Concrete Making Materials - CIDC. S. A. Reddi/Concrete_Making... · Concrete Making Materials S A...

Transcript of Concrete Making Materials - CIDC. S. A. Reddi/Concrete_Making... · Concrete Making Materials S A...

Concrete Making Concrete Making MaterialsMaterials

S A ReddiS A ReddiDyDy. MD (. MD (RetdRetd) Gammon India Ltd.) Gammon India Ltd.

General Characteristics of ConcreteGeneral Characteristics of Concrete

StrengthStrengthWorkabilityWorkabilityDurabilityDurabilityPermeabilityPermeabilityFire ResistanceFire ResistanceAbrasion ResistanceAbrasion ResistanceCreep, ShrinkageCreep, ShrinkageThermal ExpansionThermal Expansion

Concrete Making MaterialsConcrete Making Materials

CementCementMineral AdmixturesMineral AdmixturesAggregatesAggregatesWaterWaterChemical AdmixturesChemical Admixtures

CementCementISIS--456 Specifies 10 Types456 Specifies 10 TypesMore Common CementsMore Common Cements

Ordinary Portland Cement, Ordinary Portland Cement, GrGr 33, 43,5333, 43,53Portland Portland PozzalanaPozzalana Cement (PPC)Cement (PPC)Portland Slag Cement (PSC)Portland Slag Cement (PSC)Low Heat Portland Cement (LHPC)Low Heat Portland Cement (LHPC)Sulfate Resisting Portland Cement (SRC)Sulfate Resisting Portland Cement (SRC)

More Common CementsMore Common Cements

Only OPC Graded as 33, 43 & 53Only OPC Graded as 33, 43 & 53Other Cements not Strength GradedOther Cements not Strength GradedIS Code for PPC specifies Strength IS Code for PPC specifies Strength equivalent to OPC 33; some equivalent to OPC 33; some manufacturers are able to get higher manufacturers are able to get higher strengths, but are not authorized to offer strengths, but are not authorized to offer them in higher Gradesthem in higher GradesOnly OPC recommended for Higher Only OPC recommended for Higher grades of Concretegrades of Concrete

Portland Portland PozzalanaPozzalana CementCement

As Per IS Code, PPC has 28 day strength As Per IS Code, PPC has 28 day strength of 33mPa only; not suitable / not of 33mPa only; not suitable / not recommended for Concrete of higher recommended for Concrete of higher strengths; Certainly not for PSCstrengths; Certainly not for PSCIndian Manufacturers do not declare the Indian Manufacturers do not declare the fly ash content; depending on the fly ash content; depending on the manufacturer, the fly ash content varies; manufacturer, the fly ash content varies; resultant uncertain Qualityresultant uncertain QualityAdvantageous for concrete in Sea WaterAdvantageous for concrete in Sea Water

EN Standards EN Standards PFA UsePFA Use

Use only PFA obtained by electrostatic / Use only PFA obtained by electrostatic /

mechanical precipitation. Ash obtained by mechanical precipitation. Ash obtained by

other means shall not be usedother means shall not be used

PFA to be processed to remove all PFA to be processed to remove all

impurities / oversize materials to ensure impurities / oversize materials to ensure

reasonable gradation and particle size reasonable gradation and particle size

As per Euro Code for Concrete, Only As per Euro Code for Concrete, Only

Processed Fly ash permitted in Concrete Processed Fly ash permitted in Concrete

Portland Blast Furnace Slag CementPortland Blast Furnace Slag CementPBFSCPBFSC

Produced by grinding together Portland Produced by grinding together Portland Cement and Blast Furnace Slag Cement and Blast Furnace Slag Suitable for concrete in aggressive soils Suitable for concrete in aggressive soils and waterand waterUse compulsory for concrete exposed to Use compulsory for concrete exposed to Sulfate attack, refer Table 4 of IS 456Sulfate attack, refer Table 4 of IS 456PSC with slag content more than 50% PSC with slag content more than 50% exhibits better sulfate resisting propertiesexhibits better sulfate resisting propertiesThis is generally not available in the This is generally not available in the Indian marketIndian market

Portland Blast Furnace Slag Portland Blast Furnace Slag Cement PBFSC IS 455Cement PBFSC IS 455

