Compressors - O & M-Manual_Compressors

-

Upload

juned-hamid-khan -

Category

Documents

-

view

285 -

download

0

Transcript of Compressors - O & M-Manual_Compressors

-

8/10/2019 Compressors - O & M-Manual_Compressors

1/64

ManualonCompressors

andCompressed Air Systems

Confederation of Indian IndustryCII Sohrabji Godrej Green Business Centre

-

8/10/2019 Compressors - O & M-Manual_Compressors

2/64

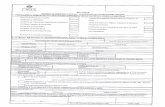

CONTENTS

Chapter Page. No

About the Manual 1

I Types of air compressors 2

II Sizing and Selection of Air Compressors 5

III Testing of air compressors 10

IV Compressed Air Plant Layout and Distribution 15

V Compressor cooling system 19

VI Compressed air Dryers 21

VII Accessories 28

VIII Energy conservation aspects in compressed air system 33

IXCase studies on Energy Conservation inCompressed Air Systems

41

Annexure 57

-

8/10/2019 Compressors - O & M-Manual_Compressors

3/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

About the Manual

Compressed air is one of the major energy consuming utility in any industrial

operation and is often referred to as the Fourth utility.

Various estimates indicate that about 1500 MW is consumed nationwide by

compressed air systems. This presents an excellent opportunity for Energy

Conservation.

The energy saving opportunities in an industry varies from 15 30%.

It is in the national and business interest that compressed air generated must be used

efficiently. This not only results in energy savings, but also improves the bottom line.

This manual is intended to bring in awareness and educate users on energy

conservation aspects both during design and day-to-day operations.

The contents will be a ready reference on compressed air for operating &

maintenance personnel, energy consultants , designers and others alike.

The manual encapsulates the latest trends and technologies available in compressed

air systems, design aspects, testing of compressors & performance analysis, energy

saving measures etc.,

Case studies, which have been implemented in varied sectors of industries, have also

been presented in this manual. Users of this manual should fine tune the case studies

to suit their respective units.

-

8/10/2019 Compressors - O & M-Manual_Compressors

4/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

CHAPTER I

Types of Air Compressors

Air compressors are mainly classified into two types, based on their construction and

operation.! Positive displacement type

! Dynamic type

They are as described below in detail:

1.1 Positive displacement type air compressors

Positive displacement compressors mechanically displace a fixed volume of air into areduced volume. They deliver a nearly constant volume, when operated at a fixedspeed; while the discharge pressure is determined by the system load conditions. The

different types of positive displacement compressors are as follows:

1.1.1 Reciprocating air compressors:

Compressed air is generated by the to & fro movement of the piston in thecompression chamber (Just like an IC Engine). Each movement compresses a fixedquantity of free air at a specific pressure. According to the type of construction,reciprocating compressors can be further classified as single stage / double stage andsingle acting / double acting compressors. The vertical type air compressors aresuitable for applications ranging between 50 - 150 CFM, and the horizontal balancetype is most suited for applications ranging from 200 - 5000 CFM. The schematic

representation of double stage reciprocation is given in figure.

2.1Double stage Reciprocating Compressor

-

8/10/2019 Compressors - O & M-Manual_Compressors

5/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

1.1.2 Rotary type air Compressors:

Air is compressed by two rotating, intermeshing rotors (in some cases one rotor iskept stationery and the other rotates). The action of the rotary screw / lobe can becompared to a reciprocating compressor. The different types of rotary type aircompressors are schematically given below in the figure.

1.1.2 Rotary Compressors

1.2 Dynamic type air compressors

Dynamic compressors mechanically impart a velocity to the air, through the use ofimpellers rotating at high speed, in an enclosed housing. The air is forced into aprogressively reduced volume. The volumetric flow will vary inversely with thedifferential pressure across the compressor. The dynamic type of air compressors areclassified into:

1.2.1 Centrifugal air compressors:

The centrifugal air compressor consists of an impeller, mounted on a shaft andpositioned within a housing, consisting of an inlet duct, a volute and a diffuser. Theimpeller rotates at high speed and imparts a velocity to the air. The diffusersurrounds the impeller and acts to convert the kinetic energy of the air into potentialenergy at a higher-pressure level. The schematic of a centrifugal compressor is givenbelow.

1.2.1Centrifugal compressor

-

8/10/2019 Compressors - O & M-Manual_Compressors

6/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

1.2.2 Axial flow air compressors

The axial flow type air compressor is essentially a large capacity, high speed machine,with characteristics quite different from the centrifugal. Each stage consists of tworow of blades, one row rotating and the next row stationery. The rotor blades impart

velocity and pressure to the gas as the motor turns, the velocity being converted to

pressure in the stationery blades.

1.2.3 Roots compressors

This is really a blower and is generally limited to a pressure of 1 bar in ingle stage anda pressure of 2.2 bar in two stage combination. The schematic of the roots blower isshown in the Fig below.

1.2.3 Roots compressor

-

8/10/2019 Compressors - O & M-Manual_Compressors

7/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

CHAPTER II

Sizing and Selection of Air Compressors

The selection of type of compressor and capacity to be installed is very critical. This

plays a major role in total compressor energy consumption during normal operationin the plant.

2.1 Estimation of compressed air consumption

The total compressed air consumption is the quantity of compressed air required byall the pneumatic equipments connected in the plant, operating in full load condition.

Guidelines for air consumption of various equipment is provided in Annexure-1

2.1.1 Utilisation factor (Use factor or Load factor)

Typically in a plant, during normal operating condition, pneumatic devices are oftenoperated at less than full load capacity. The ratio of actual air consumption in a plantto the maximum continuous air consumption is known as load factor.

Load factor = Actual air consumption in 24 hoursMaximum continuous air consumption in 24 hours

Load factor plays a vital role in estimating the total compressed air requirement at thedesign stage. Depending on the plant and the operating conditions appropriate loadfactor has to be considered for intermittent air requirements while estimating thetotal air requirement.

For establishing the load factor, it is highly desirable to utilize experiences withsimilar plants. The load factor can be determined with the help of work-study.

Another source of information and guidance would be equipment suppliers andcompressor manufacturers.

2.2 Selection of compressors

For the selection of type of compressor the choices are many. This makes thedecision of the factory manager on the selection, tougher. He has to select the rightcompressors for the manufacturing process, so as to be cost competitive. For this,the emphasis should be on energy efficiency (life cycle cost analysis) and minimum

maintenance (high reliability).

-

8/10/2019 Compressors - O & M-Manual_Compressors

8/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

Having calculated the total average capacity requirement, the factory manager canselect the type of compressors required, from the figure.

Chart to Guide selection of air compressor(Source: Indian standards IS 6206 1985)

-

8/10/2019 Compressors - O & M-Manual_Compressors

9/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

The chart has the capacity (calculated average air consumption) across the X axis andpressure across the Y axis. Having known the pressure requirement and the averageair consumption, the type of compressor best suited can be selected from the givencurves. The graph is self-explanatory.

Annexure 2 gives a few examples on the various types of compressors and

capacities required, for various applications / industry. While selecting thecompressors, the following points should be kept in view:

a)As a first step, identify the base load and fluctuating load.

b) For base (Steady) loads: Select centrifugal compressors (best for very highcapacity) or screw compressors.

c) For fluctuating loads: Select screw compressor with built-in VFD (the bestoption) or reciprocating compressors.

2.3 Sizing of Compressed air receivers

An adequate air receiver should be provided for the compressed air system. Themain functions of the compressed air receivers are as follows:

! Provides additional cushion to take care of sudden compressed air demand excessto the installed compressor capacity from the plant.

