Code of Practice - Electricity transmission and ... · 7.9.1 Cable identification ... the...

Transcript of Code of Practice - Electricity transmission and ... · 7.9.1 Cable identification ... the...

Code of Practice Electricity transmission and distribution asset management _______________________________________________________________________________________________

February 2009

Code of Practice - Electricity transmission and distribution asset management

CONTENTS 1 PREFACE...............................................................................................................................................4 2 APPLICATION AND OBJECTIVES...............................................................................................5 3 SCOPE ....................................................................................................................................................6 4 DEFINITIONS........................................................................................................................................7 5 DESIGN AND CONSTRUCTION..................................................................................................11

5.1 Application .................................................................................................................................11 5.2 General ........................................................................................................................................11

5.2.1 Materials .............................................................................................................................11 5.2.2 Environmental Considerations .................................................................................11 5.2.3 Thermal Ratings ..............................................................................................................12 5.2.4 Short Circuit Ratings.....................................................................................................12 5.2.5 Mechanical Loading Conditions...............................................................................12 5.2.6 Electrical Service Conditions and Physical Environment .............................12 5.2.7 Prevention of Unauthorised Access .......................................................................12 5.2.8 Installation .........................................................................................................................12 5.2.9 Water Crossings..............................................................................................................12 5.2.10 Records ...............................................................................................................................12

5.3 Overhead Lines ........................................................................................................................13 5.3.1 General ................................................................................................................................13 5.3.2 Conductor Tensions ......................................................................................................13 5.3.3 Structures and Footings ..............................................................................................13 5.3.4 Facade Mounted Cables...............................................................................................13 5.3.5 Safety Clearances ...........................................................................................................13 5.3.6 Overhead Service Lines ...............................................................................................15

5.4 Underground Cables..............................................................................................................16 5.4.1 General ................................................................................................................................16 5.4.2 Installation .........................................................................................................................16 5.4.3 Parts of an Underground Cable Installed Above Ground..............................16 5.4.4 Underground Service Lines........................................................................................16

5.5 Substations................................................................................................................................17 5.5.1 General ................................................................................................................................17 5.5.2 Substation Electricity Works .....................................................................................17 5.5.3 Clearances to Exposed Live Electricity Works ..................................................17 5.5.4 Structural Design of Buildings and Roofed Enclosures ................................17 5.5.5 Kiosk Type Substations ...............................................................................................18 5.5.6 Ground Type Substations ...........................................................................................18 5.5.7 Pole Mounted Substations..........................................................................................18

5.6 Earthing and Electrical Protection...................................................................................19 5.6.1 General ................................................................................................................................19 5.6.2 Step and Touch Potentials..........................................................................................19

NSW Department of Water and Energy, February 2009 Page 1 of 45

Code of Practice - Electricity transmission and distribution asset management

6 MAINTENANCE .................................................................................................................................20

6.1 General ........................................................................................................................................20 6.2 Maintenance of Overhead Lines .......................................................................................20 6.3 Maintenance of Underground Cables.............................................................................20 6.4 Maintenance of Substations ...............................................................................................21 6.5 Maintenance of Protection and Earthing Systems ...................................................21 6.6 Environmental Considerations..........................................................................................21

7 SAFE ELECTRICAL WORK PRACTICES................................................................................22 7.1 General ........................................................................................................................................22 7.2 Qualifications and Training ................................................................................................22

7.2.1 General Requirements ..................................................................................................22 7.2.2 Employer Responsibility..............................................................................................23 7.2.3 Employees in Training ..................................................................................................23

7.3 General Safety Provisions...................................................................................................23 7.3.1 Basic Safety Principles ................................................................................................23 7.3.2 Hazard Identification and Risk Assessment .......................................................23 7.3.3 Hazard Control .................................................................................................................23 7.3.4 Minimum Safe Working Distances ..........................................................................24 7.3.5 Correct Labelling and Recording of Electricity Works ...................................24 7.3.6 Hazardous Electrical Occurrences or Effects ....................................................24 7.3.7 Precautions for Energisation and Re-energisation of

Electricity Works .............................................................................................................25 7.3.8 First-aid ...............................................................................................................................25 7.3.9 Protective Clothing ........................................................................................................25 7.3.10 Work in Confined Spaces ............................................................................................26

