Company · 2018-06-25 · Profile Of M.M. Knitwear Ltd. P a g e | 2 An ISO 9001:2015 Certified...

Transcript of Company · 2018-06-25 · Profile Of M.M. Knitwear Ltd. P a g e | 2 An ISO 9001:2015 Certified...

Profile Of M.M. Knitwear Ltd. P a g e | 2 An ISO 9001:2015 Certified Company

M.M. Knitwear Ltd. is 100% export oriented Knitting, Dyeing and Garments composite unit. Since

2001 specializing in all kinds of knitted items. It is housed in its own building surrounding an area of

5,50,000 SFT. And 5,000 workers and stuff. The determination to achieve superior customer service and on

time delivery has earned MMKL recognition as an invaluable player and the desire to succeed in

customer satisfaction with every order makes the MMKL team even stronger it’s these fundamental that

keep this unit in the game and wining every time. Since the beginning MMKL has a very good reputation

as a financially sound and ethical business house. It has a long term association with selected factories,

some of them are certified in terms of social and quality compliance by world’s highest rating bodies,

and outstanding sourcing capabilities. Thus MMKL has been able to prove itself to be a reliable supplier

for knit item in any style and design.

Management:

Md. Mofizul Islam : Managing Director

Md. A.K.M.Shaheed Ahmed : Executive Director

Md. Mamunur Rashid : Director

Md. Nurul Islam : Director (Production)

Md. Abdul Haque : Sr. General Manager (Accounts & Finance)

Md. Monirul Islam : General Manager (Operation)

Mamun Or Rashid : General Manager (Knitting)

Md. Abdul Hye Chanchal : General Manager (Marketing & Merchandising)

Registered Name of the Company : M. M. Knitwear Ltd.

Name of Owner : Md. Mofizul Islam (Managing Director)

: (+88-01711-510764)

Contact Person : Md. Abdul Hye (Chanchal)

General Manager (Marketing & Merchandising)

Mobile: +88-01716-498856

Email: [email protected]

: Md. Mahbub Alam

A.G.M. (Marketing & Merchandising)

: Mobile: +88-01713-211453

Email: [email protected]

Factory Address : Konabari, Nilnagar, Gazipur.

: Phone No. +88-02-9297137, 9289027, 9297840

: Mobile No. +88-01713-006740 (Director)

+88-01713-016641 (Director)

Head Office Address : Road # 10, House #16(3rd Floor),

: Sector # 1, Uttara, Dhaka – 1230,

: Phone No. : 0088-02-8921471, 8950966, 8950969.

: Fax No. : 0088-02-8922483,

: E-mail : [email protected]

Bank Name : United Commercial Bank Ltd.

: Bangshal Branch,

: Dhaka-1000,

: Bangladesh.

: Swift: UCBLBDDHBNG

: Our C/D A/C No: 0251101000000278

The M.M. Knitwear story..…

The M.M. Knitwear story..…

Profile Of M.M. Knitwear Ltd. P a g e | 3 An ISO 9001:2015 Certified Company

Year of establishment : July’2001.

Estimated turnover for year 2018 : 65.00 Million U.S Dollars.

Type of the Company : 100% Export Oriented Composite Knitwear Industry

: Dyeing & Garments Manufacturer & Exporter.

Main Product : Basic & Fancy T-Shirt, Polo Shirt,

: Ruggby Shirt, Tank top, Knitted Jacket,

: Cut N Sewn Dress/Shorts, Long pant and So On.

Production Capacity : If only Basic T-Shirt/Tops = 1,10,000 Pcs/Day.

: If only Polo or Fancy Items = 60,000 Pcs/Day.

: Average Styles = 95,000 Pcs/Day

Total Factory Space : 5,50,000 SFT.

Quality Policy:

Strive to achieve total customer satisfaction by exceeding customer expectation of product quality,

product performance, and delivery.

Commit to implement of quality systems, which conform to international standards.

Make concept of continuous improvement synonymous with total quality management pay attention to

detail and strict adherence to buyer’s requirements in terms of quality and design.

