Complete Product Line - karnes.bg

Transcript of Complete Product Line - karnes.bg

Com

plet

e P

rodu

ct L

ine

CERTIFIEDISO 9001:2000

Cutting Edge Technology

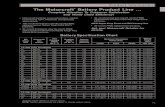

Important Calculations

R.P.M. = (3.82 x Surface Feet Per Minutes)Diameter Of Cutter

Surface Feet Per Minute = 0.262 x Diameter of Cutter x R.P.M.

Inches Per Revolution = Chip Load x Number of Flutes

Inches Per Minute = R.P.M. x Inches Per Revolution

Inches Per Revolution = Inches Per MinuteR.P.M.

Chip Load = Inches Per Revolution

Number of Flutes

Chip Load = Inches Per MinuteR.P.M x Number of Flutes

Weight Of Fractional Carbide Rod (lbs) =2( )

2Shank Diameter

X X3.142 Overall Length X .509

Weight Of Metric Carbide Rod (lbs) =50.8( )

2Shank DiameterX X3.142 Overall Length

X .50925.4

1-2

33-43

32

30-31

20-29

7-19

3-6

44

1-2

1-2

Endmill Tech

About Us

Fractional Burs

Bur Tech

Reamers

Drills

Metric Endmills

V4 Endmills

Flowport Mills

Fractional Endmills

Metric Burs

Bur Sets

Manicure Burs

Dental Burs

Wood Routers

Quality Program

Order/Quote Forms

Wood Router Tech

Index

1-2

1-2

66-69

69

70-74

75-116

117-118

119-121

122-124

Resharpening

Mastercut Tool Corp. employs skilled craftsmen and advanced equipment to provide excellent resharpening services. We can sharpen dull cutters regardless of the manufacturer. This is an excellent and efficient way to get new tool performance at a fraction of the cost. Please inquire about our resharpening price list.

Terms and Conditions of SalePRODUCTS IN THIS CATALOG ARE SUB-

JECT TO CHANGE WITHOUT NOTICE

To Order: Faxed orders are required. Please specify quantity and EDP numbers.

Minimum Orders: $50.00 for standard items, $200 dollars for special orders. Or-ders below $50.00 are subject to a $7.50

handling fee.

Standard Payment Terms: Net 30 Days, Past due after 30 days from billing date.

Freight: Minimum freight charge, $3.50. Orders totaling $1,500.00 or more are shipped freight prepaid. Freight is

F.O.B. shipping point.

Returns: Contact our customer service department for an RMA number. A 15% re-stocking fee applies to returned items. Mastercut Tool Corp. allows one annual

return of slow moving items as long as such return is accompanied by a stock replace-ment order of equal of greater value. No

returns on specials.

Visit the Mastercut Tool Website for more information

and our complete on-line catalog

http://[email protected]

Special Tooling for your Requirements

When you need a non-standard tool for a specific job, give us a call. Requirements for special tooling or modifications of existing standard items will be given prompt, expert attention.

�www.mastercuttool.com �-727-726-5336

Mastercut tool offers unique advantages to industry. We offer personalized service and quality that matches or betters anyone’s. Our low overhead keeps our prices competitive, while our strategic use of advanced machinery keeps deliveries to you on time. We offer the largest standard line of burs available, along with a full line of endmills, routers, and other cutting tools. Furthermore, we manufacture our products in our 37,000 square foot facility in Safety Harbor, Florida, using state of the art CNC grinding equipment.

Our efforts, from quality to investments in advanced grinders, are for one reason — to improve the competitiveness of our customers and make them more successful.

Therefore, our bottom line to you is:

Our customers’ success with our products is the measure of our success.

If you are a new customer or if you have been with us for over the past twenty years, welcome to our expanded Complete Product Catalog. We look forward to helping you become more successful.

2 www.mastercuttool.com �-727-726-5336

Technology On The Cutting Edge

In House Coating

In House Etching

Mastercut Tool is proud to announce the arrival of the Rollomatic Grindsmart 6000XL.

�www.mastercuttool.com 1-727-726-5��6

Secondary Angle

Tool Width

Tool Height

Rake angle

Primary Angle (Side)

Web

Core Diameter

2 Flute

Overall Length

FluteLength

Mill Diameter

Shank Diameter

Looking for more technical data and how-to’s?

Visit the TechZone on the Mastercut Tool Website at:

http://www.mastercuttool.comE-mail: [email protected]

Materials 2FL �FL 4FL 6FL Straight

Aluminum

Brass, Bronze

Fiberglass

Iron

Plastics

Steel nickle, Chrome

Steel: Carbon

Steel: 39-48Rc

Steel: 46-68Rc

Steel Stainless

Steel Weldments

Titanium

Zinc

Basic List of Endmill UseFACE MILLING: For small face areas of relatively shallow depth of cut. The surface finish produced can be “scratchy”.

KEYWAY PRODUCTION: Normally two separate endmills are required to produce a quality keyway.

WOODRUFF KEYWAYS: Normally produced with a single cutter in a straight plunge operation.

SPECIALITY CUTTING: Includes milling of tapered surfaces such as “T” shaped slots & dovetail production.

FINISHING PROFILING: To finish the inside/outside shape on a part with a parallel side wall.

CAVITY DIE WORK: Generally involves plunging and finishing cutting of pockets in die steel. Cavity work requires the production of three dimensional shapes. A Ball type endmill is used for the finishing cutter with this application.

4 Flute

� Flute

4 www.mastercuttool.com 1-727-726-5��6

Endmill Speeds and Feeds

Consider TiAlN Coatings to Run More Aggressive

Speeds and Feeds

Feed Per Tooth (IPT)

Endmill Diameter equals

Material Group Speed SFM up to 1/4”1/4” to

1/2”1/2” to

�/4”�/4” to 1”

Aluminum/Related Alloys 600-1200 .001-.002 .002-.004 .004-.006 .006-.008

Brass/Bronze �00-550 .001-.002 .002-.00� .00�-.004 .004-.005

Copper/Related Alloys 500-900 .001-.002 .002-.00� .00�-.005 .005-.006

Cast Iron (soft ±195bhn) 200-500 .001-.002 .002-.00� .00�-.005 .005-.008

Cast Iron (medium ±225bhn) 125-�50 .001-.002 .002-.00� .00�-.004 .004-.007

Cast Iron (hard ±275bhn) 80-�00 .0005-.001 .001-.002 .002-.00� .00�-.005

Magnesium 800-1400 .001-.00� .00�-.005 .005-.007 .007-.009

Monel/Nickel Alloys 65-175 .0005-.001 .001-.002 .002-.00� .00�-.004

Plastics 600-1200 .001-.00� .00�-.006 .006-.010 .010-.015

Steel-Heat Treated (�5-40Rc) 150-�50 .000�-.0005 .0005-.001 .001-.00� .00�-.005

Steel-Heat Treated (40-45Rc) 125-275 .0002-.0005 .0005-.001 .001-.002 .002-.004

Steel-Heat Treated (45+Rc) 50-200 .0002-.0005 .0005-.001 .001-.002 .002-.00�

Steel-Medium Carbon 175-�50 .0005-.001 .001-.002 .002-.004 .004-.006

Steel; Mold & Die 50-250 .0005-.001 .001-.002 .002-.004 .004-.007

Steel; Tool 150-250 .0005-.001 .001-.002 .002-.004 .004-.006

Stainless-Soft 250-400 .0005-.001 .001-.002 .002-.004 .004-.006

Stainless-Hard 75-250 .0005-.001 .001-.002 .002-.00� .00�-.005

Titanium Alloys 90-225 .000�-.0008 .0008-.002 .002-.00� .00�-.005

Types of Milling ProceduresCLIMB MILL CUTTER: Direction for a milling operation. The cutter tending to “Climb” into the workspace, relieving feed force requirements. First choice for CNC machining. Increases cutter tool life. Sometimes called down-milling.

CONVENTIONAL MILLING: Cutter Direction for a milling operation. The cutter tendency to push the workpiece away from the part, increasing the required feeding force. First choice for manual machining. Sometimes called up-milling.

END MILLING: Metal removal process that is achieved by feeding a workpiece into a revolving cutter. The cutting removes material as it chips.

PERIPHIAL MILLING: The machine edge surface of a part. Periphial milling is accomplished by presenting the workpiece to the circumference or the periphery of the milling cutter.

PLUNGE CUT: Axial feeding into a part. CNC machine movement in the Z-axis direction. Direct plunging into the face of a part. Plunge feeding in an axial direction. Requires a center cutting endmill.

RAMP CUT: Axial feeding into a part. CNC machine movement in the Z-axis direction and an additional axis (X or Y). Angle plunged into the face of a part, feeding in other than the axial direction. Requires a center cutting endmill. Ramp cutting will assist the endmill to enter a part face.

5www.mastercuttool.com 1-727-726-5��6

Coefficient of Friction

Material Clean Lubricated

Steel 0.8 0.16

Copper-lead alloy 0.22 -

Phosphor-bronze 0.�5 -

Aluminum-bronze 0.45 -

Brass 0.�5 0.19

Cast iron 0.4 0.21

Bronze - 0.16

Sintered bronze - 0.1�

Hard carbon 0.14 0.11-0.14

Graphite 0.1 0.1

Tungsten carbide 0.4-0.6 0.1-0.2

Plexiglas 0.4-0.5 0.4-0.5

Polystyrene 0.�-0.�5 0.�-0.�5

Polythene 0.2 0.2

Teflon 0.04 0.04

Aluminum-aluminum 1.�5 0.�

Cadmium-cadmium 0.5 0.05

Chromium-chromium 0.41 0.�4

Copper-copper 1 0.08

Iron-iron 1 0.15-0.20

Magnesium-magnesium 0.6 0.08

Nickel-nickel 0.7 0.28

Platinum-platinum 1.2 0.25

Silver-silver 1.4 0.55

Zinc-zinc 0.6 0.04

Glass-glass 0.9-1.0 0.1-0.6

Glass-metal 0.5-0.7 0.2-0.�

Diamond-diamond 0.1 0.05-0.1

Diamond-metal 0.1-0.15 0.1

Sapphire-sapphire 0.2 0.2

Hard carbon on carbon 0.16 0.12-0.14

Graphite-graphite (in vacuum) 0.5-0.8 -

Graphite-graphite 0.1 0.1

Tungsten carbide-tungsten carbide 0.2-0.25 0.12

Plexiglas-plexiglas 0.8 0.8

Polystyrene-polystyrene 0.5 0.5

Wood on wood (clean) 0.25-0.5 -

Wood on wood (wet) 0.2 -

Wood on metals (clean) 0.2-0.6 -

Wood on metals (wet) 0.2 -

Brake material on cast iron 0.4 -

Brake material on cast iron (wet) 0.2 -

Materials Index of Friction Chart

6 www.mastercuttool.com 1-727-726-5��6

Titanium Based CoatingsWith today’s coating technologies, you can make your tools last longer, and run harder than ever before. At Mastercut Tool Corp. we offer a full range of coatings including Titanium Nitride, Titanium Aluminum Nitride, and many more. Look below for more information. TiN and TiCN coatings are not listed in this catalog but are available on all tools by request.

Titanium Aluminum Nitride (TiAlN) Coating has an ambient surface hardness in the 3000 Vickers (low, mid 80 Rc) range. It’s main advantage is that the hardness is maintained under extreme cutting temperatures in excess of �300°F. Friction, heat buildup, galling and edge breakdown are significantly reduced and tool life and cutting performance are improved. It is a highly effective coating for machining tough-to-cut tool steels, stainless, cast iron and non-ferrous materials. It can also be used effectively for interrupted cuts. TiAlN coated carbide tools can be run at more aggressive speeds and feeds and can be used with out coolant in certain applications. It is the coating of choice for tough to cut material.

Titanium Carbon Nitride (TiCN) Coating has an ambient temperature hardness in the 4000 Vickers (low 90Rc) range. It’s use is particularly advantageous when cutting cast iron, silicon aluminum, certain non-ferrous and other abrasive materials. Tool life can be extended using the right combination of speeds feeds and coolant.

Why use a Coating?• Carbide tools life increased 2 to 5 times . Deposition temperatures as low as 480°-840°F (250°-450°C) protect carbide’s binder from deterioration, by comparison with the CVD process applied at more than 1,850°F (1,000°C)

• Isolates the tool from the part, avoids edge buildup and tool cratering.

• Reduced friction against work-piece and chips, reduced spindle torque, less vibration, better finish.

• Speed and Feed increased from 10 to 50 percent.

•Reduces or eliminates coolant (with specific coatings)

•Repeatable, stable Performance of the coatings between batches.

Titanium Nitride (TiN) Coating is bright gold in color, has an ambient temperature hardness in the 2800 Vickers (low 80Rc) range, a coefficient of friction under 0.5, and a thermal stability up to about �000°F TiN meets FDA requirements for surgi-cal tools and food contract applications. Cutting speeds, feeds, wear resistance and tool life generally improve.

