Combining X-ray and TEM techniques for microstructure studies on …€¦ · Combining X-ray and...

Transcript of Combining X-ray and TEM techniques for microstructure studies on …€¦ · Combining X-ray and...

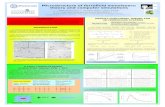

Combining X-ray and TEM techniques for microstructure studies on thin films and thin film nanocomposites

David Rafaja, Institute of Materials [email protected]

Motivation

2

Thin films of molybdenum deposited on glass substratesUsed as contacts in the Cu(In,Ga)Se2 solar cells, etc.

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

0 50 100 150 200 250 300 3505

10

15

20

25

Resis

tivity (c

m)

Temperature (°C)

RF magnetron

DC magnetron

Pulsed DC magnetron

Intrinsic resistivity of Mo

D. Rafaja, H. Köstenbauer, U. Mühle, C. Löffler, G. Schreiber, M. Kathrein, J. Winkler, Thin Solid Films 528 (2013) 42-48.

Motivation

3

Drude model of electrical conductivity

eE

mvm

eEv

tm

vv

eEvdt

dvm

max

max

max exp1

t

v

vmax

Microstructure defects act as scattering centers for electrons

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

-

3D

2D

1D

0D

Microstructure defects

4

Structural vacancies

Foreign atoms

Dislocations

Stacking faults

Twin boundaries

Grain boundaries

Interfaces & surfaces

Local phase transitions

Precipitates of other phases

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

XRD versus TEM

5

X-ray diffraction

Integral measurement of atomic positions, interplanar distances and their variations

Transmission electron microscopy

Local measurement of atomic positions, interplanar distances and their variations

𝐼 = 𝐼0

𝑛

𝑓𝑛 exp 𝑖 𝑞 ∙ 𝑟′𝑛

2

= 𝐼0

𝑛

𝑓𝑛 exp 𝑖 𝑞 ∙ 𝑟𝑛 + 𝑢𝑛

2

= 𝐼0

𝑛

𝑓𝑛 exp 𝑖 𝑞 ∙ 𝑟𝑛 exp 𝑖 𝑞 ∙ 𝑢𝑛

2

Diffracted intensity

Line positions

𝑞 =2𝜋

𝑑=

4𝜋

𝜆sin 𝜃

Line shift

Δ 𝑞 = −2𝜋Δ𝑑

𝑑2 = −4𝜋

𝜆sin 𝜃

Δ𝑑

𝑑= − 𝑞 𝜀

Line broadening

Δ 𝑞 212 =

4𝜋

𝜆sin 𝜃

Δ𝑑

𝑑

212

= 𝑞 𝜀212

Structure factor, line positions

Diffuse scattering, line broadening, …

Point defects as seen by XRD

6

Produce diffuse scattering

Affect stress-free lattice parameters

But

The measured lattice parameters are affected by:

Foreign atoms & atomic vacancies (Vegard-like dependence)

Residual stresses (Lattice deformation depending on the macroscopic direction)

Stacking faults (Change of the interplanarspacing depending on the diffraction indices)

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

How to determine the stress-free lattice parameters?

7

7

I. C. Noyan and J. B. Cohen: Residual Stress Measurement by Diffraction and Interpretation, Springer Verlag, New York, Berlin, Heidelberg, 1987.

A.J. Perry, V. Valvoda, D. Rafaja, Thin Solid Films 214 (1992) 169-174.

sin²

Lattic

e d

efo

rmation

/E

2/(+1)

The sin² plot

For known X-ray elastic constants and stress-free interplanar spacing (d0)

For known Poisson ratio, Young modulus and d0

Materials under uniaxial stress

0

First, the effect of the residual stress must be described

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

𝜀𝜓ℎ𝑘𝑙 =

𝑑𝜓ℎ𝑘𝑙 − 𝑑0

ℎ𝑘𝑙

𝑑0ℎ𝑘𝑙

= 𝜎1

2𝑠2ℎ𝑘𝑙 sin² 𝜓 + 2𝑠1

ℎ𝑘𝑙

𝜀𝜓ℎ𝑘𝑙 =

𝜎

𝐸ℎ𝑘𝑙1 + 𝜈ℎ𝑘𝑙 sin² 𝜓 − 2𝜈ℎ𝑘𝑙

𝑠1ℎ𝑘𝑙 ≡ −

𝜈ℎ𝑘𝑙

𝐸ℎ𝑘𝑙

12𝑠2

ℎ𝑘𝑙 ≡1 + 𝜈ℎ𝑘𝑙

𝐸ℎ𝑘𝑙

How to determine the stress-free lattice parameters?

8

I. C. Noyan and J. B. Cohen: Residual Stress Measurement by Diffraction and Interpretation, Springer Verlag, New York, Berlin, Heidelberg, 1987.

A.J. Perry, V. Valvoda, D. Rafaja, Thin Solid Films 214 (1992) 169-174.sin²

Inte

rpla

na

rsp

acin

g

Stress-free

interplanar

spacing

/E

2/(+1)

The sin² plot For known X-ray elastic constants

For known Poisson ratio and Young modulus

Materials under uniaxial stressMeasurements on one family of lattice planes

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

𝑑𝜓ℎ𝑘𝑙 = 𝑑0

ℎ𝑘𝑙 𝜎1

2𝑠2ℎ𝑘𝑙 sin² 𝜓 + 2𝑠1

ℎ𝑘𝑙 + 1

𝑠1ℎ𝑘𝑙 ≡ −

𝜈ℎ𝑘𝑙

𝐸ℎ𝑘𝑙

12𝑠2

ℎ𝑘𝑙 ≡1 + 𝜈ℎ𝑘𝑙

𝐸ℎ𝑘𝑙

𝑑𝜓ℎ𝑘𝑙 = 𝑑0

ℎ𝑘𝑙𝜎

𝐸ℎ𝑘𝑙1 + 𝜈ℎ𝑘𝑙 sin² 𝜓 − 2𝜈ℎ𝑘𝑙 + 1

9

How to determine the cubic stress-free lattice parameter?

