Our company uses stirred-tank photobioreactor for microalgae

cultivation.

• So far this type of reactors have been used in rather small laboratory scale

due to the problematic light provision for all cells. The bigger the vessel is,

the more critical this factor gets.

• We have designed original magnetic coupling which allows to place

multiple mixers on long axels.

• Using this approach it enables us to design stirred-tank photobioreactors

with a larger diameter and height.

• Advantages of this kind of photobioreactor: better mixing (thus light

provision) and aeration resulting in better gas solubility, thus – increase in

biomass yield.

5

Challanges

Algae cultivation has its own challenges as well:

• Strain selection - a need to select and grow highly productive algal strains.

• Energy consumption - closed photobioreactors need energy for mixing the

culture suspension, water pumping, gas compressing for bubbling (CO2

transfer), harvesting/dewatering the culture biomass, and they have

much embodied energy in the materials of construction.

• Availability of the sources of nutrients (for large scale production) - often

chemical or inorganic fertilizers are used to achieve appropriate growth

rate of microalgae.

• Distribution of CO2 - even though CO2 may be available as flue gases

from power or chemical plants on industrial scale, CO2 distribution is

problematic.

Still, because of the benefits of algae cultivation, in many cases it is worth

dealing with and overcoming these challenges!

6

Factors that affect microalgae biomass

production

• Light intensity;

• Temperature;

• Nutrients status – concentrations of carbon and nitrogen;

• Mixing;

• Aeration.

7

The effect of light intensity

• Microalgae use light as a source of energy for synthesizing the cell

protoplasm, and their growth rate is maximum at the saturation intensity

of light and decreases when its intensity increases or decreases.

• For many microalgae, increase in the light intensity causes

photoinhibition because of disruption of the chloroplast lamellae growth

and inactivation of the enzymes involved in the carbon dioxide fixation.

• Optimum light intensity for microalgae varies depending on the strain.

For example in literature can be found that for Desmodesmus sp. cultivation optimum light intensity was 98 μmol/m2/s , but for Dunaliellaviridis -700 μmol/m2/s .1,2

8

1FANG, J., HAO R., LIU, Y., LI, G., ZHOU, Y., 33 DONG, R. Isolation of a novel microalgae strain 34 Desmodesmus sp. and

optimization of environmental factors for its biomass production. Bioresource technology, 2013, 36 148, p. 249-254.2GORDILLO, Francisco JL, et al. Effects of light intensity, CO2 and nitrogen supply on lipid class composition of Dunaliellaviridis. Journal of Applied Phycology, 1998, 10.2: 135-144.

The effect of temperature

• Temperature influences the algae growth rate, cell size, biochemical

composition, and nutrient requirements.

• Cultivation at optimal temperature provides the minimum cell size as well

as efficient carbon and nitrogen utilization and reduces the risk of

photoinhibition.

• If temperature is higher/lower than the optimum - a significant decrease

in the growth rate can be observed.

• Optimum temperature for microalgae also varies depending on the strain.

For example in literature can be found that for Haematococcus pluvialiscultivation optimum temperature was 25 °C, but for Chlorella sorokiniana it was 30 °C.1,2

9

1 HATA, Norihiko, et al. Production of astaxanthin by Haematococcus pluvialis in a sequential heterotrophic-

photoautotrophic culture. Journal of Applied Phycology, 2001, 13.5: 395-402.2 MORONTA, R.; MORA, R.; MORALES, E. Response of the microalga Chlorella sorokiniana to pH, salinity and

temperature in axenic and non axenic conditions. Revista De La Facultad De Agronomia, Universidad Del Zulia, 2006,

23: 28-43..

Scale up

• The aim of the scaling-up is to obtain larger cell/product quantities at a

larger scale with at least the same viability and quality of culture as

obtained at a smaller scale.

• Bioprocess optimization traditionally starts with cultivation experiments

in flasks.

• Afterwards, the scale-up is done - the process transfer from flasks to a

laboratory-scale photobioreactor in which further experiments are

performed prior to pilot plant studies.

10

Microalgae cultivation in shake-flasks

• In order to study the influence of environmental factors and to do an

appropriate scale-up different experiments was performed in shake flasks

thus easily providing multi-parameter variation in parallel experiments.

11

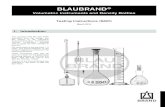

12

Figure 1. Schematic diagram of the experiment setup: 1 – air pump; 2 – CO2

cylinder; 3 – reductor; 4 – gas flow meters; 5 – filter; 6 – pure water; 7 –

condenser; 8 – microalgae cultures; 9 – thermostat; 10 – thermostat tubes; 11 –

gas sparger; 12 – orbital shaker; 13 – LED; 14 – DC/AC adapter.

13Figure 2. Experimental set up of microalgae cultivation system

Laboratory-scale stirred tank

photobioreactor

• Based on the results obtained in the shake-flasks experiments laboratory-scale stirred tank photobioreactor was developed.

14

Figure 3.

Schematic diagram

of the

photobioreactor

15Figure 4. Laboratory photobioreactor

Experiments – materials and methods

• D. Communis were grown in laboratory bottles and in a laboratory-scale stirred

tank photobioreactor.

• Different groups of experiments were set up and D. communis cultivation was

performed in 500 ml laboratory bottles. The range of CO2 concentration used in

the air-CO2 mixture was 0-16 v/v% supplied with a flow rate of 0.5 vvm (gas

volume per unit liquid culture volume and per minute), light intensities range

was 100-600 µmol m2s-1 (illumination provided by LED cases), temperature 21-29 °C, shaking – 150 rpm. Working volume – 400 ml, BG-11 medium.

• Based on the obtained results 6.0 liter laboratory-scale stirred tank

photobioreactor was developed. It was equipped with a novel upper magnetic

stirrer drive and a standard Rushton-type impeller (100-300 rpm), illumination

(300-870 µmol m2s-1 ) provided by a LED case around the bioreactor.

Temperature 25±1 ºC , air-CO2 mixture (96:4 v/v%) supplied continuously with

a flow rate of 0.25 vvm. Working volume 4.0 l, BG-11 medium.

16

Effect of different temperatures

17Figure 5. 21 ºC (1), 23 ºC (2), 25 ºC (3), 27 ºC (4), and 29 ºC (5)

Effect of light intensity

18

Figure 6. 200 µmol m2s-1 (1), 300 µmol m2s-1 (2), 400 µmol m2s-1 (3), 500 µmol m-

2s-1 (4) and 600 µmol m2s-1 (5)

Effect of CO2 concentration

19Figure 7. 4 v/v% (1), 8 v/v% (2) and 16 v/v% (3) of CO2

Comparison of cultivation results obtained in

laboratory bottle and laboratory-scale photobioreactor

20

Figure 8. (1) - 0.4 l laboratory bottle; (2) - 4.0 l laboratory-scale photobioreactor; (3) – the light

intensity profile for the experiment in photobioreactor.

Conclusions

1. Optimum D. communis cultivation conditions in laboratory flasks: air-CO2 mixture of 96:4 v/v%, light intensity of 300 µmol m2s-1 ,

temperature 25 °C.

2. Cultivation in flasks gave 17 % higher productivities of biomass than

cultivation in photobioreactor.

3. Lower biomass yield in photobioreactor could be explained by observed

cells mechanical damages.

4. Results can be improved by using shear sensitive mixing system, e.g.,

marine impeller.

21