7.4 Operating Work ........................................................................................................................26 7.5 Access Permits ........................................................................................................................26 7.6 Work on Low Voltage Electricity Works........................................................................27

7.6.1 De-energised LV Electricity Works..........................................................................27 7.6.2 Live LV Electricity Works ............................................................................................27

7.7 Work on High Voltage Electricity Works .......................................................................27 7.7.1 De-energised HV Electricity Works .........................................................................27 7.7.2 Live HV Electricity Works ............................................................................................28

7.8 Work on Overhead Lines .....................................................................................................28 7.9 Work on Underground Cables ...........................................................................................29

7.9.1 Cable identification ........................................................................................................29 7.9.2 Precautions for Work on or Near Cables ..............................................................29

7.10 Access into Substations ......................................................................................................30 7.11 Work in Substations...............................................................................................................30 7.12 Tools and Safety Equipment ..............................................................................................30

NSW Department of Water and Energy, February 2009 Page 2 of 45

Code of Practice - Electricity transmission and distribution asset management

Appendix: Acts, Regulations, Australian Standards, Codes and Guides relating to the Design, Construction, Maintenance and Safe Electrical Operation and Work Practices for Transmission & Distribution Systems ......................31

SECTION A: STANDARDS, CODES AND GUIDES RELATING TO OVERHEAD LINES AND SERVICES...................................................................31

SECTION B: STANDARDS, CODES AND GUIDES RELATING TO CABLES

AND SERVICES...........................................................................................................35 SECTION C: STANDARDS, CODES AND GUIDES RELATING TO

SUBSTATIONS ............................................................................................................36 SECTION D: STANDARDS, CODES AND GUIDES RELATING TO

PROTECTION AND EARTHING SYSTEMS ......................................................40 SECTION E: STANDARDS, CODES AND GUIDES RELATING TO SAFE

ELECTRICAL OPERATION AND WORK PRACTICES.................................42 SECTION F: RELEVANT ACTS AND REGULATIONS ............................................................43

NSW Department of Water and Energy, February 2009 Page 3 of 45

Code of Practice - Electricity transmission and distribution asset management

1 PREFACE This Code has been made available by the Department of Water and Energy without significant amendment of the Code prepared for the Electricity Association of NSW by a working group with representatives from the following organisations: Energy Australia

Integral Energy NorthPower Great Southern Energy Railway Services Authority BHP TransGrid Advance Energy

The Code was circulated to the following groups prior to finalisation: Consumer groups

Public/regional interests Occupational health and safety agencies Insurance interests Electrical contractors Distribution equipment suppliers and Service Providers Network Operators

This Code has been recognised by the Director-General of the Department of Water and Energy for the purposes of network operator’s licences. The use and impact of this Code will be monitored through the Industry Safety Steering Committee (ISSC) who may seek to revise the Code as may be appropriate from time to time. Comments are welcome and can be sent to the Department as follows: Manager, Energy Networks Performance Policy

Department of Water and Energy Level 17 Elizabeth Street SYDNEY 2000

Note: This Code is one of a number which will apply to the design, construction

and/or maintenance of electricity works or installations. Other Codes of Practice which may be applicable include:

- Contestable Works - Installation Safety Management - Service and Installation Rules - Distribution Risk Management

NSW Department of Water and Energy, February 2009 Page 4 of 45

Code of Practice - Electricity transmission and distribution asset management

2 APPLICATION AND OBJECTIVES

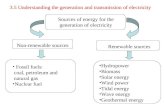

The Electricity Supply Act 1995 (The Act) provides the framework for promoting industry efficiency generally through establishing a balance of competition and regulation. There is also scope for benefit to customers as a whole in limited standardisation of infrastructure design and service procedures which promote: • community safety, • compatibility among electricity supply systems, • economies of scale, and • freedom for buyers to exercise choice. This Code of Practice is intended to promote common practices in electricity transmission and distribution to embed in the State’s electricity supply infrastructure, its operation and maintenance, features which are generally accepted as appropriate for meeting the needs of the public in terms of safety, access and network impacts. This Code of Practice aims to provide guidance as to cost effective practices and procedures which are intended to protect the interest of customers and the public. The Code is intended to be adopted by licence holders under The Act. There may be local reasons for departing from or not adopting this Code in its entirety. A licence holder is required to state its policy on the adoption of this Code in its licence compliance annual report. The availability of this Code will also support the streamlining of the regulatory regime under The Act by providing guidance on achieving the minimum standard of electrical safety to customers, the public and industry workers, contractors and their employees. This Code shall be followed unless there is an alternative course of action which achieves the same or better outcomes. Being a guide, this Code does not in general stipulate prescriptive details on the design, construction, operation and maintenance of all electrical assets, nor provide all relevant information. Individual organisations shall produce their own detailed manuals and work procedures where necessary, with due regard to all relevant standards which are appended in this Code.