I. C. Noyan and J. B. Cohen: Residual Stress Measurement by Diffraction and Interpretation, Springer Verlag, New York, Berlin, Heidelberg, 1987.

A.J. Perry, V. Valvoda, D. Rafaja, Thin Solid Films 214 (1992) 169-174.sin²

Lattic

e p

ara

mete

rs

Stress-free

lattice

parameter

/E

2/(+1)

The sin² plot For known X-ray elastic constants

For known Poisson ratio and Young modulus

Cubic materials under uniaxial stress

Measurements on different families of lattice planes (GAXRD)

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

𝑎𝜓ℎ𝑘𝑙 = 𝑎0 𝜎

1

2𝑠2ℎ𝑘𝑙 sin² 𝜓 + 2𝑠1

ℎ𝑘𝑙 + 1

𝑠1ℎ𝑘𝑙 ≡ −

𝜈ℎ𝑘𝑙

𝐸ℎ𝑘𝑙

12𝑠2

ℎ𝑘𝑙 ≡1 + 𝜈ℎ𝑘𝑙

𝐸ℎ𝑘𝑙

𝑎𝜓ℎ𝑘𝑙 = 𝑎0

𝜎

𝐸ℎ𝑘𝑙1 + 𝜈ℎ𝑘𝑙 sin² 𝜓 − 2𝜈ℎ𝑘𝑙 + 1

10

Anisotropy of elastic constants

40 60 80 100 120

0

5000

10000

Inte

nsity (

co

un

ts)

Diffraction angle (°2)

36 38 40 42 44 62 64 66

0

5000

10000

Inte

nsity (

co

un

ts)

Diffraction angle (°2)

11

1

20

0

22

0

31

1

22

2 40

0

33

1

42

0

11

1

20

0

22

0

Rietveld refinement using MAUD (L. Lutterotti): http://www.ing.unitn.it/~maud/M. Ferrari, L. Lutterotti, J. Appl. Phys. 76 (11) (1994) 7246-7255.

- Residual stress

- Anisotropy of elastic constants

- Preferred orientation of crystallites (inclined texture)

CuK radiation

CAE (Cr,Al,Si)N

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

11

Calculation of the cubic stress-free lattice parameter

I.C. Noyan, J.B. Cohen: Residual stresses - Measurement by diffraction and interpretation, Springer, New York, 1987.

V. Valvoda, R. Kužel, R. Černý, D. Rafaja, J. Musil, S. Kadlec, A.J. Perry, Thin Solid Films 193/194 (1990) 401.

C. Kral, W. Lengauer, D. Rafaja, P. Ettmayer, J. Alloys Comp. 265 (1998) 215.

0.0 0.2 0.4 0.6 0.8 1.04.11

4.12

4.13

4.14

4.15

4.16

4.17

11

12

00

22

0

31

12

22

40

0

33

14

20

42

2

33

3

La

ttic

e p

ara

me

ter

(Å)

sin2

a0

slope =

= 0.32 sin²0 = 0.48 a0 = 4.1391 Å

Isotropic cubic materials (sin² method):

1

2sin 0

2

CAE (Cr,Al,Si)N

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

𝑎𝜓 = 𝑎0

𝜎

𝐸1 + 𝜈 sin²𝜓 − 2𝜈 + 1

1 + 𝜈

𝐸𝜎𝑎0

Anisotropy of the elastic constants

12

A. Reuss, Z. angew. Math. Mech. 9 (1929) 49.E. Kröner, Z. Physik, 151 (1958) 504.R.W. Vook and F. Witt, J. Appl. Phys. 36 (1965) 2169.

Elastic constants of -Fe

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

13

Anisotropy of the elastic lattice deformation

0.0 0.2 0.4 0.6 0.8 1.00.411

0.412

0.413

0.414

0.415

0.416

0.417

111

200

220

311

222

400

331

420

422

333

Lattic

e p

ara

mete

r (n

m)

sin2

CAE (Cr,Al,Si)N

12sin 1

2

221

0 hkhkhk ssaa

2222

222222

2221

221

111

1

22

2

kh

hkkh

BAE

s

BAE

s

hk

hkhk

hk

hkhk

For uni-axial residual stress

D. Rafaja, M. Dopita, M. Růžička, V. Klemm, D. Heger, G. Schreiber, M. Šíma, Surf. Coat. Technol. 201 (2006) 2835. D. Rafaja, C. Wüstefeld, J. Kutzner, A.P. Ehiasarian, M. Šíma, V. Klemm, D. Heger, J. Kortus, Z. Krist. 225 (2010) 599-609.

hks1

hks2

001

01

2

0221

2

0221

2

2

sin

sin

aaA

aB

aB

aAahk

… slope

… scatter

… shift

Lattice parameter

14

Anisotropy of the elastic lattice deformation

0.0 0.2 0.4 0.6 0.8 1.04.11

4.12

4.13

4.14

4.15

4.16

4.171

11

20

0

22

0

31

12

22

40

0

33

14

20

42

2

33

35

11

La

ttic

e p

ara

me

ter

(Å)

sin2

100 111

R.W. Vook, F. Witt, J. Appl. Phys. 36 (1965) 2169.

