Ctm Edited

-

Upload

navdeep143 -

Category

Documents

-

view

91 -

download

7

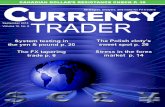

Transcript of Ctm Edited

IND

USTRIAL VISIT

(CHEN

AB TEXTILE MILL AN

D G

RAUCER &

WEIL)

Navdeep singh

SUBMITTED TOMrs. Joyti Sharma

2

3

PREFACEIndustrial visit is one of the important aspect of our syllabus of BBA 1st year. Industrial visit is important attempt to make students aware of functioning of the organizations relating in many spheres like marketing, production, finance and HR etc. For the industrial visit we went to Chenab textile mill (CTM) and Grauer and Weil. CTM is located in KATHUA and Grauer and Weil is located in SIDCO industrial complex, SAMBA. CTM is a part of SUTLEJ TEXTILES AND INDUSTRIES LTD. Which is part of K.K.BIRLA group of companies? According to company’s history it was actually situated in Rakhoo chak and was spread over 800 canals whereas Grauer and Weil is a part of group of Grauer and Weil India ltd. and spread over 80 canal in SAMBA. CTM is a top most company in J&K producing yarn in different varities where as Grauer and Weil manufactures industrial product such as polishing compounds, fibers and chemicals etc.

4

We arrived for visit at 9 o’ clock in the morning from our college (GOVT.MAM PG COLLEGE) to CTM and Grauer and Weil and spent 2 to 3 hours there and met production manager, Mr. R P Sharma and H R manager, Mr. O P Sandhvani and factory manager, Mr. C S Rathore who provide relative information regarding organization working of different departments. And in Grauer and Weil we met senior manager Mr. Deshpande who guides us relating wit establishment of plant and its working in the state. Therefore we concluded that both these organizations are working with members from all the parts of country and are being capable of expanding their business. Visiting CTM and Grauer and Weil adds to my understanding and gave me a lot to learn.

5

ACKOWLEDGEMENT

I have immense pleasure to acknowledge my sincere

gratefulness towards my erudite and vibrant supervisor,

Mrs. Jyoti Sharma, Professor, Govt. M.A.M PG

College, Jammu, who has been a constant source of

inspiration to me during the course of the study. His

intellectual and diligent guidance always kept me

geared for giving my best for this project.

I am obliged to Prof. Dr. Ajit Angral (Principal, Govt.

M.A.M PG College, Jammu) and all other faculty

members who were always there to extend their

helping hand to me.

I am pleased to express my thankfulness to respondents

for giving their precious time and relevant information

for my study.

Last but not least, I owe my earnest thankfulness to

THE ALMIGHTY for bestowing me with the

willpower and patience that has made this endeavor a

success, my family and friends who have helped me in

bringing out the best in the industrial visit, directly or

indirectly.

6

TABLE OF CONTENT (Including list of tables and illustrations):-

TOPICS Page No

1. Introduction of the organization :-

A)Introduction to the parent company- SULTEJ

Historical background of Sutlej

Sutlej- Management

Sultej- Group

8-14

B) Profile of Chenab Textile Mills.

Brief history of CTM

Board members of CTM

Organisation Structure

Brief review of all Dept.

Values, Mission & Vision of the company.

Companies Quality Objectives.

Companies Quality Policy.

C) SWOT Analysis of the company.

D) Manufacturing process of yarn.

Process of spinning.

E) Company History.

History & Development.

Inauguration of second unit.

Modernization in CTM.

ISO 9002 certificate.

Development of CTM

F) Source of Raw Materials.

7

G) Financial status of the company.

Turnover of CTM.

Gross fixed assets & net fixed assets of CTM.

8

Introduction to the parent company

Group: - K K BIRLA GROUP CTM which is a part of the Sutlej Textiles and industries Ltd. is itself a part of K. K. Birla Group of Companies. Mr. C S Nopany is the chairman of the K. K. Birla Group of Companies, which has interests in diverse fields like Fertilizers, Engineering, Textiles, Sugar, Tea, Coffee, Food Products, Media, Information Technology, Biotechnology and Shipping.

