Crescnt 1

-

Upload

crescentfoundry -

Category

Documents

-

view

22 -

download

1

Transcript of Crescnt 1

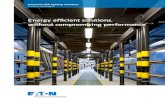

Technological advancements within the area of

engineering have given birth to improved tool and

techniques. And as an obvious result cast iron products

of superior quality stand as a staggering reality

Hold hand of the

experienced

manufacturers who

has the right amount

of knowledge,

industry know how,

experience and skill

set.

when choosing a

service provider

certain things

should be kept in

mind. The service

provider should

have an organized

platform and

should be able to

offer all the

necessary foundry

facilities

We have

comprehensive

international standard

production facilities

The highlights of our production

facilities are:

Location : Vadodara, Gujarat & Kolkata, West Bengal (India)

A Combined Melting Capacity of Over 75,000 MT

6 Induction Furnaces & 6 Cupolas with Linde® Oxygen Plant to Reduce Carbon

Footprint of Melting

Material: Grey/Ductile Iron (GG 20/25 for Grey Iron and GGG 50 for Ductile

Iron)

Sinto® Horizontal Flask-Less High Pressure Moulding Line with Box Size

700x600x250/250

MS Fabrication Unit Capable of Producing Customized Fabricated Products.

Multiple CNC and 4 Axis VMC Machines for Developing New Patterns

Magmasoft ® for Simulation

Comprehensive Machining Solutions

Integrated Paint-Shop for Spray Painting & Powder Coating

Black Bitumen, Water Based, Epoxy and Primer Painting Facility also Available.

Fully Equipped Chemical, Physical, Paint and Sand Laboratories

In-House Container Loading and Weigh Bridge Facility

Integrated SAP® System To Manage All Our Information

The highlights of our production facilities are:

crescentfoundry.com

![1 $SU VW (G +LWDFKL +HDOWKFDUH %XVLQHVV 8QLW 1 X ñ 1 … · 2020. 5. 26. · 1 1 1 1 1 x 1 1 , x _ y ] 1 1 1 1 1 1 ¢ 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1](https://static.fdocuments.us/doc/165x107/5fbfc0fcc822f24c4706936b/1-su-vw-g-lwdfkl-hdowkfduh-xvlqhvv-8qlw-1-x-1-2020-5-26-1-1-1-1-1-x.jpg)

![1 1 1 1 1 1 1 ¢ 1 1 1 - pdfs.semanticscholar.org€¦ · 1 1 1 [ v . ] v 1 1 ¢ 1 1 1 1 ý y þ ï 1 1 1 ð 1 1 1 1 1 x ...](https://static.fdocuments.us/doc/165x107/5f7bc722cb31ab243d422a20/1-1-1-1-1-1-1-1-1-1-pdfs-1-1-1-v-v-1-1-1-1-1-1-y-1-1-1-.jpg)

![[XLS] · Web view1 1 1 2 3 1 1 2 2 1 1 1 1 1 1 2 1 1 1 1 1 1 2 1 1 1 1 2 2 3 5 1 1 1 1 34 1 1 1 1 1 1 1 1 1 1 240 2 1 1 1 1 1 2 1 3 1 1 2 1 2 5 1 1 1 1 8 1 1 2 1 1 1 1 2 2 1 1 1 1](https://static.fdocuments.us/doc/165x107/5ad1d2817f8b9a05208bfb6d/xls-view1-1-1-2-3-1-1-2-2-1-1-1-1-1-1-2-1-1-1-1-1-1-2-1-1-1-1-2-2-3-5-1-1-1-1.jpg)