Rockpile If you were in Roy's place, would you have sneaked down to the rockpile? Explain. What…

Conception - Albany, NY - Old world stoneoldworldstone.com/image/pdf/Archive Rockpile Issue 7...

Transcript of Conception - Albany, NY - Old world stoneoldworldstone.com/image/pdf/Archive Rockpile Issue 7...

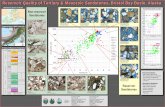

The cornerstone of the Cathedral of the Immacu-late Conception was laid on July 2, 1848. Thedesign by a young Irish immigrant architect; Pat-rick Charles Keeley of Brooklyn, NY, was builtfor $250,000 and dedicated in 1852. It includedthe nave and towers of the cathedral. The twinspires followed in 1862 and 1888. The buildingexterior was constructed of Portland Brownstoneand lavishly detailed with gothic ornament. The

Cathedral was added to the National Register ofHistoric Places in 1976.

In 2000 Bishop Howard J. Hubbard launched thefirst restoration of the Cathedral’s exterior. Theproject addressed the most critical sections ofthe cathedral’s brownstone surfaces which haddeteriorated to such a point that public safety wasjeopardized. The work was completed in 2004.

The current phase of work includes the restora-tion and renovation of the east façade and stairs.Old World Stone is working with Allegrone Ma-sonry of Pittsfield, MA. Before any demolitionwork could begin on site, Old World’s produc-tion team carefully site measured the complexdetailing of the entry portals. Carved details andsculptural profiles were marked for removal andshipment to our fabrication plant in Burlington. Afull tractor trailer load of material was shipped tobe used as references for the new carving.

The source of replacement was specified as Port-land Brownstone. Unfortunately, the quantity anddimensional requirements for this project exceedthe quarry’s current capacity. An alternate mate-rial; St. Bees from Cumbria, England was selected.The material was readily available in high beddingplanes. Shop drawing approvals are underwaywith the project architects; Mesick, Cohen, Wil-son, Baker of Albany, NY. Production in the shophas started by our team of skilled stone cuttersand carvers. Completion is scheduled for sum-mer 2010.

Inside this issue:

East Meets West atThe Pioneer CourthousePortland, OR

2

Tools of the Trade -Buying Quarry Blocks

2

Plant News– New SalesRepresentative for theNE

3

Ask a Designer -Patching vs. Replace-ment Stone

3

Contact us 4

Cathedral of the ImmaculateConception - Albany, NY

Upcoming Trade Shows

&

Conventions

AIA National ConventionMiami, FL

June 10-12

Sealant Waterproofing &Restoration Institute

Fall Technical Program

Chicago, IL

Oct. 10-12

Traditional Building &

Exhibition Conference

Chicago, IL

Oct 21-23

04400/OLD

The RockpileOLD WORLD STONE LTD.

Fabricators of Dimensional Cut Stone

Spring 2010

Original detail December 2009. Photos by D. Watters

Shop Drawings by D. Watters,

Pinnacle in production April 2010

East Meets West at the Pioneer Courthouse,Portland, OR

Tools of the Trade - Buying Quarry Blocks

Finding a matching stone for historic projectscan be challenging. Often the original quarryis closed or inaccessible. Sometimes thequarry runs out of large dimension material,and only offers small blocks or crushed aggre-gate. The Pioneer Courthouse was builtstarting in 1869. It is the oldest federalbuilding in the US, west of the Mississippi. Amajor restoration project was completed in2005. Areas of stone patching are now failing,and SWR Institute member Pioneer Water-proofing Company have the contract to re-place the damaged areas with natural stone.Faced with the challenge of finding a match,President, Mike Crawford pulled out his stonesample board from Old World Stone, and

noticed the Wallace sand-stone, from Nova Scotia.

Page 2 The Rockpile

DID YOU KNOW?

The first block of stone toarrive at Old World Stone ‘sBurlington plant was an 8

tonne block of Indianalimestone in July of 1990.

Seven acres is a lot of spaceto fill, but we have done it,

over and over again! Take avirtual tour at

www.oldworldstone.com

Sure enough, it is a perfect match! Strange,but true, a stone from the Atlantic North-east is a match for the Pacific Northwest.