Material to Machine TiN AlTiN TiCN TiAlN

Aluminum, Low Silicon < �0%

Aluminum, High Silicon > �0%

Copper, Copper Alloys

Ductile, Malleable Cast Iron

Carbon Steel, �000 Series

Alloy Steel, 4 to 9000 Series

Tool Steel

SS Steel, 300 Series

SS Steel, 400 Series

SS PH Series

Titanium, Titanium Alloys

Nickel, Nickel Alloys, Cobalt

Wood, Paper

Composites, Plastics

Titanium Nitride (TiN) Coating

Titanium Carbon Nitride (TiCN) Coating

Titanium Aluminium Nitride (TiAlN) Coating

7www.mastercuttool.com 1-727-726-5��6

D1 L1 D2 L2 4 FL SQ 2 FL SQ � FL SQ4 FL SQ

TiAlN2 FL SQ

TiAlN� FL SQ

TiAlN

1/�2 �/�2 1/8 1-1/2 50010 50011 5001� 517�0 517�1 517��

�/64 1/8 1/8 1-1/2 50220 50221 5022� 51740 51741 5174�

1/16 1/4 1/8 1-1/2 50000 50001 5000� 51750 51751 5175�

5/64 1/4 1/8 1-1/2 50110 50111 5011� 51760 51761 5176�

�/�2 �/8 1/8 1-1/2 50100 50101 5010� 51770 51771 5177�

7/64 �/8 1/8 1-1/2 50210 50211 5021� 51780 51781 5178�

1/8 1/2 1/8 1-1/2 50200 50201 5020� 51790 51791 5179�

9/64 9/16 �/16 2 50�20 50�21 50�2� 51800 51801 5180�

5/�2 9/16 �/16 2 50240 50241 5024� 51810 51811 5181�

11/64 9/16 �/16 2 50�10 50�11 50�1� 51820 51821 5182�

�/16 5/8 �/16 2 50�00 50�01 50�0� 518�0 518�1 518��

1�/64 5/8 1/4 2-1/2 50510 50511 5051� 51840 51841 5184�

7/�2 5/8 1/4 2-1/2 50400 50401 5040� 51850 51851 5185�

15/64 �/4 1/4 2-1/2 50520 50521 5052� 51860 51861 5186�

1/4 �/4 1/4 2-1/2 50500 50501 5050� 51870 51871 5187�

17/64 7/8 5/16 2-1/2 505�0 505�1 505�� 51880 51881 5188�

9/�2 7/8 5/16 2-1/2 50610 50611 5061� 51890 51891 5189�

19/64 7/8 5/16 2-1/2 50620 50621 5062� 51900 51901 5190�

5/16 7/8 5/16 2-1/2 50600 50601 5060� 51910 51911 5191�

21/64 7/8 �/8 2-1/2 506�0 506�1 506�� 51920 51921 5192�

11/�2 7/8 �/8 2-1/2 50640 50641 5064� 519�0 519�1 519��

2�/64 7/8 �/8 2-1/2 50650 50651 5065� 51940 51941 5194�

�/8 7/8 �/8 2-1/2 50700 50701 5070� 51950 51951 5195�

25/64 7/8 7/16 2-1/2 50660 50661 5066� 51960 51961 5196�

1�/�2 7/8 7/16 2-1/2 50667 50668 50669 51970 51971 5197�

27/64 7/8 7/16 2-1/2 50690 50691 5069� 51980 51981 5198�

7/16 1 7/16 2-1/2 50800 50801 5080� 51990 51991 5199�

29/64 1 1/2 � 50710 50711 5071� 52000 52001 5200�

15/�2 1 1/2 � 50720 50721 5072� 52010 52011 5201�

�1/64 1 1/2 � 507�0 507�1 507�� 52020 52021 5202�

1/2 1 1/2 � 50900 50901 5090� 520�0 520�1 520��

9/16 1-1/4 9/16 �-1/2 50910 50911 5091� 52040 52041 5204�

5/8 1-1/4 5/8 �-1/2 51000 51001 5100� 52050 52051 5205�

11/16 1-1/2 �/4 4 51110 51111 5111� 52060 52061 5206�

�/4 1-1/2 �/4 4 51100 51101 5110� 52070 52071 5207�

7/8 1-1/2 7/8 4 51200 51201 5120� 52080 52081 5208�

1 1-1/2 1 4 51�00 51�01 51�0� 52090 52091 5209�

1-1/4 2 1-1/4 4-1/2 50740 50741 5074� 52100 52101 5210�

Square End Standard Length Endmills

Cutting Edge Tolerance +.000 -.002Shank Tolerance +.000 -.0002

L2

D1 D2

L1

8 www.mastercuttool.com 1-727-726-5��6

D1 L1 D2 L2 4 FL 2 FL � FL4 FLTiAlN

2 FLTiAlN

� FLTiAlN

1/�2 �/�2 1/8 1-1/2 50014 50015 50016 517�4 517�5 517�6

�/64 1/8 1/8 1-1/2 50224 50225 50226 51744 51745 51746

1/16 1/4 1/8 1-1/2 50004 50005 50006 51754 51755 51756

5/64 1/4 1/8 1-1/2 50114 50115 50116 51764 51765 51766

�/�2 �/8 1/8 1-1/2 50104 50105 50106 51774 51775 51776

7/64 �/8 1/8 1-1/2 50214 50215 50216 51784 51785 51786

1/8 1/2 1/8 1-1/2 50204 50205 50206 51794 51795 51796

9/64 9/16 �/16 2 50�24 50�25 50�26 51804 51805 51806

5/�2 9/16 �/16 2 50244 50245 50246 51814 51815 51816

11/64 9/16 �/16 2 50�14 50�15 50�16 51824 51825 51826

�/16 5/8 �/16 2 50�04 50�05 50�06 518�4 518�5 518�6

1�/64 5/8 1/4 2-1/2 50514 50515 50516 51844 51845 51846

7/�2 5/8 1/4 2-1/2 50404 50405 50406 51854 51855 51856

15/64 �/4 1/4 2-1/2 50524 50525 50526 51864 51865 51866

1/4 �/4 1/4 2-1/2 50504 50505 50506 51874 51875 51876

17/64 7/8 5/16 2-1/2 50614 505�5 505�6 51884 51885 51886

9/�2 7/8 5/16 2-1/2 506�4 50615 50616 51894 51895 51896

19/64 7/8 5/16 2-1/2 50624 50625 50626 51904 51905 51906

5/16 7/8 5/16 2-1/2 50604 50605 50606 51914 51915 51916

21/64 7/8 �/8 2-1/2 505�4 506�5 506�6 51924 51925 51926

11/�2 7/8 �/8 2-1/2 50644 50645 50646 519�4 519�5 519�6

2�/64 7/8 �/8 2-1/2 50654 50655 50656 51944 51945 51946

�/8 7/8 �/8 2-1/2 50704 50705 50706 51954 51955 51956

25/64 7/8 7/16 2-1/2 50664 50665 50666 51964 51965 51966

1�/�2 7/8 7/16 2-1/2 50677 50678 50679 51974 51975 51976

27/64 7/8 7/16 2-1/2 50694 50695 50696 51984 51985 51986

7/16 1 7/16 2-1/2 50804 50805 50806 51994 51995 51996

29/64 1 1/2 � 50714 50715 50716 52004 52005 52006

15/�2 1 1/2 � 50724 50725 50726 52014 52015 52016

�1/64 1 1/2 � 507�4 507�5 507�6 52024 52025 52026

1/2 1 1/2 � 50904 50905 50906 520�4 520�5 520�6

9/16 1-1/4 9/16 �-1/2 50914 50915 50916 52044 52045 52046

5/8 1-1/4 5/8 �-1/2 51004 51005 51006 52054 52055 52056

11/16 1-1/2 �/4 4 51114 51115 51116 52064 52065 52066

�/4 1-1/2 �/4 4 51104 51105 51106 52074 52075 52076

7/8 1-1/2 7/8 4 51204 51205 51206 52084 52085 52086

1 1-1/2 1 4 51�04 51�05 51�06 52094 52095 52096

1-1/4 2 1-1/4 4-1/2 50744 50745 50746 52104 52105 52106

Ball End Standard Length Endmills

L2

D1 D2

L1

Cutting Edge Tolerance +.000 -.002Shank Tolerance +.000 -.0002

9www.mastercuttool.com 1-727-726-5��6

Long Length Endmills Square

D1 L1 D2 L24 FL

Uncoated2 FL

Uncoated4 FLTiAlN

2 FLTiAlN

1/8 5/8 1/8 2 5�000 5�001 5�0�0 5�0�1

1/8 �/4 1/8 2 54000 54001 54090 54091

1/8 1 1/8 � 5�040 5�041 5�070 5�071

�/16 �/4 �/16 2-1/2 54100 54101 54190 54191

�/16 1-1/8 �/16 � 5�080 5�081 5�110 5�111

�/16 1 �/16 4 5�120 5�121 5�150 5�151

1/4 1-1/8 1/4 � 54200 54201 54290 54291

1/4 1 1/4 4 5�160 5�161 5�190 5�191

1/4 1-1/2 1/4 4 5�200 5�201 5�2�0 5�2�1

1/4 1-1/2 1/4 6 5�240 5�241 5�270 5�271

5/16 1-1/8 5/16 � 54�00 54�01 54�90 54�91

5/16 1 5/16 4 5�280 5�281 5��10 5��11

5/16 1-5/8 5/16 4 5��20 5��21 5��50 5��51

5/16 1-1/2 5/16 6 5�450 5�451 5�480 5�481

�/8 1-1/8 �/8 � 54400 54401 54490 54491

�/8 1-�/4 �/8 4 54500 54501 54590 54591

�/8 2 �/8 4 5��60 5��61 5��90 5��91

�/8 1-1/2 �/8 6 5�400 5�401 5�4�0 5�4�1

�/8 � �/8 6 5�440 5�441 5�476 5�477

7/16 1 7/16 4 5�486 5�487 5�510 5�511

7/16 2 7/16 4 5�520 5�521 5�550 5�551

7/16 1-1/2 7/16 6 5�560 5�561 5�590 5�591

7/16 � 7/16 6 5�600 5�601 5�6�0 5�6�1

1/2 1 1/2 4 5�640 5�641 5�670 5�671

1/2 2 1/2 4 54600 54601 54690 54691

1/2 1-1/2 1/2 6 5�680 5�681 5�720 5�721

1/2 � 1/2 6 54700 54701 54790 54791

5/8 2-1/4 5/8 5 54800 54801 54890 54891

5/8 � 5/8 6 54900 54901 54990 54991

�/4 2-1/4 �/4 5 55000 55001 55090 55091

�/4 � �/4 6 55100 55101 55190 55191

1 2 1 6 55200 55201 55240 55241

1 � 1 6 55400 55401 554�0 554�1

1 4 1 6 55�00 55�01 55�40 55�41

L2

D1 D2

L1

Cutting Edge Tolerance +.000 -.002Shank Tolerance +.000 -.0002

10 www.mastercuttool.com 1-727-726-5��6

D1 L1 D2 L24 FL

Uncoated2 FL

Uncoated4 FLTiAlN

2 FLTiAlN

1/8 5/8 1/8 2 5�004 5�005 5�0�4 5�0�5

1/8 �/4 1/8 2 54004 54005 54094 54095

1/8 1 1/8 � 5�044 5�045 5�074 5�075

�/16 �/4 �/16 2-1/2 54104 54105 54194 54195

�/16 1-1/8 �/16 � 5�084 5�085 5�114 5�115

�/16 1 �/16 4 5�124 5�125 5�154 5�155

1/4 1-1/8 1/4 � 54204 54205 54294 54295

1/4 1 1/4 4 5�164 5�165 5�194 5�195

1/4 1-1/2 1/4 4 5�204 5�205 5�2�4 5�2�5

1/4 1-1/2 1/4 6 5�244 5�245 5�274 5�275

5/16 1-1/8 5/16 � 54�04 54�05 54�94 54�95

5/16 1 5/16 4 5�284 5�285 5��14 5��15

5/16 1-5/8 5/16 4 5��24 5��25 5��54 5��55

5/16 1-1/2 5/16 6 5��64 5��65 5��94 5��95

�/8 1-1/8 �/8 � 54404 54405 54494 54495

�/8 1-�/4 �/8 4 54504 54505 54594 54595

�/8 2 �/8 4 55504 55505 555�4 555�5

�/8 1-1/2 �/8 6 5�404 5�405 5�4�4 5�4�5

�/8 � �/8 6 5�444 5�445 5�474 5�475

7/16 1 7/16 4 5�484 5�485 5�514 5�515

7/16 2 7/16 4 5�524 5�525 5�554 5�555

7/16 1-1/2 7/16 6 5�564 5�565 5�594 5�595

7/16 � 7/16 6 5�604 5�605 5�6�4 5�6�5

1/2 1 1/2 4 5�644 5�645 5�674 5�675

1/2 2 1/2 4 54604 54605 54694 54695

1/2 1-1/2 1/2 6 5�684 5�685 5�714 5�715

1/2 � 1/2 6 54704 54705 54794 54795

5/8 2-1/4 5/8 5 54804 54805 54894 54895

5/8 � 5/8 6 54904 54905 54994 54995

�/4 2-1/4 �/4 5 55004 55005 55094 55095

�/4 � �/4 6 55104 55105 55194 55195

1 2 1 6 55204 55205 552�4 552�5

1 � 1 6 55404 55405 554�4 554�5

1 4 1 6 55�04 55�05 55��4 55��5

Long Length Endmills Ball

L2

D1 D2

L1

Cutting Edge Tolerance +.000 -.002Shank Tolerance +.000 -.0002

11www.mastercuttool.com 1-727-726-5��6

D1 L1 D2 L2 Uncoated TiAlN

�/16 5/8 �/16 2 50�02 50�92

1/4 �/4 1/4 2-1/2 50502 50592

5/16 7/8 5/16 2-1/2 50602 50692

�/8 1 �/8 2-1/2 50702 50792

7/16 1 7/16 2-1/2 50802 50892

1/2 1 1/2 � 50902 50992