! Maintains steady pressure to meet with the plant requirement

! Since the receiver serves as a reservoir, prevents frequent loading and unloadingof the compressor

! In addition the receiver precipitates some of the moisture present in compressedair. Other wise the moisture will be carried over to the air dryer, which will leadto additional load on the drier.

The minimum receiver capacity can be calculated for certain applications. At thesame time, experience in similar industry and judgment based on the operatingcondition of the plant shall be considered in selection of receiver capacity.

As per IS 7938-1976 the air receivers can be selected based on the following thumbrule.

Volume of air receiver in M3 = 1/10thof flow rate in m3/min to1/6thof flow rate in m3/min

2.4 Sizing of compressed air piping

The compressed air piping is sized based on the allowable velocity of compressed airin the pipeline, keeping a check on the pressure drop. In compressed air line if thepressure drop is high, the operating pressure at the generation end has to beincreased to match with the requirement. This will result in increased powerconsumption of the compressor.

-

8/10/2019 Compressors - O & M-Manual_Compressors

10/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

Velocities between 6 and 10 m/ sec are usual in compressed air mains. This velocityrange is sufficiently low to prevent excessive pressure drops on most systems andalso will allow moisture to precipitate.

The volume airflow changes if any of the following changes.

!

Operating pressure! Temperature! Both Pressure and Temperature

The law dealing with the expansion of air wherein pressure and temperature arechanging together is given below.

P1V1/ T1 = P2V2/ T2

Where P1, V1and T1are the original pressure, volume and temperature and P2, V2and T2are the new pressure, Volume and Temperature respectively.

The following procedure can be adopted for estimating the size of a compressed air

line.For an example

Quantity of compressed air flow - 200 cfm- 5.66 m3/min

Working pressure - 100 psig i.e 7.0 kg/ cm2(gauge)

Velocity limitation - 6 m/ sec

Apply gas laws P1V1/ T1 = P2V2/T2

Assuming the temperature remains constant.

P1V1 = P2V2

V2 = P1V1/ P2= 5.66 m3/min x 1.013 kg/ cm2

7.0 kg/ cm2= 0.819 m3/min= 0.01365 m3/ sec

Quantity of air flow = Area of pipe line xvelocity of air flow

0.01365 m3/ sec = Area of pipe line x 6 m/ sec

Area of pipe line = 2.275 x 10-3m2

!/ 4 x D2 = 2.275 x 10-3m2

Diameter of pipeline = 0.0538 m= 2.11

Hence the diameter of pipeline can be chosen as 2NB.

-

8/10/2019 Compressors - O & M-Manual_Compressors

11/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

2.5 Pressure drop in a pipeline

Pressure drop in a pipeline is depending upon the quantity of airflow, diameter of thepipeline, pipe length and pipe geometry i.e the bends in the pipe lines.

The pipelines should be with minimum number of Joints, bends and fittings. Further

to minimize the joints it should be ensured that joints are welded instead of flexibleor screwed joints, wherever possible. This facilitates minimizing the leakages andpressure drop.

The maximum pressure drop between the compressor plant and the farthestend of compressed air consumption should be 0.3 bar.

The pressure drop can be readily obtained from the graph given below.

Pressure drop in a pipeline(Source: Indian Standards IS 6206 1985)

-

8/10/2019 Compressors - O & M-Manual_Compressors

12/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

1

CHAPTER - III

Testing of Air Compressors

Over a period of time performance of the compressors and compressed air systems

get deteriorated. This could be due to various reasons such aspoor maintenance,wear & tear, use of poor quality lubricants etc.

The reduction in performance of air compressors leads to increase in overall powerconsumption, installation of additional compressors and increase in cost ofcompressed air. Hence a periodic check on the performance of compressors isrequired to ensure rated compressed air delivery, operating efficiency and specificpower consumption.

The compressed air leakage level has to be periodically monitored. The increase inleakage level leads to increased energy loss. The leakage level in the plant can bemonitored by carrying out leakage test. In this chapter the leakage test procedure is

discussed in detail.

3.1 Performance test

The following are determined by carrying out the performance test on thecompressors.

Free air delivery (FAD)

Free air delivery is the quantity of compressed air delivered by the compressor atambient pressure.

Volumetric efficiency

Volumetric efficiency is the ratio of the actual free air delivered to the compressorswept volume.

Specific power consumption

Specific power consumption of the compressor is the ratio of actual powerconsumption to the quantity of free air delivered.

After carrying out the performance test the actual performance of the compressorhas to be compared with the design values. Suitable measures could be taken to

improve the operating efficiency.

3.2 Measurement of Free air delivered by the compressor

The quantity of free air delivered by the compressor can be measured by any of thefollowing two methods.

" Nozzle method

" Pump up method

-

8/10/2019 Compressors - O & M-Manual_Compressors

13/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

1

3.2.1 Nozzle method

The compressor receiver is connected with a specially designed nozzle. Thecompressor is put into operation and the compressed air is discharged to atmospherethrough the nozzle. Sonic flow sets in the nozzle throat for a particular ratio ofupstream pressure to the down stream pressure.

When the pressure in the receiver is kept constant for a particular period of time, thecompressed air delivered by the compressor is equal to the quantity of airflowthrough the nozzle. The air flow through the nozzle can be calculated from theknown characteristics of the nozzle.

The testing arrangement is shown in the fig.

The compressor discharge is connected to a receiver. In the receiver outlet a suitablenozzle is installed for flow measurement. Before the nozzle a straightener and a

control valve are installed. Straightener is used to ensure streamlined airflow and thecontrol valve is used to set the pressures at the inlet to nozzle.

-

8/10/2019 Compressors - O & M-Manual_Compressors

14/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

1

The nozzle used for the flow measurement has to be selected based on the installedcapacity of the compressor. As per IS standard IS 10431: 1994 the recommendednozzle dimensions for flow measurement for various capacity of compressors isgiven below.

Nozzle size Capacity m3/ hr

6 3-910 9-3016 27-9022 60-17033 130-37550 300-45080 750-2000125 1800-5500165 3500-10000

The experiment can be carried out for different discharge pressure of compressors.The discharge pressures can be 40%, 60%, 100% and 110% of normal operatingpressure of compressor.

Start the compressor and discharge the compressed air to the atmosphere throughthe nozzle. It should be ensured that the pressure drop through the throttle valveshould be equal to or twice the pressure beyond throttle.

Once the system is stabilized and the pressure in the receiver is maintained constantfor a period of time the following measurements have to be carried out.

The quantity of free air delivered by the compressor can be calculated using the

following formula.

Free air delivered Qf= k x!x d2/ 4 x T1/ P1x 2 (P3-P4) (P2xRa)

T3

Where

K - Coefficient of discharge of nozzle as per IS standards

d - Diameter of the nozzle

Ra - Gas constant 287.1 J/ kg k

P1 - Absolute inlet pressure kg/ cm2

T1 - Inlet temperature KP2 - Absolute pressure in receiver kg/ cm2

T3 - Absolute temperature before nozzle kg/ cm2

P3 - Absolute pressure before nozzle kg/ cm2

S - Speed of the compressor in rpm

P3- P4- Differential pressure across the nozzle kg/ cm2

-

8/10/2019 Compressors - O & M-Manual_Compressors

15/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

1

x 100

X Nm3/min

Volumetric efficiency = Free air delivered (m3/min)Compressor swept volume (m3/min)

Compressor swept volume = !x D2x L x S x n x N4

D - Diameter of the cylinder in mL - Stroke length in m

S - Compressor speed in rpm

n - Number of cylinders in compressor

N = 1 for single acting compressor and 2 for double acting

Specific power consumption = Actual power consumptionMeasured free air delivered

3.2.2 Free air delivered measurement using Pump up test method

The pump up test method is the simplest method of estimating the capacity of thecompressor in the shop floor itself. The free air delivered can be measured by theplant team themselves without using any sophisticated measuring instruments.