NSW Department of Water and Energy, February 2009 Page 5 of 45

Code of Practice - Electricity transmission and distribution asset management

3 SCOPE

This Code outlines the policy and standards which apply to the design, construction, maintenance and operation of electricity works. The Code will apply to Network Operators, Service Providers and any of their sub-contractors working on electricity works or operating electricity transmission or distribution systems. The design, construction and maintenance provisions of the Code apply to all electricity transmission and distribution systems whether or not the system is: • out of service, or • being constructed and has never been energised. The safe electrical operation and work practices provisions apply to work on, and operation of, the electricity transmission and distribution system except where: • the system cannot be energised by operating work because of the absence of electrical

connections to any possible source of electricity supply, or • no person and no material or equipment not insulated for the voltage concerned, can

come near to any exposed conductor which is live or can be energised by operating work.

This Code does not apply to railway traction overhead wiring which is regulated by the Rail Safety Act 1993.

NSW Department of Water and Energy, February 2009 Page 6 of 45

Code of Practice - Electricity transmission and distribution asset management

4 DEFINITIONS

‘The Act’ means the Electricity Supply Act 1995. ‘Access permit’ means a pre-printed form which, when issued in accordance with a documented procedure adopted by the Network Operator, gives permission to the recipient to work on or near to, or test, electricity works. ‘Approved’ means having appropriate organisation endorsement in writing for a specific function. ‘AS’ means an Australian Standard, as published and amended by Standards Australia on the date this Code comes into operation. ‘Authorised’ means has the permission of the appropriate authority in writing for the duty concerned. ‘Bare’ in relation to a conductor means not insulated. ‘Cable’ means an insulated conductor or two or more such conductors laid together, whether with or without fillings, reinforcements or protective coverings. ‘Carriageway’ means

• that portion of a public road which is improved or designed for use by, or used by, vehicular traffic, including any road shoulder and breakdown lane but not including any footpath or other lateral part of the road not so improved, designed or used, or

• that portion of a defined vehicular track (whether formed or unformed) which is ordinarily used by the public and which is located on a road reserve or on land under the control of the Western Lands Commissioner or in a national park, State forest or Crown land, and includes the entire width of the defined vehicular track plus 2.5 metres on each side of the track.

‘Confined space’ means confined space as defined in The Occupational Health and Safety (Confined Space) Regulation, 1990 (as amended). ‘Conductor’ means a wire, cable or form of metal designed for carrying electric current. ‘Covered Conductor’ means a conductor around which is applied a specified thickness of insulating material. There are generally two types of covered conductor:

Covered Conductor (CC) where the nominal covering thickness is independent of working voltage; and

Covered Conductor Thick (CCT) where the nominal covering thickness is

dependent on the working voltage.

NSW Department of Water and Energy, February 2009 Page 7 of 45

Code of Practice - Electricity transmission and distribution asset management

‘De-energised’ means not connected to a source of electrical supply. ‘Earthed’ means electrically connected to the general mass of earth. ‘Electricity works’ means any electricity power lines or associated equipment or electricity structures that form part of a transmission or distribution system.