Welfare Facilities:

Induction of workers welfare committee aimed at improving workers morale, job satisfaction and

Attendance

Canteen service

Subsidized lunch for staff

Free snacks for workers

Full time free medical service provided by two professional doctor

Provision for day care center for workers children, annual picnic

Cultural function

Compliance Factory are obeying and maintaining international and local laws, Human rights, Social compliance,

Technical Compliance, C-Tpat, Labor law and other rules and instruction by concern authority.

Audit has been done Compliance standard: 1) amfori BSCI

2) Sedex / SMETA

3) WRAP

4) ISO 9001:2015

5) Oeko Tex

6) OCS

7) ISO 14001:2015

8) OHSAS 18001:2007

The M.M. Knitwear story..…

Profile Of M.M. Knitwear Ltd. P a g e | 4 An ISO 9001:2015 Certified Company

Our Global Client

Profile Of M.M. Knitwear Ltd. P a g e | 5 An ISO 9001:2015 Certified Company

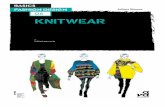

Garments Division…..

Our Certifications

Profile Of M.M. Knitwear Ltd. P a g e | 6 An ISO 9001:2015 Certified Company

List of Machineries

Name of the Machine Nos Origin 1. Single needle Plain Machine 777 nos. Japan

2. 2-needle, 5-thread over lock 080 nos. Japan

3. 2-needle, 4-thread, over lock 593 nos. Japan

4. 2-needle, 4-thread, lap seam stitching 170 nos. Japan

5. 3-needle, 5-thread, chain stitch 060 nos. Japan

6. 1-needle Button Hole 240 nos. Japan

7. 1-needle Button stitches 240 nos. Japan

8. Snap button machine 140 nos. Japan

9. Flat Lock Flatbed 105 nos. Japan

10. Flat Lock Cylinder bed 278 nos. Japan

11. Kansai Special (PMD) 060 nos. Japan

12. Bar tack Machine 050 nos. Japan

13. 3 Thread over lock 100 nos. Japan

14. Rib cutting machine 230 nos. Taiwan

15. Cutting machine 240 nos. Japan

16. Thread winder (Re-conning) 060 nos. Japan

17. Heater less steam iron & Vacuum Table 140 Sets. Japan

18. Strapping Machine, TOYO 050 nos. Japan

19. Thread Sucking Machine 060 nos. BD.

20. Metal Detector (SainTex ) 010 nos. Japan

21. Cutting Layer 010 nos. Thailand

22. Boiler 050 nos. USA & China

Total : 2085 nos.

Sample Section Floor Space : 4500 Sq. feet.

Machineries : 45 Machines + 1 Cutting Table + 2 Vacuum Iron+ 2 Inspection Table+ 1 Pattern Table.

Manpower : 60 Personnel working under the sample Manager separate Pattern master, Q.C,

Cutting man, sewing operator- asst. operator, iron folding & packing man.

Cutting Section Cutting Table : 12 cutting table of (70-90 feet each) in four separate floors.

Floor Space : 50,000 sq. feet.

Total Capacity : 1, 00,000 Pcs/Day (Average)

Manpower : 430 personnel

Embroidery Section 6 sets of Embroidery Machine with 20 head each, Applique laser cutting machine (01pc), Applique

fusing machine (01pc) and Single head manual machine (01pc)

Brand : Barudhan, Japan

Floor space : 4,000 sq.ft.

Manpower : 52 Personnel

Screen Printing Section Independed Print factory with 14 table in 100 feet in length. With Graphic design and color Team.

Capacity : 40,000 pcs/Day in Avg.

Floor space : 20,000 sq.ft.

Manpower : 300 Personnel

Garments Division…..

Profile Of M.M. Knitwear Ltd. P a g e | 7 An ISO 9001:2015 Certified Company

Sewing Section Five floor of 6 lines each & three floor of 10-lines each, 60 Production lines in total.

Floor Space : 95,000 sq. feet.

Total Capacity : 1, 00,000 Pcs/Day (Average)

Manpower : 3389 personnel.