The compressor to be tested and a known volume of receiver have to be isolatedseparately from the main line. Totally empty the compressed air receiver and closethe outlet valve of the receiver. Also it should be ensured that there is no condensatewater inside the receiver and the drain valve is also fully closed.

Start the compressor and note down the time taken for raise in pressure in thereceiver to the normal operating pressure (P2)from the initial pressure (P1). The same

exercise can be repeated for about three times.

The free air delivered by the compressed air can be calculated using the followingformula.

Free air delivered by the compressor = P2 - P1 VPatm T

Where

P2 - Final pressure in the receiver kg/ cm2(abs)

P1 - Initial pressure in the receiver kg/ cm2(abs)

Patm - Atmospheric pressure kg/ cm2(abs)V - Volume of compressed air storage m3

T - Time taken to build up pressure from P1to P2in minutes

While estimating the volume of compressed air storage the volume of after cooler,volume of pipeline from the after cooler to the receiver should be included alongwith receiver volume.

-

8/10/2019 Compressors - O & M-Manual_Compressors

16/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

14

Also, since the compressed air temperature at discharge is higher than the ambienttemperature, the free air delivered has to be multiplied by the following correctionfactor.

Correction factor = Tatm+ 273T1 + 273

Where

T1 - Temperature of compressor at discharge

Tatm - Ambient temperature in oC

3.3 Compressed air Leakage test

The leakage test has to be periodically carried out to estimate the compressed airleakage in the plant. The leakage test has to be carried out, when there are nocompressed air users in operation.

Run the compressor and pressurize the system to the normal pressure. Once thesystem reaches the normal operating pressure the compressor will get unloaded.

If there is no leakages inside the plant the compressor should remain in the unloadcondition and should not get loaded again. But in actual practice due to compressedair leakages the system pressure will come down and the compressor will go to loadmode.

The loading and unloading of the compressor indicates the compressed air leakageinside the plant. Note down the load / unload time (take at least 3 readings)

The compressed air leakage can be estimated using the formula given below.

The system leakages = Load time x Capacity ofLoad time + Unload time compressor

% leakage = Air leakage x 100(of air compressor capacity) Compressor capacity

3.4 Cost of compressed air leakages

One of the major opportunity for energy saving in compressed air system is to arrestair leakages. The cost of compressed air leakage at 7.0 bar pressure is given below :

Table: Cost of compressed air leakage

Orifice size(mm)

Energy loss(kW)

*Cost of air leakage(Rs/ year)

0.8 0.2 80001.6 0.8 320003.1 3.0 1200006.4 12.0 480000

*Based on Rs.5/ kWh; 8000 operating hours; air at 7.0 bar pressure

-

8/10/2019 Compressors - O & M-Manual_Compressors

17/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

15

CHAPTER IV

Compressed Air Plant Layout and Distribution

The design of compressed air plant layout and distribution of compressed air plays a

significant role in the total energy consumption. While selecting the compressed airlayout and distribution, at the design stage itself it should be ensured that thepressure drop in the system is very minimal, so that the minimum operating pressureset point for the compressor can be maintained.

4.1 Plant Layout

Compressed air layout can be of two types such as centralized compressor systemand decentralized compressor system. Suitable compressed air system can be selectedbased on the plant. Each system has its own advantages.

The location of the compressors, suction pipe work and discharge pipe work are vital

in configuring the plant layout.

4.1.1 Selection of plant layout

Centralized and decentralized compressor layouts have their own advantages anddisadvantages. The selection would vary from plant to plant.

In centralized compressor system all the compressors are located in a single house.This provides greater cost effectiveness in process plants.

Decentralized compressor system is more suitable for engineering industry havingmultiple production lines and requiring compressed air at different pressures. The

compressors are dedicated to the individual production lines and operated at thepressure matching with the plant requirement.

For instance if a compressor is located indoor in a centralized compressor room thecompressed air system is protected from the weather, allows for easy access formaintenance and maximize plant floor space. However, centralized compressed airsystems usually require additional space to provide adequate ventilation andadditional piping to reach the user end which can increase pressure drops.

The decentralized air layout allows for compressors to be located closest to thelargest air users and reduces pressure drop through the airlines. However this

configuration can also result in noise and heat complaints inside the plant.4.1.2 Location of compressors

Ideally compressors should be located where it can induct clean, dry and cool air.One of the major issues related to the compressor location is the ambienttemperature.

-

8/10/2019 Compressors - O & M-Manual_Compressors

18/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

16

The compressed air system exposed to extremely high temperatures can result inhigher specific power consumption, unscheduled shutdowns, increased maintenanceand decrease in lubricant life.

Ventilation is equally important for all compressors regardless of type of cooling.

It would be interesting to note that for every 4oC reduction in intake airtemperature there is 1% reduction in compressor power consumption.

At design stage, it is important to plan for proper ventilation and access tocompressor location. The locations exceeding temperature of 45oC should beavoided. A free space of about 1 m around the compressor needs to be provided formaintenance and 1 m for motor starter access panel.

Addressing the issue of ventilation at the design stage can help in increasing the lifeof the compressor, Lubricating oil and the coolant.

The following points should be considered while locating the compressors.

! Low humidity to reduce water entrainment!Adequate ventilation especially for air cooled unit.! Minimum suction piping! Minimum of bends

4.1.3 Suction pipe work

The suction pipe work plays an important role in terms of improving the operationand performance of the compressor. The following points should be consideredwhile designing the suction pipe work for air compressor installations.

! The piping should be kept short to avoid excessive condensation and pressureloss.

!A high efficiency filter should be fitted to collect particulate matter. Generallyfilters with dry disposable elements are suitable.

! Sufficient access should be provided for inspection and cleaning of filters. Theintake silencer fitted with filter should be located upstream of the silencer tominimize the effect of pulsation.

! The piping should be large enough to avoid excessive energy losses. For every25 m bar pressure lost at the inlet, the compressor efficiency is reduced by

approximately 2%.

4.1.4 Discharge pipe work

The following points have to be considered while designing the discharge pipe workfor the compressor.

! Discharge piping should be full bore i.e. the size of the compressor outlet. Pipework should fall in direction of flow towards the air receiver and after cooler.

-

8/10/2019 Compressors - O & M-Manual_Compressors

19/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

17

! The air receiver should be located close to the air compressor and the pipe workshould be as short as possible.

! Safety valve should be fitted for positive displacement compressors Normally, itis set to release when the line pressure exceeds the operating pressure by 5-10%.

4.2 Compressed air Distribution

Compressed air layout should be selected, to minimize the length of piping betweenthe air compressor and the farthest user of compressed air user.

In systems with a large distribution network, it is preferable to have compressorcentrally located, to minimise the length of piping between the compressor and thefarthest end in the plant.

Some common layouts used are shown in Fig below:

4.2 Different compressed air Layouts

-

8/10/2019 Compressors - O & M-Manual_Compressors

20/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

18

Out of these four headers, loop header is the most desired and energy efficient layoutto minimum pressure drop. In some cases, where there is a minimal usage ofcompressed air at farthest ends, a dedicated small capacity compressor can beinstalled.

