Constant Temp Bath PDF

-

Upload

arunachalam-narayanan -

Category

Documents

-

view

221 -

download

0

Transcript of Constant Temp Bath PDF

-

7/29/2019 Constant Temp Bath PDF

1/14

DEVELOPMENT OF A CONSTANT TEMPERATUREBATH USING PHASE CHANGE MATERIALS FOR LOW

TEMPERATURE APPLICATIONS

B. SRIRAM (31509114050) III MECH

K. VINOTH KUMAR (31509114058) III MECH

N. ARUNACHALAM (31509114005) III MECH

A. PADMANATHAN (31509114304) III MECH

SUPERVISOR: Dr. N. LAKSHMI NARASIMHAN

ASSOCIATE PROFESSOR

MECHANICAL DEPARTMENT

-

7/29/2019 Constant Temp Bath PDF

2/14

PROBLEM DEFINITION

A constant temperature bath employing a thermal energy

storage material and operating between 0 to 50C is to be built

and tested. Comparison on the performance between the

systems with and without a thermal storage material shall be

carried out experimentally.

2

-

7/29/2019 Constant Temp Bath PDF

3/14

MOTIVATION

Chillers for Diffusion Vacuum Pumps have been fabricated

and deployed successfully at our Crystal Growth Centre by our

senior students.

There exists a scope for modifying the design of chillers to

function as a Constant Temperature Bath.

Integration of a Thermal Storage Device to such Constant

Temperature Baths is a novel idea and studies are needed tounderstand the system performance in real situations.

3

-

7/29/2019 Constant Temp Bath PDF

4/14

OBJECTIVES

To design and build a unit that can maintain temperatures in

the range 0 to 50 C for 20 lit water capacity.

To design and integrate a thermal storage device with the

.

To test the performance of the unit with and without a

thermal storage system.

4

-

7/29/2019 Constant Temp Bath PDF

5/14

PROPOSED DESIGN

Temperature of Bath = 0 to 50C

Tank Capacity = 20 litres

Mwater = 20 kgQLoad for 0 to 30C = 2500 Watts (estimated)

QChiller = 1 TR (selected)

QHeater for 30 to 50C = 1 kW (selected)Tank Dimensions (Inner Dimensions) = 303025 cm3

Identified PCM - HS7N (-7 to -5C) or

Frost (-1 to +1C)Identified Supplier - Pluss Polymers Ltd., Noida

5

-

7/29/2019 Constant Temp Bath PDF

6/14

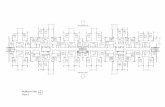

SCHEMATIC OF THE PROPOSED UNIT

WITHOUT PCM

Refrigeration unit

Heater unit

PID controller

6

Temperature sensor(Pt 100)

-

7/29/2019 Constant Temp Bath PDF

7/14

PROPESED UNIT WITH PCM

PCM

Refrigeration unit

Heater unit

7

PID controller

Temperature sensor

(Pt 100)

-

7/29/2019 Constant Temp Bath PDF

8/14

SPECIAL FEATURES

Our system is Cost Effective when compared to the market

availability.

Energy conservation can be made by employing PCM.

By going for mass production, the cost can be reduced to a

considerable extent.

8

-

7/29/2019 Constant Temp Bath PDF

9/14

TIME SCHEDULE OF ACTIVITIES

Activity Period MilestoneLiterature

Survey on

PCMs

0-1 months

Design of heat

exchanger and

PCM

1-2 months Fixing the size of the

unit and capacity

Procurement of

materials

3 months Preparation of quotes,

procurement

Fabrication of 3 months Construction of the

ready for testingExperimentation 3 months Testing the actual

performance of the

unit.

Documentation 1 month Preparing the final

report.

9

TOTAL TIME : 12 MONTHS

-

7/29/2019 Constant Temp Bath PDF

10/14

TIME SCHEDULE OF ACTIVITIES (Bar Chart)

Fabrication

Experimentation

Documentation

s

0 2 4 6 8 10 12

Literature survey

Design of Heat

Exchanger

Procurement of

MaterialsEve

nt

Months10

-

7/29/2019 Constant Temp Bath PDF

11/14

BUDGET ESTIMATION

(i) NON CONSUMABLES

S. No Items ApproximateCost (Rs.)

1. Compressor 6000/-

2. Condenser 1200/-3. Heat Exchanger 4000/-

4. Evaporator Vessel 1300/-

5. Heater 1500/-

6. PID 3000/-

7. RTD 1000/-8. Temperature Indicator 5000/-

9. Refrigerant Gas 3000/-

10. PCM 2000/-

11. Insulation 1500/-

12. Pressure Gauges 1000/-13. Thermocouple 1500/-

Total (A) 32000/-

11

-

7/29/2019 Constant Temp Bath PDF

12/14

Budget Estimation (Contd)

(ii) CONSUMABLES

S. No Items Approximate Cost(Rs)

1. Copper and Silver Brazing Rods 1000/-

2. Adhesives 500/-

3. Thermal Paste 500/-4. Miscellaneous 1000/-

Total (B) 3000/-

TOTAL BUDGET ESTIMATE (A+B+C) : Rs.41,000/-

S. No Items Approximate Cost(Rs)

1. Fabrication and labour charges 6000/-

Total (C) 6000/-

12

-

7/29/2019 Constant Temp Bath PDF

13/14

EXPECTED OUTCOME

Development of a cost effective low temperature bath.

Understanding the actual performance of the bath with a

Latent Heat Storage.

A Publication in National/International level.

13

-

7/29/2019 Constant Temp Bath PDF

14/14

THANK YOU

![322BCH###################################### … · All the factors that affect enzyme kinetics are constant except pH where it varies in each tube Time = 5 min Temp= 37 oC [S] =](https://static.fdocuments.us/doc/165x107/5e78d0c764014172bd4e282c/322bch-all-the-factors-that-affect-enzyme.jpg)