‘Employee’ means a worker in the employment of an employer (whether under a contract of employment or apprenticeship) and includes a contractor or sub-contractor, and a person employed by a contractor or sub-contractor, who carries out work for an employer. ‘Employer’ means a Network Operator or Service Provider, as the case may be. ‘Exposed conductor’ means an electrical conductor, approach to which is not prevented by a barrier of rigid material or by insulation which is adequate under a relevant Australian Standard specification for the voltage concerned. ‘Extra low voltage’ means voltage normally not exceeding 32 volts alternating current or 115 volts direct current. ‘Fire rating’ means the minimum period of time during which an element of a structure may be expected to function satisfactorily while subjected to the Standard Fire Test provided for in the Australian Building Code. ‘Ground type substation’ means a semi-enclosed, free standing substation which is connected to a high voltage aerial line or underground cable. ‘High voltage’ or ‘HV’ means a voltage normally exceeding 1,000 volts alternating or exceeding 1,500 volts direct current. ‘Insulated’ means separated from adjoining conducting material by a non-conducting substance which provides resistance to the passage of current, or to disruptive discharges through or over the surface of the substance at the operating voltage, and to obviate danger of shock or injurious leakage of current. ‘Insulated conductor’ means a conductor which is wholly covered with insulating material in accordance with the relevant AS or equivalent. ‘Isolated’ means disconnected from all possible sources of electrical energy by the opening of switches, withdrawal of circuit breakers, removal of fuses, links, connections and the like and rendered incapable of being made live unintentionally. ‘Kiosk type substation’ means a totally enclosed, free-standing, self-contained substation not designed for bodily entry and which is generally operated from door openings. ‘Live’ means connected to a source of electrical supply or subject to hazardous induced or capacitive voltages. ‘Low voltage’ or ‘LV’ means voltage exceeding 32 V a.c. / 115 V d.c. but not exceeding 1000 V a.c. / 1500 V d.c.

NSW Department of Water and Energy, February 2009 Page 8 of 45

Code of Practice - Electricity transmission and distribution asset management

‘Maximum design temperature’ means the maximum temperature which the conductors may reach under the influence of load current (excluding fault current), ambient temperature of the air and solar radiation. ‘Near’ means a situation where there is a reasonable possibility of a person, either directly or through any conducting medium, coming within the relevant safe working distances specified in this Code. ‘Network Operator’ means a Network Operator as defined by The Act. ‘Neutral conductor’ means a conductor of a Low Voltage system which is earthed at its origin. ‘Nominal voltage (U)’ means the AC (phase to phase RMS) or DC voltage by which a system of supply is designated. ‘Operating Work’ means work involving the operation of switches, the opening or closing of links or other connections intended for ready removal, the removal or replacement of fuses, proving that electricity works is de-energised and the earthing and short-circuiting of electricity works. ‘Overhead line’ means any aerial conductor or conductors with associated supports, insulators and other apparatus erected, or in the course of erection, for the purpose of the transmission, distribution or conveyance of electrical energy. ‘Other cable systems’ means, telecommunications and control cables, aerial earthed cables or electrolysis drainage cables attached to or crossing a Network Operator’s overhead line or otherwise in the proximity of the overhead line. ‘Pole mounted substation’ means a substation mounted on one or more poles. ‘Premises’ means any house, building or structure including the land associated with it. ‘Protective equipment’ means equipment which is intended to isolate the active conductors of a circuit if an electrical fault occurs. ‘The Regulation’ means the Electricity Supply (Safety and Network Management) Regulation 2008. ‘Road’ means any thoroughfare ordinarily used by vehicular traffic. ‘Safe’ means not posing a risk to life, health or property. ‘Screened cable’ means that the insulation covering the conductor cores is covered by a conducting or semi conducting material which is connected to a neutral or earth.

NSW Department of Water and Energy, February 2009 Page 9 of 45

Code of Practice - Electricity transmission and distribution asset management

‘Service line’ means the part of an electricity distribution system that forms the terminating span of an electric line which:

• is constructed or designed or ordinarily used for the supply of electricity at low voltage, and

• is intended to supply electrical energy to a customer either from a main or directly from the premises or structure of the Network Operator.

‘Service Provider’ means a Service Provider as defined in the Code of Practice - Contestable Works.

‘Substation’ or ‘Electrical station’ means any premises or place in which high voltage supply is converted, controlled or transformed. ‘Supply’ means supply of electricity. ‘Underground cable’ means a cable which is placed under the ground and may include portions which are erected above the ground. ‘Voltage’ means a potential difference between conductors and between conductors and earth.

NSW Department of Water and Energy, February 2009 Page 10 of 45

Code of Practice - Electricity transmission and distribution asset management

5 DESIGN AND CONSTRUCTION

5.1 Application

This section of the Code applies to all electricity works placed into service on or after the recognition of this Code by the Department of Water and Energy and to any part of an electricity works which is upgraded, renewed or replaced after that commencement. Electricity works in service prior to the commencement of this Code are covered by the regulation or law in force at time of their construction.