The following points should be considered for the distribution pipe work.

! The drainage points should be installed with the aid of equal Ts. Due to suddenchange in direction of flow these fittings assist the separation of water dropsfrom the air.

! The pipe work should fall in the direction of flow. The gradient can be kept atapproximately 1 in 100.

! Distribution branch connections should be taken from the top of the main toreduce water entrainment in the air.

! Drain traps should be provided at all low points

! The drain traps should be protected from the ingress of foreign matter byinstalling a strainer.

! The drain traps in the main line can be installed at every 30-40 m for effectivewater removal.

! Install pressure gauges in various sections of the entire distribution system formonitoring the pressure in different sections of the network

! The number of joints and bends in the distribution network should be minimum

possible. Further to minimising the joints, it should be ensured that joints arewelded, instead of flexible or screwed joints wherever possible. This facilitates inminimizing the leakages and pressure drop.

-

8/10/2019 Compressors - O & M-Manual_Compressors

21/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

19

CHAPTER - V

Compressor Cooling System

Cooling of air compressors merits tremendous improtants since it affects the energy

efficiency. Cooling systems could be either air cooled or water cooled :a) Air cooled compressors: These compressors use fan for forced cooling of thecompressors. Due to the low cooling efficiency, this type of cooling is mostly usedfor low capacity compressors having intermittent usage.

b) Water cooled compressors:For heavy duty or continuous applications watercooling system is adopted, as the efficiency of cooling is high.

5.1 Cooling water pumps

The cooling water pumps are designed such that, only one pump caters to a series of

compressors. This is a common feature in almost all the industries. The pumps aredesigned keeping in view that all compressors are operated continuously. But inactual practice, only 50 to 60 % of the compressors are operated. This results inpumping of excess water, leading to higher power consumption. A VariableFrequency Drive (VFD) for the cooling water pumps can be considered whereverdedicated systems are not possible. This will result in considerable amount of powersavings, as well as good process control.

Alternatively, dedicated cooling water pumps i.e., a separate pump for eachcompressor can be installed at the design stage itself. This not only saves power, butalso increases the flexibility of operation. The suggested norms below can beconsidered for optimising the water & power consumption vis-a-vis the CFMgenerated.

! Water consumption/ CFM = 350 LPM/ 1000 CFM(Typical 7.0 ksc Compressor)

! Power consumption/ CFM = 2.0 kW/ 1000 CFM(Typical 20 m head pump)

Soft, clean water is required for cooling the compressor cylinder jackets, intercoolerand after cooler. The temperature of cooling water should be as low as possible.Lower the temperature of the cooling water better will be the volumetric efficiency.

Ultimately this will result in reduction in overall power consumption.

5.2 Cooling tower

Cooling tower is an area which merits due importance, since it also consumes power.

For compressors the cooling tower should be designed for heat duty specified by thecompressor manufacturer. To select a cooling tower the water flow rate, water inlettemperature, water outlet temperature and ambient wet bulb temperatures must beconsidered.

-

8/10/2019 Compressors - O & M-Manual_Compressors

22/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

20

At design stage any margin on wet bulb temperature is not recommended. In somecases it is useful to provide design margins on cold well temperature. The margin oncold well temperature will result in increase in capital cost. It is usually noteconomical to design a tower with approach below 3oC.

Film flow fills are utilized for compressor applications in case where clean water is

available. If the water quality is poor i.e suspended solids > 100 ppm splash fills maybe used.

Usually, the cooling tower fans operate continuously throughout the year. The load islower during nights and higher during day time. This fluctuation has to be kept in

view and a temperature indicator controller (TIC) has to be incorporated in coolingtower fan. This temperature control should automatically cut off cooling tower fan at30o C and start the cooling tower fan at 32o C (Suggested temperatures are typicallydesired temperatures).

-

8/10/2019 Compressors - O & M-Manual_Compressors

23/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

21

CHAPTER VI

Compressed Air Dryers

6.1 Moisture in Atmospheric air

The atmospheric air has certain amount of moisture. The moisture holding capacityof air depends on the ambient temperature. Higher the temperature; more is themoisture holding capacity of air in the form of water vapour and vice versa.

Saturated air at a given temperature is the air that contains the maximum amount ofwater in the form of water vapour. Any excess water vapour will be condensed in theform of water.

6.2 Dew point temperature

The extent of drying compressed air is expressed by the term Atomospheric dew

point, which is the temperature at which moisture present in the air startscondensing at atmospheric pressure. Lower the dew point, more dry is the air. Air at-40oC atmospheric dew point means no moisture would condense unlesstemperature of the air is reduced to less than 40oC, at atmospheric pressure.

The moisture content corresponding to various dew points is shown in the tablebelow:

Table. Dew point temperature

Dew point atatmospheric pressure

(oC)

Moisturecontent (PPM)

0 3800-5 2500-10 1600-20 685-30 234-40 80-60 6.5-80 0.3

6.3 Effect of water vapour in compressed air

The compressor compresses the air with certain amount of water vapour dependingupon the temperature and relative humidity. When the compressed air is cooled inthe after cooler the water vapour in the compressed air gets condensed andsignificant amount of water is removed. Typically the after cooler removes about50-60% of water vapour.

-

8/10/2019 Compressors - O & M-Manual_Compressors

24/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

22

When the air leaves the after cooler and passes through the compressed air lines, thetemperature of the compressed air further reduces. The remaining water vapour inthe air starts condensing.

The effects of water particles in the compressed air are given below.

!

The water particles travel at the same velocity of compressed air and damages thepneumatic valves or instruments at the user ends.

! Corrosion in the distribution pipe work

! Impaired finishing processes particularly in paint spraying

6.4 Compressed air Drying

The water vapour in the compressed air has to be removed. This can be achieved bypassing the compressed air through the air dryers.

There are two methods of compressed air drying

! Refrigeration drying!Adsorption drying

6.4.1 Refrigeration drying:

Refrigeration drying is based on the principle that when the temperature of thecompressed air is lowered, the moisture holding capacity is reduced. By lowering thetemperature the water vapour in the compressed air is condensed and removed.

The schematic diagram of the refrigeration type air dryer is shown in fig.

6.4.1 Refrigeration type Dryer

It is a simple mechanical refrigeration system, wherein the dew point is reduced bychilling. Additionally there is a second heat exchanger, where in the outgoing cool airpre cools the incoming compressed air. The maximum achievable atmospheric dewpoint in this kind of refrigeration system is 20oC.

-

8/10/2019 Compressors - O & M-Manual_Compressors

25/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

2

6.4.2 Adsorption Drying

In adsorption drying compressed air is passed through a bed of desiccant materialwhere the moisture adheres to the surface.

These desiccants have a very large internal surface. These desiccants once saturated

with moisture can be regenerated and reused.

These adsorption dryers can be classified into the following:

a. Desiccant heated, blower reactivated type

b. Desiccant heat less purge type

c. Desiccant Heat of compression type

The operation of the above mentioned dryer is explained in detail below.

a. Desiccant heated blower reactivated type

This dryer consists of two pressure vessels filled with desiccants, which has theproperty to adsorb water. While one vessel is in service, the other vessel will bein regeneration mode. Regeneration involves heating and cooling of thedesiccant, before put into use.

A blower and external heater is used to achieve the regenerating temperature.The operating cost is higher because of the heater (electrical or steam) and alsobecause there is a purge loss of about 1-2% of compressed air. The vessel, whichis regenerated, is purged with dry air before it is taken into service. These dryersare normally used for capacities higher than 250cfm.