Fineness, Compressive strength same as 33 Fineness, Compressive strength same as 33 Grade OPCGrade OPCLow rate of strength gain, formwork removal Low rate of strength gain, formwork removal times increased, slower rate of constructiontimes increased, slower rate of constructionRequires longer curing period Requires longer curing period Use of slag cement improves durability of Use of slag cement improves durability of concrete particularly in marine environmentconcrete particularly in marine environmentIRC 21:2000, permits unrestricted use of OPC, IRC 21:2000, permits unrestricted use of OPC, SRPC & slag cement for all structures SRPC & slag cement for all structures

Portland Blast Furnace Slag Portland Blast Furnace Slag Cement PBFSC IS 455Cement PBFSC IS 455

Slag cements are manufactured by Slag cements are manufactured by grinding and mixing granulated slag with grinding and mixing granulated slag with Portland cement clinker and calcium Portland cement clinker and calcium sulfatesulfate1 1 tonnetonne of OPC needs 1.5 t of raw of OPC needs 1.5 t of raw material and 3.53 kJ energymaterial and 3.53 kJ energy1 1 tonnetonne of blast furnace cement of blast furnace cement containing 65% slag needs only 0.5 t of containing 65% slag needs only 0.5 t of raw material and 1.67 kJ energy; raw material and 1.67 kJ energy; So slag should be used more widely to So slag should be used more widely to save energy. save energy.

Curing period when using PBFSC Curing period when using PBFSC or or PozzolonaPozzolona cementcement

Curing period with OPC: min 7 days Curing period with OPC: min 7 days

Curing period where mineral admixtures or Curing period where mineral admixtures or blended cements are used: min 14 days blended cements are used: min 14 days

Curing period for concrete exposed to dry and Curing period for concrete exposed to dry and hot weather conditions: min 10 days hot weather conditions: min 10 days

Prestressed concrete contains higher quantities Prestressed concrete contains higher quantities of cement, generating more heat of hydration; of cement, generating more heat of hydration; requires effective curing at early stages.requires effective curing at early stages.

SulphateSulphate Resisting Portland Cement Resisting Portland Cement IS 12330 (SRPC)IS 12330 (SRPC)

TricalcuimTricalcuim aluminatealuminate is restricted to low valueis restricted to low valueUse of SRPC beneficial where the concrete is Use of SRPC beneficial where the concrete is exposed to exposed to sulphatesulphate attackattackIS 456 prescribes use of SRPC for certain level IS 456 prescribes use of SRPC for certain level of sulfates in the soil or certain concentrations of sulfates in the soil or certain concentrations in water in water Fineness, soundness, setting time same as OPCFineness, soundness, setting time same as OPCLower compressive strength at 3 and 7 days; Lower compressive strength at 3 and 7 days; 28 day strength is same as OPC 33 grade 28 day strength is same as OPC 33 grade Used in marine structures, foundations and Used in marine structures, foundations and basements, buried pipes in marshy region or basements, buried pipes in marshy region or sulfate bearing soils, sewage treatment workssulfate bearing soils, sewage treatment works

Difficulties in Use of PPC, PBFSCDifficulties in Use of PPC, PBFSC

PFA and GGBS do not react very quickly at PFA and GGBS do not react very quickly at early ages at normal temperatures; In cold early ages at normal temperatures; In cold climates, the reaction can be considerably climates, the reaction can be considerably retarded, affecting early strength development retarded, affecting early strength development

Long term strength development and Long term strength development and impermeability improved provided concrete is impermeability improved provided concrete is not allowed to dry out not allowed to dry out

Thus prolonged curing of surface of concrete Thus prolonged curing of surface of concrete with blended cement is of utmost importance with blended cement is of utmost importance

Low Heat Portland Cement IS : 12600Low Heat Portland Cement IS : 12600

Low heat cement is particularly suited for Low heat cement is particularly suited for making concrete for Dams and other types of making concrete for Dams and other types of water retaining structures, bridge abutments, water retaining structures, bridge abutments, massive retaining walls, piers and slabs etc.massive retaining walls, piers and slabs etc.Evolves less heat than OPCEvolves less heat than OPCFineness : Not less than 320 Fineness : Not less than 320 sqmsqm. per kg. . per kg. Compressive Strength at 3 days 10 Compressive Strength at 3 days 10 MPaMPa