D. Rafaja, V. Valvoda, R. Kužel, A.J. Perry, J.R. Treglio, Surf. Coat. Technol. 86-87 (1996) 302-308.

D. Rafaja, M. Dopita, M. Růžička, V. Klemm, D. Heger, G. Schreiber, M. Šíma, Surf. Coat. Technol. 201 (2006) 2835-2843.

F. Attar, T. Johannesson, Thin Solid Films 258 (1995) 205.

00101

2

02212

0221

2221

221

111

1

2

221

0

22sinsin

1

22

2

12sin

aaAaBaBaAa

BAE

s

BAE

s

ssaa

hk

hk

hkhk

hk

hkhk

hkhkhk

Anisotropy of the (cubic) elastic constants:

2222

222222

kh

hkkh

100

111

slope scatter shift

200 = 0.214 sin²0 = 0.353 a0 = 4.1391 Å

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

15

Anisotropy of the elastic constants

0.0 0.2 0.4 0.6 0.8 1.04.11

4.12

4.13

4.14

4.15

4.16

4.171

11

20

0

22

0

31

12

22

40

0

33

14

20

42

2

33

35

11

La

ttic

e p

ara

me

ter

(Å)

sin2

J.F. Nye: Physical Properties of Crystals – Their Representation by Tensors and Matrices, Clarendon Press, Oxford, 1985.

I.C. Noyan, J.B. Cohen: Residual stresses - Measurement by diffraction and interpretation, Springer, New York, 1987.

D. Rafaja, M. Dopita, M. Růžička, V. Klemm, D. Heger, G. Schreiber, M. Šíma, Surf. Coat. Technol. 201 (2006) 2835-2843.

122sin3sin

3;

12sin

12000

2

00

2

12110

4421

12110

01211221

0121

1

2

221

0

SaSaSaSSaa

SSSS

SSSsSSs

ssaa

hk

hkhk

hkhkhk

Anisotropy of the cubic elastic constants (Reuss approach):

2222

222222

kh

hkkh

100

111

1211

44

12110

00

2

21

SS

S

SSa

SaA

A = 3.0

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

16

Elastic compliance

4421

1211001211221

0121

001

2

221

0

;3;

12sin

SSSSSSSsSSs

afassaa

hkhk

hkhkhk

S matrix from the ab initio calculation:

- abinit code (DFT using PAW) for calculation of the atomic positions

- stress-strain approach for calculation of the elastic constants

440000000

044000000

004400000

00020954-54-

00054-20954-

00054-54-209

10 114 PaS

-12 -9 -6 -3 0 3 6 9

4.11

4.12

4.13

4.14

4.15

4.16

4.17

111

200

220

311

222

400

331

420

422

333

La

ttic

e p

ara

me

ter

(Å)

½s2

hkl sin

2 + 2s

1

hkl (TPa

-1)

0aslope =

a0

a0 = (4.1394 0.0006) Å

= -(1.22 0.06) GPa

http://www.abinit.org.J.P. Perdew, K. Burke, M. Ernzerhof, Phys. Rev. Lett. 80/4 (1998) 891.H. Yao, L. Ouyang, W.-Y. Ching, J. Am. Ceram. Soc. 90/10 (2007) 3194.

D. Rafaja, C. Wüstefeld, J. Kutzner, A.P. Ehiasarian, M. Šíma, V. Klemm, D. Heger, J. Kortus, Z. Krist. 225 (2010) 599-609.

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

Stress-free lattice parameter of a Mo thin film

17

-2.0 -1.5 -1.0 -0.5 0.0 0.5 1.0 1.5 2.00.3135

0.3140

0.3145

0.3150

0.3155

0.3160110

200

220

310

222

321

(a)

211

La

ttic

e p

ara

me

ter

(nm

)

f() = ½s2

hkl sin

2 + 2s

1

hkl (10

-12Pa

-1)

0.0 0.2 0.4 0.6 0.8

0.3140

0.3145

0.3150

0.3155

0.3160110

200211

220

310

222

321

(b)

La

ttic

e p

ara

me

ter

(nm

)

sin2

D. Rafaja, H. Köstenbauer, U. Mühle, C. Löffler, G. Schreiber, M. Kathrein,

J. Winkler, Thin Solid Films 528 (2013) 42-48.

A.G. Every, A.K. McCurdy, in D.F. Nelson (ed.): Springer Materials – The

Landolt-Börnstein Database (http://www.springermaterials.com);

http://dx.doi.org/10.1007/10046537_11.

A. Reuss, Z. angew. Math. Mech. 9 (1929) 49.

A.J. Perry, V. Valvoda, D. Rafaja, Thin Solid Films 214 (1992) 169-174.

001

2

221

0

4421

12110

01211221

0121

12sin

;3;

afassaa

SSSS

SSSsSSs

hkhkhk

hkhk

X-ray elastic constants of Mo:

S11 = 2.63 (1/TPa), S12 = −0.68 (1/TPa),

S44 = 9.20 (1/TPa)

Reuss approach

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

Stress-free lattice parameter of a Mo thin film

18

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.50.3144

0.3145

0.3146

0.3147

0.3148

0.3149

0.3150 DC/25°C

RF/25°C

DC/350°C

DC/150°C

RF/150°C

Substitutional atoms (at.%)

Lattic

e p

ara

mete

r (n

m)

Intrinsic value

𝑎 Mo, Sub = 0.314817 nm −1.099 × 10−4[ nm at.%] × 𝑐 Sub [at.%]

𝑎 Mo, Sub = 0.315017 nm −1.099 × 10−4[ nm at.%] × 𝑐 Sub [at.%]

Substitutional atoms: Fe and Cr

Effect of

interstitial atoms

D. Rafaja, H. Köstenbauer, U. Mühle, C. Löffler, G. Schreiber, M. Kathrein, J. Winkler, Thin Solid Films 528 (2013) 42-48.