The schematic of the dryer is shown.

6.4.2 (a) Desiccant heated blower reactivated type dryer

-

8/10/2019 Compressors - O & M-Manual_Compressors

26/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

2

b. Desiccant heat less purge type

The operation is very similar to the blower-reactivated type, only differencebeing that no heating of the desiccant is done. Pure dry air is used for purgingthrough the saturated desiccant. These are used for capacities less than 250 cfm.The operating cost is very high due to purge losses of about 10-12%.

The schematic of the dryer is shown below.

6.4.2 (b) Desiccant heatless purge type dryer

c. Desiccant Heat of Compression type dryer

This is a break-through in drying technology where the operating cost is zero orvery minimal. HOC dryers are available from 400 cfm to 5000 cfm capacities.The discharge compressed air, which is at a temperature of 135 o C (in the caseof reciprocating compressor) is used to regenerate the desiccant. There are noelectrical heaters and no purging loss. This makes the dryer very attractive interms of operating cost. The desiccant can be Activated Alumina or Silica geldepending on the dew point required.

The dryer consists of two vessels - A and B. Vessel A will be in service for4 hours. Meanwhile vessel B is reactivated which involves heating for 2 1/2 hrsand cooling for 1 1/2 hrs. After this, vessel B is taken into service and vesselA is reactivated. The regeneration cycle consisting of heating and cooling cycle

as explained below:

Vessel A in service, vessel B in heating:Air from compressor enters 4-wayvalves V2 and V1 and directly to vessel B so as to start the heating process.From vessel B the air through valve V3 and V2 enters after cooler AC1, whereit loses some of the moisture. Through V3 again air enters vessel A wheremoisture is adsorbed by the desiccant and finally leaves through V1 to an After-cooler AC2 where it is cooled to about 35-40oC.

-

8/10/2019 Compressors - O & M-Manual_Compressors

27/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

2

After getting filtered in the After-filter, air goes to process, which is dry to anatmospheric dew point of -40o C. The heating cycle is normally for 2 1/2 hoursduration.

Vessel A in service, vessel B in cooling:Air from compressor passes throughV2, gets cooled in AC1 and enters vessel B through V3. After cooling the desiccantin vessel B air passes through 4-way valves V1, V2 and V3 and enters vessel A,which is in service.

The air on getting dry, enters After-cooler AC2 via V1, gets cooled to about 35-40oC.This air dried to an atmospheric dew point of -40o C is now ready for use. Thecooling cycle is normally for about 1 hour duration.

Cooling

6.4.2 (c) Vessel A in service and Vessel B in Heating mode

6.4.2 (d) Vessel A in service and Vessel B in Cooling mode

-

8/10/2019 Compressors - O & M-Manual_Compressors

28/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

2

6.4.3 Desiccant Selection

Adsorption property is exhibited by some forms of silica, alumina (includingbauxite), carbon and certain silicates (molecular sieves). Silica and alumina are usedprimarily to remove moisture while carbon is used for organic vapours. Molecularsieves can give very low atmospheric dew points, as low as -80o C while activated

alumina gives about -40oC.

While using desiccants, it should be noted that attrition (grinding) occurs due to airpressure surges. This desiccant powder is carried away by air because of which after-filters needs to be installed before the dry air is taken for use. Molecular sieves havethe capacity of adsorbing small molecules of water. Extremely low dew points can beachieved by passing an air stream over molecular sieves. Normally, air is passedthrough a standard desiccant before it is passed through molecular sieves.

6.4.4 Desiccant Life

Adsorbing capacity of desiccant materials decreases with age. Contaminants like oilor dust particles will add to this effect. Heat is also one of the factors, whichcontributes to desiccant ageing. Many manufacturers recommend a desiccant life ofthree to five years, based on the operating conditions.

The condition of the desiccant should be checked periodically. Any effort to monitorthe desiccant condition will give significant benefits in the form of high quality air,reduced frequency of desiccant change and reduced maintenance cost.

6.5 Compressed air dryers - comparison

The comparison between the above discussed dryers is given below.

Table. Compressed air dryers comparison

Type of dryer Capitalcost

Runningcost

DewpointoC

Pressuredrop

Bestsuitable for

Max allowablepressure drop

Kg / cm2

Desiccant heatlesspurge type

Low High -40 Medium 150 cfm 0.5

Desiccant heatedblower reactivatedtype

High Medium -20 to -40oC

High 100-750 cfmor decided

by dew point

0.5

Desiccant Heat ofcompression

High Very low -20 to -40oC

High >1000 cfmfor

lubricatedcompressor

0.5

Refrigeration typedryer

Medium Low +3 Low 100 cfm 0.2 0.3

-

8/10/2019 Compressors - O & M-Manual_Compressors

29/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

27

6.6 Pressure drop across the Dryers

Pressure drop across the compressed air dryer adds to indirect energy cost. Theoperating pressure of the compressor has to be set considering the pressure lossacross the air dryer and the total compressed air requirement.

If the pressure loss across the dryer is higher, accordingly the operating pressure ofthe compressor has to be raised and ultimately will result in increased powerconsumption.

In refrigeration type dryers the design of heat exchangers decides the pressure dropacross the dryer.The maximum allowable pressure loss across the refrigerationdryer is 0.2-0.3 kg/cm2.

In case of adsorption dryers the pressure drop is affected by the filter used. Improperfilters can cause significant pressure drop across the dryer.

The maximum allowable pressure drop across the desiccant type dryer is0.5 kg/ cm2.

-

8/10/2019 Compressors - O & M-Manual_Compressors

30/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

28

CHAPTER VII

Accessories

Some of the accessories used in compressed air system are Drain traps,

compressed air filters, oil/ water separators, Pressure regulators. Theseaccessories play a major role in maintaining the quality of compressed air, effectiveutilisation and enhancing energy efficiency.

7.1 Drain valves

Condensate from compressed air is always detrimental to the life of pneumaticequipments. This condensate should be removed as and when formed at variousstages.

Condensation formation takes place at after coolers, air receivers, filters, pipe lines,drop legs etc. The effective removal of condensate will reduce the moisture load on

the air dryers and ensure the quality of air at the user ends.

Removal of condensate is done by automatic drain valve. In automatic drain valvethere is no need for manual intervention. The automatic drain valves can be classifiedas follows:

a. Electronic timer based drain valves

b. Condensate sensing drain valves

a. Electronic timer based drain valve:

The drain valve is controlled by an electronic timer. The opening of drain valve is

based on the preset timings. The cycle time of the drain valve opening isadjustable.

The cycle time can be set based on the condensate formation rate.

-

8/10/2019 Compressors - O & M-Manual_Compressors

31/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

29

b. Condensate sensing drain valve:

In condensate sensing drain valve the operation is based on the level ofcondensate collected. The condensate is collected in the drain valve container.There is a probe kept inside that senses the level of condensate. Once the level ofcondensate reaches the set value, the controller activates the solenoid valve anddischarges the condensate.

As the level of condensate drops, the probe again senses the lower level and thesolenoid valve is shutoff. This discharges only the condensate and eliminatespassing of compressed air through the valves. The condensate sensing drain

valves are more energy efficient since there is no compressed air loss.

7.2 Filters

The compressed air treatment for ensuring the quality of compressed air is not onlylimited to moisture removal. The other contaminants present in the compressed airsuch as dust, oil, rust, Bacteria & Viruses etc will lead to detrimental effects.