5/8 1-1/4 5/8 �-1/2 51002 51092

�/4 1-1/2 �/4 4 51102 51192

7/8 1-1/2 7/8 4 51202 51292

6 Flute Endmills

D1 L1 D2 L24 FL

Uncoated2 FL

Uncoated4 FLTiAlN

2 FLTiAlN

1/8 �/8 �/8 � 52207 52208 52297 52298

�/16 1/2 �/8 � 52�07 52�08 52�97 52�98

7/�2 9/16 �/8 � 52407 52408 52497 52498

1/4 5/8 �/8 � 52507 52508 52597 52598

5/16 �/4 �/8 �-1/2 52607 52608 52697 52698

�/8 �/4 �/8 �-1/2 52707 52708 52797 52798

Square End

Ball End

D1 L1 D2 L24 FL

Uncoated2 FL

Uncoated4 FLTiAlN

2 FLTiAlN

1/8 �/8 �/8 � 52202 5220� 52292 5229�

�/16 1/2 �/8 � 52�02 52�0� 52�92 52�9�

7/�2 9/16 �/8 � 52402 5240� 52492 5249�

1/4 5/8 �/8 � 52502 5250� 52592 5259�

5/16 �/4 �/8 �-1/2 52602 5260� 52692 5269�

�/8 �/4 �/8 �-1/2 52702 5270� 52792 5279�

L2

D1 D2

L1 Flat

L2

D1 D2

L1 Flat

L2

D1 D2

L1

3/8 Common Shank Double End Endmills

Cutting Edge Tolerance +.000 -.002Shank Tolerance +.000 -.0002

12 www.mastercuttool.com 1-727-726-5��6

Stub Length Endmills

Square End

Ball End

D1 L1 D2 L24FL

Uncoated2 FL

Uncoated4 FLTiAlN

2 FLTiAlN

1/�2 1/16 1/8 1-1/2 56�00 56�01 56��� 56��4

�/64 �/�2 1/8 1-1/2 56�50 56�51 56�8� 56�84

1/16 1/8 1/8 1-1/2 56400 56401 564�� 564�4

�/�2 �/16 1/8 1-1/2 56500 56501 565�� 565�4

1/8 1/4 1/8 1-1/2 57000 57001 57092 5709�

5/�2 5/16 �/16 2 56600 56601 566�� 566�4

�/16 �/8 �/16 2 57100 57101 57192 5719�

7/�2 7/16 1/4 2 57200 57201 57292 5729�

1/4 1/2 1/4 2 57�00 57�01 57�92 57�9�

5/16 1/2 5/16 2 57400 57401 57492 5749�

�/8 5/8 �/8 2 57500 57501 57592 5759�

7/16 5/8 7/16 � 57550 57551 576�� 576�4

1/2 5/8 1/2 2-1/2 57600 57601 57692 5769�

5/8 �/4 5/8 � 57700 57701 57792 5779�

�/4 1 �/4 � 57800 57801 578�� 578�4

1 1 1 � 57850 57851 5788� 57884

D1 L1 D2 L24FL

Uncoated2 FL

Uncoated4 FLTiAlN

2 FLTiAlN

1/�2 1/16 1/8 1-1/2 56�04 56�05 56��7 56��8

�/64 �/�2 1/8 1-1/2 56�54 56�55 56�87 56�88

1/16 1/8 1/8 1-1/2 56404 56405 564�7 564�8

�/�2 �/16 1/8 1-1/2 56504 56505 565�7 565�8

1/8 1/4 1/8 1-1/2 57004 57005 57096 57097

5/�2 5/16 �/16 2 56604 56605 566�7 566�8

�/16 �/8 �/16 2 57104 57105 57196 57197

7/�2 7/16 1/4 2 57204 57205 57296 57297

1/4 1/2 1/4 2 57�04 57�05 57�96 57�97

5/16 1/2 5/16 2 57404 57405 57496 57497

�/8 5/8 �/8 2 57504 57505 57596 57597

7/16 5/8 7/16 � 57554 57555 576�7 576�8

1/2 5/8 1/2 2-1/2 57604 57605 57696 57697

5/8 �/4 5/8 � 57704 57705 57796 57797

�/4 1 �/4 � 57804 57805 578�7 578�8

1 1 1 � 57854 57855 57887 57888

L2

D1 D2

L1

L2

D1 D2

L1

Cutting Edge Tolerance +.000 -.002Shank Tolerance +.000 -.0002

1�www.mastercuttool.com 1-727-726-5��6

Standard Length Double End Endmills

Square End

Ball End

D1 L1 D2 L24 FL

Uncoated2 FL

Uncoated4 FLTiAlN

2 FLTiAlN

1/�2 �/�2 1/8 2 58000 58001 580�0 580�2

�/64 1/8 1/8 2 58050 58051 58080 58081

1/16 �/16 1/8 2 58100 58101 581�0 581�1

�/�2 1/4 1/8 2 58150 58151 58180 58181

1/8 �/8 1/8 2 58200 58201 582�0 582�1

5/�2 7/16 �/16 2-1/2 58250 58251 58280 58281

�/16 1/2 �/16 2-1/2 58�00 58�01 58��0 58��1

7/�2 9/16 1/4 2-1/2 58�50 58�51 58�80 58�81

1/4 5/8 1/4 2-1/2 58400 58401 584�0 584�1

5/16 �/4 5/16 �-1/2 58450 58451 58480 58481

�/8 �/4 �/8 �-1/2 58500 58501 585�0 585�1

7/16 7/8 7/16 4 58550 58551 58580 58581

1/2 1 1/2 4 58600 58601 586�0 586�1

9/16 1-1/4 9/16 6 58650 58651 58680 58681

5/8 1-1/4 5/8 6 58700 58701 587�0 587�1

�/4 1-1/2 �/4 6 58750 58751 58780 58781

7/8 1-1/2 7/8 6 58800 58801 588�0 588�1

1 1-1/2 1 6 58850 58851 58880 58881

D1 L1 D2 L24 FL

Uncoated2 FL

Uncoated4 FLTiAlN

2 FLTiAlN

1/�2 �/�2 1/8 2 58004 58005 580�4 580�5

�/64 1/8 1/8 2 58054 58055 58084 58085

1/16 �/16 1/8 2 58104 58105 581�4 581�5

�/�2 1/4 1/8 2 58154 58155 58184 58185

1/8 �/8 1/8 2 58204 58205 582�4 582�5

5/�2 7/16 �/16 2-1/2 58254 58255 58284 58285

�/16 1/2 �/16 2-1/2 58�04 58�05 58��4 58��5

7/�2 9/16 1/4 2-1/2 58�54 58�55 58�84 58�85

1/4 5/8 1/4 2-1/2 58404 58405 584�4 584�5

5/16 �/4 5/16 �-1/2 58454 58455 58484 58485

�/8 �/4 �/8 �-1/2 58504 58505 585�4 585�5

7/16 7/8 7/16 4 58554 58555 58584 58585

1/2 1 1/2 4 58604 58605 586�4 586�5

9/16 1-1/4 9/16 6 58654 58655 58684 58685

5/8 1-1/4 5/8 6 58704 58705 587�4 587�5

�/4 1-1/2 �/4 6 58754 58755 58784 58785

7/8 1-1/2 7/8 6 58804 58805 588�4 588�5

1 1-1/2 1 6 58854 58855 58884 58885

L2

D1 D2

L1

L2

D1 D2

L1

Cutting Edge Tolerance +.000 -.002Shank Tolerance +.000 -.0002

14 www.mastercuttool.com 1-727-726-5��6

D1 L1 D2 L24FL

Uncoated2 FL

Uncoated4 FLTiAlN

2 FLTiAlN

1/�2 1/16 1/8 1-1/2 57016 57015 57058 57059

�/64 �/�2 1/8 1-1/2 57127 57128 57158 57159

1/16 1/8 1/8 1-1/2 57227 57228 57258 57259

�/�2 �/16 1/8 1-1/2 57027 57026 57�58 57�59

1/8 1/4 1/8 1-1/2 57007 57008 57098 57099

5/�2 5/16 �/16 2 571�7 571�6 57458 57459

�/16 �/8 �/16 2 57107 57108 57198 57199

7/�2 1/2 1/4 2-1/2 57207 57208 57298 57299

1/4 1/2 1/4 2-1/2 57�07 57�08 57�98 57�99

5/16 1/2 5/16 2-1/2 57407 57408 57498 57499

�/8 1/2 �/8 2-1/2 57507 57508 57598 57599

7/16 1/2 7/16 2-1/2 575�5 575�6 57568 57569

1/2 5/8 1/2 � 57607 57608 57698 57699

5/8 �/4 5/8 4 57707 57708 57740 57741

�/4 1 �/4 4 57807 57808 57840 57841

D1 L1 D2 L24FL

Uncoated2 FL

Uncoated4 FLTiAlN

2 FLTiAlN

1/�2 1/16 1/8 1-1/2 57019 57020 57062 5706�

�/64 �/�2 1/8 1-1/2 57119 57120 57162 5716�

1/16 1/8 1/8 1-1/2 57219 57220 57262 5726�

�/�2 �/16 1/8 1-1/2 57022 57021 57�62 57�6�

1/8 1/4 1/8 1-1/2 57002 5700� 57094 57095

5/�2 5/16 �/16 2 57419 57420 57462 5746�

�/16 �/8 �/16 2 57102 5710� 57210 57211

7/�2 5/8 1/4 2-1/2 57202 5720� 57294 57295

1/4 1/2 1/4 2-1/2 57�02 57�0� 57�94 57�95

5/16 1/2 5/16 2-1/2 57402 5740� 57494 57495

�/8 1/2 �/8 2-1/2 57502 5750� 57594 57595

7/16 1/2 7/16 2-1/2 575�0 575�1 5756� 57564

1/2 5/8 1/2 � 57602 5760� 57694 57695

5/8 �/4 5/8 4 57702 5770� 577�5 577�6

�/4 1 �/4 4 57802 5780� 578�5 578�6

Square End Stub-Length Double End Endmills

Ball End Stub-Length Double End Endmills

L2

D1 D2

L1

L2

D1 D2

L1

Cutting Edge Tolerance +.000 -.002Shank Tolerance +.000 -.0002

15www.mastercuttool.com 1-727-726-5��6

2 Flute Corner Radius EndmillsD! L1 D2 L2

.015Radius

.020Radius

.0�0Radius

.045Radius

.060Radius

1/8 1/2 1/8 1-1/2 6�001 6�011 6�021 6�0�1 6�041

�/16 5/8 �/16 2 6�101 6�111 6�121 6�1�1 6�141

1/4 �/4 1/4 2-1/2 6�201 6�211 6�221 6�2�1 6�241

5/16 1�/16 5/16 2-1/2 6��01 6��11 6��21 6���1 6��41

�/8 1 �/8 2-1/2 6�401 6�411 6�421 6�4�1 6�441

1/2 1 1/� � 6�501 6�511 6�521 6�5�1 6�541

5/8 1-1/4 5/8 �-1/2 6�601 6�611 6�621 6�6�1 6�641

�/4 1-1/2 �/4 4 6�701 6�711 6�721 6�7�1 6�741

Straight Flute EndmillsSquare End

D! L1 D2 L24 FL

Uncoated2 FL

Uncoated4 FLTiAlN

2 FL TiAlN

1/8 1/2 1/8 1-1/2 59000 59001 59090 59091

�/16 5/8 �/16 2 59100 59101 59190 59191

7/�2 5/8 1/4 2-1/2 59200 59201 59290 59291

1/4 �/4 1/4 2-1/2 59�00 59�01 59�90 59�91

5/16 1�/16 5/16 2-1/2 59400 59401 59490 59491

�/8 1 �/8 2-1/2 59500 59501 59590 59591

1/2 1 1/2 � 59600 59601 59690 59691

5/8 1-1/4 5/8 �-1/2 59700 59701 59790 59791

Ball EndD! L1 D2 L2

4 FLUncoated

2 FLUncoated

4 FLTiAlN

2 FL TiAlN

1/8 1/2 1/8 1-1/2 59004 59005 59094 59095

�/16 5/8 �/16 2 59104 59105 59194 59195

7/�2 5/8 1/4 2-1/2 59204 59205 59294 59295

1/4 �/4 1/4 2-1/2 59�04 59�05 59�94 59�95

5/16 1�/16 5/16 2-1/2 59404 59405 59494 59495

�/8 1 �/8 2-1/2 59504 59505 59594 59595

1/2 1 1/2 � 59604 59605 59694 59695

5/8 1-1/4 5/8 �-1/2 59704 59705 59794 59795

4 Flute Corner Radius EndmillsD! L1 D2 L2

.015Radius

.020Radius

.0�0Radius

.045Radius

.060Radius

1/8 1/2 1/8 1-1/2 6�000 6�010 6�020 6�0�0 6�040

�/16 5/8 �/16 2 6�100 6�110 6�120 6�1�0 6�140

1/4 �/4 1/4 2-1/2 6�200 6�210 6�220 6�2�0 6�240

5/16 1�/16 5/16 2-1/2 6��00 6��10 6��20 6���0 6��40

�/8 1 �/8 2-1/2 6�400 6�410 6�420 6�4�0 6�440

1/2 1 1/� � 6�500 6�510 6�520 6�5�0 6�540

5/8 1-1/4 5/8 �-1/2 6�600 6�610 6�620 6�6�0 6�640

�/4 1-1/2 �/4 4 6�700 6�710 6�720 6�7�0 6�740

Cutting Edge Tolerance +.000 -.002Shank Tolerance +.000 -.0002

L2

D1 D2

L1

Corner Radius

L2

D1 D2

L1

16 www.mastercuttool.com 1-727-726-5��6

Series 620 - Medium Pitch Rougher (.062 Pitch)For maximum stock removal of mild, stainless, and hardened steels and alloys.

D! L1 D2 L2 No. of Flutes Uncoated TiAlN

1/4 �/4 1/4 2-1/2 � 62000 62090

5/16 �/4 5/16 2-1/2 � 62100 62190

�/8 7/8 �/8 2-1/2 � 62200 62290

1/2 1 1/2 � 4 62�00 62�90

5/8 1-1/4 5/8 �-1/2 4 62400 62490

�/4 1-1/2 �/4 4 4 62500 62590

1 1-1/2 1 4 5 62600 62690

Series 62� - Fine Pitch Roughers (.048 Pitch)For maximum stock removal of titanium, inconel, waspaloy, and other advanced materials.