5.2 General

All electricity works shall be designed to be safe for the electrical conditions likely to be experienced during service and the physical environment in which they will operate, taking into account acceptable risk management techniques. [Note: When purchasing new equipment, it is considered prudent to take into account Australia’s possible response to international trends to change the supply voltages of 220V and 240V to 230V.] The documents referred to in the appendices to this Code should be considered for the design and construction of electricity works. Where there are variations between the documents referred to in Appendices A, B, C, D and E, and this Code, the Code is to take precedence.

5.2.1 Materials All materials used for electricity works, their components, conductors, accessories and support structures shall ensure safe operational performance.

5.2.2 Environmental Considerations

The design, construction and installation of electricity works shall take into consideration environmental issues and concerns. Factors to consider include, but are not limited to:

• the promotion of energy efficiency, • the efficient use of non-renewable resources, • the use of renewable resources, • the social impact of new projects, and community concerns, • the minimisation of environmental damage, including visual impacts, • tree management programmes, • a reduction in and the correct disposal of waste products, and • the consideration of Electromagnetic Field (EMF) issues.

NSW Department of Water and Energy, February 2009 Page 11 of 45

Code of Practice - Electricity transmission and distribution asset management

5.2.3 Thermal Ratings The thermal capacity of electricity works shall be sufficient to pass the electrical load for which they are designed, without reduction of mechanical properties to a level below that which provides safe operational performance. 5.2.4 Short Circuit Ratings The electricity works shall be of sufficient capacity to pass short circuit currents which will enable the correct operation of protective devices so that a fault is cleared without reduction of mechanical properties to a level below that which provides safe operational performance. 5.2.5 Mechanical Loading Conditions The electricity works shall have sufficient mechanical strength to withstand anticipated mechanical stresses due to environmental and electrical service conditions. 5.2.6 Electrical Service Conditions and Physical Environment In determining the electrical service conditions and the physical environment under which the electricity works will operate, due and reasonable care shall be given to the consideration of extremes that may occur, the likelihood of their occurrence and the associated risk. 5.2.7 Prevention of Unauthorised Access All electricity works with exposed live parts shall be so designed and constructed that unauthorised access to any person is prevented as far as is reasonably practicable. 5.2.8 Installation Electricity works shall be installed in accordance with relevant standards. 5.2.9 Water Crossings Water crossings (overhead and underground) shall be designed, constructed, installed and maintained in a manner that complies with the requirements of the appropriate authorities, including the installation and maintenance of appropriate signage. 5.2.10 Records All design, construction, operation and maintenance records that are relevant to safety shall be kept in an accessible form.

NSW Department of Water and Energy, February 2009 Page 12 of 45

Code of Practice - Electricity transmission and distribution asset management

5.3 Overhead Lines

5.3.1 General Overhead lines shall be designed and constructed to:

• have insulation appropriate for the nominal voltage, • carry the electrical load currents for which they are designed, • allow the passage of electrical short circuit currents which will enable the

correct operation of protective devices, • ensure they are structurally secure for the environmental and service

conditions for which they are designed, • maintain safe clearances, • ensure that safe operational performance will occur, and • prevent unauthorised access to the electricity works. This includes overhead service lines, insulated and covered cable systems.

5.3.2 Conductor Tensions The conductors for use with overhead lines shall be designed to withstand the mechanical loads over the designed operational life, without failure. 5.3.3 Structures and Footings The structures and footings for use with overhead lines shall be designed to withstand the mechanical loads over the designed operational life, without failure. Due consideration shall be given to the environmental conditions likely to be experienced during service.

5.3.4 Facade Mounted Cables

Cables and accessories used for facade mounting shall be constructed with suitably insulated conductors and be manufactured to be durable for the environmental service conditions likely to be experienced.

5.3.5 Safety Clearances

Overhead lines and other cable systems shall be designed to maintain safety clearances to the ground and buildings or structures under the environmental and electrical service conditions determined for the line.

NSW Department of Water and Energy, February 2009 Page 13 of 45

Code of Practice - Electricity transmission and distribution asset management

5.3.5.1 Clearances to Ground of Exposed and Insulated Conductors Overhead lines, excluding service lines, “other cable systems” and aerial lines within substations, shall have all conductors located so that the distances to ground in any direction from any position to which any part of such conductors either sag at maximum design temperature or move as a result of wind pressure which could reasonably be expected to occur at the location of the overhead line, are not less than the distances specified in Table 1.