Company: - Sutlej Textiles and Industries Limited (Sutlej)

was incorporated on 22nd June, 2005 and was created out of a corporate restructuring exercise in which the Textiles Divisions of Sutlej Industries Limited (SIL) and Damanganga Processors Limited (DPL) were demerged into Sutlej with effect from July 1, 2005. The restructuring is aimed at making Sutlej into a focused and an integrated company in the Textiles Industry with its range of products varying from yarn to fabrics to home furnishing and now garments.

Historical Background

9

Sutlej has inherited the legacy of SIL, which was promoted by late Mr. G.D. Birla in 1934 under the name of Sutlej Cotton Mills Limited, which was subsequently changed to Sutlej Industries Limited in 1995.

Originally, SIL was set up with a composite textile mill at Okara now in Pakistan. After the partition in 1947, the factory at Okara was seized by the Government of Pakistan.

In the year 1963, SIL established Rajasthan Textile Mills (RTM) at Bhawanimandi, District Jhalawar, Rajasthan to produce cotton yarn. In 1970, it diversified into Synthetic blended yarn. In 1981 SIL leased a spinning unit called Chenab Textile Mills (CTM) from Texmaco Ltd. situated at Kathua (Jammu & Kashmir), manufacturing cotton yarn and synthetic yarn. Subsequently in 1997, SIL purchased all the assets of CTM.

In 2001, SIL forward integrated its operations by establishing Damanganga Fabrics (DGF) at Daheli in Gujarat to manufacture and process fabrics.

Sutlej has recently installed facilities to manufacture Home Furnishings and Garments units at DGF.

Sutlej is today an integrated player in the textiles industry with a value chain extending from yarn at one end and extending to fabric, garments and home textiles at the other, enabling it to address opportunities in every intervening segment.

.

CTM - Management

10

The management of CTM is vested in its board of directors comprising of eminent industrialists, professionals and persons having wide range of industrial experience.

Dr. K.K. Birla was the Chairman of Sutlej and was the

Chairman of the K. K. Birla Group of Companies. Dr Birla was also a former member of the Rajya Sabha.

Mr. Chandra Shekhar Nopany is the owner and Vice

Chairman of Sutlej. He also holds a Masters Degree in Science of Industrial Administration from Carnegie Mellon University, Pittsburgh, USA and is a Chartered Accountant. He is an eminent industrialist and is actively involved in various sectors such as Sugar, Textiles and Shipping. He is the past President of Indian Chamber of Commerce, Kolkata. Presently, he is also the President of Indian Sugar Mills Association.

The Authorised Share Capital of the Sutlej is Rs.17.90 crores comprising of 1, 3900000 Equity Shares of Rs.10 each and 40,00,000 Preference Shares of Rs.10 each.

The Paid up Capital of Sutlej is Rs.10.92 crores comprising of 1,09,21,908 Equity Shares of Rs.10/- each, which have been allotted pursuant to the Schemes of Arrangement to the shareholders of SIL & DPL and will be listed at Bombay Stock Exchange and The National Stock Exchange of India Limited.

IN WORDS:- Management has been defined in a variety of ways. It may be

considered in terms that describe what managers do in the operation

of their organization plan, organize, initiate and control operation.

They plan by setting strategies and goal selecting the best course of

action to achieve the plan. They organize the tasks necessary for the

operational plan, set these tasks into homogeneous groups and

assigns authority delegation. They control the program standards

11

and avoiding deviation from standards. Otherwise the term

management refers to the mustering of physical and human

resources to carry planned activities and control performance in

order to ensure that what is done, what is expected and so realize

the objective of an establishment. Thus company in the best

position to develop the business maximize the profitability and to

maintain the customers satisfaction with its best quality production.

The relations between workers and management continue to be very

cordial and harmonious during the history. Its proof is that here

never has been any strike or lockout. The company is managed by a

team of professionally competent managers, who are well versed

and learned persons in their work.