Wallace Sandstone

Wallace sandstone has beenquarried and finished for manymajor projects for the last 150years. It is used widely in newbuildings, restoration and land-scaping. Known as one of themost durable sandstones in theworld, this Nova Scotia sand-stone has long been the firstchoice for architects, stonecarvers, and homeowners.Gracing buildings like the Cana-dian Parliament, New YorkState Capital Building, Bostonchurches, universities, govern-ment buildings and privatehomes across North Americawith it's classic olive grey color.

Not all stone is created equal. Finding the right stoneat the right time, for the right price is a challenge. KeithDeeley, General Manager at Old World Stone is re-sponsible for selecting all of the quarry blocks we pur-chase, and arranging for their transport and delivery toour Burlington fabrication plant.

Indiana Limestone is the most common material wepurchase. It is readily available in large dimensionsquared blocks and is delivered by the truckload di-rectly from the quarries in Indiana to our yard. Keithcan select from a variety of grades in buff, gray or varie-gated and have it in stock within a week or so. Thematerial meets or exceeds all ASTM Building Stone Re-quirements for limestone. Other limestones are pur-chased locally, or from Texas,

Sandstones areslightly more com-plicated. Theirbedding planes aregenerally moreprominent and clayor mineral depositswill cause the stoneto split along theselines. Keith mustbe careful to selectquarry blocks with-out weak beddingplanes or to antici-pate the break andutilize the remain-

ing stone to its

best advantage.The blocks tendto be irregular inshape. Oftenthere is a largewaste factor withsandstone be-cause of thesenatural variations.A visit to thequarry to selectthe blocks is often necessary to ensure the highest qual-ity. Still, without x-ray vision, it is a gamble. We carrysandstones from the Maritimes, and import from Ohio,Kentucky, Connecticut, New York, and Great Britainand others.

Trans-Atlantic deliveries require a sophisticated systemof loading containers, de-contamination, strapping toanchor the load, and delivery to a shipping yard. Cus-toms clearances, duty and brokerage are all coordi-nated by Keith with help from Anne in Accounting.Timing is critical when shipping across the ocean.Freshly quarried stone is wet and will freeze if tempera-tures on the open seas drop. We generally do notplace an order for stone between the months of Octo-ber and April. Two months is the normal shipping timeduring the rest of the year, subject to availability of thestone.

It is critical to plan ahead and make sure that enoughstone, in the right dimensions is available for the entireproject when you need it. Don’t assume that it is justsitting in our yard waiting for you. Please call ahead.

Large scale operations at Reed Quarries, Bloomington, IN

Checking the bedding planes, Kipton Quarry, Oberlin, OH

Plant News - Sales Representative for the NE

Ask a Designer—Patching vs. Replacement Stone

It all comes down to time and money! As restora-tion consultants, we are often asked to advise onthe use of patching versus stone replacement. Eachhas its place in the building restoration market-place, however, we like to point out the advantagesof a sustainable repair method.

Stone replacement can take many forms. It can be apartial unit referred to as a “dutchman” or “stonegraft”. Where a corner or spalled edge is damagedor missing it can be replaced with a small piece.Larger units involving the entire exposed face of astone can also be replaced. This is often necessarywhere surface damage occurs throughout most ofthe face of the unit, or multiple small areas of dam-age have occurred. This method is advisable whenthe full depth of the stone does not have to be re-moved or it is impractical to remove due to aload-bearing situation. Full unit replacement is

recommended where severe erosion, vandalism orstructural instability has occurred.The first step in replacing a stone is to find thematching material. Can you salvage original mate-rial from the building? Can it be obtained in suit-able dimensions? Does it match the grain, colour,density and porosity of the original? Are skilledmasons available to execute the repair properly?At Old World Stone, we have trained visiting ma-sons to accurately cut and fit replacement“dutchmen” so they blend almost invisibly into thesurrounding stonework. Finishing of the repairoften requires field tooling and light sandblast abra-sion to blend with the adjacent weathered stone-work.