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

Vegard-like dependence of the stress-free lattice parameter

19

D. Rafaja, C. Wüstefeld, M. Dopita, M. Růžička, V. Klemm, G. Schreiber,

D. Heger, M. Šíma, Surf. Coat. Technol. 201 (2007) 9476-9484.

D. Rafaja, C. Wüstefeld, M. Dopita, V. Klemm, D. Heger, G. Schreiber,

M. Šíma, Surf. Coat. Technol. 203 (2008) 572-578.

D. Rafaja, C. Wüstefeld, M. Motylenko, C. Schimpf, T. Barsukova, M.R.

Schwarz, E. Kroke, Chem. Soc. Rev. 41 (2012) 5081-5101.

0.0 0.2 0.4 0.60.405

0.410

0.415

0.420

0.425

0.445

0.450

0.455

0.460

La

ttic

e p

ara

me

ter

(nm

)

mol AlN in TM1-x

AlxN

Zr1-xAlxN: a = [0.458(1) – 0.026(1)·x] nm

Ti1-xAlxN: a = [0.42418(2) – 0.01432(2)·x] nm

Cr1-xAlxN: a = [0.41486(2) – 0.00827(1)·x] nm

Cr1-xAlxN

Ti1-xAlxN

Zr1-xAlxN

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

Phase diagrams of the Ti1-xAlxN

20

B. Alling, A.V. Ruban, A. Karimi, O.E. Peil, S.I. Simak,

L. Hultman, I. A. Abrikosov, Phys. Rev. B 75 (2007) 045123.

P.H. Mayrhofer, D. Music, J.M. Schneider, Appl. Phys. Letters

88 (2006) 071922.

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

Thermodynamically metastable system stabilized by low mobility of adatoms

21

Lattice parameters of (TM,Al)N with TM = Cr, Ti, Zr

Latt

ice p

ara

mete

r

TMN(TM,Al)N

Latt

ice p

ara

mete

r

[TM]/([TM]+[Al])

Vegard-like dependence of the lattice parameters

Combination of the chemical analysis and the structure analysis

Lattice parameter of TM1-xAlxN increases with increasing TM content

Single phase

Dual phase(TM,Al)N + AlN

Overall

composition

Composition

of fcc-(TM,Al)N

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

Coexistence of fcc-(Ti,Al)N and w-AlN

22

20 30 40 50 60 70

111

200

220

311

222

400

331

420

422

511/3

33

100

002

101

102

110

103

112

201

202

203

114

212

213

Inte

nsity (

arb

.units)

Diffraction angle (°2)

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

As seen by XRD:

Minor phase consisting of

small crystallites is mainly

visible via ‘diffuse scattering’

The stress-free lattice

parameter corresponds to

the chemical composition of

the respective phase

D. Rafaja, Ch. Wüstefeld, M. Dopita, M. Motylenko,

C. Baehtz, IUCrJ 1 (6) (2014) 446-456.

Phase transition fcc w

23

2 nm

__[120]

[001]

[112]

_[111]

w fcc

D. Rafaja, C. Wüstefeld, M. Dopita, M. Motylenko, C. Baehtz, C. Michotte, M. Kathrein, Surf. Coat. Technol. 257 (2014) 26-37.

_[110]

_[210]

Stacking faults

24

(11-20)_

(101)

111 0001

(111)

(0002)

Fm3m P63mc

fcc

wurtziteA

bB

c

C

a

A

bB

c

C

aA

A

bB

aA

bB

aA

bB

aA

Phase transition via formation of stacking faults on the (111)fcc and (0002)w planes

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

D. Rafaja, C. Wüstefeld, M. Dopita, M. Motylenko, C. Baehtz, C. Michotte, M. Kathrein, Surf. Coat. Technol. 257 (2014) 26-37.

Correlated positions of stacking faults

25

Layer Microstructure feature/defect Sequence of the lattice planes

1 Regular fcc stacking ABCABC

2 Intrinsic SF ABCAB|ABC

3 Alternating arrangement of SFs (narrowly spaced SFs) ABCAB|AB|ABC

4 Twin ABC|B|A|C

5 Extrinsic SF ABCA|C|BCABC

S. Martin, C. Ullrich, D. Šimek, U. Martin, D. Rafaja, J. Appl. Cryst. 44 (2011) 779-787.

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

Stacking along (111)fcc || (002)hcp

26D. Borisova, V. Klemm, S. Martin, S. Wolf, D. Rafaja, Adv. Eng. Mat. 15 (2013) 571-582.

... as seen by HRTEM & FFT/HRTEM

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

Microstructure of deformed TRIP steels

27

... as seen by EBSD (phase contrast & band contrast)

fcc austenite

band contrast

SG: Fm-3m

a = 3.5953 Å

hcp -martensite

SG: P63/mmc

a = 2.540 Å

c = 4.111 Å

bcc ’-martensite

SG: Im-3m

a = 2.875 Å

hcpfcc

hcpfcc

dd

aa

002111

2

S. Martin, C. Ullrich, D. Šimek, U. Martin, D. Rafaja, J. Appl. Cryst. 44 (2011) 779-787.D. Borisova, V. Klemm, S. Martin, S. Wolf, D. Rafaja, Adv. Eng. Mat. 15 (2013) 571-582.

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

Paterson & Warren approach

28

m

L

a

d

d

d

dd

affected

22

*

4

31

mlkh

L

a

a

d

d affected

2224

3

mlkh

L

G

Gaa

affected

hkl

hkl

222

04

31

M.S. Paterson, J. Appl. Phys. 23 (1952) 805.

B.E. Warren, E.P. Warekois, J. Appl. Phys. 24 (1953) 951.

B.E. Warren, J. Appl. Phys. 32 (1961) 2428.

C.N.J. Wagner: Local atomic arrangements studied by X-ray diffraction, Gordon and Breach, New York, 1966.