. BRIEF HISTORY OF CHENAB TEXTILE MILLS

This is a reference about the establishment of this organization at

Kathua in the book titled “Indira Gandhi Reminiscences”, written

by K.K.Birla. He has written that Sh.D.P.Dhar while he was a

minister met sh. G.D. Birla to do something for the industrially

backward state of J&K and requested to start some industry there.

Late Pt. Jawahar Lal Nehru too spoke to Sh.G.D.Birla, who in turn

advised Mr.K.K.Birla to establish a textile mill there.

12

Chenab Textile Mills Kathua, is a Birla’s concern (K.K.Birla Group

of Industries), installed in early 1961and its testing period of two

years. Its foundation stone was laid on 12th April, 1962 by the state

industrial minister “Mr. Bakshi Gulam Mohd.The foundation stone

was laid for the first cotton unit comprising of 12600 spindles.This

section was fully functional with a short duration of three years

only.

Chenab textile mills is a part of Sultej industries ltd.A Blue chip

Company of the K.K.Birla Group (one of the top twenty Business

Houses in India)

A Chenab Textile Mill is one of the leading companies in the textile

industry. This company is situated in the mid heart of beautiful city

Kathua. Chenab Textile Mills, equipped with most modern and

state of the art textile machines and sophisticated quality control

equipments, started its operations in 1978 and today is well

established and known for its quality products. Mill's strength lies

in its trained and dedicated workforce and continuous upgrading of

human resources skills. It has been selected by the Government of

Jammu & Kashmir for the special award for its contribution

towards generation/promotion of employment in the State and

contribution to State revenue. At present this Mill is divided in 10

13

units running with the capacity of 170000 spindles Approx. This

will be producing 110 tones of yarns per day. The main production

of this mill is synthetic yarn (Polyester, Acrylic.ViscoseCotton,

cotton mélange, polyester\acrylic yarn, viscose\acrylic yarn,

polyester/viscose yarn, acrylic/cotton yarn & viscose/cotton yarn)

as well as cotton yarn. This mill is fully determined to get ISO-9002

certificate for quality. This mill is equipped with high production

machines of latest techniques. This mill is on the path of progress

by its slogan:-

"WORK IS WORKSHIP”

K.K.BIRLAGROUP

BOARD MEMBERS OF CTM

14

Group President :Sh.S.K.Khandelia

Joint executive President :- Sh. K.C.Sharma

Chairman :-K.K.Birla

Vice Chairman :-C.S.Nopany

Secretary :- D.R.Prabhu

BOARD OF DIRECTORS OF CTM

Dr. K.K. Birla NED/PGMr.C.S. Nopany NEED #Mr.U.K. Khaitan I/NEDMr.S.M. Aggarwal NEDMr.J.S .Varshneya I/NED

Mr.Bodhiswar Rai I/NED

Mr. Rajaram Muchhal I/NED

Mr. Amit Dalal I/NEDMr. R.N. Laddha WTD

NED :- Non Executive Directors WTD :- Whole Time Director # :- Related to Dr.K.K.Birla I :- Independent PG :- Promoters Group

. ORGANIZATION STRUCTURE:

15

Organization is a group of persons working together to achieve a

common goal. Organization indicates conscious combinations of

systematic arrangement of various resources in the term 6 M’s

Men

Machine

Material

Money

Management information

Marketing

An organization structure means establishment of a hierarchy

according to the authority and responsibility. Every decision of

work has to follow the channel and no activity of an enterprise can

go out of it.

A BRIEF REVIEW OF ALL DEPARTMENTS

Chenab Textile Mills is a very big concern. The Chenab Textile

Mills is spread of canals, has been acquired on lease basis for a

period of 99 years. It has been functioning smoothly and employs

about 9000 workers and 750 staff members.

Chenab Textile Mills has the following departments;

Marketing Department

Sales & Excise Department

Financial Department

Raw Material Department

Time Office Department

Store Department

16

Human Resource Department

EDP (Electronic Data Processing Unit) Department

Budget & costing Department

Typing Department

Report Section

Process House

Spinning Quality Control Department

General Department

Finishing Department

Finishing Cotton Department

Finishing Maintenance Department

Mixing & Waste Department

Building & Engineering Department

Outstation Staff Department

Watch & Ward Department

Other Subordinate Departments.