TABLE 1

Nominal system voltage (U)

(Volts)

Over the carriageway

of roads (mm)

Over land other than the

carriageway of roads (mm)

Over land which due to its condition is not

traversable by vehicles (mm)

Exposed or insulated U < 1 000 OR

Insulated conductor with earthed screen U > 1 000

5 500

5 500

4 500

Insulated conductor without an earthed screen U > 1 000

6 000 5 500 4 500

Exposed or covered conductor 1 000 < U < 33 000

33 000 < U < 132 000 132 000 < U < 220 000 220 000 < U < 330 000 330 000 < U < 500 000

6 700 6 700 7 500 8 000 9 000

5 500 6 700 7 500 8 000 9 000

4 500 5 500 6 000 6 700 7 500

5.3.5.2 Clearances to Ground of Insulated Service Lines

Aerial service lines and “other cable system” shall have the line located so that the distances to ground in any direction from any position to which any part of such lines either sag at maximum design temperature or move as a result of wind pressure which could normally prevail, are not less than the distances specified in Table 2.

TABLE 2 Service line and “other cable systems” location Distance from ground any direction

(mm) Over the centre of each carriageway of a public road 5 500

Over any part of a Freeway, Primary Arterial Rd or Highway 5 500 Over any part of a carriageway of a public road (other than

the centre) 4 900

Over a vehicular crossing of a footway in a public road (other than a residential driveway)

4 500

Over land which is not associated with a residential dwelling which is likely to be used by vehicles

4 500

Over a vehicular crossing of a footway in a public road for a residential driveway and any other part of a footway

3 000

Over land which is, or likely to be, used by vehicles and is associated with a residential dwelling

3 000

Land not likely to be used by vehicles 2 700

NSW Department of Water and Energy, February 2009 Page 14 of 45

Code of Practice - Electricity transmission and distribution asset management

5.3.5.3 Clearances from Structures

The minimum clearance from any structure or line support (other than the structure supporting the line) to any position an overhead conductor may swing or sag shall be such as to prevent injury to persons or damage to property. The minimum clearances shall be obtained by reference to ENA C(b)1 as amended. For service lines reference shall be made to the ”Code of Practice for Service and Installation Rules”.

5.3.5.4 Clearances to Conductors of Other Circuits

The arrangement of and clearances between circuits, either attached to a common structure, unattached, in shared spans or crossing, must be designed for the environmental and electrical service conditions likely to be experienced in service. Clearances to railway traction overhead wiring shall be in accordance with the requirements of the railway owner. 5.3.5.5 Alterations to Ground Levels

Where any land above which overhead lines have been erected undergoes a change of use that varies the ground clearances, the portions of those overhead lines which are situated over the land shall be reconstructed to satisfy clauses 5.3.5, 5.3.5.1, 5.3.5.2, 5.3.5.3 and 5.3.5.4 above.

5.3.6 Overhead Service Lines

Overhead service lines shall comply with the ”Code of Practice for Service and Installation Rules”.

NSW Department of Water and Energy, February 2009 Page 15 of 45

Code of Practice - Electricity transmission and distribution asset management

5.4 Underground Cables

5.4.1 General

Underground cables shall be designed and constructed to ensure that:

• they have insulation appropriate for the nominal voltage, • they will carry load currents for which they are designed, • they (and their cable screens or sheaths when applicable) will pass short

circuit currents which will enable the correct operation of protective devices,

• safe separation clearances from other services are maintained, and • safe operational performance will occur. 5.4.2 Installation

Cables shall be installed in a manner that takes into account the local environmental and service conditions, taking into account the location of other utilities services. Suitable precautions shall be taken during installation and jointing that safeguard against:

• the possibility of transferred earth potentials when installing cables, • the possibility of induced voltages when installing long lengths of cable

close to in-service cables, • the possibility of mechanical damage to existing cables or joints when

excavating or installing cable, and • damage to the environment.

5.4.3 Parts of an Underground Cable Installed Above Ground

Where an underground cable is located above the surface of the ground it shall be mechanically protected to a height of 2400mm from any surface on which a person can stand to the point where it enters the ground.