B.E. Warren: X-ray Diffraction, Dover Inc., New York, 1969/1990.

Comments and corrections to the Warren approach:

L. Velterop, R. Delhez, Th.H. de Keijser, E.J. Mittemeijer, D. Reefman, J. Appl. Cryst. 33 (2000) 296.

E. Estevez-Rams, M. Leoni, P. Scardi, B. Aragon-Fernandez, H. Fuess, Phil. Mag. 83 (2003) 4045.

E. Estevez-Rams, U. Welzel, A. Pentón Madrigal, E.J. Mittemeijer, Acta Cryst. A64 (2008) 537.

lkhLklKhkH ;;21

21

fcc (hkl) hcp (HKL):

fcc SF hcp

222,311,200

fcc

400,220,111

222,131,022,111

Anisotropy of fcc lattice parameters

29

Measured lattice parameters: Macroscopic (residual) stress (crystal anisotropy of the elastic constant s1(hkl)) Stacking faults with the density (contrast factors of stacking faults) Sample displacement p (if not corrected using internal standard)

Austenite (fcc), symmetrical diffraction geometry, uniaxial stress

cotcos4

3

3

3

cotcos4

3

100

1

111

1

100

1

0

0

100

1

111

1

100

11

1

0

0

pG

sssa

aa

ssss

pGsa

aa

hk

hk

hk

hkl

hk

hkl

hkhk

2222

222222

lkh

lhlkkhhkl

Strong correlation between and G for low-angle diffraction lines

0.0 0.1 0.2 0.3

-0.4

-0.2

0.0

0.2

0.4

0.6

111

200

220

311222

400

331

420422 333511

Ghkl

hkl

mlkh

L

Gaffected

hkl

222

hklhklG 42.247.0

B.E. Warren: X-ray Diffraction, Dover Inc., New York, 1969/1990.

R.W. Vook, F. Witt, J. Appl. Phys. 36 (1965) 2169.D. Šimek, D. Rafaja, M. Motylenko, V. Klemm, G. Schreiber, A. Brethfeld, G. Lehmann, steel research int. 79 (10) (2008) 800.D. Rafaja, C. Krbetschek, D. Borisova, G. Schreiber, V. Klemm, Thin Solid Films 530 (2013) 105.

… due to applied stress and formation of stacking faults

30

X-ray diffraction line broadening

G.K. Williamson, W.H. Hall, Acta Metallugica 1 (1953) 22-31.

The Williamson-Hall plot

Size of the diffraction vector (4 sin/)

XR

D lin

e b

roa

de

nin

g

Reciprocal crystallite size

Slope is proportional

to microstrain

tan2cos

2

sin2

2

12

2

12

D

K

D

Kq

0.4 0.6 0.8 1.04

5

6

7

8

9

110

200

211

220 310

222

321

Lin

e b

roadenin

g (

10

-3 n

m-1)

sin

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

Δ 𝑞 212 =

4𝜋

𝜆sin 𝜃

Δ𝑑

𝑑

212

= 𝑞 𝜀212

Anisotropic XRD line broadening

310.0 0.2 0.4 0.6 0.8 1.00

2

4

6

8

110 200

211 220

310

222 3

21

(b)

2

hkl (

10

-3n

m-2)

sin2

0.0 0.3 0.6 0.9 1.2 1.50

2

4

6

8

110 200

211 220

310

222 3

21

(a)

2

hkl (

10

-3n

m-2)

(1-)*sin2

𝜀ℎ𝑘𝑙2 = 2𝜋𝑏2𝑀2𝐶ℎ𝑘𝑙𝜚𝑑𝑖𝑠𝑙

𝐶ℎ𝑘𝑙 = 𝐶100 1 − 𝜁Γ

Γ =ℎ2𝑘2 + 𝑘2𝑙2 + 𝑙2ℎ2

ℎ2 + 𝑘2 + 𝑙2 2

𝛽ℎ𝑘𝑙2 =

0.9

𝐷

2

+ 4 𝜀ℎ𝑘𝑙2 sin 𝜃

𝜆

2

𝛽ℎ𝑘𝑙2 =

0.9

𝐷

2

+

+8𝜋𝑏2𝑀2𝐶100

𝜆𝜚𝑑𝑖𝑠𝑙 1 − 𝜁Γ sin 𝜃 2

𝛽ℎ𝑘𝑙2 =

0.9

𝐷

2

+ 4 𝜀1002 1 − 𝜁Γ

sin 𝜃

𝜆

2

Electrical conductivity of Mo thin films

32

Effect of individual microstructure defects

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

𝜚 = 𝜀1002 × 1.10 ± 0.01 × 105µΩcm + Δ𝑎 × 7.47 ± 0.04 × 103 µΩcm nm

+𝑐𝑠𝑢𝑏𝑠𝑡 × 4.18 ± 0.26 µΩcm at.% + 7.87 ± 0.27 µΩcm

Intrinsic electrical conductivity of molybdenum: 5.46 µΩcm

Grain boundaries: (2.41±0.09) µΩcm

Dislocations: 𝜀1002 × 1.10 ± 0.01 ×

105µΩcm;

max. (3.63±0.04) µΩcm

Substitutional atoms: 𝑐𝑠𝑢𝑏𝑠𝑡 ×4.2 ± 0.3 µΩcm at.%;

max. 11.7 µΩcm @ 2.8 at.%

Interstitial atoms: 𝑐𝑖𝑛𝑡𝑒𝑟 × 4.5 ±0 50 100 150 200 250 300 350

5

10

15

20

25

Resis

tivity (c

m)

Temperature (°C)

D. Rafaja, H. Köstenbauer, U. Mühle, C. Löffler, G. Schreiber, M. Kathrein,

J. Winkler, Thin Solid Films 528 (2013) 42-48.

Anisotropic line broadening (hexagonal)