D! L1 D2 L2 No. of Flutes Uncoated TiAlN

1/4 �/4 1/4 2-1/2 � 62001 62091

5/16 �/4 5/16 2-1/2 � 62101 62191

�/8 7/8 �/8 2-1/2 � 62201 62291

1/2 1 1/2 � 4 62�01 62�91

5/8 1-1/4 5/8 �-1/2 4 62401 62491

�/4 1-1/2 �/4 4 4 62501 62591

1 1-1/2 1 4 6 62601 62691

Series 622 - Coarse Pitch Roughers (.�05 Pitch)For maximum stock removal of aluminum, brass, bronze, and other lightweight alloys.

D! L1 D2 L2 No. of Flutes Uncoated TiAlN

1/4 �/4 1/4 2-1/2 � 62002 62092

5/16 �/4 5/16 2-1/2 � 62102 62192

�/8 7/8 �/8 2-1/2 � 62202 62292

1/2 1 1/2 � � 62�02 62�92

5/8 1-1/4 5/8 �-1/2 � 62402 62492

�/4 1-1/2 �/4 4 � 62502 62592

1 1-1/2 1 4 � 62602 62692

Rougher UseRoughers, or “hoggers”, are useful for rapid removal of large amounts of material. The chip groove design allows for more cutting fluid to the cutting edge and dissipates heat better. There is a wide range of variations in rougher profile forms for different material groups. The coarser the pitch of the roughing edge, the more material removed and the less smooth the finish. In addition most roughers have eccentric relief so regrinding can be done only using the cutting face. This saves you if you have access to regrinding equipment.

Cutting Edge Tolerance +.000 -.002Shank Tolerance +.000 -.0002

L2

D1 D2

L1

17www.mastercuttool.com 1-727-726-5��6

60° 3 Flute High Helix Twistermill

D1 L1 D2 L2 Uncoated TiAlN

1/4 �/4 1/4 2-1/2 6800� 6809�

5/16 1�/16 5/16 2-1/2 6810� 6819�

�/8 1 �/8 2-1/2 6820� 6829�

1/2 1 1/2 � 68�0� 68�9�

5/8 1-1/4 5/8 �-1/2 6840� 6849�

�/4 1-1/2 �/4 4 6850� 6859�

45° 2 Flute High Helix Hypermill

D1 L1 D2 L2 Uncoated TiAlN

1/4 1 1/4 2-1/2 68001 68091

5/16 1 5/16 � 68101 68191

�/8 1 �/8 2-1/2 68201 68291

1/2 1-1/4 1/2 � 68�01 68�91

5/8 1-5/8 5/8 �-1/2 68401 68491

�/4 1-�/4 �/4 4 68501 68591

D1 L1 D2 L2 Uncoated TiAlN

1/8 1/2 1/8 1-1/2 550�0 55050

5/�2 9/16 5/�2 2 550�1 55051

�/16 �/4 �/16 2 550�2 55052

1/4 �/4 1/4 2-1/2 550�� 5505�

5/16 �/4 5/16 2-1/2 550�4 55054

�/8 7/8 �/8 2-1/2 550�5 55055

1/2 1 1/2 � 550�6 55056

9/16 1-1/4 9/16 � 550�7 55057

5/8 1-1/4 �/4 �-1/2 550�8 55058

�/4 1-1/2 �/4 4 550�9 55059

1 1-1-2 1 4 55040 55060

55° 2 Flute High Helix AlumaZips

See the Mastercut Tool website for more in-depth information

about High Performance Endmills

Designed for high speed milling of inconel, titanium, stainless, and steel alloys.

Designed for high speed milling of aluminum.

Designed for high speed milling of aluminum.