7 days 16 7 days 16 MPaMPa28 days 35 28 days 35 MPaMPa

Cement For Dams, Mass Concrete Cement For Dams, Mass Concrete StructuresStructures

Mass concrete generates more heat of Mass concrete generates more heat of hydration, result in cracks. Hence prefer use :hydration, result in cracks. Hence prefer use :

oo Low Heat Portland Cement Low Heat Portland Cement ororoo 43 43 grgr OPC with fly ash / GGBS OPC with fly ash / GGBS ororoo PPC, PSC as they have lower heat of hydrationPPC, PSC as they have lower heat of hydrationoo Low Heat Portland Cement Low Heat Portland Cement ororoo 43 grade OPC with mineral admixtures (fly ash 43 grade OPC with mineral admixtures (fly ash

/ GGBS); reducing heat of hydration / GGBS); reducing heat of hydration ororoo

Cement for Concrete in Hot WeatherCement for Concrete in Hot Weather

Finer cements exhibit accelerated setting Finer cements exhibit accelerated setting and increased heat of hydration.and increased heat of hydration.Blended cements or OPC with site mixing Blended cements or OPC with site mixing of GGBS or fly ashof GGBS or fly ash-- recommended for low recommended for low heat of hydration, improved cohesiveness heat of hydration, improved cohesiveness and better response to vibration. and better response to vibration. Cement should be stacked in advance to Cement should be stacked in advance to enable it to cool down to the ambient enable it to cool down to the ambient temperature before it is batched into the temperature before it is batched into the concrete mixer concrete mixer

Cement for Cement for Coastal Regions Coastal Regions

SRC not suitable if SRC not suitable if chlorides and chlorides and sulfates presentsulfates present

Due to higher free Due to higher free chloride corrosion is chloride corrosion is initiated.initiated.

Use OPC+GGBS / Use OPC+GGBS / fly ash or OPC with fly ash or OPC with 5 5 -- 8% C3A content8% C3A content

Cement For High Performance Cement For High Performance Concrete (HPC)Concrete (HPC)

53 grade OPC from selected sources 53 grade OPC from selected sources

recommended.recommended.

There is a definite correlation between the There is a definite correlation between the

strength of cement and strength of strength of cement and strength of

concrete.concrete.

HPC cannot be produced using lower HPC cannot be produced using lower

grades of cement grades of cement

Control of PFA,GGBSControl of PFA,GGBSMaintain lists of authorized sources. Maintain lists of authorized sources. InclInclsource, type, description for traceability source, type, description for traceability

Purchase from sources with third party Purchase from sources with third party certification of the quality system to ISO certification of the quality system to ISO 9000 or where conformity to ISO is 9000 or where conformity to ISO is subject to assessment of audit subject to assessment of audit

Tests for blend level certification by Tests for blend level certification by recognized organizationrecognized organization

Weekly test certificates for mean Weekly test certificates for mean fineness values fineness values

PPC PPC -- Control of MaterialsControl of MaterialsIndian SceneIndian Scene

Absence of third party certification Absence of third party certification

Difficulties in identifying source of fly ash Difficulties in identifying source of fly ash

No known suppliers of processed fly ash No known suppliers of processed fly ash

Cement producers process PFA before Cement producers process PFA before

blending? Method of blending not known blending? Method of blending not known

–– whether interwhether inter--ground with clinker or ground with clinker or

blended with cementblended with cement

Need for Ordinary Portland Cement (OPC)Need for Ordinary Portland Cement (OPC)The claims of manufacturers that PPC can The claims of manufacturers that PPC can replace OPC 43 & 53 grade are not valid, replace OPC 43 & 53 grade are not valid, but incorrect & misleading. but incorrect & misleading. PPC suitable for ordinary & standard PPC suitable for ordinary & standard concretes up to M 35 grade; OPC concretes up to M 35 grade; OPC definitely required for all higher gradesdefinitely required for all higher gradesUse of PPC results in extra cost to the Use of PPC results in extra cost to the user, as more cement is required to get user, as more cement is required to get the same strengththe same strengthFormwork required to be retained for Formwork required to be retained for longer period for concrete with PPC longer period for concrete with PPC

Cement Content for Durable ConcreteCement Content for Durable ConcreteWidespread MisconceptionWidespread Misconception