Finishing Section Four separate floors.

Floor space : 42,000 sq. feet

Total Capacity : 95,000 Pcs/Day (Average)

Manpower : 1065 personnel.

Office staff A large team of Technical personnel are directly working, assisting the workers and Coordinating

pattern, cutting, sewing, and quality, finishing-packing. About 700 people are working as a supervisor,

line chief, Floor in charge, section manager.

Quality Team Independent quality team of 454 people is working to ensure customer’s required quality standard.

Factory regular AQL system is 2.5 but in certain case it depends on customer requirement.

Logistic Team A team of 15 personnel working under the Commercial Manager to ensure proper and timely

documentation to continue smooth procedure of Export - import , Banking and other logistic support.

Auditing Team There is an Internal Auditing system is continuously going on by the professional auditors. What are

making everybody to be more careful, responsible and minimizing wastage and process loss.

Garments Division…..

Profile Of M.M. Knitwear Ltd. P a g e | 8 An ISO 9001:2015 Certified Company

We are among the best knitting industries of Bangladesh and manufacture the best quality Garments for

our clients. Over the years our quality products and reputation have created a strong business relation

with the world’s famous clothing brands. We use the latest technology and environment friendly

production process to deliver the best quality to our clients. Our units are:

Circular Knitting Unit: We have a large circular knitting unit having 110 machines with 20GG, 24GG, 28GG cylinder and

optimum attachment to produce all types of weft knitted fabric. Machines are Fukuhara, Fukuhama and

Jiunn long baranded. We also have 28 machines with open width take down and 05 engineering striper

machine. List of machines with diameter as bellow:

Name of Machine Dia Guage Nos. Origin Nos.

1. S/ J 16”-20” 24 Taiwan 05

2. S/ J 21” 24/28 Taiwan 02

3. S/ J 22” 24/28 Taiwan 02

4. S/ J 23” 24/28 Taiwan 02

5. S/ J 24” 24/28 Taiwan 02

6. S/ J 25” 24/28 Taiwan 01

7. S/ J 26” 24 Taiwan 02

8. S/ J 27” 24 Taiwan 01

9. S/ J/FLEECE 28’’ 24/20 Taiwan 04

10. S/ J/FLEECE 29’’ 24/20 Taiwan 03

11. S/ J/FLEECE 30” 24/20/28 Taiwan 09

12. S/ J/FLEECE 32” 24/20/28 Taiwan 11

13. S/ J/FLEECE 34” 24/20 Taiwan 10

14. S/ J/FLEECE 36” 24/20 Taiwan 10

15. S/ J/FLEECE 38” 24/20 Taiwan 09

16. S/ J/FLEECE 40” 24/20 Taiwan 07

17. S/ J/FLEECE 42” 24/20 Taiwan 04

18. RIB/ INTERLOCK 30” 18/24 Taiwan 02

19. RIB/ INTERLOCK 32” 18/24 Taiwan 03

20. RIB/ INTERLOCK 34” 18/24 Taiwan 03

21. RIB/ INTERLOCK 36” 16/18/24 Taiwan 03

22. RIB/ INTERLOCK 38” 18/24 Taiwan 03

23. RIB/ INTERLOCK 40” 18/24 Taiwan 02

24. RIB/ INTERLOCK 42” 18/24 Taiwan 04

25. RIB/ INTERLOCK 44” 18/24 Taiwan 01

26. ENG. STRIPE, S/J 30” 24/20 JAPAN 02

27. ENG. STRIPE, S/J 34” 24/20 JAPAN 02

28. ENG. STRIPE, S/J 36” 24/20 JAPAN 01

Total: 110

Flat Knitting Unit:

We have computerized flat knit machines branded around star, kauo heng, Jy lee having jaquarded

option to produce different types of collar, Cuff and bottoms.

29. FLATKNIT 40”-84” 14 Taiwan 28

Knitting Division…..