𝛽ℎ𝑘𝑙 =2𝑙

𝜋𝑐2𝑑ℎ𝑘𝑙

𝛾

1 − 𝛾

C. Schimpf. M. Motylenko, D. Rafaja, Mater. Char. 86 (2013) 190

Turbostratic disorder (𝛾 = 0.07)

Basal plane corrugations (∆𝑐 = 0.05 Å)

Dislocations E001<110> (𝑀2𝜚 = 5 × 1013 m−2)

Basal plane stacking faults (𝛼𝑠𝑓 = 0.015)

𝛽ℎ𝑘𝑙 =𝑙2

𝑐3𝑑ℎ𝑘𝑙 ∆𝑐

𝛽ℎ𝑘𝑙 = 𝜒ℎ𝑘𝑙

1

𝑑ℎ𝑘𝑙𝑏

𝜋

2𝑀2𝜚

𝛽ℎ𝑘𝑙 =3𝑙

𝑐2𝑑ℎ𝑘𝑙𝛼𝑠𝑓

A.V. Kurdyumov, Sov. Phys. Cryst. 20 (1976) 596 | K. Ufer et al., Z. Krist. 219 (2004) 519

P. Klimanek & R. Kužel. J. Appl. Cryst. 21 (1988) 59 | R. Kužel & P. Klimanek, ibid. 363

B.E. Warren, X-ray diffraction, Addison-Wesley, Mass., USA (1969)

33

34

X-ray diffraction line broadening

Size of the diffraction vector

XR

D lin

e b

roadenin

gReciprocal

cluster size

Reciprocal crystallite size

Misorientation

of adjacent

crystallites

G.K. Williamson, W.H. Hall, Acta Metallugica 1 (1953)

22-31.

D. Rafaja, V. Klemm, G. Schreiber, M. Knapp, R. Kužel,

J. Appl. Cryst. 37 (2004) 613-620.

The Williamson-Hall plotModified Williamson-Hall

plot

Size of the diffraction vector (4 sin/)

XR

D lin

e b

roadenin

g

Reciprocal crystallite size

Slope is proportional

to microstrain

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

tan2cos

2

sin2

2

12

2

12

D

K

D

Kq

35

Phenomenon of the partial coherence of crystallites

222

33

*

*

hklhklhklhkl

rqi

V

rqi

FFTFFTqI

qFFTrderrrderqF

Diffraction on a single crystallite:

1

1 11

2

11

2

1

cos2K

j

jK

i

jiijii

K

i

i

K

i

i

K

i

i

K

i

i

RRqqFqFqFqI

qFqFqFqI

Diffraction on a cluster of mutually (partially)

coherent crystallites:

D. Rafaja, V. Klemm, G. Schreiber, M. Knapp, R. Kužel, J. Appl. Cryst. 37 (2004) 613.

Kinematical

approximation

Coherence term: interference of waves diffracted

by different crystallites

36

Phenomenon of the partial coherence of crystallites

222

33

*

*

hklhklhklhkl

rqi

V

rqi

FFTFFTqI

qFFTrderrrderqF

Diffraction on a single crystallite:

1

1 11

2

11

2

1

cos2K

j

jK

i

jiijii

K

i

i

K

i

i

K

i

i

K

i

i

RRqqFqFqFqI

qFqFqFqI

D. Rafaja, V. Klemm, G. Schreiber, M. Knapp, R. Kužel, J. Appl. Cryst. 37 (2004) 613.

-10 -5 0 5 10

0

2

4

6

8

10

Y A

xis

Titl

e

X axis title

Intensity

q

Kinematical

approximation

Coherence term: interference of waves diffracted

by different crystallites

Diffraction on a cluster of mutually (partially)

coherent crystallites:

Simulation of the reciprocal space maps

37

000

111

200

002202

311

004

113313

313

004

113

311

204

204

202

115115

315

315

200

_111

_113

_113

_204_

204

_115

_115

_202

_202

_200

_200

_311

_311

_313

_313

_315

_315

qx

qz

Mutually rotated and

shifted spherical

crystallites

-0.25 -0.2 -0.15 -0.1 -0.05 0 0.05 0.1 0.15 0.2 0.25-0.25

-0.2

-0.15

-0.1

-0.05

0

0.05

0.1

0.15

0.2

0.25

Intensity = |F1|2 + |F

2|2

qx [Å-1]

q

z [

Å-1

]

-0.25 -0.2 -0.15 -0.1 -0.05 0 0.05 0.1 0.15 0.2 0.25-0.25

-0.2

-0.15

-0.1

-0.05

0

0.05

0.1

0.15

0.2

0.25

Intensity = |F1|2 + |F

2|2 + |F

1||F

2| cos(q.D)

qx [Å-1]

q

z [

Å-1

]

-0.25 -0.2 -0.15 -0.1 -0.05 0 0.05 0.1 0.15 0.2 0.250

2

4

6

8

10

12

14x 10

11

qz [Å-1]

Inte

nsity (

arb

.units)

q = 0.03

1

1 11

2cos2

K

j

jK

i

jiijii

K

i

i RRqqFqFqFqI

D. Rafaja, V. Klemm, Ch. Wüstefeld, M. Motylenko,

M. Dopita, M. Schwarz, T. Barsukova, E. Kroke,

Z. Kristallogr. Suppl. 27 (2008) 15.

Simulation of the reciprocal space maps

38

-0.25 -0.2 -0.15 -0.1 -0.05 0 0.05 0.1 0.15 0.2 0.25-0.25

-0.2

-0.15

-0.1

-0.05

0

0.05

0.1

0.15

0.2

0.25

Intensity = |F1|2 + |F

2|2

qx [Å-1]

q

z [

Å-1

]