Many Engineers feel that for durable concrete, Many Engineers feel that for durable concrete, higher cement content is necessary. This is a higher cement content is necessary. This is a myth. There is a critical cement content for the myth. There is a critical cement content for the concrete mix, beyond which it is counter concrete mix, beyond which it is counter productive, adding to cost without benefit productive, adding to cost without benefit Excess cement content is harmful to the Excess cement content is harmful to the structure, may lead to lower strengths as well structure, may lead to lower strengths as well as cracks due to excess heat generated as cracks due to excess heat generated Min specified cement content, coupled with low Min specified cement content, coupled with low water content and admixtures satisfy the needwater content and admixtures satisfy the need

Maximum Cement Content IS 456Maximum Cement Content IS 456Max cement content shall not exceed 450 Max cement content shall not exceed 450 kg / cum; This value is for cement only, kg / cum; This value is for cement only, does not include fly ash and slag does not include fly ash and slag Heat generated during hydration Heat generated during hydration proportional to quantity of cement; proportional to quantity of cement; cement content higher than necessary cement content higher than necessary may lead to increased risk of cracking may lead to increased risk of cracking due to drying shrinkage / to early due to drying shrinkage / to early thermal cracking thermal cracking Possible to proportion mixes of all grades Possible to proportion mixes of all grades with minimum specified cement content with minimum specified cement content

Effects of Increased Cement Content Effects of Increased Cement Content on Durability of Concreteon Durability of Concrete

Risk of cracking due to drying shrinkage Risk of cracking due to drying shrinkage or early age thermal cracking & increased or early age thermal cracking & increased risk of damage due to alkali silica reactionrisk of damage due to alkali silica reaction

More cement does not add value to More cement does not add value to concrete or increase its strength concrete or increase its strength

Increased cement content reduces Increased cement content reduces strength strength

OPC with Low C3A ContentOPC with Low C3A ContentNote 7, Table 4 of IS 456Note 7, Table 4 of IS 456

““ Where chloride is encountered along Where chloride is encountered along with with sulphatessulphates in soil or ground water, in soil or ground water, OPC with C3A content 5OPC with C3A content 5--8% shall be 8% shall be desirable to be used in concrete, instead desirable to be used in concrete, instead of sulfate resisting cementof sulfate resisting cement““Alternatively PSC having more than 50% Alternatively PSC having more than 50% slag or a blend of OPC and Slag may be slag or a blend of OPC and Slag may be usedused

Blended Cements Blended Cements –– The Way AheadThe Way Ahead

The benefits of cost savings should be shared The benefits of cost savings should be shared with the users, to encourage greater use with the users, to encourage greater use

Recommend blending PFA / GGBS at project Recommend blending PFA / GGBS at project sites where facilities can be established. This sites where facilities can be established. This provides greater flexibility in proportioning provides greater flexibility in proportioning concrete mixes based on properties needed concrete mixes based on properties needed

Encourage independent facilities for processing Encourage independent facilities for processing PFA to remove impurities and PFA to remove impurities and realiserealise better better grading of PFA particles grading of PFA particles

Advantages of Bulk CementAdvantages of Bulk Cement••Lower unit costLower unit costCement directly fed into the batching Cement directly fed into the batching plant silo by the plant silo by the bulkerbulker within the unit within the unit rate for supplyrate for supplySaving in cost of labor, opening the bags Saving in cost of labor, opening the bags and feeding them into Dense Phase and feeding them into Dense Phase SystemSystemSaving in cost of ownership and operating Saving in cost of ownership and operating the Dense Phase Systemthe Dense Phase SystemReduced cost of storage Reduced cost of storage

Mineral AdmixturesMineral Admixtures-- IS 456IS 456Fly AshFly AshGGBFSGGBFSMetakaolinMetakaolinRice Husk AshRice Husk AshSilica FumeSilica Fume