VALUES, MISSION AND VISION OF THE COMPANY.

VALUES:-

CARE: - Giving back to the society, servicing the

community and providing respectful conduct to the public

and our peers.

CRAFT: - Treating the science of textile yarns with

dedication and reverences of an art form, we believe in our

work as a merger of technology and craft.

17

MISSION: -

To be the largest single point provider for all blends and shades of

spun yarns and an organization that prides itself on integrity,

environmental consciousness, scheduled delivery and adherence to

international quality norms - to the best of our customer’s

satisfaction.

VISION: -

To be a leading player in the global textile industry, providing

comprehensive textile solution under one roof, highlighted by

quality, variety and impeccability for our esteemed customers.

COMPANY’S QUALITY OBJECTIVES

1. Consistent yarn quality.

2. Competitive yarn price.

3. Scheduled timely delivery.

4. Systematic training.

5. Continual improvement in product process requirement.

7. Development of new variety of yarn.

COMPANY’S QUALITY POLICY

It is the quality of CTM to produce and supply Standard

quality yarn concisely at competitive prices on scheduled

time to achieve highest level of satisfaction.

18

To fulfill the quality policy.

To attend Company’s work system policy

Work system relating to all departments training and

involvement of all concerned.

Production facilities and technology shall be updated

continually to meet the customers ever increasing quality and

product requirements.

Stress will be given on research for improvement in existing

quality and development of new varieties of yarns.

C. SWOT ANALYSIS OF THE COMPANY

STRENGTHS:-

Various incentives provided by J&K Govt. such rebates in

taxes like octroi, toll tax and other duties on inter – state

borders and continuous supply of electricity at very cheaper

rates.

Availability of labour at comparatively cheaper wages.

Good effective distribution channel.

High quality products manufactured by the mill.

Consumer of multiple fiber (man made and synthetic),

making it a versatile developer

Strong R&D and innovation focus helping accelerate new

design.

Modern technology and assets reflected in the fact that about

71% of gross block is less than seven yrs old.

19

Amongst the lowest cost producer of fabric in India, large

and reputed customer base within India and abroad.

WEAKNESSES:-

High prices of the yarn.

Less number of agents and less deals in some areas

Much dependent upon depots for the distribution system.

Nearness to the raw material resources but distant from

consumer market.

High transportation costs.

OPPORTUNITIES:-

Following the introduction of WTO, the company has the

potential to cater to a large and growing textiles market.

Cater expansion will enable the company to diversify its

product basket and reduce cost even further.

Increase in the demand of cotton yarn, staple yarn etc.

Export to other countries.

Erection of new yarn required industries.

The company has large sum of labour staff, proper

channelization can decrease the costs to a greater amount.

THREATS:-

20

Entry of new Textile Industries.

Low prices of some competitors.

Presence of small scale manufactures.

Hardening of rupee and raising interest rate.

Cotton is being increasingly preferred over man made

fiber.

Better management by rival firms.

D. MANUFACTURING PROCESS OF YARN.

1. Mixing: In mixing department various types of fibers are mixed

and blended in different proportions to produce different qualities

of blended yarns.

2. Blow-room: After mixing the processed materials passed through the blower. Here hot air is blown with great speed to dye the above material. It is then processed to acquire the shape of sheet roll (lap form).

3. Carding machine: Carding may be defined as the process of reducing the entangled mass of fiber web by working between two closely spaced relatively moving surfaces clothed with wire points. The functions of carding machine are further removal of impurities, dropping out the fibers short in length and removal of immature fibers. Carding machine converts the useful fiber into silver form (called carding silver).

4. Super-lapping machine: The fibers obtained from carding machine are fed in the second machine and super laps are produced.

5. Comber machine: Super laps are fed in comber machines for the parallelization of cotton fiber to produce combed silver processed for manufacturing the milling yarn.

