Connection Design Moment

-

Upload

akshit-dhawan -

Category

Documents

-

view

210 -

download

1

Transcript of Connection Design Moment

BUILD-01 (TELCON)

CONNECTION DESIGN FOR FRAME-1

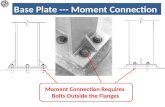

Design momoment resisting Connection( Ref :- Four Tension Bolt End Plate Design Proceedure of AISC (ASD) - (9th Edition))( Ref :- Page no 4-118 of AISC )

Input Data V

Connection Location :- NODE-135

Condition :- DL+WLN1H M D

Moment ( M ) = -55 KNm

End Shear ( V ) = -41 KN

Axial Tension ( H ) = 0

No(n) of Bolts / flange = 4

Bolt Details :-

Fy(Bolt) = 640 mpa ( Grade : 8.8 Class bolts)

Diameter (db) of Bolt = 20 mm

Gross Area (Ag) of Bolt = 314.16 mm2

Net Area (An) of Bolt = 241.9032 mm2

Beam Details:-

Depth (D) = 250 mm

Width (bfb) of Flange = 150 mm

Thickness (tf) of Flange = 5 mm

Thickness (tw ) of web = 4 mm

End Plate Details :-

Max Thickness = 20 mm

Fy = 345 mpa UPTO 20mm THIKNESS 345 Mpa

Analysis :-

End Plate Width = bp = bf + 20 mm = 150 + 20 = 170 mm

Flange Force (Ff) = M / (D-tf) = -55 x 1000 / ( 250 - 5 ) = -225.41 KN

Tensile Force ( T ) per bolt = Ff /n + H/(2n) = -225.41 / 4 + 0 / ( 2 x 4 ) = -56.35 KN

Shear Force per bolt = V/(2n) = -41 /( 2 x 4 ) = -5.125 KN

Checking Bolt Capacity as per IS : 800 Refer :- Clause no 8.9.4 of IS : 800

Actual Tensile Stress ( sft.cal ) in bolt = -232.9546 mpa < 286 x 1.33 (O.K.)

Actual Shear Stress ( tvf.cal) in bolt = -16.31334 mpa < 191 x 1.33 (O.K.)

Combined Shear & Tension Interaction Check( Ref :- Clause no :- 8.9.4.5)

Interaction Check = (sft.cal/sft + tvf.cal/tvf)) = -0.899937 < 1.4 x 1.33 (O.K.)

End Plate Thickness :-

Pe = Effective bolt distance to be used to compute bending moment in end plate

Pe = Pf - (db/4)-0.707w

Where

Pf = Distance of bolt to nearer surface of tension flange = 50 mm

w = weld size = 8 mm

Pe = 50 - ( 20 / 4 ) - 0.707 x 8 = 39.344 mm

Me = Moment to be resisted by end plate

Where

Ca = 1.11 for fy = 345 mpa

0.939336

Af ( Tension Flange Area) = bfb x tf = 750 mm2

Aw ( Area of Beam Web ) = ( D- 2 x tf )x tw = 960 mm2

Therefore

1.1373793961691

Me = -2521719.2858178 Nmm

Fb = Allowable Bending Stress = 0.75 x Fy x 1.33 = 344.1375 mpa

tp = 16.081758452153 mm

Use 16 mm Thk End Plate

HENCE USE 16 mm THICK PLATE & 20 mm DIA. BOLTS

Me =a m x Ff x Pe /4

am = Ca x Cb x (Af / Aw) 1/3 ( Pe / db )1/4

Cb = ( bfb/bp) 0.5 =

am =

Required Plate Thickness tp = ( 6 x Me / ( Fb x bp )) 0.5

BUILD-01 (TELCON)

CONNECTION DESIGN FOR FRAME-1

Design momoment resisting Connection( Ref :- Four Tension Bolt End Plate Design Proceedure of AISC (ASD) - (9th Edition))( Ref :- Page no 4-118 of AISC )

Input Data V

Connection Location :- NODE-135

Condition :- 1.3DL+CL+EQXH M D

Moment ( M ) = 50.83 KNm

End Shear ( V ) = -42.27 KN

Axial Tension ( H ) = -0.81

No(n) of Bolts / flange = 4

Bolt Details :-

Fy(Bolt) = 640 mpa ( Grade : 8.8 Class bolts)

Diameter (db) of Bolt = 20 mm

Gross Area (Ag) of Bolt = 314.16 mm2

Net Area (An) of Bolt = 251.328 mm2

Beam Details:-

Depth (D) = 400 mm

Width (bfb) of Flange = 250 mm

Thickness (tf) of Flange = 8 mm

Thickness (tw ) of web = 4 mm

End Plate Details :-

Max Thickness = 20 mm

Fy = 345 mpa UPTO 20mm THIKNESS 345 Mpa

Analysis :-

End Plate Width = bp = bf + 20 mm = 250 + 20 = 270 mm

Flange Force (Ff) = M / (D-tf) = 50.83 x 1000 / ( 400 - 8 ) = 129.01 KN

Tensile Force ( T ) per bolt = Ff /n + H/(2n) = 129.01 / 4 + -0.81 / ( 2 x 4 ) = 32.15 KN

Shear Force per bolt = V/(2n) = -42.27 /( 2 x 4 ) = -5.28375 KN

Checking Bolt Capacity as per IS : 800 Refer :- Clause no 8.9.4 of IS : 800

Actual Tensile Stress ( sft.cal ) in bolt = 127.9256 mpa < 286 (O.K.)

Actual Shear Stress ( tvf.cal) in bolt = -16.81866 mpa < 191 (O.K.)

Combined Shear & Tension Interaction Check( Ref :- Clause no :- 8.9.4.5)

Interaction Check = (sft.cal/sft + tvf.cal/tvf)) = 0.359237 < 1.4 (O.K.)

End Plate Thickness :-

Pe = Effective bolt distance to be used to compute bending moment in end plate

Pe = Pf - (db/4)-0.707w

Where

Pf = Distance of bolt to nearer surface of tension flange = 50 mm

w = weld size = 8 mm

Pe = 50 - ( 20 / 4 ) - 0.707 x 8 = 39.344 mm

Me = Moment to be resisted by end plate

Where

Ca = 1.11 for fy = 345 mpa

0.96225

Af ( Tension Flange Area) = bfb x tf = 2000 mm2

Aw ( Area of Beam Web ) = ( D- 2 x tf )x tw = 1536 mm2

Therefore

1.3811725668

Me = 1752630.4453 Nmm

Fb = Allowable Bending Stress = 0.75 x Fy = 258.75 mpa

tp = 12.268705443 mm

Use 16 mm Thk End Plate

HENCE USE 16 mm THICK PLATE & 20 mm DIA. BOLTS

Me =a m x Ff x Pe /4

am = Ca x Cb x (Af / Aw) 1/3 ( Pe / db )1/4

Cb = ( bfb/bp) 0.5 =

am =

Required Plate Thickness tp = ( 6 x Me / ( Fb x bp )) 0.5