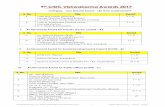

PFA Processing Plant

SAR 2 Y2K

Road Tanker

Storage Silo

Oversize PFAClassifier

Selection

PFA

Raw Feed

Processed PFA

From ESP

Difficulties in UsingDifficulties in UsingFly Ash GGBSFly Ash GGBS

Substantial Substantial increaseincreaseIncreasedIncreasedFinishing Finishing

timetime

Increased Increased Reduced Reduced BleedingBleeding

Increased by about 10 to 20 Increased by about 10 to 20 kN/mkN/m22

Formwork Formwork Pressure Pressure

Substantial Substantial IncreaseIncreaseIncreased Increased Setting Setting

TimeTime

Small Small difference difference Increased Increased WorkabilityWorkability

Use of Silica Flume Use of Silica Flume

CSF is high reactive CSF is high reactive pozzolonpozzolon, , -- 50 times 50 times finer than cementfiner than cement

--distributes in homogeneous pattern in distributes in homogeneous pattern in transition zone,transition zone,

--Augments adherence to aggregates & Augments adherence to aggregates & mechanical properties.mechanical properties.

Reduces permeability, heat of hydration Reduces permeability, heat of hydration and increases ultimate strengthand increases ultimate strength..

Silica Fume DosageSilica Fume Dosage

Normally, 5% replacement of cement Normally, 5% replacement of cement adequate ; may be increased to 7.5% adequate ; may be increased to 7.5% Silica fume expensive : Silica fume expensive : RsRs 25 25 -- 30 per kg 30 per kg Resist temptation to specify higher Resist temptation to specify higher dosages dosages In HSC, silica fume mainly used for In HSC, silica fume mainly used for improving workability, impermeability; improving workability, impermeability; strength increases are incidental strength increases are incidental Typically mixing time of concrete with Typically mixing time of concrete with silica fume increased by 50% silica fume increased by 50%

Mineral Admixtures Mineral Admixtures Advantages of Site MixingAdvantages of Site Mixing

Possible to vary proportions to achieve Possible to vary proportions to achieve optimum concrete properties & economic optimum concrete properties & economic advantagesadvantagesSavings in transport costs, compared with Savings in transport costs, compared with transporting PFA/ GGBS to a factory for transporting PFA/ GGBS to a factory for blending and then delivering a composite blending and then delivering a composite cement to sitecement to siteProportioning confirmed by Automatic weighingProportioning confirmed by Automatic weighingSuitable where different % of Mineral Suitable where different % of Mineral admixtures are specified; consistent strength admixtures are specified; consistent strength achieved with low standard deviation 2 achieved with low standard deviation 2 MPaMPawith site blendingwith site blending

Minimum Cement ContentMinimum Cement ContentRequirement for DurabilityRequirement for Durability

Function of Atmospheric ExposureFunction of Atmospheric ExposureRefer Table 5, IS 456Refer Table 5, IS 456Mild, Moderate Exposure 300 kg/cumMild, Moderate Exposure 300 kg/cumSevere Severe 320320Very Severe 340Very Severe 340Extreme 360Extreme 360

Minimum Cement ContentMinimum Cement ContentSame for all grades of concreteSame for all grades of concrete

Cement content prescribed in IS 456 is Cement content prescribed in IS 456 is irrespective of Grade of Cement or irrespective of Grade of Cement or concreteconcreteCement content is Inclusive of additions Cement content is Inclusive of additions such as fly ash or ground granulated such as fly ash or ground granulated blast furnace slagblast furnace slag

VizagVizag Sea Port Sea Port Concrete MixConcrete Mix Grade M40Grade M40

CementCement : 123 : 123 GGBSGGBS : 287: 287Total Total CementetiousCementetious materialmaterial : 410: 410WaterWater : 135: 135AdmixtureAdmixture : 3.5: 3.5

a/c ratioa/c ratio : 4.70: 4.70w/cw/c ratioratio : 0.33: 0.33

IS 9103:1999 classifies concrete IS 9103:1999 classifies concrete admixturesadmixtures

Accelerating admixturesAccelerating admixturesRetarding admixturesRetarding admixturesWaterWater--reducing admixturesreducing admixturesAirAir--entraining admixturesentraining admixturesSuperplasticising admixturesSuperplasticising admixtures

Chemical AdmixturesChemical Admixtures--DosageDosageUse min. dosage, consistent with Use min. dosage, consistent with workability and retardation requirements workability and retardation requirements Introduces additional air in concrete, Introduces additional air in concrete, reduces strength. Concrete with admix reduces strength. Concrete with admix should have a lower W/C ratio to should have a lower W/C ratio to compensate for the loss of strength due compensate for the loss of strength due to air entrainment to air entrainment Max. dosage :(% by weight of cement) Max. dosage :(% by weight of cement)