21

6. Drawing machine: The carding silver is now fed into drawing

machine. This machine works on parallelization and blending of

fiber.

7. Simplex machine: The fiber obtained drawing machine is fed

from one end into next machine and is drafted into Hank Roving

according to the counts to be spun. In this process twisting is done

to produce the Rove. The twist is sufficient to hold the fibers in a

Roving and is capable of being untwisted at ring frames.

8. Ringing of frames: This is an important operation in the manufacturing of yarn. In this process spinning is done and yarn is produced.

9. Auto coner: Its function is to remove the defects of the single yarn. If yarn is to be made is of single ply, then it goes directly for packing.

10. Cheese winding and reeling: This process prepares single yarn into the ply yarn as per the demand of the customer.

11. Cone winding and reeling: The main function of this process is

to remove weak portions of yarn and to remove extra surface

material for final packing of yarn. In case of yarn required in hanks,

it is reeled in hanks by reeling machines.

12. Bundling: In this process bundles of hank yarn are prepared.

13. Packing: These bundles are packed in boxes and are made to

sell as final product (yarn).

PROCESS OF SPINNING

22

(Dyeing)

(Blow room)

Trumac with Multimixer, LMW

(CARDING)

23

(DRAWING)

(Ring Frame)

(Auto Coner)

24

(TFO Twisting)

(Elasto Twister)

(Hairyness & Evenness tester)

25

(Uster Tester -3 to check Yarns

imperfections)

(Colour Matching Computer)

(Packing cartons)

E. COMPANY HISTORY

26

HISTORY AND DEVELOPMENT:

Initial capacity was 4000 kgs. Of staple yarn per day its initial capital was Rs. 83 lacks. In 1973 it rolled to 98.84 lacks. In 1962, when CTM was installed; there was no railway station in J&K state. Raw material and the finished yarn were transported via Pathankot (app. 25kms.From kathua). Raw Material was purchased from various places like Bhatinda, Amritsar, Malot and Delhi. The cost of production was too high because of large expenditure on transportation of goods and raw material State Government provided incentives and rebates in takes such as octroi, toll tax and other duties on inter- state borders.The incentives included the continuous supply of electricity at very cheaper rates than the other states. The labour was also available at the comparatively cheaper wages. There is no source of raw material in J&K as the major agricultural production is rice, wheat and beans etc. Previously there was no market for the product-the finished goods, in the state but little consumption of the product has developed in the region of Samba and Srinagar.The main markets at that time for selling the finished goods, staple yarn were Ludhiana, Amritsar, Panipat and Delhi. Initially the unit was producing only staple yarn but later on it diversified partially to cotton yarn production too along with the staple yarn.

Modernization in CTM:In 1981, old machineries were replaced with the modernized hi-tech machinery. In cotton section 3080 more spindles were meant for the production of acrylic yarn. With that the unit entered in exporting of the quality yarn to Nepal and Australia.In the recent years (since 1991-92) the mill has been modernized by replacing the new sophisticated and prestigious machinery in place of the old. The mill has installed in the recent years certain years certain modern machines like Open-Ended, Roller Spinner Machines with the RPM of high speed. Rupees 4 crores have been sent for the modernization of the unit during the years 1991-93. An automatic winding machine of speed performance is going to be launched at or before next year. Hence modernization, the fast growing need of the unit is on the move keeping aits prestigious place in the highly competitive market of the business world.The expansion of plant has been done by 2,112 spindles to manufacture ply dyed yarn.

27

Units Years of Inauguration No. of spindles

1 1962 14304

2 1976 7968

3 1990 9984

4 1992 8640

5 1993 5760

6 1995 8448

7 1997 15240

8 2000 27600

9 2006 40704

10 2008 31104

TOTAL 169752

ISO 9002 Certificate

In Oct 1998, Chenab Textile Mills Kathua finally got ISO 9002

certificate from the international standards organization for its unit

4 and 5 out of six unit it has CTM was trying hard since many years

to received the ISO 9002 certificate. Now its aim is to received the

ISO 9002 certificate for its remaining units. Now it has ten units.