5.4.4 Underground Service Lines

Underground service lines shall comply with the ”Code of Practice - Service and Installation Rules”.

NSW Department of Water and Energy, February 2009 Page 16 of 45

Code of Practice - Electricity transmission and distribution asset management

5.5 Substations 5.5.1 General Substations shall be designed and constructed to ensure: • Compliance with the relevant building codes, where applicable. • Safe access and egress. • The buildings and enclosures are to be structurally secure, taking into

account the local environmental and service conditions. • The buildings and enclosures are to be secured in a manner that

ensures all reasonable care is taken to prevent entry by unauthorised persons.

• The electricity works shall have insulation appropriate for the nominal voltage.

• The electricity works shall carry electrical load currents for which they are designed.

• The electricity works shall carry short circuit currents which will enable the correct operation of protective devices.

• Safe clearances to electricity works are maintained. • Safe operational performance. 5.5.2 Substation Electricity Works

Substation plant and equipment including busbars, cables, circuit breakers and ancillary equipment, transformers, capacitors and surge diverters shall meet standards which will ensure safe operational performance.

5.5.3 Clearances to Exposed Live Electricity Works

Substations shall be designed to provide safe operating and working clearances from exposed live equipment and lines.

5.5.4 Structural Design of Buildings and Roofed Enclosures

The requirements of the Building Code of Australia apply. In addition consideration should be given to:

• the provision for plant and equipment that may be installed, • the provision for ventilation requirements for plant and equipment that

may be installed, • the control of ground waters in sub-surface buildings, • the containment of insulating liquids, • the provision of fire protection, • the control of the products of explosion that may occur, and • the provision for impulse loading and forces due to short circuit

conditions.

NSW Department of Water and Energy, February 2009 Page 17 of 45

Code of Practice - Electricity transmission and distribution asset management

5.5.5 Kiosk Type Substations

Kiosk type substations shall be installed in accordance with the Building Code of Australia.

The enclosure of a kiosk type substation shall be robust and sturdy.

5.5.6 Ground Type Substations

The structures supporting aerial lines in ground type substations shall allow for mechanical loading and for forces under short circuit conditions.

5.5.6.1 Walls and Fences

Walls and fences enclosing the substation shall:

• be so arranged to prevent unauthorised entry, • display appropriate warning signs, • be suitably earthed where appropriate, • comply with the Building Code of Australia, and • provide safe horizontal and vertical clearances to any live and

exposed equipment [AS 2067 - 1984 is a guide in this regard].

5.5.7 Pole Mounted Substations

Pole mounted substations shall comply with the following:

• Structures supporting aerial lines on pole type substations shall allow for mechanical loading and forces under short circuit conditions.

• All parts of supporting platforms and equipment which are mounted on or attached to the pole or crossarms, except for conductors, are at a height not less than in Table 3 below:

TABLE 3

Location Height above ground (mm)

More than 500 mm from the vertical projection of the kerb line in the direction away from the vehicular carriageway

3 600

Elsewhere 4 600

• Any electricity works mounted below 3600mm shall not protrude more than 200 mm from the pole and maintain a minimum of 500 mm from the vertical projection of the kerb line, and not facilitate unauthorised climbing of the pole.

NSW Department of Water and Energy, February 2009 Page 18 of 45

Code of Practice - Electricity transmission and distribution asset management

5.6 Earthing and Electrical Protection

Earthing and electrical protection systems shall be designed and installed to safely manage abnormal network conditions likely to be experienced, without significant risk of injury to people or damage to property. 5.6.1 General Earthing and protection systems shall be designed and installed to ensure: • the reliable passage of fault current, • the reliable passage of Single Wire Earth Return (SWER) load currents

to ground and/or source, • the reliable operation of circuit protection devices, • that step, touch and transfer potentials are limited to safe levels, • appropriate co-ordination with other utilities’ systems, • suitability for the environmental and earthing conditions, • protection against likely mechanical damage, inadvertent interference

and chemical deterioration, and • mechanical stability and integrity of connections. 5.6.2 Step and Touch Potentials All exposed conductive material (excluding the current carrying conductors) which is accessible to persons and which could be energised in the event of a primary insulation failure of the circuit, shall be effectively earthed to avoid injury from electric shock.