-0.25 -0.2 -0.15 -0.1 -0.05 0 0.05 0.1 0.15 0.2 0.25-0.25

-0.2

-0.15

-0.1

-0.05

0

0.05

0.1

0.15

0.2

0.25

Intensity = |F1|2 + |F

2|2 + |F

1||F

2| cos(q.D)

qx [Å-1]

q

z [

Å-1

]

-0.25 -0.2 -0.15 -0.1 -0.05 0 0.05 0.1 0.15 0.2 0.250

2

4

6

8

10x 10

11

qz [Å-1]

Inte

nsity (

arb

.units)

q = 0.14

000

111

200

002202

311

004

113313

313

004

113

311

204

204

202

115115

315

315

200

_111

_113

_113

_204_

204

_115

_115

_202

_202

_200

_200

_311

_311

_313

_313

_315

_315

qx

qz

Mutually rotated and

shifted spherical

crystallites

1

1 11

2cos2

K

j

jK

i

jiijii

K

i

i RRqqFqFqFqI

D. Rafaja, V. Klemm, Ch. Wüstefeld, M. Motylenko,

M. Dopita, M. Schwarz, T. Barsukova, E. Kroke,

Z. Kristallogr. Suppl. 27 (2008) 15.

Simulation of the reciprocal space maps

39

-0.25 -0.2 -0.15 -0.1 -0.05 0 0.05 0.1 0.15 0.2 0.25-0.25

-0.2

-0.15

-0.1

-0.05

0

0.05

0.1

0.15

0.2

0.25

Intensity = |F1|2 + |F

2|2

qx [Å-1]

q

z [

Å-1

]

-0.25 -0.2 -0.15 -0.1 -0.05 0 0.05 0.1 0.15 0.2 0.25-0.25

-0.2

-0.15

-0.1

-0.05

0

0.05

0.1

0.15

0.2

0.25

Intensity = |F1|2 + |F

2|2 + |F

1||F

2| cos(q.D)

qx [Å-1]

q

z [

Å-1

]

-0.25 -0.2 -0.15 -0.1 -0.05 0 0.05 0.1 0.15 0.2 0.250

1

2

3

4

5

6x 10

11

qz [Å-1]

Inte

nsity (

arb

.units)

q = 0.4

000

111

200

002202

311

004

113313

313

004

113

311

204

204

202

115115

315

315

200

_111

_113

_113

_204_

204

_115

_115

_202

_202

_200

_200

_311

_311

_313

_313

_315

_315

qx

qz

Mutually rotated and

shifted spherical

crystallites

1

1 11

2cos2

K

j

jK

i

jiijii

K

i

i RRqqFqFqFqI

D. Rafaja, V. Klemm, Ch. Wüstefeld, M. Motylenko,

M. Dopita, M. Schwarz, T. Barsukova, E. Kroke,

Z. Kristallogr. Suppl. 27 (2008) 15.

Effect of the partial coherence on the XRD line broadening

Diffraction vector

XR

D l

ine b

road

en

ing

000

111

200

002 202

311

004

113313

313

004

113

311

204

204

202

115115

315

315

200

_111

_113

_113

_204_

204

_115

_115

_202

_202

_200

_200

_311

_311

_313

_313

_315

_315

qx

qz

Non-overlapping reciprocal lattice points: “classical” kinematical diffraction theory

Size of the reciprocal

lattice points

0cos1

1 1

K

j

jK

i

jiijii RRqqFqF

K

i

i qF1

2

40

44141

Effect of the partial coherence on the XRD line broadening

Diffraction vector

XR

D l

ine b

road

en

ing

000

111

200

002 202

311

004

113313

313

004

113

311

204

204

202

115115

315

315

200

_111

_113

_113

_204_

204

_115

_115

_202

_202

_200

_200

_311

_311

_313

_313

_315

_315

qx

qz

Partially overlapping reciprocal lattice points: mutual coherence of crystallites

0cos1

1 1

K

j

jK

i

jiijii RRqqFqF

Size of the reciprocal

lattice points

42

XRD line broadening and microstructure features

Diffraction vector

XR

D l

ine b

road

en

ing

Reciprocal

crystallite size

Non-overlapping reciprocal lattice points: XRD distinguishes individual crystallites

0cos1

1 1

K

j

jK

i

jiijii RRqqFqF

Scherrer formula is valid

K

i

i qF1

2

43

XRD line broadening and microstructure features

qx

qz

Disorientation

of crystallites

Diffraction vector

XR

D l

ine b

road

en

ing

Disorientation

of crystallites

Onset of the partial coherence: XRD sees the disorientation of individual crystallites

Reciprocal

crystallite size

44

XRD line broadening and microstructure features

Partial overlap of the reciprocal lattice points: XRD sees the crystallites larger

Diffraction vector

XR

D l

ine b

road

en

ing

Disorientation

of crystallites

Reciprocal

crystallite size

0cos1

1 1

K

j

jK

i

jiijii RRqqFqF

45

XRD line broadening and microstructure features

Extrapolation to q = 0: in analogy with the “classical” diffraction theory, XRD

sees the size of the clusters of crystallites

Diffraction vector

XR

D l

ine b

road

en

ing

Size of clusters of

partially coherent

crystallites

Disorientation

of crystallites

Reciprocal

crystallite size

Elastic anisotropy & partial coherence

46

0.2 0.3 0.4 0.5 0.65

10

15

20

25

30

35

111

200

220

311

222

400

331

420

422

511

Lin

e b

roa

den

ing

(1

0-3 Å

-1)

sin

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

47

(Cr,Al,Si)N nanocomposites

CrystallitesClusters

Cr0.92Al0.08N0.2 0.4 0.6 0.8 1.00.02

0.04

0.06

0.08

0.10

0.12

Lin

e b

roadenin

g (

nm

-1)

sin

Crystallite size: 9 nm

Cluster size: 36 nm

=0.50°=0.56°

5 nm

Crystallites

Clusters

Cr0.92Al0.08N

D. Rafaja, Ch. Wüstefeld, M. Dopita, M. Růžička, V. Klemm, G. Schreiber, D. Heger, M. Šíma, Surf. Coat. Technol. 201 (2007) 9476.