Filters are used to remove the contaminants especially dust, oil and moisture. Someof the filter media used is Ceramics, Sintered Bronze, Boro Silicate glass micro fibreand activated carbon.

The contaminants and various ways & means of effective removal of thosecontaminants are explained in detail below.

-

8/10/2019 Compressors - O & M-Manual_Compressors

32/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

30

7.2.1 Solids

Solids, i.e., dust is found in compressed air depending on :

! Suction air quality

! Desiccant, activated carbon provided in dryers

!

Pipeline rust and scale

It is preferable to remove dust to the extent required at the point of use. Filtersshould have a low-pressure drop, as the energy loss across the filter is in the form ofpressure drop.A surface filter like pleated paper, ceramic or sintered bronzefilter can be used for dust removal. Pleated paper / cellulose are best suited,as they offer very low-pressure drop and can handle high dust loads withoutsignificant pressure drop.A pressure drop of 0.3 to 1.0 psi is allowable.

7.2.2 Oil

Oil from the compressor comes as vapour and liquid aerosol. The vapour cools andbecomes liquid in the line. For most industrial applications only the liquid oil need tobe removed and is done by a coalescing filter. Coalescers are depth filters and mostenergy efficient. E.g. a wet 0.01 micron filters @ 99.999% efficiency has a pressuredrop of 6 psi, while a 0.01 micron filters @ 99.97% efficiency has a pressure drop of3 psi only.

Hence it is recommended to install 99.97 % efficiency, 0.01micron coalescingfilter for industrial applications.

7.2.3 Bacteria / Viruses

In food and pharmaceutical plants the intake air must be free from bacteria andviruses. This can be achieved by heating the compressed air above 180oC thencooling it to normal temperature. The compressed air can also be passed throughsterile filters, which capture bacteria of sizes 0.3 2.0"and viruses.

7.3 Pressure drop in filters

After the installation of filters, over a period of time the pressure drop across thefilters increases. The increased pressure drop across the filters leads to resetting ofcompressors at slightly higher pressure to match with the requirement.

It costs 7% of the total energy for 1 kg/ cm2

pressure drop at 7-8 kg/ cm2

operatingpressure.

-

8/10/2019 Compressors - O & M-Manual_Compressors

33/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

31

This can be higher for higher pressure. Hence,

! The filters have to be sized properly

! The filters have to be replaced when the pressure drop is high.

Fig. 7.3 Pressure drop in filters

It is advisable to change the filters, when the pressure drop reaches 0.5 ksc. A stand-by filter can also be arranged to facilitate the changing of filters. Typically a filterelement should have a working life of 12 months or 6000 working hrs.

7.4 Separators

Moisture is found in liquid as well as in suspended form. Moisture in liquid form iscalled as condensate and the moisture in suspended form is called asaerosol.

Aerosol is normally removed using water separators. The common types of waterseparators are:

" Ceramic cartridge

" Baffle plate

"

Demister pad typeThe demister pad type is the most desired and energy efficient water separator, as itis good in removing water droplets and has a lower pressure drop also.

7.5 Pressure Switches

The possibility of lowering the compressor delivery pressure settings should beexplored by a careful study of pressure requirements of various equipment and thepressure drop in the line between compressed air generation and utilization points.

-

8/10/2019 Compressors - O & M-Manual_Compressors

34/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

3

A reduction in the delivery pressure by 1 bar in a compressor would reduce thepower consumption by 6 10 %.

Hence, it is suggested to use Pressure switches such that the compressor cuts-in andcuts-out at optimum levels.

In a battery of compressors, the pressure setting can be adjusted such that only onecompressor caters to the load variation while others operate at full load.

7.6 Energy Meter

For individual compressors/ sections, sub meters could be installed to record powerconsumption. This would help in identifying any deviations in power consumptionand hence record the variation in consumptions..

-

8/10/2019 Compressors - O & M-Manual_Compressors

35/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

3

CHAPTER VIII

Energy Conservation Aspects in Compressed Air System

Energy conservation opportunities in air compressors and compressed air systems

are tremendous. Many of the energy savings ideas can be adopted either at the designstage or during operation.

The energy saving potential in compressed air systems vary from 20 30%. Thefollowing are some of the aspects to be considered :

8.1 Minimize unload power consumption by correctly sizing the compressor

The total energy consumption of the compressed air system depends on correct typeof size of compressors. If the installed compressor capacity is much higher than thecompressed air requirement of the plant the compressor often falls in unloadingmode.

The loading / unloading of the compressor is done based on the receiver pressure. Ifthe compressed air delivery is more than the requirement of the plant, the systempressure increases. Once the system pressure reaches the unload set pressure thecompressor gets unloaded.

The compressor remains in the unload mode till the system pressure drops due tocompressed air consumption in the plant and reaches the set load pressure.

During unloading the suction valve of the compressor is closed. There is noair intake / delivery from the compressor i.e there is no useful work done bythe compressor. The power consumption of the compressor is used only to

overcome the internal frictional losses.

The unload power consumption of the compressors is significant. In case ofreciprocating compressors the unload power consumption is in the range of 15-20%of load power consumption. For screw compressors the unload power is still higher,which would be in the range of 30-35% of load power consumption.

Hence energy saving can be achieved by minimizing the unload power consumption.The unloading of the compressor can be minimized by correctly sizing thecompressor at the design stage itself i.e excess cushion on capacity of the compressorhas to be reduced.Maximum 10% excess on capacity of compressor is allowed.

In the existing system the following options can be considered to minimize theunload power consumption.

a. Installation of ON/ OFF type of compressor

b. Reducing the speed of the compressor

-

8/10/2019 Compressors - O & M-Manual_Compressors

36/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

3

For smaller capacity of compressors i.e < 100 cfm ON/ OFF type compressors canbe selected instead of Load / Unload type compressors. In ON/OFF type, once therequired pressure is achieved the compressor is switched off. Hence there is nounload power consumption.

In case of the belt driven reciprocating compressors the speed can be permanently

reduced by altering the pulley sizes to minimize the unload power consumption.

Precaution has to be taken that the speed reduction in reciprocating compressor doesnot exceed 20% of the rated speed of the compressor. In reciprocating compressorsthe lubricating oil pump is directly connected to the main drive. Hence any furtherreduction in speed of the compressor may affect the lubrication system.

8.2 Suction air intake to air compressor

The compressors generate heat, due to their continuous operation. This heat getsdissipated inside the compressor room / chamber / leading to hot air feed to thecompressor intake. This results in lower volumetric efficiency and higher powerconsumption. For an approximate 4o C rise in temperature, the power consumptionincreases by 1% for the same output.

Effect on intake air temperature on power consumptionInlet temperature

(oC)Relative air delivery

(%)Power saved

(%)10.0 102.0 +1.415.5 100.0 Nil21.1 98.1 - 1.326.6 96.3 - 2.532.2 94.1 - 4.037.7 92.8 - 5.043.3 91.2 - 5.8

Hence, it is recommended to provide a separate suction duct from outside(atmosphere) to the compressor directly.

8.3 Segregation of HP & LP Compressed air system:

Pressure Vs Power Consumption

Higher the pressure, higher is the power consumption. In any industry, the

compressor is selected for the high pressure requirement, though there are bothhigher and low pressure users.

While calculating the average compressed air consumption of the plant, the totalrequirement of Low Pressure (2.5 to 3.5 bar) and High Pressure (above 3.5 bar)compressed air has to be estimated. If any, say LP or HP air constitutes more than30 % of the average compressed air consumption and then separate compressed airsystem has to be installed. The segregation of HP & LP compressed air user hasmany advantages.

