CORROSION. Rusting of iron is the commonest form of corrosion. It is the process that gradually...

-

Upload

esmond-hawkins -

Category

Documents

-

view

214 -

download

1

Transcript of CORROSION. Rusting of iron is the commonest form of corrosion. It is the process that gradually...

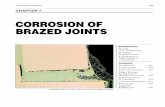

CORROSION

Rusting of iron is the commonest form of corrosion. It is the process that graduallydestroys motor car bodies, steel bridges and other structures and iron roofing andguttering.Rust is the reddish-coloured, flaky or porous deposit that forms on exposediron and steel; it is hydrated iron oxide, Fe2O3.xH20 where x can vary from about0.5 to 2. This means that the composition of rust varies somewhat, depending uponthe conditions under which it is formed.Corrosion of metals involves oxidation

This means that the more easily a metal is oxidised, the more easily it will corrode.Magnesium is oxidised more easily than iron, so we expect magnesium to corrodemore easily than iron. That is what we observe: a piece of cleaned shiny magnesium

ribbon tarnishes more rapidly than a clean shiny iron nail. Gold is very difficult tooxidise, so we expect gold not to corrode. Again that is our observation: a gold ring or bracelet does not tarnish (corrode).

Predicting the tendency of metals to corrode

HOW RUSTING OCCURS

At some spot on the iron surface (often a spot under stress),iron atoms lose electrons to form Fe

2+ ions:Fe(s) → Fe

2+(aq) +2e

–Sites where this oxidation occurs are called anodic sites.The electrons then flow through the iron to some other spot in the surface usually where an impurity such as carbon (which can act as a cathode) ispresent and there, the electrons reduce oxygen dissolved in the thin film of

moisture on the iron surface or in the water touching the iron if the iron object iscompletely submerged:

O2(g) + 2H2O(l ) + 4e- → 4OH-(aq)

Sites where this reduction of oxygen occurs are called cathodic sites.In order for this galvanic cell to continue to operate, there has to be a migrationof ions through the moisture layer from one location to the other. Because salt water is a better conductor than fresh water (which nevertheless is slightly conducting because of dissolved CO2

and so on) rusting proceeds more quickly in salt water. This migration of ions to preserve electrical neutrality in the galvanic cell moves Fe2

and OH– towards each other to form insoluble iron(II) hydroxide:

Instead of a well-preserved steel hull they found it badly corroded. The most obviousproduct of corrosion was stalactite-like structures called rusticles. Scientists found totheir surprise that much of the corrosion was caused by certain bacteria. The Titanichas provided scientists with a new understanding of deep sea corrosion processes.

The Titanic will eventually be destroyed by nature as the iron-eating bacteria continueto corrode the structure of the ship. It is estimated that total corrosion will occur withinthe next 75–90 years. Although the wreck will never be raised due its poor conditionmany artefacts have already been recovered and restored

http://www.msichicago.org/online-science/

How to Prevent Corrosion

When metal is exposed to moisture in the air, damage can occur. Most metals react with oxygen creating rust that can lead to corrosion. When water from rain, humidity or other sources comes in contact with a metal surface, oxygen is dissolved causing a reaction. However, there are ways that you can protect metal surfaces from corrosion, thereby increasing durability and wear of a product with metal parts

http://www.ehow.com/how_5017220_prevent-corrosion.html

Apply coatings like inorganic paints. This extra layer of coating between the metal and the atmosphere helps to prevent against corrosion. These special purpose paints combine tiny zinc or aluminum metals foils with a silicone resin that provides protection similar to metal plating. However, unlike the extremely high temperatures needed to apply metal plating, anti-corrosive paints can be applied in air temperatures just like other paints.

![Numerical Approach for Atmospheric Corrosion … the rusting process [2]. In addition, the covered rust layer affects the wetting time of the rusted steel surface, and Thee et al.](https://static.fdocuments.us/doc/165x107/5afcf6ad7f8b9a864d8cd6e2/numerical-approach-for-atmospheric-corrosion-the-rusting-process-2-in-addition.jpg)