Plasticizer 1 Plasticizer 1 Super plasticizer 2Super plasticizer 2RetarderRetarder 0.6 0.6

Super plasticizersSuper plasticizersIncrease workability, facilitate placement of Increase workability, facilitate placement of

concconc in congested reinforcement, in congested reinforcement, inaccessible areasinaccessible areasReduce water content and consequently Reduce water content and consequently reduces cement consumptionreduces cement consumptionProduce high performance concreteProduce high performance concreteImproves surface finish, Improves surface finish, pumpabilitypumpabilityImproves durabilityImproves durabilityReduces temperature rise, due to reduced Reduces temperature rise, due to reduced cement contentcement content

WaterWaterStrength of concrete is inversely Strength of concrete is inversely proportional to the amount of water proportional to the amount of water added in the mixadded in the mixOnly about 80 liters of water is required Only about 80 liters of water is required for hydration of cementfor hydration of cementCodes specify a Codes specify a maximum of 186 litersmaximum of 186 liters of of water per cum concrete; reduction of water per cum concrete; reduction of 30% possible if super30% possible if super--plasticizers usedplasticizers usedThus water need not exceed 130 litersThus water need not exceed 130 litersExcess water evaporates, creates voids, Excess water evaporates, creates voids, reduces concrete strength!reduces concrete strength!

IS 456:2000 IS 456:2000 ClCl. 5.3 . 5.3 –– AggregatesAggregatesShall comply with IS 383. Shall comply with IS 383. PPreference shall be given reference shall be given to natural aggregatesto natural aggregates

This addition encourages This addition encourages use of natural gravel, IS use of natural gravel, IS 383 permits use of gravel 383 permits use of gravel

Use of gravel preferable Use of gravel preferable as it reduces as it reduces w/cw/c ratio, ratio, reduces cement or reduces cement or increases workability increases workability

IS 383 AggregatesIS 383 Aggregates

Fine aggregate includes natural sand, crushed Fine aggregate includes natural sand, crushed stone sand and crushed gravel sand stone sand and crushed gravel sand

Coarse aggregate includes :Coarse aggregate includes :

a) Uncrushed gravel or stone. which results a) Uncrushed gravel or stone. which results from natural disintegration of rock from natural disintegration of rock

b) Crushed gravel or stone b) Crushed gravel or stone

c) Blending of (a) and (b)c) Blending of (a) and (b)

---------- Clause 2.2 of IS 383Clause 2.2 of IS 383--------

IS 383 Coarse AggregatesIS 383 Coarse AggregatesIS,IS, IRC , MOST Specs for Road and IRC , MOST Specs for Road and

Bridge Works Bridge Works permit use of Gravel permit use of Gravel

Available in plenty in river beds / Available in plenty in river beds / deposits in deposits in most parts of India. most parts of India.

Cheaper than crushed aggregate Cheaper than crushed aggregate

Environmental friendly; Many cities Environmental friendly; Many cities have banned use of crushers have banned use of crushers

Should be the first choice at any siteShould be the first choice at any site

Aggregates Aggregates ““Concrete ManualConcrete Manual””US Bureau of ReclamationUS Bureau of Reclamation

““Concrete is composed of sand, gravel, Concrete is composed of sand, gravel, crushed rock, or other aggregates held crushed rock, or other aggregates held together by a harden paste of hydraulic together by a harden paste of hydraulic cement and watercement and water””““Concrete aggregate usually consists of Concrete aggregate usually consists of natural sand and gravel, crushed rock, or natural sand and gravel, crushed rock, or mixture of these materialsmixture of these materials““Natural sands and gravels are by far the Natural sands and gravels are by far the most common and are used whenever most common and are used whenever they are of satisfactory quality and they are of satisfactory quality and obtained economicallyobtained economically

Aggregates Aggregates ““Concrete ManualConcrete Manual””US Bureau of ReclamationUS Bureau of Reclamation