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

(Ti,Al,Si)N nanocomposites

48

20 40 60 80 1000.1

0.2

0.3

0.4

0.5

Lin

e b

roadenin

g [nm

-1]

q [nm-1]

… Ti0.38Al0.62N

… Ti0.40Al0.53Si0.07N

Crystallite size

D = (2.4 0.2) nm

Cluster size

D = (8.5 1.0) nm

Partially coherent crystallites

Non-coherent crystallites

2 nm

Ti0.38Al0.62N – partially coherent

2 nm

Ti0.40Al0.53Si0.07N – non coherent

D. Rafaja, A. Poklad, V. Klemm, G. Schreiber, D. Heger, M. Šíma, Mat. Sci. Eng. A 462 (2007) 279.

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

49

“Local heteroepitaxy” of crystallites as seen by TEM

2 nm

fcc-(Ti,Al)N and w-AlN nanocrystallites are

separated by a-Si3N4

Local heteroepitaxy between fcc-(Ti,Al)N

and w-AlN nanocrystallites

Crystallite size: (2.4 0.2) nm

Cluster size: (8.5 1.0) nmTi0.40Al0.53Si0.08N

Crystallite size: (2.4

0.2) nm

2 nmTi0.38Al0.62N

CrystallitesClusters of crystallites

Cubic

phase

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

50

“Local heteroepitaxy” of crystallites as seen by XRD

20 40 60 80 1000.1

0.2

0.3

0.4

0.5

Lin

e b

roadenin

g [nm

-1]

q [nm-1]

… Ti0.38Al0.62N

… Ti0.40Al0.53Si0.08N

Crystallite size

(2.4 0.2) nm

Cluster size

(8.5 1.0) nm

D. Rafaja, A. Poklad, V. Klemm, G. Schreiber, D. Heger, M. Šíma, Freiberger Forschungshefte B 331 (2005) 36-38.

Partially coherent crystallites

Non-coherent crystallites

0.0 0.2 0.4 0.6 0.80.410

0.413

0.416

0.419

0.422

0.425

Latt

ice

pa

ram

ete

r [n

m]

sin2

|| << 1 GPa

H = (25.4 0.6) GPa

Local

heteroepitaxy

= -(9.0 0.5) GPa

H = (30.6 1.3) GPa

No local heteroepitaxy

The sin² plot Modified Williamson-Hall

plot

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

51

Effect of “local heteroepitaxy” on the hardness

2 3 4 5 6 7 8 924

27

30

33

36

1

2

3

4

5

1

2

3

4

5

Ha

rdn

ess (

GP

a)

Crystallite size (nm)

2 3 4 5 6 7 8 924

27

30

33

36

D. Rafaja, A. Poklad, V. Klemm, G. Schreiber, D. Heger, M. Šíma, Mat. Sci. Eng. A 462 (2007) 279–282.

“Hall-Petch“ and inverse

“Hall-Petch” relationship

describing the dependence

of the hardness on the

crystallite size

Considerable contribution

of the local heteroepitaxy

to the hardness

… Ti1-xAlxN

… Ti1-x-yAlxSiyN

Partially

coherent

crystallites

Non-coherent

crystallites

FRIENDS2, Advanced coating and characterization techniques, Microstructure studies

Summary

52

X-ray diffraction

Non-destructive method

Analysis of large sample volumes

Visualization of microstructure defects is possible only through the strain fields

Excellent precision of the lattice spacing determination

Transmission electron microscopy

Destructive method

Local analytical method

Direct visualization of microstructure defects is possible

Medium precision of the lattice spacing determination

53

Acknowledgement

Materials Science (TU Freiberg)

Ch. Wüstefeld

Dr. M. Motylenko

A. Poklad

Ch. Schimpf

Dr. V. Klemm

Dr. U. Mühle

Dr. M. Dopita

R. Popp

A. Leuteritz

G. Schreiber

Dr. D. Heger

D. Chmelik

U. Ratayski

Inorganic Chemistry(TU Freiberg)

Prof. Dr. E. Kroke

Dr. M.R. Schwarz

T. Barsukova

Helmholtz Centre(Dresden)

ESRF (Grenoble)

Dr. C. Bähtz

TU Darmstadt

HASYLAB Hamburg

Dr. M. Knapp (KIT)CERATIZIT

C. Michotte (Mamer)

Dr. M. Kathrein & Ch. Czettl (Reutte)

SHM Šumperk

Dr. M. Šíma

Dr. M. Jílek

University of Bayreuth

Dr. D. Frost

Dr. L. Dubrovinsky

Prof. N. Dubrovinskaia

Plansee CM (Lechbruck)

Dr. P. Polcik

C. Polzer

Helmholtz Centre(Potsdam)

HASYLAB Hamburg

Dr. Ch. Lathe

Theoretical Physics(TU Freiberg)

Prof. Dr. J. Kortus

J. Kutzner

Sheffield Hallam University

Prof. Dr. A.P. Ehiasarian

Plansee SE (Reutte)

Dr. H. Köstenbauer

54

Financial support

Thank you for your kind attention

Supported from the funds of the European Community and the Saxony Government

Dr. Erich Krüger

Research Foundation:

Freiberg High-Pressure

Research Centre