Cutting Edge Tolerance +.000 -.002Shank Tolerance +.000 -.0002

L2

D1 D2

L1

L2

D1 D2

L1

L2

D1 D2

L1

18 www.mastercuttool.com 1-727-726-5��6

Engraving BlanksD1 L1 D2 L2 Single End Double End

1/8 �/8 1/8 1-1/2 78000 78001

1/8 �/8 1/8 2 78100 78101

�/16 1/2 �/16 2 78200 78201

1/4 1/2 1/4 2 78�00 78�01

1/4 1/2 1/4 2-1/2 78400 78401

1/4 1/2 1/4 � 78500 78501

5/16 1/2 5/16 2-1/2 78600 78601

�/8 1/2 �/8 2-1/2 78700 78701

7/16 1/2 7/16 � 78800 78801

1/2 1/2 1/2 � 78900 78901

Taper Endmills

D1 D1-1 L1 D2 L2Centerline

Angle2FL SQUARE 2FL BALL

1/8 1/4 �/4 1/4 � 5 6100� 61006

1/8 1/4 1/2 1/4 � 7 6110� 61106

�/�2 1/4 1/2 1/4 � 10 6120� 61206

1/8 �/8 1-1/2 �/8 �-1/2 5 61�0� 61�06

1/8 �/8 �/4 �/8 �-1/2 7 6140� 61406

1/8 �/8 �/4 �/8 �-1/2 10 6150� 61506

1/4 1/2 1-1/4 1/2 4 5 6160� 61606

�/16 1/2 1-1/4 1/2 4 7 6170� 61706

1/8 1/2 1 1/2 4 10 6180� 61806

D1 L1 D2 L22 FL SQ

Uncoated2 FL SQ

TiAlN

1/8 1/2 1/8 1-1/2 50201-90 51791-90

�/16 5/8 �/16 2 50�01-90 518�1-90

1/4 �/4 1/4 2-1/2 50501-90 51871-90

5/16 7/8 5/16 2-1/2 50601-90 51911-90

�/8 7/8 �/8 2-1/2 50701-90 51951-90

7/16 1 7/16 2-1/2 50801-90 51991-90

1/2 1 1/2 � 50901-90 520�1-90

5/8 1-1/4 5/8 �-1/2 51001-90 52051-90

�/4 1-1/2 �/4 4 51101-90 52071-90

2 Flute Drill Mills

Cutting Edge Tolerance +.000 -.002Shank Tolerance +.000 -.0002

L2

D1 D2

L1

D1-1

L2

D1 D2

L1

L2

D1 D2

L1

19www.mastercuttool.com 1-727-726-5��6

D1 D2 L2 Flutes 60° 82° 90°

1/8 1/8 1-1/2 1 24001 24002 2400�

1/8 1/8 1-1/2 � 24004 24005 24006

1/8 1/8 1-1/2 6 24007 24008 24009

�/16 �/16 2 1 24011 24012 2401�

�/16 �/16 2 � 24014 24015 24016

�/16 �/16 2 6 24017 24018 24019

1/4 1/4 2 1 24021 24022 2402�

1/4 1/4 2 � 24024 24025 24026

1/4 1/4 2 6 24027 24028 24029

�/8 1/4 2-5/8 1 240�1 240�2 240��

�/8 1/4 2-5/8 � 240�4 240�5 240�6

�/8 1/4 2-5/8 6 240�7 240�8 240�9

1/2 1/4 2-7/8 1 24041 24042 2404�

1/2 1/4 2-7/8 � 24044 24045 24046

1/2 1/4 2-7/8 6 24047 24048 24049

5/8 �/8 � 1 24051 24052 2405�

5/8 �/8 � � 24054 24055 24056

5/8 �/8 � 6 24057 24058 24059

�/4 1/2 � 1 24061 24062 2406�

�/4 1/2 � � 24064 24065 24066

�/4 1/2 � 6 24067 24068 24069

1 1/2 �-1/4 1 24071 24072 2407�

1 1/2 �-1/4 � 24074 24075 24076

1 1/2 �-1/4 6 24077 24078 24079

Carbide CountersinksBrazed to steel shank

D2 L2 STD

.0925 �-�/2 80000

3/32 �-�/2 8000�

3/32 2 80002

�/8 �-�/2 80�0�

�/8 2 80�02

�/8 3 80�03

�/8 �2 80��2

3/�6 2 80202

D2 L2 STD

�/4 2 80302

�/4 2-�/2 80303

�/4 3 80304

�/4 �2 803�2

5/�6 2-�/2 8040�

5/�6 3 80402

3/8 2-�/2 8050�

3/8 3 80502

D2 L2 STD

3/8 4 80503

�/2 3 80702

�/2 4 80704

�/2 6 80705

5/8 3-�/2 80802

5/8 6 80804

3/4 4 80902

3/4 6 80904

Please call on quotations on Rods

Shank Tolerance +.000 -.0002

Carbide Centerless Ground Rod

L2

D1 D2

L2

D2

20 www.mastercuttool.com 1-727-726-5��6

D� L� D2 L2 4 FL SQ 2 FL SQ 3 FL SQ4 FL SQ

TiAlN2 FL SQ

TiAlN3 FL SQ

TiAlN

1 � � �8 8�000 8�00� 8�003 8�030 8�03� 8�033

1.5 5 � �8 8�050 8�05� 8�053 8�080 8�08� 8�083

2 6 � �8 8��00 8��0� 8��03 8��30 8��3� 8��33

2.5 7 � �8 8��50 8��5� 8��53 8��80 8��8� 8��83

� 12 � �8 8�200 8�20� 8�203 8�230 8�23� 8�233

�.5 12 4 50 8�250 8�25� 8�253 8�280 8�28� 8�283

4 14 4 50 8�300 8�30� 8�303 8�330 8�33� 8�333

4.5 14 5 50 8�350 8�35� 8�353 8�380 8�38� 8�383

5 16 5 50 8�400 8�40� 8�403 8�430 8�43� 8�433

6 19 6 6� 8�450 8�45� 8�453 8�480 8�48� 8�483

7 19 8 6� 8�500 8�50� 8�503 8�530 8�53� 8�533

8 19 8 6� 8�550 8�55� 8�553 8�580 8�58� 8�583

9 22 10 70 8�600 8�60� 8�603 8�630 8�63� 8�633

10 22 10 70 8�650 8�65� 8�653 8�680 8�68� 8�683

11 25 11 70 8�700 8�70� 8�703 8�730 8�73� 8�733

12 25 12 75 8�750 8�75� 8�753 8�780 8�78� 8�783

14 �0 14 88 8�800 8�80� 8�803 8�830 8�83� 8�833

16 �2 16 88 8�850 8�85� 8�853 8�880 8�88� 8�883

18 �6 18 100 8�900 8�90� 8�903 8�930 8�93� 8�933

20 �8 20 100 8�950 8�95� 8�953 8�980 8�98� 8�983

22 �8 22 100 82000 8200� 82003 82030 8203� 82033

25 �8 25 100 82050 8205� 82053 82080 8208� 82083

Square End Standard Length Endmills

Cutting Edge Tolerance +.00 -.05Shank Tolerance +.000 -.005

L2

D1 D2

L1

21www.mastercuttool.com 1-727-726-5��6

D� L� D2 L24 FL BALLUncoated

2 FL BALLUncoated

4 FL BALLTiAlN

2 FL BALLTiAlN

1 � � �8 8�004 8�005 8�034 8�035

1.5 5 � �8 8�054 8�055 8�084 8�085

2 6 � �8 8��04 8��05 8��34 8��35

2.5 7 � �8 8��54 8��55 8��84 8��85

� 12 � �8 8�204 8�205 8�234 8�235

�.5 12 4 50 8�254 8�255 8�284 8�285

4 14 4 50 8�304 8�305 8�334 8�335

4.5 14 5 50 8�354 8�355 8�384 8�385

5 16 5 50 8�404 8�405 8�434 8�435

6 19 6 6� 8�454 8�455 8�484 8�485

7 19 8 6� 8�504 8�505 8�534 8�535

8 19 8 6� 8�554 8�555 8�584 8�585

9 22 10 70 8�604 8�605 8�634 8�635

10 22 10 70 8�654 8�655 8�684 8�685

11 25 11 70 8�704 8�705 8�734 8�735

12 25 12 75 8�754 8�755 8�784 8�785

14 �0 14 88 8�804 8�805 8�834 8�835

16 �2 16 88 8�854 8�855 8�884 8�885

18 �6 18 100 8�904 8�905 8�934 8�935

20 �8 20 100 8�954 8�955 8�984 8�985

22 �8 22 100 82004 82005 82034 82035

25 �8 25 100 82054 82055 82084 82085

Ball End Standard Length Endmills

Cutting Edge Tolerance +.00 -.05Shank Tolerance +.000 -.005

L2

D1 D2

L1

22 www.mastercuttool.com 1-727-726-5��6

D� L� D2 L24FL SQ

Uncoated2FL SQ

Uncoated4FL SQTiAlN

2FL SQTiAlN

� 25 � 65 83000 8300� 83030 8303�

4 25 4 65 83050 8305� 83080 8308�

5 25 5 75 83�00 83�0� 83�30 83�3�

6 25 6 75 83�50 83�5� 83�80 83�8�

8 25 8 75 83200 8320� 83230 8323�

10 �8 10 100 83250 8325� 83280 8328�

12 50 12 100 83300 8330� 83330 8333�

14 56 14 125 83350 8335� 83380 8338�

16 75 16 150 83400 8340� 83430 8343�

18 75 18 150 83450 8345� 83480 8348�

20 75 20 150 83500 8350� 83530 8353�

25 75 25 150 83550 8355� 83580 8358�

Square End Long Length Endmills

D� L� D2 L24FL BALL Uncoated

2FL BALL Uncoated

4FL BALLTiAlN

2FL BALLTiAlN

� 25 � 65 83004 83005 83034 83035

4 25 4 65 83054 83055 83084 83085

5 25 5 75 83�04 83�05 83�34 83�35

6 25 6 75 83�54 83�55 83�84 83�85

8 25 8 75 83204 83205 83234 83235

10 �8 10 100 83254 83255 83284 83285

12 50 12 100 83304 83305 83334 83335

14 56 14 125 83354 83355 83384 83385

16 75 16 150 83404 83405 83434 83435

18 75 18 150 83454 83455 83484 83485

20 75 20 150 83504 83505 83534 83535

25 75 25 150 83554 83555 83584 83585

Ball End Long Length Endmills

Cutting Edge Tolerance +.00 -.05Shank Tolerance +.000 -.005

L2

D1 D2

L1

L2

D1 D2

L1

2�www.mastercuttool.com 1-727-726-5��6

Extra Long LengthD� L� D2 L2 4FL SQ 2FL SQ 4FL BALL 2FL BALL

6 �8 6 100 30�-�000 300-�000 3��-�000 3�0-�000

6 75 6 150 30�-�002 300-�002 3��-�002 3�0-�002

6 75 8 200 30�-�004 300-�004 3��-�004 3�0-�004

8 42 8 100 30�-�006 300-�006 3��-�006 3�0-�006

8 75 8 150 30�-�008 300-�008 3��-�008 3�0-�008

8 75 8 200 30�-�0�0 300-�0�0 3��-�0�0 3�0-�0�0

8 75 10 200 30�-�0�2 300-�0�2 3��-�0�2 3�0-�0�2

10 75 10 150 30�-�0�4 300-�0�4 3��-�0�4 3�0-�0�4

10 75 10 200 30�-�0�6 300-�0�6 3��-�0�6 3�0-�0�6

12 75 12 150 30�-�0�8 300-�0�8 3��-�0�8 3�0-�0�8

12 75 12 200 30�-�020 300-�020 3��-�020 3�0-�020

14 62 14 125 30�-�022 300-�022 3��-�022 3�0-�022

14 75 14 150 30�-�024 300-�024 3��-�024 3�0-�024

14 75 16 200 30�-�026 300-�026 3��-�026 3�0-�026

16 75 16 200 30�-�028 300-�028 3��-�028 3�0-�028

18 75 18 200 30�-�030 300-�030 3��-�030 3�0-�030

20 75 20 200 30�-�032 300-�032 3��-�032 3�0-�032

D� L� D2 L2 Standard TiAlN

� 12 � �8 8�202 8�232

4 14 4 50 8�302 8�332

5 16 5 50 8�402 8�432

6 19 6 6� 8�452 8�482

7 19 8 6� 8�502 8�532

8 21 8 6� 8�552 8�582

9 22 10 70 8�602 8�632

10 25 10 70 8�652 8�682

11 25 11 70 8�702 8�732

12 25 12 75 8�752 8�782

14 �0 14 88 8�802 8�832

16 �2 16 88 8�852 8�882

18 �5 18 100 8�902 8�932

20 �8 20 100 8�952 8�982

22 �8 22 100 82002 82032

25 �8 25 100 82052 82082

6 Flute Endmills

Cutting Edge Tolerance +.00 -.05Shank Tolerance +.000 -.005

L2

D1 D2

L1

L2

D1 D2

L1

24 www.mastercuttool.com 1-727-726-5��6

D� L� D2 L24FL

Uncoated2FL

Uncoated4FL

TiAlN2FL

TiAlN

� 9 � 50 86700 8670� 86706 86707

4 10 4 6� 867�6 867�7 86722 86723

5 12 5 6� 86732 86733 86738 86739

6 16 6 6� 86748 86749 86754 86755

8 18 8 75 86762 86763 86768 86769

10 18 10 75 86778 86779 86784 86785

12 25 12 100 86794 86795 86800 8680�

16 �2 16 150 868�0 868�� 868�6 868�7

Standard Length Double End Square Endmills

D� L� D2 L24FL

Uncoated2FL

Uncoated4FL

TiAlN2FL

TiAlN

� 9 � 50 86708 86709 867�4 867�5

4 10 4 6� 86724 86725 86730 8673�

5 12 5 6� 86740 8674� 86746 86747

6 16 6 6� 86756 86757 86826 86827

8 18 8 75 86770 8677� 86776 86777

10 18 10 75 86786 86787 86792 86793

12 25 12 100 86802 86803 86808 86809

16 �2 16 150 868�8 868�9 86824 86825

D� L� D2 L22 FL SQ

Uncoated2 FL SQ

TiAlN

� 12 � �8 8�20�-90 8�23�-90

5 16 5 50 8�40�-90 8�43�-90

6 19 6 6� 8�45�-90 8�48�-90

8 19 8 6� 8�55�-90 8�58�-90

10 22 10 70 8�65�-90 8�68�-90

12 25 12 75 8�75�-90 8�78�-90

16 �2 16 88 8�85�-90 8�88�-90

18 �6 18 100 8�90�-90 8�93�-90

Standard Length Double End Ball Endmills

2 Flute Drill Mills

Cutting Edge Tolerance +.00 -.05Shank Tolerance +.000 -.005

L2

D1 D2

L1

L2

D1 D2

L1

L2

D1 D2

L1

25www.mastercuttool.com 1-727-726-5��6

D� L� D2 L24 FL SQ

Uncoated2 FL SQ

Uncoated4 FL SQ

TiAlN2 FL SQ

TiAlN

1 2 � �8 85000 8500� 85030 8503�

1.5 � � �8 85050 8505� 85080 8508�

2 4 � �8 85�00 85�0� 85�30 85�3�

2.5 5 � �8 85�50 85�5� 85�80 85�8�

� 6 � �8 85200 8520� 85230 8523�

�.5 7 4 50 85250 8525� 85280 8528�

4 8 4 50 85300 8530� 85330 8533�

4.5 9 5 50 85350 8535� 85380 8538�

5 10 5 50 85400 8540� 85430 8543�

6 12 6 50 85450 8545� 85480 8548�

8 12 8 50 85500 8550� 85530 8553�

10 14 10 50 85550 8555� 85580 8558�

12 16 12 6� 85600 8560� 85630 8563�

Square End Stub Length End Endmills

D� L� D2 L24 FL BALLUncoated

2 FL BALLUncoated

4 FL BALLTiAlN

2 FL BALLTiAlN

1 2 � �8 85004 85005 85034 85035

1.5 � � �8 85054 85055 85084 85085

2 4 � �8 85�04 85�05 85�34 85�35

2.5 5 � �8 85�54 85�55 85�84 85�85

� 6 � �8 85204 85205 85234 85235

�.5 7 4 50 85254 85255 85284 85285

4 8 4 50 85304 85305 85334 85335

4.5 9 5 50 85354 85355 85384 85385

5 10 5 50 85404 85405 85434 85435

6 12 6 50 85454 85455 85484 85485

8 12 8 50 85504 85505 85534 85535

10 14 10 50 85554 85555 85584 85585

12 16 12 6� 85604 85605 85634 85635

Ball End Stub Length Endmills

Cutting Edge Tolerance +.00 -.05Shank Tolerance +.000 -.005

L2

D1 D2

L1

L2

D1 D2

L1

26 www.mastercuttool.com 1-727-726-5��6

D� L� D2 L24 FL SQ

Uncoated2 FL SQ

Uncoated4 FL SQ

TiAlN2 FL SQ

TiAlN

1 2 � �8 86000 8600� 86030 8603�

1.5 � � �8 86050 8605� 86080 8608�

2 4 � �8 86�00 86�0� 86�30 86�3�

2.5 5 � �8 86�50 86�5� 86�80 86�8�

� 6 � �8 86200 8620� 86230 8623�

�.5 7 4 50 86250 8625� 86280 8628�

4 8 4 50 86300 8630� 86330 8633�

4.5 10 5 50 86350 8635� 86380 8638�

5 10 5 50 86400 8640� 86430 8643�

6 12 6 6� 86450 8645� 86480 8648�

8 12 8 6� 86500 8650� 86530 8653�

10 12 10 70 86550 8655� 86580 8658�

12 16 12 75 86600 8660� 86630 8663�

Square End Double End Stub Length Endmills

D� L� D2 L24 FL BALLUncoated

2 FL BALLUncoated

4 FL BALLTiAlN

2 FL BALLTiAlN

1 2 � �8 86004 86005 86034 86035

1.5 � � �8 86054 86055 86084 86085

2 4 � �8 86�04 86�05 86�34 86�35

2.5 5 � �8 86�54 86�55 86�84 86�85

� 6 � �8 86204 86205 86234 86235

�.5 7 4 50 86254 86255 86284 86285

4 8 4 50 86304 86305 86334 86335

4.5 10 5 50 86354 86355 86384 86385

5 10 5 50 86404 86405 86434 86435

6 12 6 6� 86454 86455 86484 86485

8 12 8 6� 86504 86505 86534 86535

10 12 10 70 86554 86555 86584 86585

12 16 12 75 86604 86605 86634 86635

Ball End Double End Stub Length Endmills

Cutting Edge Tolerance +.00 -.05Shank Tolerance +.000 -.005

L2

D1 D2

L1

L2

D1 D2

L1

27www.mastercuttool.com 1-727-726-5��6

D� L� D2 L24 FL

Uncoated2 FL

Uncoated4 FLTiAlN

2 FLTiAlN

� 12 � �8 87008 87009 870�4 870�5

4 14 4 50 87024 87025 87030 8703�

5 16 5 50 87040 8704� 87046 87047

6 19 6 6� 87056 87057 87062 87063

8 19 8 6� 87072 87073 87078 87079

10 22 10 70 87088 87089 87094 87095

12 25 12 75 87�04 87�05 87��0 87���

16 �2 16 88 87�20 87�2� 87�26 87�27

Ball End

D� L� D2 L24 FL

Uncoated2 FL

Uncoated4 FLTiAlN

2 FLTiAlN

� 12 � �8 87000 8700� 87006 87007

4 14 4 50 870�6 870�7 87022 87023

5 16 5 50 87032 87033 87038 87039

6 19 6 6� 87048 87049 87054 87055

8 19 8 6� 87064 87065 87070 8707�

10 22 10 70 87080 8708� 87086 87087

12 25 12 75 87096 87097 87�02 87�03

16 �2 16 88 87��2 87��3 87��8 87��9

Straight Flute EndmillsSquare End

D1 L1 D2 L24FL

.25MM4FL

.50MM4FL

.75MM4FL

1.00MM4FL

1.25MM4FL

1.50MM

4 14 4 50 8�300R0.25 8�300R0.50 8�300R0.75 8�300R�.00 -- --

6 19 6 6� 8�300R0.25 8�450R0.50 8�450R0.75 8�450R�.00 8�450R�.25 8�450R�.50

8 19 8 6� 8�550R0.25 8�550R0.50 8�550R0.75 8�550R�.00 8�550R�.25 8�550R�.50

10 25 10 70 8�650R0.25 8�650R0.50 8�650R0.75 8�650R�.00 8�650R�.25 8�650R�.50

12 25 12 75 8�750R0.25 8�750R0.50 8�750R0.75 8�750R�.00 8�750R�.25 8�750R�.50

16 �2 16 88 8�850R0.25 8�850R0.50 8�850R0.75 8�850R�.00 8�850R�.25 8�850R�.50

20 �8 20 100 8�950R0.25 8�950R0.50 8�950R0.75 8�950R�.00 8�950R�.25 8�950R�.50

D1 L1 D2 L22FL

.25MM2FL

.50MM2FL

.75MM2FL

1.00MM2FL

1.25MM2FL

1.50MM

4 14 4 50 8�30�R0.25 8�30�R0.50 8�30�R0.75 8�30�R�.00 -- --

6 19 6 6� 8�30�R0.25 8�45�R0.50 8�45�R0.75 8�45�R�.00 8�45�R�.25 8�45�R�.50

8 19 8 6� 8�55�R0.25 8�55�R0.50 8�55�R0.75 8�55�R�.00 8�55�R�.25 8�55�R�.50

10 25 10 70 8�65�R0.25 8�65�R0.50 8�65�R0.75 8�65�R�.00 8�65�R�.25 8�65�R�.50

12 25 12 75 8�75�R0.25 8�75�R0.50 8�75�R0.75 8�75�R�.00 8�75�R�.25 8�75�R�.50

16 �2 16 88 8�85�R0.25 8�85�R0.50 8�85�R0.75 8�85�R�.00 8�85�R�.25 8�85�R�.50

20 �8 20 100 8�95�R0.25 8�95�R0.50 8�95�R0.75 8�95�R�.00 8�95�R�.25 8�95�R�.50

Metric Corner Radius Endmills4 Flute

2 Flute

Cutting Edge Tolerance +.00 -.05Shank Tolerance +.000 -.005

L2

D1 D2

L1

L2

D1 D2

L1

Corner Radius

28 www.mastercuttool.com 1-727-726-5��6

D� L� D2 L2No. OfFlutes

EDP#Uncoated

EDP#TiAlN

6 19 6 6� 3 86900 86903

8 19 8 6� 3 86904 86907

10 22 10 6� 3 86908 869��

12 25 12 75 4 869�2 869�5

16 �2 16 88 4 869�6 869�9

20 �8 20 100 4 86920 86923

25 �8 25 100 5 86924 86927

620 Series Medium Pitch Roughers (.062 Pitch)

D� L� D2 L2No. OfFlutes

EDP#Uncoated

EDP#TiAlN

6 19 6 6� 3 86828 8683�

8 19 8 6� 3 86832 86835

10 22 10 6� 3 86836 86839

12 25 12 75 4 86840 86843

16 �2 16 88 4 86844 86847

20 �8 20 100 4 86848 8685�

25 �8 25 100 6 86852 86855

D� L� D2 L2No. OfFlutes

EDP#Uncoated

EDP#TiAlN

6 19 6 6� 3 86856 86859

8 19 8 6� 3 86860 86863

10 22 10 6� 3 86864 86867

12 25 12 75 3 86868 8687�

16 �2 16 88 3 86872 86875

20 �8 20 100 3 86876 86879

25 �8 25 100 3 86880 86883

622 Series Coarse Pitch Roughers (.�05 Pitch)

Rougher UseRoughers, or “hoggers”, are useful for rapid removal of large amounts of material. The chip groove design allows for more cutting fluid to the cutting edge and dissipates heat better. There is a wide range of variations in rougher profile forms for different material groups. The coarser the pitch of the roughing edge, the more material removed and the less smooth the finish. In addition most roughers have eccentric relief so regrinding can be done only using the cutting face. This saves you if you have access to regrinding equipment.

