Concentric heat tube exchanger

-

Upload

shivani-patel -

Category

Documents

-

view

224 -

download

0

Transcript of Concentric heat tube exchanger

-

7/28/2019 Concentric heat tube exchanger

1/18

Concentric tube heat exchanger

Group A5

Done by

P. Neha CH10B044

A. Harika CH10B079Shilochana CH10B091

Shivani Patel CH10B101

-

7/28/2019 Concentric heat tube exchanger

2/18

Problem Statement

1800 kg/h of ethylene glycol is to be cooled from 1000Cto 600C by water available at 150C. The maximumtemperature to which water can be heated is 420C.Ethylene glycol is circulated through the tubes while

water flows through the annulus of a concentric tubeheat exchanger. Inside tube is of copper while outsideis of steel. Inside and outside diameters of copper tubeare 12.5 and 14.5 mm respectively. Inside diameter ofthe outer steel tube is 22 mm. Fouling resistances and

metal wall resistances can be neglected. Suggest asuitable design of a concentric tube heat exchanger.Will the heat exchanger does the duty if fluids streamsare swapped?

-

7/28/2019 Concentric heat tube exchanger

3/18

Data Provided

Flow rate of ethylene glycol = 1800 kg/h

Initial temperature of ethylene glycol = 1000C

Desired final temperature of ethylene glycol = 600C

Initial temperature of water = 15

0

C Acceptable final temperature of water = 420C

Inside diameter of copper tube = 12.5mm

Outside diameter of copper tube = 14.5mm

Inside diameter of steel tube = 22mm

Density of ethylene glycol = 1078 kg/m3

Viscosity of ethylene glycol = 3.2 x 10-3 N-s/m2

-

7/28/2019 Concentric heat tube exchanger

4/18

Data Provided (Continued.)

Specific heat of ethylene glycol = 2650 J/kgK

Thermal conductivity of ethylene glycol = 0.261 W/mK

Density of water = 995 kg/m3

Viscosity of water = 0.853 x 10

-3

N-s/m2

Specific heat of water = 4180 J/kgK

Thermal conductivity of water = 0.614 W/mK

Fouling resistances and metal wall resistances are considered

to be negligible.

-

7/28/2019 Concentric heat tube exchanger

5/18

Introduction

Concentric tube heat exchangers create a

temperature driving force by passing fluid

streams of different temperatures parallel to

each other, separated by a physical boundary

in the form of a pipe.

They are generally used in industries for

purposes such as material processing, foodpreparation and air-conditioning

-

7/28/2019 Concentric heat tube exchanger

6/18

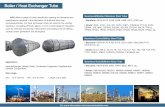

Typical concentric tube heat exchanger

-

7/28/2019 Concentric heat tube exchanger

7/18

Solution

According to conservation of energy

Heat lost by ethylene glycol = Heat gained by water

1800*2650*(100-60) = m*4180*(42-15)Hence m = 1690.59kg/h

For the outer tube:

According to correlation

V = m/(*(/4)*(D^2 D^2))Now substituting the corresponding values of all the variables

and solving for velocity

-

7/28/2019 Concentric heat tube exchanger

8/18

V = 1690.6*4*10^6/(995*3.14*(22^2-14.5^2)*3600)

= 2.19 m/s

Therefore velocity of fluid is found to be 2.19 m/s

Calculation of Reynolds number:Re = (*v*Dh/)

Where Dh is the hydraulic diameter = D0 Di

Dh = 22-14.5

= 7.5mm

Substituting all the values of variables to determine Reynolds

number

-

7/28/2019 Concentric heat tube exchanger

9/18

Re = (995*2.19*7.5*10^-3)/0.853*10^-3

= 19159.29

As the value of Reynolds number is found to be very high the

Flow is considered to be turbulent.Calculation of Nusselts number:

Correlation of nusselts number for turbulent flow is

Nu = 0.027*Re^(4/5)*Pr^(1/3) where Pr = k/(*Cp)

= 0.027*19159^0.8*6.808^0.33

= 135.56

-

7/28/2019 Concentric heat tube exchanger

10/18

As we know that Nu = h*Dh/k

Where h is the convective heat transfer coefficient

Dh is hydraulic diameter

k is the thermal conductivity of waterNow we know that Nu = 135.56

h*Dh/k = 135.56

h = 135.56*0.614/7*10^-3

= 11097.8

Therefore the convective heat transfer coefficient is found to be

11097.8

-

7/28/2019 Concentric heat tube exchanger

11/18

For the inner tube:

V = m/(*(/4)*(D^2 D^2))

Plugging in all the necessary values of variables

= 1800*4/(3600*1078*3.14*12.5^2*10^-6)= 3.78 m/s

Velocity of ethylene glycol flowing inside the tubes is 3.78 m/s

Calculation of Reynolds number:

Re = (*v*Dh/)

Plugging in all the necessary values of variables

-

7/28/2019 Concentric heat tube exchanger

12/18

Re = (1078*3.78*12.5*10^-3)/3.2*10^-3

Re = 15917

As the value is very high in this case also the flow inside the tube

is considered to be turbulent.Calculation of Nusselts number:

Correlation of nusselts number for turbulent flow is

Nu = 0.027*Re^(4/5)*Pr^(1/3) where Pr = k/(*Cp)

= 0.027*15917^0.8*32.49^0.33

= 195

-

7/28/2019 Concentric heat tube exchanger

13/18

As we know that Nu = h*Dh/k

Where h is the convective heat transfer coefficient

Dh is the diameter of tube

k is the thermal conductivity of ethylene glycolNow that we know Nu = 195

h*D/k = 195

h = 195*0.261/12.5*10^-3

= 4071.6

Therefore the convective heat transfer coefficient is found to be

4071.6

-

7/28/2019 Concentric heat tube exchanger

14/18

Calculation of overall heat transfer coefficient:

= 1/11097 + 2/401* + (1/4071)*

= 1/11097 + (2*10^-3/401)*1/ln(22/14.5) + (1/4071)*(22/14.5)

= 4.7477*10^-4

Hence Uo = 2106

-

7/28/2019 Concentric heat tube exchanger

15/18

Calculation of length of concentric tube heat exchanger:

As we know that

Where is the logarithmic mean temperature difference

Plugging in all the values and appropriate expressions to

calculate the length of the heat exchanger

-

7/28/2019 Concentric heat tube exchanger

16/18

Plugging in all the values of variables

(1800*7650*40)/3600 = 2106*3014*22*10^-3*L*((100-42)-(60-15)

ln((100-42)/(60-15)

53000 = 7452.4*L

L = 53000/7452.4

L = 7.118m

Therefore the length of the concentric tube heat exchanger is

Obtained to be 7.118m

-

7/28/2019 Concentric heat tube exchanger

17/18

Calculation of heat duty:

The amount of heat exchanged from a fluid at a higher

temperature to the fluid at lower temperature in unit time by a

heat exchanger is called its dutyHeat duty Q = UATlmtd

= 2106*3.14*22*7.118*((100-42)-(60-15)

ln((100-42)/(60-15)

= 2106*3.14*22*10^-3*7.118*51.23

= 53046.135 J

= 53.05 KJ

-

7/28/2019 Concentric heat tube exchanger

18/18

References

Fundamentals of Heat and Mass Transfer, Fifth

Edition by Frank P. Incropera and David P.

Dewitt

Wikipedia