Profile Of M.M. Knitwear Ltd. P a g e | 9 An ISO 9001:2015 Certified Company

Narrow Fabric Unit:

We have a narrow fabric unit to produce better quality accessories of garments like twill tape, dusting

etc

30. Warping Machine Taiwan 01

31. Weaving Machine (Tape) Taiwan 02

32. Bobbin Winding Machine Taiwan 01

33. Breading Machine Taiwan 02

Quality Control Unit:

We have a well equity quality control unit to product the best quality for our customers. Equipments are

as bellow:

34. Grey Inspection machine made by UZU form Taiwan 08 Nos

35. Yarn Length Tester (YLT) made by BARTHTEX form GERMANY 02 Nos

36. Yarn Tension Tester Made by SCHMDT from GARMANY 03 Nos

37. Yarn Count Testing Machine Made by SDL ATLUS from UK 01 Nos

Summary:

Total : 158 Sets.

Floor Space : 80,000 sq. feet.

Total Capacity : 28,000 Kgs/Day (Average)

20,000 Pw Collar/Day (Average)

: 20,000 Yds Tape/Day (Average)

Manpower : 390 personnel.

Dyeing Division…..

Knitting Division…..

Profile Of M.M. Knitwear Ltd. P a g e | 10 An ISO 9001:2015 Certified Company

List of Machineries

Name of Machine Capacity Nos. Origin/Brand 1. Auto-detwisting Ballooning Squeezer 70000 Kgs/Day 1 set Turkey(Mersan)