““Crushed rock is widely used for coarse Crushed rock is widely used for coarse

aggregate when suitable material from natural aggregate when suitable material from natural

deposits are not economically available deposits are not economically available

Production of workable concrete from the Production of workable concrete from the

sharp, angular, crushed fragments usually sharp, angular, crushed fragments usually

require more care and more cement than that require more care and more cement than that

of concrete made with wellof concrete made with well--rounded sand and rounded sand and

gravelgravel””

Aggregates Aggregates ““Concrete ManualConcrete Manual””US Bureau of ReclamationUS Bureau of Reclamation

““Crushed aggregate, compared to gravel, Crushed aggregate, compared to gravel,

demands more sand to compensate for demands more sand to compensate for

the sharp, angular shape of the particles the sharp, angular shape of the particles

in order to obtained a mix comparable in in order to obtained a mix comparable in

workability workability

““About 27 % natural sand was used with About 27 % natural sand was used with

the crushed lime stone the crushed lime stone …… , but only about , but only about

22% was required with gravel22% was required with gravel””

Use of Gravel (shingle) as AggregateUse of Gravel (shingle) as Aggregate

Gravel has been in use for major projects Gravel has been in use for major projects in India since last 50 years :in India since last 50 years :

Dams : Dams : BhakraBhakra to to SardarSardar SarovarSarovar dam dam Canal linings : Canal linings : TeestaTeesta to to SardarSardar SarovarSarovar canalcanalPower Stations : Power Stations : BhakraBhakra to to TeestaTeesta, , TrombayTrombayPSC bridges : > 200 PSC bridges : > 200 nosnos including the tallest including the tallest

bridge (bridge (KandroorKandroor), longest (), longest (GangaGanga bridge, bridge, PatnaPatna), Road cum Rail Bridge (Brahmaputra)), Road cum Rail Bridge (Brahmaputra)PSC silos : PSC silos : NangalNangal, , GorakhpurGorakhpurAqueducts : Aqueducts : DeoDeo aqueduct, aqueduct, SardarSardar SarovarSarovar

IS 456:2000 IS 456:2000 ClCl. 5.3.3 . 5.3.3 –– Size of AggregatesSize of Aggregates

Where there is no restriction to the Where there is no restriction to the flow of concrete into sections, 40mm flow of concrete into sections, 40mm or larger size may be permittedor larger size may be permitted

In thin concrete elements , closely In thin concrete elements , closely spaced reinforcement or smaller spaced reinforcement or smaller cover, consideration should be given cover, consideration should be given to the use of 10mm nominal to the use of 10mm nominal maximum size. maximum size.

Fine AggregateFine Aggregate

Many contract specifications restrict grading to Many contract specifications restrict grading to zone II of IS 383; zone II of IS 383; Such restrictions are not Such restrictions are not warranted; IS 383 permits fine aggregates warranted; IS 383 permits fine aggregates complying with any grading zonecomplying with any grading zoneScreening, washing or both as necessary Screening, washing or both as necessary are required only if the fine aggregate does not are required only if the fine aggregate does not confirm to IS 383; washing definitely necessary confirm to IS 383; washing definitely necessary in case of pumped concrete, otherwise choking in case of pumped concrete, otherwise choking of pipeline may occur of pipeline may occur

Fine AggregateFine Aggregate

When the sand grading becomes When the sand grading becomes finer,thefiner,theextra water demand of the finer material extra water demand of the finer material should be offset by reducing the fine should be offset by reducing the fine aggregate content by 5aggregate content by 5--8% of the total 8% of the total aggregate content; the coarse aggregate aggregate content; the coarse aggregate content is increased correspondinglycontent is increased correspondinglyThe Engineer should be ready to take this The Engineer should be ready to take this practical step when the sand grading is practical step when the sand grading is known to have changedknown to have changed

Surface Surface RetardersRetardersUsed for preparation of construction Used for preparation of construction joints by green cutting of concrete after joints by green cutting of concrete after final setting of concrete final setting of concrete They expose aggregates uniformly by They expose aggregates uniformly by removing cement sand matrix for 5 to removing cement sand matrix for 5 to 7mm after eight hours of concreting or 7mm after eight hours of concreting or final setting time whichever is earlier final setting time whichever is earlier when water under pressure is sprayed when water under pressure is sprayed from distance 500mm approximately from distance 500mm approximately Surface Surface retarderretarder saves cost of chipping saves cost of chipping labor, produces more effective joint labor, produces more effective joint