TiN and TiCN also available!

Cutting Edge Tolerance +.00 -.05Shank Tolerance +.000 -.005

L2

D1 D2

L1

62� Series Fine Pitch Roughers (.048 Pitch)

29www.mastercuttool.com 1-727-726-5��6

D� L� D2 L2EDP#

UncoatedEDP#TiAlN

6 20 6 6� 88250 88253

8 22 8 6� 88254 88257

10 25 10 70 88258 8826�

12 25 12 75 88262 88265

16 �0 16 88 88266 88269

20 �8 20 100 88270 88273

60° 3 Flute High Helix TwisterMill

D� L� D2 L2EDP#

UncoatedEDP#TiAlN

6 25 6 6� 88200 88203

8 25 8 6� 88204 88207

10 25 10 70 88208 882��

12 �2 12 75 882�2 882�5

16 42 16 88 882�6 882�9

20 48 20 100 88220 88223

45° 2 Flute High Helix HyperMill

D� L� D2 L2EDP#

UncoatedEDP#TiAlN

� 12 � �8 88000 88005

4 14 4 50 88020 88025

5 19 5 50 88030 88035

6 19 6 6� 88040 88045

8 19 8 6� 88060 88065

10 22 10 70 88080 88085

12 25 12 8� 88�00 88�05

14 �0 14 8� 88�20 88�25

16 �2 16 88 88�40 88�45

20 �8 20 100 88�60 88�65

25 �8 25 100 88�80 88�85

55° 2 Flute High Helix AlumaZips

See the Mastercut Tool website for more in-depth information

about High Performance Endmills Cutting Edge Tolerance +.00 -.05Shank Tolerance +.000 -.005

L2

D1 D2

L1

L2

D1 D2

L1

L2

D1 D2

L1

�0 www.mastercuttool.com 1-727-726-5��6

MaterialSurface Feet Per Minute

Chip Load Per Tooth (IPT)

1/8 1/4 1/2 1

Aluminium Alloys �,200 0.00�0 0.0020 0.0040 0.0080

Carbon Steel 300 - 600 0.00�0 0.00�5 0.0030 0.0060

Cast Iron 350 - 550 0.00�0 0.00�5 0.0030 0.0060

Copper Alloys 500 - 900 0.00�0 0.0020 0.0030 0.0060

Steel (Annealed) 350 - 500 0.00�0 0.0020 0.0030 0.0050

Steel (�8-24 HRC) �50 - 500 0.0004 0.0008 0.00�5 0.0045

Steel (25-37 HRC) �25 - 200 0.0003 0.0005 0.00�0 0.0030

Stainless Steel (Free Machining) 250 - 400 0.0005 0.00�0 0.0020 0.0030

Stainless Steel (Other) �50 - 300 0.0005 0.00�0 0.0020 0.0030

Inconel, Monel 60 - �00 0.0005 0.00�0 0.00�5 0.0030

Titanium �75 - 300 0.0005 0.0008 0.00�5 0.0030

Recommended starting speeds and feeds for variable-helix endmills

D1 L1 D2 L2 Square CR Corner Radius Ball

� 12 � �8 V4-8�200 .25-.38 V4-8�200R.25 V4-8�204

4 14 4 50 V4-8�300 .25-.38 V4-8�300R.25 V4-8�304

5 16 5 50 V4-8�400 .25-.38 V4-8�400R.25 V4-8�404

6 19 6 6� V4-8�450 .38-.5� V4-8�450R.50 V4-8�454

8 19 8 6� V4-8�550 .38-.5� V4-8�550R.50 V4-8�554

10 22 10 70 V4-8�650 .38-.5� V4-8�650R.50 V4-8�654

12 25 12 75 V4-8�750 .64-.76 V4-8�750R.75 V4-8�754

14 25 14 88 V4-8�800 .64-.76 V4-8�800R.75 V4-8�804

16 �2 16 88 V4-8�850 .76-.89 V4-8�850R.75 V4-8�854

18 �6 18 100 V4-8�900 .76-.89 V4-8�900R.75 V4-8�904

20 �8 20 100 V4-8�950 .76-.89 V4-8�950R.75 V4-8�954

25 �8 25 100 V4-82050 .76-.89 V4-82050R.75 V4-82054

V4- TiAlN 4FL Metric Standard Length

D1 L1 D2 L2 Square CR Corner Radius Ball

1/8 �/8 1/8 1-1/2 V4-50200 .0�-.0�5 V4-50200R.0�5 V4-50204

�/16 7/16 �/16 2 V4-50300 .0�-.0�5 V4-50300R.0�5 V4-50304

1/4 5/8 1/4 2-1/2 V4-50500 .0�5-.02 V4-50500R.020 V4-50504

5/16 1�/16 5/16 2-1/2 V4-50600 .0�5-.02 V4-50600R.020 V4-50604

�/8 7/8 �/8 2-1/2 V4-50700 .0�5-.02 V4-50700R.020 V4-50704

7/16 1 7/16 2-�/4 V4-50800 .0�5-.02 V4-50800R.020 V4-50804

1/2 1 1/2 � V4-50900 .025-.03 V4-50900R.030 V4-50904

9/16 1-1/8 9/16 �-1/2 V4-509�0 .025-.03 V4-509�0R.030 V4-509�4

5/8 1-1/4 5/8 �-1/2 V4-5�000 .035-.04 V4-5�000R.040 V4-5�004

�/4 1-1/2 �/4 4 V4-5��00 .035-.04 V4-5��00R.040 V4-5��04

1 1-1/2 1 4 V4-5�300 .035-.04 V4-5�300R.040 V4-5�304

SQUARE CORNER RADIUS BALLV4 - TiAlN 4FL Fractional Standard LengthSQUARE CORNER RADIUS BALL

SQUARE CORNER RADIUS BALL

L2

D1 D2

L1

Introducing Mastercut’s new line of Variable Helix Endmills. The V4 Endmill

reduces harmonic vibrations creating

a smoother running endmill.

�1www.mastercuttool.com 1-727-726-5��6

D1 L1 D2 L2 Square CR Corner Raduis Ball

1/8 1/4 1/8 1-1/2 V4-57000 .0�-.0�5 V4-57000R.0�5 V4-57004

5/�2 5/16 �/16 2 V4-56600 .0�-.0�5 V4-56600R.0�5 V4-56604

�/16 �/8 �/16 2 V4-57�00 .0�-.0�5 V4-57�00R.0�5 V4-57�04

7/�2 7/16 1/4 2 V4-57200 .0�-.0�5 V4-57200R.0�5 V4-57204

1/4 1/2 1/4 2 V4-57300 .0�5-.02 V4-57300R.020 V4-57304

5/16 1/2 5/16 2 V4-57400 .0�5-.02 V4-57400R.020 V4-57404

�/8 5/8 �/8 2 V4-57500 .0�5-.02 V4-57500R.020 V4-57504

7/16 5/8 7/16 2-1/2 V4-57550 .0�5-.02 V4-57550R.020 V4-57554

1/2 5/8 1/2 2-1/2 V4-57600 .025-.03 V4-57600R.030 V4-57604

5/8 �/4 5/8 � V4-57700 .035-.04 V4-57700R.040 V4-57704

�/4 1 �/4 4 V4-57800 .035-.04 V4-57800R.040 V4-57804

V4 - TiAlN 4FL Fractional Stub Length

D1 L1 D2 L2 Square CR Corner Radius Ball

1/4 1-1/8 1/4 � V4-54200 .0�5-.02 V4-54200R.020 V4-54204

�/8 1-1/8 �/8 � V4-54400 .0�5-.02 V4-54400R.020 V4-54404

1/2 2 1/2 4 V4-54600 .025-.03 V4-54600R.030 V4-53604

5/8 2-1/4 5/8 5 V4-54800 .03-.035 V4-54800R.035 V4-54804

�/4 2-1/4 �/4 5 V4-55000 .03-.035 V4-55000R.035 V4-55004

V4 - TiAlN 4FL Fractional Long Length

D1 L1 D2 L2 Square CR Corner Radius Ball

� 6 � �8 V4-85200 .25-.38 V4-85200R.25 V4-85204

4 8 4 50 V4-85300 .25-.38 V4-85300R.25 V4-85304

5 10 5 50 V4-85400 .25-.38 V4-85400R.25 V4-85404

6 12 6 50 V4-85450 .38-.50 V4-85450R.50 V4-85454

8 12 8 50 V4-85500 .38-.50 V4-85500R.50 V4-85504

10 14 10 50 V4-85550 .38-.50 V4-85550R.50 V4-85554

12 16 12 6� V4-85600 .64-.76 V4-85600R.75 V4-85604

V4 - TiAlN 4FL Metric Stub Length

D1 L1 D2 L2 Part Number CR Partnumber Part Number

� 25 � 65 V4-83000 .25-.38 V4-83000R.25 V4-83004

4 25 4 65 V4-83050 .25-.38 V4-83050R.25 V4-83054

5 25 5 75 V4-83�00 .25-.38 V4-83�00R.25 V4-83�04

6 25 6 75 V4-83�50 .38-.5� V4-83�50R.50 V4-83�54

8 25 8 75 V4-83200 .38-.5� V4-83200R.50 V4-83204

10 �8 10 100 V4-83250 .38-.5� V4-83250R.50 V4-83254

12 50 12 100 V4-83300 .64-.76 V4-83300R.75 V4-83304

14 56 14 125 V4-83350 .64-.76 V4-83350R.75 V4-83354

SQUARE CORNER RADIUS BALL

SQUARE CORNER RADIUS BALL

SQUARE CORNER RADIUS BALL

V4 - TiAlN 4FL Metric Long LengthSQUARE CORNER RADIUS BALL

L2

D1 D2

L1

�2 www.mastercuttool.com 1-727-726-5��6

D1 L1 D2 L2 Part Number

1/4 1/4 1/4 6 64000

�/8 �/8 �/8 6 64001

�/8 �/8 �/8 7 64002

1/2 1/2 1/2 6 6400�

1/2 1/2 1/2 7 64004

D1 L1 D2 L2 Part Number

1/4 1/4 1/4 6 64010

�/8 �/8 �/8 6 64011

�/8 �/8 �/8 7 64012

1/2 1/2 1/2 6 6401�

1/2 1/2 1/2 7 64014

3 Flute Ball FlowPort Rougher Mill

3 Flute Ball FlowPort Mill

Flowport Mill

Other sizes and styles available, call customer service for more information.

Part NumberDIEGRINDER

��www.mastercuttool.com 1-727-726-5��6

Fractional Solid Carbide Drills2 Flute - 118° Four Facet Point� Flute - 1�0° High Performance Point