Development of CTM

Since the commercial production stated in Jan 1965, the mills has

28

been continuously investing in modernization and expansion of

capacities. As on 31st of March, 2000 the installed capacity of mills

is around 60,000 spindles. The production capacity increased by

12000 Kgs of staple yarn per day. As per the company installed its

first unit whose capacity is today is about 14304, the 2nd unit of

company is established in 1976and capacity of the unit is 7968, the

3rd unit is inaugurated in 1990 increased its capacity upto 9984

spindles. The capacity of fourth is 8640 spindles get inaugurated in

1992. The fifth unit of CTM is prepared in 1993 get a modernized

with the 5760 spindles. The sixth unit having a capacity of 8448

spindles today gets established in 1995. The seventh unit is

established in 1997 get the capacity of 15240 spindles. The eighth

unit is established in 2000 at present working with the power of

27600 spindles. The ninth unit having the capacity of 40704 gets

established on 2006.the tenth unit is under construction of 31104

spindles, after the completion of tenth unit, the company has a total

capacity of 169752 spindles.

F. SOURCE OF RAW MATERIAL:

Raw material consumed by this mill is of two type’s i.e. Natural fiber, man made fiber.The cotton fiber comes in the first category and polyester, viscose and acrylic comes in second comes in second category. During the early Eighties, man made fiber was imported from Japan, Italy and Yugoslavia. But now it is purchased form various part. Various sources of man made fiber are described below:-Source of Polyesters:

Reliance industries Limited, Bombay.

29

Bongaigoan Refinery and Petrochemicals Limited, Assam. J.K Synthetics Limited, New Delhi. Indian Organics Chemical Limited, Bombay. Orissa Synthetics Limited, Bombay. Indorama Synthetics Limited, New Delhi. India Poly Fiber Limited, Barabanki.

Source of Acrylic: Indian Petrochemical and & corporation Limited, Baroda. Indian Acrylic Limited, New Delhi. J.K Synthetics Limited, New Delhi. Pashupati Acryl on Limited, New Delhi. Consolidated Fiber and Chemicals Limited, Calcutta. Acrylic Fiber, Kota

Source of Viscose Grasim industries Limited, Nagada. S.I.V Industries Limited Udaipur and Coimbatore

Sources of Black polyester: O.T.C., Orissa Indian Poly Fibre Limited, Barabanki(U.P) J.K Synthetics, Kota.

Inventory Level:The sources of raw material are away from the company. Therefore, to avoid the lay offs; the company maintains inventory level for two -three (2- 3) months.

30

PRODUCT RANGE

CHENAB TEXTILE MILLS HAS A LARGE VARITIES OF RING SPUN COUNT

RANGING NE-8 TO NE-72 IN BOTH RAW WHITE, DYED AND MELANGE.

1. 100% COTTON YARN

2. 100% POLYSTER YARN

3. 100% VISCOSE YARN

4. 100% ACRYLIC

5. 100% COTTON MELANGE

6. POLY/ACRYLIC YARN

7. VISCOSE/ACRYLIC YARN

8. VISCOSE/COTTON YARN

9. ACRYLIC/COTTON YARN

10. POLY/VISCOSE YARN

31

I. FINANCIAL STATUS OF THE COMPANY.

TURNOVER OF CHENAB TEXTILE MILLS

(KATHUA)

(VALUES IN LACS.)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 150

10000

20000

30000

40000

50000

60000

70000

80000

90000

100000

TURNOVER (DOMISTIC AND EXPORT)

Series6

Series5

Series4

Series3

Series2

Series1

32

GROSS FIXED ASSETS AND NET FIXED ASSETS OF CHENAB TEXTILE MILLS (KATHUA)

VALUES IN LACS.

GROSS FIXED ASSETS AND NET FIXED ASSETS

0

10000

20000

30000

40000

50000

60000

YEARS

GROSS FIXED ASSETS

NET FIXED ASSETS

33