Dutchmen require the installation of dowels or pinsto reinforce their connections. Stainless steel ornon-ferrous anchorages are used. Epoxy adhesivesbond the old with the new and to affix the anchor-ages. The adhesive must be kept back from theface of the repair to prevent smearing and stainingon the face. The joint between the old and the newshould be razor thin, less than 1/32nd of an inch.Mortar joints between stones are maintained attheir normal 1/4” to 3/8” dimension.

Sculptural detail can be replaced with stone grafts.Archival photos help show lost elements. Wemodel in clay, get approvals, create a mould, cast aplaster master, then cut in stone, and install withpins and epoxy.

Replacing full units of stone or small stone dutch-men is more costly initially than patching , however,in the long term it outlasts multiple patching re-pairs. Replacement with stone is the only optionin traffic areas such as stair nosings, and is highlyrecommended on sculptures, projecting elementssuch as sills, and bandcourses, and in areas of highvisibility. Stone grafting also maintains the historicintegrity of the building materials.

Page 3Spring 2010

WHO’S WHO

President:R. John Bridges

General Manager:Keith Deeley

V.P. Sales & MarketingLaurie Wells

Estimating & DesignDavid Watters

Technical Sales Rep.NE United StatesMary Bulso

AccountingAnne Thurston

Mary Bulso joins the team at Old World Stone to help service our con-tacts in the US North East markets. Mary is based in the Boston areawhere she has been involved hands-on in the construction industry forover 10 years. She has worked as a project coordinator, estimator, spe-cial projects engineer, and field engineer on numerous major renovation,restoration and new construction projects. Mary shares our passion forall things stone, especially old stone buildings and monuments. Towardsthat end, Mary returned to school at the Wentworth Institute of Tech-nology, to obtain her Bachelor of Science degree in Construction Man-agement. She is continuing at the University of Massachusetts in theGraduate School of Architecture and Design to obtain her Master of Sci-ence degree in Design & Historic Preservation. Mary is a LEED Ac-credited Professional. She is actively involved with APT North EastChapter, Preservation Massachusetts, Forest Hills Education Trust, andis a volunteer with the National Parks Heritage Corridor.Please contact Mary Bulso for your stone projects. She is a knowl-edgeable and enthusiastic representative for Old World Stone.

DID YOU KNOW?Stone grafts or dutchmanrepairs are the traditionalmethod of repair in the

craft of masonry. Exam-ples can be found in an-cient buildings including

Buckingham Palace,England, and The Temple

of Karnak, Egypt.

They Last!

Mary Bulso LEED APTechnical Sales Rep.

NE United StatesTel: 774-571-3787

Young Ben Franklin statue “before” and “after”, PS-157, Brooklyn NY

Near invisible stone graft with weathered surfaces

CONTACT USfax 905-319-2477 or [email protected]

OLD WORLD STONE LTD.1151 Heritage Road

Burlington, ON L7L 4Y1Canada

Phone: 905- 332-5547Toll Free: 1-800-281-9615

Fax: 905-319-2477Email: [email protected]

www.oldworldstone.com

The Tradition Continues...

Canadian Association ofHeritage Professionals

Proud members of the followingorganizations:

Sealant, Waterproofing& Restoration Institute

To find out more about the content of this newsletter or about our company please fill out the form below and fax back to us. Wewill promptly respond to your request . Thank you for your interest.

⃞ I have a question about stone for new construction ⃞ I have a question about stone for a restoration project

⃞ Send me a Free Brochure ⃞ I prefer to receive The Rockpile newsletter via e-mail

⃞ Send a free copy of this newsletter to a friend ⃞ Please remove my name from further mailings

Details of my inquiry_________________________________________________________________________________________

_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

Name and Title ____________________________________________________________________________________________

Company ____________________________________________________________________________________________

Address ____________________________________________________________________________________________

City _____________________ State/Prov. ______________ Zip/Postal Code________________________________

Phone _____________________ e-mail ________________________________________________________________

PRSRT STDU.S. POSTAGE

PAIDBUFFALO NY

PERMIT # 3071