-

8/10/2019 Compressors - O & M-Manual_Compressors

37/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

3

They are:

" Reduces the leakages proportionally, as the leakage levels are high at higherpressures.

" Reduces the overall operating cost. Say a 20 % reduction in pressure results in

20% reduction in power consumption of the compressors. Moreover, the wear &tear of the compressors are less at low pressures.

8.4 Minimize unload power consumption when combination of reciprocatingand screw compressors are in operation

Utilisation of both reciprocating compressors and the latest screw compressors isquite common. During normal operation, when there is a fluctuation in compressedair requirement both the reciprocating compressors and the screw compressors getunloaded.

The unload power consumption of the reciprocating machines is much lower than

the unload power consumption of screw compressors. In reciprocating machines theunload power consumption is only about 15-20% of the load power consumptionwhere as in screw compressors it is in the range of 30-35% of load power.

Hence the screw compressor should never be allowed to unload. The pressuresettings of the compressors should be reset in such a way that the screw compressorshould be always on loading and the reciprocating compressor gets loaded/unloadeddepending upon the requirement.

8.5 Install screw compressors with built-in variable frequency drives (VFD) forfluctuating loads

Variable speed drives eg. (variable frequency drives) can be installed for all types ofair compressors. However, it is best suited for screw air compressors. Theadvantages of installing VFD for screw air compressors are:

"All the compressors connected to a common system operate at a constantpressure. The operating pressure will be lesser than the average operatingpressure of loading / unloading system. Hence, energy saving is achieved due topressure reduction.

" The compressors will not operate in load / unload mode. This saves the unloadpower consumption.

"

Air leakages in the compressed air system also come down since the averageoperating pressure is less.

Generally, high capacity air compressors are operated with loading / unloadingcontrol, as in the case of screw & reciprocating compressors and with inlet vanecontrol for centrifugal compressors.

-

8/10/2019 Compressors - O & M-Manual_Compressors

38/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

3

In loading / unloading type of control, receiver pressure is sensed and thecompressor load / unloads depending on the pressure. Hence a compressor operateswithin a band of pressure range. Generally air compressors operate with 1 kscpressure range.

For example, for a compressor operating between load pressure of 6 ksc & unload

pressure of 7 ksc; the average pressure is 6.5 ksc, (bandwidth 1 ksc). The powerconsumption of the compressor operating constantly at 6 ksc with VFD comesdown by 5 to 6 %. By installing a VFD, it is possible to maintain a bandwidth of0.1 ksc.

The major advantage of variable speed drive is that if 4 or 5 compressors areconnected to a common header, then by installing VFD in one compressor, theenergy savings due to pressure reduction is achieved in all the compressors

Since the average operating pressure with VFD is less (6 ksc instead of 6.5 ksc as perearlier example) the air leakages in the system is also minimized.

The installation of VFD facilitates to reduce / increase the speed of the compressordepending on the requirement. This completely avoids unloading and saves unloadpower consumption, which is normally 25 to 35% of the full load consumption.

The screw compressors with built in variable frequency drive facilitates fine - tuningof the compressor capacity precisely to meet the fluctuating compressed air demand.This leads to precise pressure regulation. It accurately measures the system pressureand adjusts the speed to automatically maintain a constant pressure.

Hence it is recommended to install screw compressors with built-in VFD forfluctuating loads, at design stage itself.

8.6 Minimize compressed air pressure fluctuation by installing intermediatecontrol system

The quantity of compressed air requirement varies depending on the users. Thevariation in quantity is substantial due to sudden requirement in the intermittentusers. Majority of time the duration of usage may be small but quantity requirementis significant. This leads to fluctuation in overall system pressure.

A sudden air demand leads to reduction in overall system pressure and makes thecompressor to load. There is time delay between the reduction in system demand andthe compressor to sense the pressure to come to load mode. Majority of time thetime delay is so much that by the time the compressor comes to the load mode thedemand vanishes and the compressor pumps air into the system to the higher-pressure limit.

Thus the system operates for artificial demand and not for the real demand. Thecompressor must be always ready to satisfy these peaks in anticipation.

-

8/10/2019 Compressors - O & M-Manual_Compressors

39/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

3

If the pressure is simply reduced, that would result in negative impact on productionsuch as decrease in efficiency of production and quality related problems. Hence aproper balancing of supply and demand is needed to satisfy the production withoutcreating an artificial demand. This can be achieved by installing an intermediatecontroller between the compressor and the end users.

The intermediate controller creates a useful storage by introducing a controlleddifferential pressure across an upstream receiver. This storage isolates thecompressor from demand side. Peaks are dealt with the reserve energy stored.

Thus by providing air at controlled differential at an optimum pressure, mass of air isreduced and high pressure storage is created to increase the unload time ofcompressors. The increase in unload time leads to reduction in overall energyconsumption of compressors.

8.7 Minimize compressed air leakages

Quantity of air losses through small holes, cracks, leaky couplings, joints, etc, can addup to a very large value. With proper installation and maintenance, leakage lossesshould not exceed 5% of the total capacity of the compressor. Keeping this in view,the compressed air system has to be provided with good controls, so as to keep theleakage levels to a bare minimum of 5% of the total compressed air generation.

The following should be taken care of at design stage, so as to reduce leakage levelsat:

" Welded joints should be used instead of screwed joints as far as possible.

" Install ball valves at the user ends, to facilitate easy opening & closing of valves.

-

8/10/2019 Compressors - O & M-Manual_Compressors

40/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

3

" Initiate a system to replace the flexibles, rubber hoses, joints, packings, etc., inregular intervals (Say once in 3 months).

" The compressors are to be provided with hour meters for measuring the loading/ Unloading periods. The increase in the loading period for the same productionlevels, indicates the increase in leakage levels.

"

Normally, most of the engineering plants operate for two shifts only. However,some units (eg.,heat treatment shops, etc.,) have to operate continuously in theseplants. In order to support this activity the whole compressed air system has tofunction continuously. In such large size plants, having many individual workshops and a centralized compressor house, individual shop-wise solenoid control

valves for compressed air lines have to be installed.

" The solenoid valve helps in cutting the compressed air supply to the individualshop when there is no activity. This minimise the leakage loss and pressure dropto a considerable level. Hence, it is recommended to install individual shop wisesolenoid control valves for the compressed air line at design itself, so as to

minimise the compressed air leakages during non-active periods.

The relation between hole size, quantity of compressed air leakage and power loss isgiven below.

Hole Diameter(mm)

Air leakage @ 6 Bars(m3/ min)

Power Required forcompression

(kW)1 0.06 0.33 0.6 3.15 1.6 8.310 6.3 33

8.8 Substitution of compressed air

Compressed air is highly energy intensive and costly. So the factory manager has tothink of the possibilities of replacing compressed air, with an equivalent energysource at design stage.

The possible areas for substituting compressed air are:

Agitation: Normally compressed air is utilised for agitation purposes in ETP tanks,Pretreatment tanks, etc., For agitation purposes, the quantity of air required isimportant than the pressure (required only to push through the water columnthrough a max of 10m (1.0 ksc) height). This can be replaced with a Roots Blower.

A high-pressure blower, can generate pressures upto 2.0 ksc) agitation, therebysaving enormous power and cost on layout.