Cutting Edge Tolerance +.000 -.005Shank Tolerance +.000 -.0002

Wire# D1 L1 D2 L2 2 Flute � Flute

#70 .0280 5/16 .0280 1-1/4 40-0280 ~

#69 .0292 5/16 .0292 1-1/4 40-0292 ~

#68 .0�10 5/16 .0�10 1-1/4 40-0�10 ~

~ 1/�2 5/16 1/�2 1-1/4 40-0�12 ~

#67 .0�20 5/16 .0�20 1-1/4 40-0�20 ~

#66 .0��0 5/16 .0��0 1-1/4 40-0��0 ~

#65 .0�50 5/8 .0�50 1-1/2 40-0�50 ~

#64 .0�60 5/8 .0�60 1-1/2 40-0�60 ~

#6� .0�70 5/8 .0�70 1-1/2 40-0�70 ~

#62 .0�80 5/8 .0�80 1-1/2 40-0�80 ~

#61 .0�90 5/8 .0�90 1-1/2 40-0�90 ~

~ .0�94 5/8 .0�94 1-1/2 40-0�94 ~

#60 .0400 �/4 .0400 1-1/2 40-0400 ~

#59 .0410 �/4 .0410 1-1/2 40-0410 ~

#58 .0420 �/4 .0420 1-1/2 40-0420 ~

#57 .04�0 �/4 .04�0 1-1/2 40-04�0 ~

#56 .0465 �/4 .0465 1-1/2 40-0465 ~

~ �/64 �/4 �/64 1-1/2 40-0469 ~

#55 .0520 �/4 .0520 1-1/2 40-0520 ~

#54 .0550 �/4 .0550 1-1/2 40-0550 ~

~ .0591 �/4 .0591 1-1/2 40-0591 ~

#5� .0595 �/4 .0595 1-1/2 40-0595 ~

~ 1/16 �/4 1/16 1-1/2 40-0625 ~

#52 .06�5 �/4 .06�5 1-1/2 40-06�5 ~

#51 .0670 �/4 .0670 1-1/2 40-0670 ~

#50 .0700 7/8 .0700 1-�/4 40-0700 ~

#49 .07�0 7/8 .07�0 1-�/4 40-07�0 ~

#48 .0760 7/8 .0760 1-�/4 40-0760 ~

~ 5/64 7/8 5/64 1-�/4 40-0781 ~

#47 .0785 7/8 .0785 1-�/4 40-0785 ~

~ .0787 7/8 .0787 1-�/4 40-0787 ~

#46 .0810 7/8 .0810 1-�/4 40-0810 ~

#45 .0820 7/8 .0820 1-�/4 40-0820 ~

#44 .0860 1 .0860 2 40-0860 ~

#4� .0890 1 .0890 2 40-0890 ~

#42 .09�5 1 .09�5 2 40-09�5 ~

~ �/�2 1 �/�2 2 40-09�8 ~

#41 .0960 1 .0960 2 40-0960 ~

#40 .0980 1 .0980 2 40-0980 ~

~ .0984 1 .0984 2 40-0984 ~

#�9 .0995 1-1/4 .0995 2-1/4 40-0995 ~

#�8 .1015 1-1/4 .1015 2-1/4 40-1015 ~

D1

L2

L1

D2

�4 www.mastercuttool.com 1-727-726-5��6

Wire# D1 L1 D2 L2 2 Flute � Flute

#�7 .1040 1-1/4 .1040 2-1/4 40-1040 ~

#�6 .1065 1-1/4 .1065 2-1/4 40-1065 ~

~ 7/64 1-1/4 7/64 2-1/4 40-1094 ~

#�5 .1100 1-1/4 .1100 2-1/4 40-1100 ~

#�4 .1110 1-1/4 .1110 2-1/4 40-1110 ~

#�� .11�0 1-1/4 .11�0 2-1/4 40-11�0 ~

#�2 .1160 1-1/4 .1160 2-1/4 40-1160 ~

~ .1181 1-1/4 .1181 2-1/4 40-1181 ~

#�1 .1200 1-1/4 .1200 2-1/4 40-1200 ~

~ 1/8 1-1/4 1/8 2-1/4 40-1250 41-1250

#�0 .1285 1-�/8 .1285 2-1/2 40-1285 41-1285

#29 .1�60 1-�/8 .1�60 2-1/2 40-1�60 41-1�60

~ .1�78 1-�/8 .1�78 2-1/2 40-1�78 41-1�78

#28 .1405 1-�/8 .1405 2-1/2 40-1405 41-1405

~ 9/64 1-�/8 9/64 2-1/2 40-1406 41-1406

#27 .1440 1-�/8 .1440 2-1/2 40-1440 41-1440

#26 .1470 1-�/8 .1470 2-1/2 40-1470 41-1470

#25 .1495 1-�/8 .1495 2-1/2 40-1495 41-1495

#24 .1520 1-�/8 .1520 2-1/2 40-1520 41-1520

#2� .1540 1-�/8 .1540 2-1/2 40-1540 41-1540

~ 5/�2 1-�/8 5/�2 2-1/2 40-1562 41-1562

#22 .1570 1-�/8 .1570 2-1/2 40-1570 41-1570

~ .1575 1-�/8 .1575 2-1/2 40-1575 41-1575

#21 .1590 1-�/8 .1590 2-1/2 40-1590 41-1590

#20 .1610 1-�/8 .1610 2-1/2 40-1610 41-1610

#19 .1660 1-5/8 .1660 2-�/4 40-1660 41-1660

#18 .1695 1-5/8 .1695 2-�/4 40-1695 41-1695

~ 11/64 1-5/8 11/64 2-�/4 40-1719 41-1719

#17 .17�0 1-5/8 .17�0 2-�/4 40-17�0 41-17�0

#16 .1770 1-5/8 .1770 2-�/4 40-1770 41-1770

~ .1772 1-5/8 .1772 2-�/4 40-1772 41-1772

#15 .1800 1-5/8 .1800 2-�/4 40-1800 41-1800

#14 .1820 1-5/8 .1820 2-�/4 40-1820 41-1820

#1� .1850 1-5/8 .1850 2-�/4 40-1850 41-1850

~ �/16 1-5/8 �/16 2-�/4 40-1875 41-1875

#12 .1890 1-5/8 .1890 2-�/4 40-1890 41-1890

#11 .1910 1-5/8 .1910 2-�/4 40-1910 41-1910

#10 .19�5 1-5/8 .19�5 2-�/4 40-19�5 41-19�5

#9 .1960 1-�/4 .1960 � 40-1960 41-1960

~ .1968 1-�/4 .1968 � 40-1968 41-1968

#8 .1990 1-�/4 .1990 � 40-1990 41-1990

#7 .2010 1-�/4 .2010 � 40-2010 41-2010

~ 1�/64 1-�/4 1�/64 � 40-20�1 41-20�1

Fractional Solid Carbide Drills2 Flute - 118° Four Facet Point� Flute - 1�0° High Performance Point

Cutting Edge Tolerance +.000 -.005Shank Tolerance +.000 -.0002

D1

L2

L1

D2

�5www.mastercuttool.com 1-727-726-5��6

Coolant Hole Drills are available! Contact our engineering department

Wire# D1 L1 D2 L2 2 Flute � Flute

#6 .2040 1-�/4 .2040 � 40-2040 41-2040

#5 .2055 1-�/4 .2055 � 40-2055 41-2055

#4 .2090 1-�/4 .2090 � 40-2090 41-2090

#� .21�0 1-�/4 .21�0 � 40-21�0 41-21�0

~ .2165 1-�/4 .2165 � 40-2165 41-2165

~ 7/�2 1-�/4 7/�2 � 40-2188 41-2188

#2 .2210 1-�/4 .2210 � 40-2210 41-2210

#1 .2280 1-�/4 .2280 � 40-2280 41-2280

#A .2�40 2 .2�40 �-1/4 40-2�40 41-2�40

~ 15/64 2 15/64 �-1/4 40-2�44 41-2�44

~ .2�62 2 .2�62 �-1/4 40-2�62 41-2�62

#B .2�80 2 .2�80 �-1/4 40-2�80 41-2�80

#C .2420 2 .2420 �-1/4 40-2420 41-2420

#D .2460 2 .2460 �-1/4 40-2460 41-2460

#E 1/4 2 1/4 �-1/4 40-2500 41-2500

~ .2559 2 .2559 �-1/4 40-2559 41-2559

#F .2570 2 .2570 �-1/4 40-2570 41-2570

#G .2610 2-1/8 .2610 �-1/2 40-2610 41-2610

~ 17/64 2-1/8 17/64 �-1/2 40-2656 41-2656

#H .2660 2-1/8 .2660 �-1/2 40-2660 41-2660

#I .2720 2-1/8 .2720 �-1/2 40-2720 41-2720

~ .2756 2-1/8 .2756 �-1/2 40-2756 41-2756

#J .2770 2-1/8 .2770 �-1/2 40-2770 41-2770

#K .2810 2-1/8 .2810 �-1/2 40-2810 41-2810

~ 9/�2 2-1/8 9/�2 �-1/2 40-2812 41-2812

#L .2900 2-1/8 .2900 �-1/2 40-2900 41-2900

#M .2950 2-�/8 .2950 4 40-2950 41-2950

~ .295� 2-�/8 .295� 4 40-295� 41-295�

~ 19/64 2-�/8 19/64 4 40-2969 41-2969

#N .�020 2-�/8 .20�0 4 40-�020 41-�020

~ 5/16 2-�/8 5/16 4 40-�125 41-�125

~ .�150 2-�/8 .�150 4 40-�150 41-�150

#O .�160 2-�/8 .�160 4 40-�160 41-�160

#P .�2�0 2-�/8 .�2�0 4 40-�2�0 41-�2�0

~ 21/64 2-�/8 21/64 4 40-�281 41-�281

#Q .��20 2-�/8 .��20 4 40-��20 41-��20

~ .��46 2-�/8 .��46 4 40-��46 41-��46

#R .��90 2-�/8 .��90 4 40-��90 41-��90

~ 11/�2 2-�/8 11/�2 4 40-�4�8 41-�4�8

Fractional Solid Carbide Drills2 Flute - 118° Four Facet Point� Flute - 1�0° High Performance Point

Cutting Edge Tolerance +.000 -.005Shank Tolerance +.000 -.0002

D1

L2

L1

D2

�6 www.mastercuttool.com 1-727-726-5��6

Wire# D1 L1 D2 L2 2 Flute � Flute

#S .�480 2-�/8 .�480 4 40-�480 41-�480

~ .�54� 2-�/4 .�54� 4-1/4 40-�54� 41-�54�

#T .�580 2-�/4 .�580 4-1/4 40-�580 41-�580

~ 2�/64 2-�/4 2�/64 4-1/4 40-�594 41-�594

#U .�680 2-�/4 .�680 4-1/4 40-�680 41-�680

~ .�740 2-�/4 .�740 4-1/4 40-�740 41-�740

~ �/8 2-�/4 �/8 4-1/4 40-�750 41-�750

#V .�770 2-�/4 .�770 4-1/4 40-�770 41-�770

#W .�860 2-7/8 .�860 4-1/2 40-�860 41-�860

~ 25/64 2-7/8 25/64 4-1/2 40-�906 41-�906

~ .�9�7 2-7/8 .�9�7 4-1/2 40-�9�7 41-�9�7

#X .�970 2-7/8 .�970 4-1/2 40-�970 41-�970

#Y .4040 2-7/8 .4040 4-1/2 40-4040 41-4040

~ 1�/�2 2-7/8 1�/�2 4-1/2 40-4062 41-4062

#Z .41�0 2-7/8 .41�0 4-1/2 40-41�0 41-41�0

~ .41�4 2-7/8 .41�4 4-1/2 40-41�4 41-41�4

~ 27/64 2-7/8 27/64 4-1/2 40-4219 41-4219

~ .4��1 2-7/8 .4��1 4-1/2 40-4��2 41-4��2

~ 7/16 2-7/8 7/16 4-1/2 40-4�75 41-4�75

~ .4527 � .4527 4-�/4 40-4527 41-4527

~ 29/64 � 29/64 4-�/4 40-45�1 41-45�1

~ 15/�2 � 15/�2 4-�/4 40-4688 41-4688

~ .4724 � .4724 4-�/4 40-4724 41-4724

~ �1/64 � �1/64 4-�/4 40-4844 41-4844

~ .4921 � .4921 4-�/4 40-4921 41-4921

~ 1/2 � 1/2 4-�/4 40-5000 41-5000

~ 17/�2 4 17/�2 6 40-5�12 41-5�12

~ 9/16 4 9/16 6 40-5625 41-5625

~ 19/�2 4 19/�2 6 40-59�8 41-59�8

~ 5/8 4 5/8 6 40-6250 41-6250

~ 21/�2 4 21/�2 6 40-6562 41-6562

~ 11/16 4 11/16 6 40-6875 41-6875

~ 2�/�2 4 2�/�2 6 40-7188 41-7188

~ �/4 4 �/4 6 40-7500 41-7500

~ 7/8 4 7/8 6 40-8750 41-8750

~ 1 4 1 6 40-1 41-1

Fractional Solid Carbide Drills2 Flute - 118° Four Facet Point� Flute - 1�0° High Performance Point