2. Air Turning Machine 12000 Kgs/Day 2 sets Korea(Dongnam)

3. Steam Boiler (:By N/Gas) 10000 Kgs/Day 1sets UK (Cochran)

4. Air Compressor 8.5 M3/Min 2 sets Germany(Rollair)

5. Air Compressor 6.5 M3/Min 2 sets Turkey(Dilgakiran)

6. Air Compressor 7.5 M3/Min 1 sets Germany(Rollair)

7. Air Compressor 4.6 M3/Min 1 sets Germany(Rollair)

8. Compare 5 M3/Min 1 sets U.K

9. Sample Winch 15 Kgs/Batch 4 sets China(Suntex)

10. Sample Winch 30 Kgs/Batch 2 sets China(Suntex)

11. Sample Winch 10 Kgs/Batch 1 set Bangladesh

12. Sample Winch 20 Kgs/Batch 1 set Bangladesh

13. Sample Winch 50 Kgs/Batch 1 set Bangladesh

14. Semi-Automatic Vertical Winch-1 chamber 100 Kgs/Batch 1 set Korea(Sungmoo)

15. Semi-Automatic Vertical Winch-1 chamber 150 Kgs/Batch 1 set Taiwan(Tongjeng)

16. Semi-Automatic Vertical Winch-2 chamber 200 Kgs/Batch 1 set Korea (Sungmoo)

17. Semi-Automatic Vertical Winch-1 chamber 300 Kgs/Batch 1 set Taiwan(Tongjeng)

18. Semi-Automatic Vertical Winch-3 chamber 300 Kgs/Batch 1 set Korea(Sungmoo)

19. Semi-Automatic Vertical Winch-4 chamber 400 Kgs/Batch 1 set Korea (Sungmoo)

20. Semi-Automatic Vertical Winch-1 chamber 120 Kgs/Batch 2 set Fong’s ( China )

21. Semi-Automatic Vertical Winch-2 chamber 200 Kgs/Batch 1 set Fong’s ( China )

22. Semi-Automatic Vertical Winch-2 chamber 400 Kgs/Batch 1 set Fong’s ( China )

23. Semi-Automatic Vertical Winch-3 chamber 600 Kgs/Batch 2 set Fong’s ( China )

24. Semi-Automatic Vertical Winch-4 chamber 800 Kgs/Batch 2 set Fong’s ( China )

25. Semi-Automatic Vertical Winch-1 chamber 900 Kgs/Batch 1 set Taiwan(Tongjeng)

26. Dms Ht Jumbo Jet Flow (HP Winch) 500 Kgs/Batch 1 Set Turkey(Dilmenler)

27. Dms Ht Jumbo Jet Flow (HP Winch) 1500 Kgs/Batch 1 Set Turkey (Dilmenler)

28. Dms Ht Jumbo Jet Flow (HP Winch) 1200 Kgs/Batch 1 Set Turkey(Dilmenler)

29. Dms Ht Jumbo Jet Flow (HP Winch) 900 Kgs/Batch 1 Set Turkey(Dilmenler)

30. Dms Ht Jumbo Jet Flow (HP Winch) 750 Kgs/Batch 1 Set Turkey(Dilmenler)

31. Dms Ht Jumbo Jet Flow (HP Winch) 600 Kgs/Batch 1 Set Turkey(Dilmenler)

32. Dms Ht Jumbo Jet Flow (HP Winch) 450 Kgs/Batch 1 Set Turkey(Dilmenler)

33. Dms Ht Jumbo Jet Flow (HP Winch) 300 Kgs/Batch 1 Set Turkey(Dilmenler)

34. Natural Gas Dryer Machine 3 Chamber 14000 Kgs/Day 1 no. Turkey(Dilmenler)

35. Tubular) Compactor (60) 16000 Kgs/Day 1 Set USA(Tubetex)

36. Pin chain compactor 6000-8000 Kg/D 3 Set Italy(Laffer)

37. Sun-Supper ‘S’ Tenter(98 Roller&8Chember) 10000 Kgs/Day 2 Set Korea(Ilsung)

38. Slitting Machine 12000 Kgs/Day 2 Set Italy(Bianco)

39. Back Sewing TMS 60000 Kgs/Day 2 Set Turkey(Dilmenler)

40. Brush Sueding M/C 1 Set Italy

41. Brushsueding M/C 700 kgs/Day 1 Set Italy

42. Scalavos M/C 1000 kgs/Day 1 Set Greece

43. Scalavos M/C 700 kgs/Day 1 Set Greece

Dyeing Division…..

Profile Of M.M. Knitwear Ltd. P a g e | 11 An ISO 9001:2015 Certified Company

Laboratory:

Name of Machine Nos. Origin/Brand 1. Spectra Flash Sf 600 Plus Spectro Photo Meter (Data Color) 1 Set U.S.A

2. Infrared sample Dyeing Machine 2 Set U.K

3. Color Fastness to washing 1 set Korea

4. Croc meter 1 set U.K

5. Light box 1 set U.K

6. Electric balance 1 set U.S.A

7. Washing machine 1 set Italy

8. Tumble Dryer 1 set Italy

9. Perspire meter 1 Set U.K

10. Pilling Tester 1 Set U.K

11. Rota Wash 1 Set

12. Electrolux Wascator 1 Set

13. STD Front Tumble Dryer 1 Set

14. Lab Oven & Incubator 1 Set

15. PH Meter/ Temperature Meter 1 Set

16. Electronic Yarn Count System 1 Set

Power System:

Name of Machine Capacity Nos. Brand/Origin A. Natural Gas Generator (Waukesha) 1125 KVA(Each) 2 Sets Waukesha/U.S.A

B. Diesel Power Generator 3500 KVA 2 Sets U.K

C. Diesel Power Generator 635 KVA 1 Sets U.S.A

Water Sources: A. Deep Tube-well 4” 1500 M3/H 2 Set Italy

B. Deep Tube-well 6” 2500 M3/H 1 Set Italy

C. Deep Tube-well 2” 30 M3/H 2 Set Italy

D. W.T.P 1000 M3/H 1 Set India

E. 10,000 Ltr. Capacity Overhead Tank. 2 Nos

F. 40,000 Ltr. Capacity Overhead Tank (Only Fire Hose).

G. 30,000 Ltr. Capacity Overhead Tank (Steel building). 2 Nos

H. 35,000 Ltr. Capacity Overhead Tank(Unit-03). 2 Nos

ETP plant : E.T.P (Capacity-80,000 Ltr. Per Hours) 8000 M3/H 1 Set India

Summary:

Floor Space : 1,70,000 Sq.feet.

Capacity : Average 24,000 Kgs Per Day.

Manpower : 440 personnel.

Dyeing Division…..