Conjet Brochure Web

description

Transcript of Conjet Brochure Web

-

Jetfr

ame

101

APPLIED WATERJET TECHNOLOGY

CONJET ABP.O. BOx 507 SE-136 25 HANINGESWEDENPhone: +46 (0)8 55 65 22 40Fax: +46 (0)8 55 65 22 60e-mail: [email protected]: www.conjet.com

Jetframe 101 Nalta

Nalta is an expression from Vilhelmina in Lappland in

northern Sweden. It means half of half and half of that or just

something very small.

-

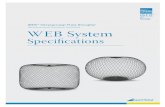

Conjet Jetframe 101

T H E W I D E S T R A N G E O F H Y D R O D E M O L I T I O N E Q U I P M E N T

Conjet Technology removes concrete without causing cracks or damaging the reinforcement, resulting in a good bonding surface.The Conjet Jetframe 101 Nalta has been designed to replace hand lances for a large number of hydrodemolition applications, increasing productivity and improving safety for operators. The compact and lightweight Jetframe 101 Nalta is supplied with high pressure water from a standard hand lance pump and can operate on flat as well as curved surfaces with a radius as small as 400mm. It consists of a feed beam with an oscillating lance, hydraulic unit and a radio remote control box. The Nalta is mainly used for the hydrodemolition of concrete, but is also suitable for other applications, such as surface preparation and descaling of steel. Its main advantages compared to hand lances are: Operation is done from a suitable safe distance Increased production rate No rest needed between sessions Can work with higher reaction forces One-man operation

Features Underwater operation Operation on curved pillars down to a radius of

400mm The feed beam can be extended to 3m using

extra sections The robot can climb on standard scaffolding pipes A trolley makes the Naltas hydraulic unit easy

to transport Highly versatile Can access areas unavailable to other

hydrodemolition robots due to its minute size

The worlds smallest hydrodemolition robot, replacing your hand lance or operating underwater

The feed beam is attached at each end to the step units. They fix onto the scaffolding pipes and automatically climb up or down as the process progresses.

Turning points are set manually by physical stop blocks mounted

on the feed beam. The process is

completely mechanical, allowing the robot to

work under water.

The cradle moves, oscillating the

lance between two turning points on the

feed beam. At each turning point, the

lance angle of attack inverts.

The feed beam is built using one to

three 1m sections. By adding extra

sections, it is possible to extend

the beam length up to 3m.

World wide experienceJetframe 101 has been successfully working with a wide range of projects throughout the world, from high pillars to narrow pipes. We use our experience to help you with your project.

Optional rotor head for surface preparationSeveral rotor heads are optionally available for different surface preparation tasks. For example, a fine surface finish can be achieved on steel using 3000 bar.

Specialapplications

Since the Nalta climbs on standard scaffolding pipes, the applications are endless. Whether the work area is flat or round, wide or narrow, the bearing frame can be adapted to suit the environment. Examples of special applications for the Nalta are shown to the right. Is your project too complex for ordinary hydrodemolition robots? Ask Conjet about adapting the Nalta to match your needs!

Compact and portable hydraulic unitThe Jetframe 101 Nalta system is powered by a hydraulic unit that operates on a single phase 230V, 10A supply. It is mounted on a trolley for easy transport, and can be placed up to 20m away from the Nalta.

Pipes set up for working around a pillar. The Nalta can operate on pillars down to a radius of 400mm. The lance is bent to accomodate for the curved surface.

Special application for working inside pipes or tubes.

This Nalta is equipped with a special rotor

for cleaning the inside surface of

the tube.By placing the feed beam outside the frame, the Nalta can be positioned in very narrow slots.

260 mm

Removing concrete from a square pillar. LAquila, Italy.

Cleaning the inside of a process tank.Italy.

Working on the ceiling of a parking deck. Italy.

Mounted on a frame with wheels, for horizontal work.Stockholm, Sweden.

Removing concrete from a round pillar. France.

Cleaning the outside surface of a pipe. France.

The operator controls all movements of the Jetframe 101 Nalta from a handheld radio control box.

Opt

iona

l rot

or

head

-

Distributor/Agent

AppliedWaterjet

Technology

AppliedWaterjet

Technology

AppliedWaterjet

Technology

AppliedWaterjet

Technology

CONJET ABP.O. BOx 507 SE-136 25 HANINGESWEDENPhone: +46 (0)8 55 65 22 40Fax: +46 (0)8 55 65 22 60e-mail: [email protected]: www.conjet.com

CE, EMC certifiedPictures are illustrative only and do not necessarily show the configuration of the products on the market at the given point in time. These products must be used in conformity with safe practice and applicable statues, regulations, codes and ordinances. Subject to change without prior notice. Copyright Conjet AB, Sweden 2013 All unauthorized copying or sampling strictly prohibited

JETFRAME 101 DATA SHEET

Suggested powerpacks:

Configurations

Technical Data-standard configuration

Cover chart-standard configuration

Dimensions-hydraulic unit

TO

OL

S?

Nalta Oscillator (standard)

Nalta Rotor

Custom

Do not forget the powerpack supplying the robot with high pressure water! Suitable powerpacks for Jetframe are regular hand lance pumps, which range in power from 120 kW to 250 kW, depending on the application. Further information concerning powerpacks can be found in the powerpack brochure and product overview brochure.

3312

801

0 13

- 13

11

Length per feed beam section(2 included in the delivery and maximum 3 sections may be connected)

990 mm (3 ft 3 in)

Weight per feed beam section 8 kg (18 lb)Weight oscillating cassette 12 kg (26 lb)Weight step unit 9 kg (20 lb)Weight hydraulic unit 90 kg (198 lb)Maximum reaction force 600 NPower supply 230 V, 10 A / 3 phase, 380 - 480 VMaximum operating pressure 3000 bar

300 mm

260 mm

1 section = 990 mm

530 mm

700

mm

330 mm510 mmAny length

300 mm

![Kdc brochure [web]](https://static.fdocuments.us/doc/165x107/55c2b7e6bb61ebed338b468a/kdc-brochure-web.jpg)