Cutting Edge Tolerance +.000 -.005Shank Tolerance +.000 -.0002

D1

L2

L1

D2

�7www.mastercuttool.com 1-727-726-5��6

2 Flute 27° Helix

Fractional Stub Length Drills

Cutting Edge Tolerance +.000 -.005Shank Tolerance +.000 -.0002

D1 L1 D2 L2 Part # TiN Part #

0.1065 5/8 0.1065 2 4�-1065 4�-1065TN

0.11�0 5/8 0.11�0 2 4�-11�0 4�-11�0TN

1/8 5/8 1/8 2 4�-1250 4�-1250TN

0.1�60 5/8 0.1�60 2 4�-1�60 4�-1�60TN

9/64 5/8 9/64 2 4�-1406 4�-1406TN

0.1495 �/4 0.1495 2-1/2 4�-1495 4�-1495TN

5/�2 �/4 5/�2 2-1/2 4�-1562 4�-1562TN

0.1570 �/4 0.1570 2-1/2 4�-1570 4�-1570TN

11/64 �/4 11/64 2-1/2 4�-1719 4�-1719TN

�/16 �/4 �/16 2-1/2 4�-1875 4�-1875TN

1�/64 �/4 1�/64 2-1/2 4�-20�1 4�-20�1TN

0.21�0 1 0.21�0 2-1/2 4�-21�0 4�-21�0TN

7/�2 1 7/�2 2-1/2 4�-2188 4�-2188TN

15/64 1 15/64 2-1/2 4�-2�44 4�-2�44TN

1/4 1 1/4 2-1/2 4�-2500 4�-2500TN

0.2570 1 0.2570 2-1/2 4�-2570 4�-2570TN

17/64 1 17/64 2-1/2 4�-2656 4�-2656TN

0.2720 1 0.2720 2-1/2 4�-2720 4�-2720TN

0.2786 1-1/4 0.2756 2-1/2 4�-2756 4�-2756TN

9/�2 1 9/�2 2-1/2 4�-2812 4�-2812TN

19/64 1-1/4 19/64 2-�/4 4�-2969 4�-2969TN

5/16 1-1/4 5/16 2-�/4 4�-�125 4�-�125TN

21/64 1-1/4 21/64 2-�/4 4�-�281 4�-�281TN

11/�2 1-1/4 11/�2 � 4�-�4�8 4�-�4�8TN

2�/64 1-1/4 2�/64 � 4�-�594 4�-�594TN

�/8 1-1/4 �/8 � 4�-�750 4�-�750TN

25/64 1-1/4 25/64 � 4�-�906 4�-�906TN

1�/�2 1-1/4 1�/�2 � 4�-4062 4�-4062TN

27/64 1-1/4 27/64 � 4�-4219 4�-4219TN

7/16 1-1/4 7/16 � 4�-4�75 4�-4�75TN

29/64 1-1/4 29/64 � 4�-45�1 4�-45�1TN

15/�2 1-1/4 15/�2 � 4�-4688 4�-4688TN

�1/64 1-1/4 �1/64 � 4�-4844 4�-4844TN

1/2 1-1/4 1/2 � 4�-5000 4�-5000TN

9/16 1-1/4 9/16 �-1/2 4�-5625 4�-5625TN

5/8 1-1/2 5/8 �-1/2 4�-6250 4�-6250TN

�/4 1-1/2 �/4 4 4�-7500 4�-7500TN

D1

L2

L1

D2

�8 www.mastercuttool.com 1-727-726-5��6

DIN 338 2 Flute 27° Helix

Metric Standard Length Drills

Cutting Edge Tolerance +.000 -.127Shank Tolerance +.000 -.005

D1 L1 D2 L2 PART# TiN PART#

� �� � 61 47-1181 47-1181TN

�.1 �6 �.1 65 47-1220 47-1220TN

�.2 �6 �.2 65 47-1260 47-1260TN

�.� �6 �.� 65 47-1299 47-1299TN

�.4 �9 �.4 70 47-1��9 47-1��9TN

�.5 �9 �.5 70 47-1�78 47-1�78TN

�.6 �9 �.6 70 47-1417 47-1417TN

�.7 �9 �.7 70 47-1457 47-1457TN

�.8 4� �.8 75 47-1496 47-1496TN

�.9 4� �.9 75 47-15�5 47-15�5TN

4 4� 4 75 47-1575 47-1575TN

4.1 4� 4.1 75 47-1614 47-1614TN

4.2 4� 4.2 75 47-1654 47-1654TN

4.� 47 4.� 80 47-169� 47-169�TN

4.4 47 4.4 80 47-17�2 47-17�2TN

4.5 47 4.5 80 47-1772 47-1772TN

4.6 47 4.6 80 47-1811 47-1811TN

4.7 47 4.7 80 47-1850 47-1850TN

4.8 52 4.8 86 47-1890 47-1890TN

4.9 52 4.9 86 47-1929 47-1929TN

5 52 5 86 47-1969 47-1969TN

5.1 52 5.1 86 47-2008 47-2008TN

5.2 52 5.2 86 47-2047 47-2047TN

5.� 52 5.� 86 47-2087 47-2087TN

5.4 57 5.4 9� 47-2126 47-2126TN

5.5 57 5.5 9� 47-2165 47-2165TN

5.6 57 5.6 9� 47-2205 47-2205TN

5.7 57 5.7 9� 47-2244 47-2244TN

5.8 57 5.8 9� 47-228� 47-228�TN

5.9 57 5.9 9� 47-2�2� 47-2�2�TN

6 57 6 9� 47-2�62 47-2�62TN

6.1 6� 6.1 101 47-2402 47-2402TN

6.2 6� 6.2 101 47-2441 47-2441TN

6.� 6� 6.� 101 47-2480 47-2480TN

6.4 6� 6.4 101 47-2520 47-2520TN

6.5 6� 6.5 101 47-2559 47-2559TN

6.6 6� 6.6 101 47-2598 47-2598TN

6.7 6� 6.7 101 47-26�8 47-26�8TN

6.8 69 6.8 109 47-2677 47-2677TN

6.9 69 6.9 109 47-2717 47-2717TN

3mm to 7mm

D1

L2

L1

D2

�9www.mastercuttool.com 1-727-726-5��6

D1 L1 D2 L2 PART# TiN PART#

7 69 7 109 47-2756 47-2756TN

7.1 69 7.1 109 47-2795 47-2795TN

7.2 69 7.2 109 47-28�5 47-28�5TN

7.� 69 7.� 109 47-2874 47-2874TN

7.4 69 7.4 109 47-291� 47-291�TN

7.5 69 7.5 109 47-295� 47-295�TN

7.6 75 7.6 117 47-2992 47-2992TN

7.7 75 7.7 117 47-�0�1 47-�0�1TN

7.8 75 7.8 117 47-�071 47-�071TN

7.9 75 7.9 117 47-�110 47-�110TN

8 75 8 117 47-�150 47-�150TN

8.1 75 8.1 117 47-�189 47-�189TN

8.2 75 8.2 117 47-�228 47-�228TN

8.� 75 8.� 117 47-�268 47-�268TN

8.4 75 8.4 117 47-��07 47-��07TN

8.5 75 8.5 117 47-��46 47-��46TN

8.6 81 8.6 125 47-��86 47-��86TN

8.7 81 8.7 125 47-�425 47-�425TN

8.8 81 8.8 125 47-�465 47-�465TN

8.9 81 8.9 125 47-�504 47-�504TN

9 81 9 125 47-�54� 47-�54�TN

9.1 81 9.1 125 47-�58� 47-�58�TN

9.2 81 9.2 125 47-�622 47-�622TN

9.� 81 9.� 125 47-�661 47-�661TN

9.4 81 9.4 125 47-�701 47-�701TN

9.5 81 9.5 125 47-�740 47-�740TN

9.6 87 9.6 1�� 47-�780 47-�780TN

9.7 87 9.7 1�� 47-�819 47-�819TN

9.8 87 9.8 1�� 47-�858 47-�858TN

9.9 87 9.9 1�� 47-�898 47-�898TN

10 87 10 1�� 47-�9�7 47-�9�7TN

10.2 87 10.2 1�� 47-4016 47-4016TN

10.5 87 10.5 1�� 47-41�4 47-41�4TN

11 94 11 142 47-4��1 47-4��1TN

11.5 94 11.5 142 47-4528 47-4528TN

12 101 12 151 47-4724 47-4724TN

DIN 338 2 Flute 27° Helix

Metric Standard Length Drills

7mm to �2mm

Cutting Edge Tolerance +.000 -.127Shank Tolerance +.000 -.005

D1

L2

L1

D2

40 www.mastercuttool.com 1-727-726-5��6

Metric Medium Length Drills

Cutting Edge Tolerance +.000 -.127Shank Tolerance +.000 -.005

D1 L1 D2 L2 STD PART # TiN PART #

�.1 16 �.1 46 50-1220 51-1220

�.2 18 �.2 49 50-1260 51-1260

�.� 18 �.� 49 50-1299 51-1299

�.4 20 �.4 52 50-1��9 51-1��9

�.5 20 �.5 52 50-1�78 51-1�78

�.6 20 �.6 52 50-1417 51-1417

�.7 20 �.7 52 50-1457 51-1457

�.8 22 �.8 55 50-1496 51-1496

�.9 22 �.9 55 50-15�5 51-15�5

4 22 4 55 50-1575 51-1575

4.1 22 4.1 55 50-1614 51-1614

4.2 22 4.2 55 50-1654 51-1654

4.� 24 4.� 58 50-169� 51-169�

4.4 24 4.4 58 50-17�2 51-17�2

4.5 24 4.5 58 50-1772 51-1772

4.6 24 4.6 58 50-1811 51-1811

4.7 24 4.7 58 50-1850 51-1850

4.8 26 4.8 62 50-1890 51-1890

4.9 26 4.9 62 50-1929 51-1929

5 26 5 62 50-1969 51-1969

5.1 26 5.1 62 50-2008 51-2008

5.2 26 5.2 62 50-2047 51-2047

5.� 26 5.� 62 50-2087 51-2087

5.4 28 5.4 66 50-2126 51-2126

5.5 28 5.5 66 50-2165 51-2165

5.6 28 5.6 66 50-2205 51-2205

5.7 28 5.7 66 50-2244 51-2244

5.8 28 5.8 66 50-228� 51-228�

5.9 28 5.9 66 50-2�2� 51-2�2�

6 28 6 66 50-2�62 51-2�62

6.1 �1 6.1 70 50-2402 51-2402

6.2 �1 6.2 70 50-2441 51-2441

6.� �1 6.� 70 50-2480 51-2480

6.4 �1 6.4 70 50-2520 51-2520

6.5 �1 6.5 70 50-2559 51-2559

6.6 �1 6.6 70 50-2598 51-2598

6.7 �1 6.7 70 50-26�8 51-26�8

6.8 �4 6.8 74 50-2677 51-2677

6.9 �4 6.9 74 50-2717 51-2717

7 �4 7 74 50-2756 51-2756

7.1 �4 7.1 74 50-2795 51-2795

7.2 �4 7.2 74 50-28�5 51-28�5

7.� �4 7.� 74 50-2874 51-2874

7.4 �4 7.4 74 50-291� 51-291�

7.5 �4 7.5 74 50-295� 51-295�

7.6 �7 7.6 79 50-2992 51-2992

7.7 �7 7.7 79 50-�0�1 51-�0�1

7.8 �7 7.8 79 50-�071 51-�071

7.9 �7 7.9 79 50-�110 51-�110

2 Flute 25° Helix ��8° 4 Facet PointD1

L2

L1

D2

41www.mastercuttool.com 1-727-726-5��6

D1 L1 D2 L2 STD PART# TiN PART#

8 �7 8 79 50-�150 51-�150

8.1 �7 8.1 79 50-�189 51-�189

8.2 �7 8.2 79 50-�228 51-�228

8.� �7 8.� 79 50-�268 51-�268

8.4 �7 8.4 79 50-��07 51-��07

8.5 �7 8.5 79 50-��46 51-��46

8.6 40 8.6 84 50-��86 51-��86

8.7 40 8.7 84 50-�425 51-�425

8.8 40 8.8 84 50-�465 51-�465

8.9 40 8.9 84 50-�504 51-�504

9 40 9 84 50-�54� 51-�54�

9.1 40 9.1 84 50-�58� 51-�58�

9.2 40 9.2 84 50-�622 51-�622

9.� 40 9.� 84 50-�661 51-�661

9.4 40 9.4 84 50-�701 51-�701

9.5 40 9.5 84 50-�740 51-�740

9.6 4� 9.6 89 50-�780 51-�780

9.7 4� 9.7 89 50-�819 51-�819

9.8 4� 9.8 89 50-�858 51-�858

9.9 4� 9.9 89 50-�898 51-�898

10 4� 10 89 50-�9�7 51-�9�7

10.1 4� 10.1 89 50-�976 51-�976

10.2 4� 10.2 89 50-4016 51-4016

10.� 4� 10.� 89 50-4055 51-4055

10.4 4� 10.4 89 50-4094 51-4094

10.5 4� 10.5 89 50-41�4 51-41�4

10.6 4� 10.6 89 50-417� 51-417�

10.7 4� 10.7 89 50-421� 51-421�

10.8 4� 10.8 89 50-4252 51-4252

11 47 11 95 50-4��1 51-4��1

11.2 47 11.2 95 50-4409 51-4409

11.5 47 11.5 95 50-4528 51-4528

11.8 47 11.8 95 50-4646 51-4646

12 51 12 102 50-4724 51-4724

12.5 51 12.5 102 50-4921 51-4921

1� 51 1� 102 50-5118 51-5118

1�.5 51 1�.5 102 50-5�15 51-5�15

14 56 14 111 50-5512 51-5512

14.5 56 14.5 111 50-5709 51-5709

15 56 15 111 50-5906 51-5906

15.5 58 15.5 115 50-6102 51-6102

16 58 16 115 50-6299 51-6299

16.5 60 16.5 119 50-6496 51-6496

17 60 17 119 50-669� 51-669�

17.5 62 17.5 12� 50-6890 51-6890

18 62 18 12� 50-7087 51-7087

18.5 64 18.5 127 50-728� 51-728�

19 64 19 127 50-7480 51-7480

19.5 66 19.5 1�1 50-7677 51-7677

20 66 20 1�1 50-7874 51-7874

Metric Medium Length Drills2 Flute 25° Helix ��8° 4 Facet Point

Cutting Edge Tolerance +.000 -.127Shank Tolerance +.000 -.005

D1

L2

L1

D2

42 www.mastercuttool.com 1-727-726-5��6

D1 L1 D2 L2 PART#

� 12 � 46 45-1182

�.1 14 �.1 49 45-1220

�.2 14 �.2 49 45-1260

�.� 14 �.� 49 45-1299

�.4 15 �.4 52 45-1��9

�.5 15 �.5 52 45-1�79

�.6 15 �.6 52 45-1417

�.7 15 �.7 52 45-1457

�.8 17 �.8 55 45-1496

�.9 17 �.9 55 45-15�5

4 17 4 55 45-1575

4.1 17 4.1 55 45-1614

4.2 17 4.2 55 45-1654

4.� 18 4.� 58 45-169�

4.4 18 4.4 58 45-17�2

4.5 18 4.5 58 45-177�

4.6 18 4.6 58 45-1811

4.7 18 4.7 58 45-1850

4.8 20 4.8 62 45-1890

4.9 20 4.9 62 45-1929

5 20 5 62 45-1970

5.1 20 5.1 62 45-2008

5.2 20 5.2 62 45-2047

5.� 20 5.� 62 45-2087

5.4 21 5.4 66 45-2126

D1 L1 D2 L2 PART#

5.5 21 5.5 66 45-2166

5.6 21 5.6 66 45-2205

5.7 21 5.7 66 45-2244

5.8 21 5.8 66 45-228�

5.9 21 5.9 66 45-2�2�

6 21 6 66 45-2�6�

6.1 2� 6.1 70 45-2402

6.2 2� 6.2 70 45-2441

6.� 2� 6.� 70 45-2480

6.4 2� 6.4 70 45-2520

6.5 2� 6.5 70 45-2559

7 25 7 74 45-2756

7.5 25 7.5 74 45-295�

8 27 8 79 45-�150

8.5 27 8.5 79 45-��46

9 29 9 84 45-�54�

9.5 29 9.5 84 45-�740

10 �1 10 89 45-�9�8

10.5 �1 10.5 89 45-41�4

11 �� 11 95 45-4��1

11.5 �� 11.5 95 45-4528

12 �5 12 102 45-4724

12.5 �5 12.5 102 45-4921

1� �5 1� 102 45-5118

14 �7 14 107 45-5512

DIN 6539 2 Flute 27° Helix

Metric Stub Length Drills

D1 L1 D2 L2 Point Angle EDP#

1/8 �/8 1/8 2 90 90500

�/16 �/4 �/16 � 90 90510

1/4 �/4 1/4 � 90 90520