-

8/10/2019 Compressors - O & M-Manual_Compressors

41/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

3

Cooling: Compressed air for cooling is a common practice in Engineering, autocomponent & tyre industry. Cooling also requires large quantity of air at lowpressure. Compressed air for cooling purposes can be replaced with a blowercooling. This not only saves power, but also provides effective cooling.

Air Curtain: Compressed air for providing air curtains is also a common practice

adopted in many industries. Air curtains are required, so as to avoid heat loss fromthe ovens, shots from shot blasting machine, etc, Compressed air for such aircurtains can be replaced with a blower.

Power saving of 50% is possible by replacing the compressed air with blower air. Soit is recommended to substitute compressed air with a suitable equivalent source, saya roots blower, blower etc.

8.9 Install transvector nozzles for cleaning hoses

The use of compressed air for cleaning applications is common in the industry. Thecleaning application requires large quantity of air at low pressure (2.5 ksc), whilecompressed air at 6.0 ksc is normally used for cleaning applications. This is mainlydue to the usage of centralized compressed air for cleaning applications.

As a first step, one should think of operating a separate on/off package aircompressor at low pressure for cleaning applications.

Wherever such separate compressed air system for cleaning cannot be justified,transvector nozzles can be installed for the compressed air cleaning hoses, tominimise the compressed air consumption.

Transvector nozzles are based on the venturi effect - The passing of high-pressure air

through a constricted hole, creates a vacuum: This results in the atmospheric airgetting sucked through the circumferential holes provided. Results show that almost30 to 40 % of the atmospheric air is utilised, thereby reducing the compressed airconsumption. This offers agood potential to consider installation of transvectornozzles for the cleaning hosesat design stage.

-

8/10/2019 Compressors - O & M-Manual_Compressors

42/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

4

8.10 Install electrical tools as much as possible, instead of pneumatic tools

The replacement of pneumatic tools with electrical tools will result in a powersavings of 30%. Moreover, pneumatic tools are highly leak-prone. This results inunnecessary wastage of compressed air and energy.

Hither to, the electrical tools had some design problems like overweight, overheating,frequent armature failures, etc,. Now these have been taken care of and new

generation of high frequency electrical tools is also available.So it is recommendedto consider electrical tools in place of pneumatic tools at design stage itself.

-

8/10/2019 Compressors - O & M-Manual_Compressors

43/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

4

CHAPTER - IX

Case Studies on Energy Conservation inCompressed Air Systems

Case study - 1

Optimally utilize the compressor depending upon the requirement

Background

In a textile industry a screw compressor 600 cfm capacity is in continuous operation.Majority of compressed air users are pneumatic instruments, pneumatic valves andactuators. In addition to the above-mentioned users, compressed air is also utilized toremove the yarn whenever there is a yarn breakage.

During normal operation the quantity of compressed air requirement in the plant is about

100 cfm. Whenever there is a yarn breakage, there is a sudden increase in quantity ofcompressed air requirement, which breakage is as high as 500-550 cfm.

Since the compressed air requirement during normal operating condition is much lower thanthe installed capacity majority of time the compressor is getting unloaded. Duringunloading there is no useful work done by the compressor. The unload powerconsumption is used only to overcome the internal frictional losses.

Hence substantial energy saving can be achieved by minimizing / avoiding unloading of thecompressor.

-

8/10/2019 Compressors - O & M-Manual_Compressors

44/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

4

Previous status

The operating parameters of the compressor during normal operating condition are asbelow.

Table. Operating parameters

Loading time%

Unloading time%

Load powerkW

Unload powerkW

17 83 108 38

Energy saving project

The following measures have been taken up to minimize the unloading of the screwcompressor.

"A reciprocating compressor of capacity 125 cfm was installed to meet the compressed

air requirements during the normal operating condition.

" The screw compressor was kept as standby and given automatic starting facility based onthe system pressure.

" Whenever the system pressure falls due to sudden use of compressed air for yarnremoval, the screw compressor automatically started to meet the compressed airrequirement.

Implementation methodology and time frame

A new reciprocating compressor was bought exactly to meet the actual compressed air

requirement. The set point for automatic starting of the screw compressor was given slightlylower than the load pressure of the reciprocating compressor.

The plant team did not face any major problem during implementation. The project wascompleted within a week time.

Benefits

The unload power consumption of the screw compressor was totally eliminated and resultedin substantial energy saving.

Financial Analysis

The annual energy saving achieved was Rs 7.44 Lakhs. This required an investment ofRs 1.50 Lakhs, which was paid back in3 Months.

-

8/10/2019 Compressors - O & M-Manual_Compressors

45/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

4

Case study 2

Replace old inefficient compressor with new efficient compressor

Background

Over a period of time the compressor operating efficiency comes down and the quantity offree air delivered reduces due reasons such as poor maintenance, wear and tear etc.

If the operating efficiency of the compressor is low the specific power consumption(kW/ cfm) increases and hence the cost of compressed air goes up.

The quantity of free air delivered, operating efficiency and the specific power consumptionof the compressor can be determined by carrying out a performance test.

If the specific power consumption increases by 25 - 30 % as compared to a new efficientcompressor, it makes economic sense to replace the compressor with new efficientcompressor.

Previous status

In one of the cement industry a reciprocating compressor of capacity (Free air delivered)34.32 m3/min was in operation. The normal operating pressure is 6.0 kg/ cm2.

Performance test was carried out and results are as follows:

"Actual free air delivered - 26.08 m3/min

" Specific power consumption - 6.82 kW/m3/min

The specific power consumption was observed to be very high. Typically for reciprocatingcompressor the specific power consumption at an operating pressure of 6 kg/ cm2would beabout 5.5 kW/m3/min.

Energy saving project

The existing old inefficient compressor was replaced with energy efficient compressor of thesame capacity.

Implementation methodology and time frame

The plant team did not face any major problem during implementation of the above project.

The project was implemented in two weeks.The performance of the compressor has to be monitored by carrying out performance testatleast once in 6 months. Any increase in specific power consumption is an indication ofinefficient operation.

The reason for increase in power consumption should be identified and attended duringregular maintenance.

-

8/10/2019 Compressors - O & M-Manual_Compressors

46/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

4

Benefits

There was a significant reduction in specific power consumption and hence the cost ofcompressed air.

Reduction in specific power consumption - 1.2 kW/m3/min.

Financial Analysis

The annual energy saving achieved was Rs 6.28 Lakhs. This required an investment ofRs 6.00 Lakhs, which was paid back in12 Months.

-

8/10/2019 Compressors - O & M-Manual_Compressors

47/64

Manual on Compressors and Compressed Air Systems

Confederation of Indian Industry

CII Sohrabji Godrej Green Business Centre

4

Case study 3

Segregate high pressure and low pressure compressed air users

Background

The compressed air pressure requirement varies depending upon the process requirement.The operating pressure of the compressor is set in such a way that the maximum pressurerequirement in the plant can be met. For other low pressure applications air regulators areused to reduce the compressed air pressure at user ends.

Use of compressed air regulators is an inefficient practice. The pressure loss across the airregulator leads to energy loss.

In compressors, the power consumption is proportional to the operating pressure.The loading power consumption reduces with reduction in operating pressure and vice

versa.

Hence energy saving can be achieved by segregating high pressure and low pressurecompressed air users and compressors can be dedicated for low pressure applicationssupplying compressed air at lower pressure matching with the requirement.

Present status

In one of the process industry 5 Nos of reciprocating compressors of 2700 m3/ hr capacityeach are available for compressed air generation. Three compressors are in continuousoperation. The total quantity of compressed air supply at a pressure of6.5 kg/ cm2is about 7000 m3/ hr.