NSW Department of Water and Energy, February 2009 Page 19 of 45

Code of Practice - Electricity transmission and distribution asset management

6 MAINTENANCE

6.1 General

All electricity works shall be maintained to ensure safety to persons and reliability of supply, taking into account the associated risks. The relevant documents referred to in the appendices to this Code should be considered for the maintenance of electricity works. Where there are variations between the documents referred to in Appendices A, B, C, D and E, and this Code, the Code is to take precedence.

A system of maintenance shall consist of the following elements: • a list of network assets and their respective locations, • a schedule of maintenance activities based on an assessment of risk, and • a record of maintenance work carried out.

6.2 Maintenance of Overhead Lines

Overhead lines, their structures and their components shall be maintained to be in a safe operating condition. The integrity of insulation of overhead lines shall be maintained. A system of maintenance for overhead lines, their structures and components shall consider: • inspection and/or testing programmes, • maintenance programmes, • replacement programmes for components approaching the end of their

serviceable life, and • tree management programmes designed to:

◊ ensure public safety, ◊ minimise the risk of fires caused by contact between trees and

overhead lines, ◊ reduce the number of interruptions to supply caused by trees, and ◊ protect the electricity distributor’s assets from damage.

6.3 Maintenance of Underground Cables

Underground cable systems shall be maintained in a safe operating condition. A system of maintenance for underground cable systems shall consider: • inspection and/or testing programmes, • maintenance programmes, and • replacement programmes for components approaching the end of their

serviceable life.

NSW Department of Water and Energy, February 2009 Page 20 of 45

Code of Practice - Electricity transmission and distribution asset management

6.4 Maintenance of Substations

Substation buildings, walls, fences, enclosures, associated plant, equipment and lines shall be maintained in a safe operating condition. A system of maintenance for substations shall consider: • inspection and/or testing programmes, • maintenance programmes, and • replacement programmes for components approaching the end of their

serviceable life.

6.5 Maintenance of Protection and Earthing Systems

Protection and earthing systems shall be inspected and maintained in a safe and reliable operating condition. A system of maintenance for protection and earthing systems shall consider: • inspection and/or testing programmes, • maintenance programmes, and • replacement programmes for components approaching the end of their

serviceable life. Earthing systems shall be inspected and tested at intervals commensurate with risk of corrosion or mechanical damage to ensure that design requirements are met. The results of visual inspections and resistance to ground tests must be recorded and reviewed to identify any changes in results that should influence the frequency of inspection, tests and maintenance. The results of visual inspections and performance tests of protection systems shall be recorded and reviewed to identify changes that would influence the frequency of inspections, tests, maintenance and replacements.

6.6 Environmental Considerations

The maintenance of electricity works shall take into consideration environmental issues and concerns. Factors to consider, include, but are not limited to: • the minimisation of environmental damage, including visual impacts, • tree management programmes, • a reduction in and the correct disposal of waste products, and • the consideration of Electromagnetic Field (EMF) issues.

NSW Department of Water and Energy, February 2009 Page 21 of 45

Code of Practice - Electricity transmission and distribution asset management

7 SAFE ELECTRICAL WORK PRACTICES

7.1 General

This Section applies to work on or near exposed electricity works, for which the “Scope” of this Code applies. The relevant documents referred to in the appendices to this Code should be considered for the operation of electricity works and work practices. Where there are variations between the documents referred to in Appendices A, B, C, D and E, and this Code, the Code is to take precedence.

7.2 Qualifications and Training

7.2.1 General Requirements

No work to which this Code applies shall be carried out unless the employee:

• has received training which is appropriate for the type of work concerned,

and has been authorised by their employer after the training has been satisfactorily completed,

• is capable to safely perform the work required to be undertaken, • has demonstrated competency of the relevant work procedures and safety

instructions, and • has during the previous 12 months, received appropriate instruction in the

following procedures that are relevant to the nature of the work, ◊ resuscitation, ◊ releasing a person from live electricity works, ◊ rescuing a person from a pole, structure or elevating work platform,

and ◊ rescuing a person from confined space.

NSW Department of Water and Energy, February 2009 Page 22 of 45

Code of Practice - Electricity transmission and distribution asset management

7.2.2 Employer Responsibility

The employer shall ensure that appropriate training courses have been undertaken by the respective employees so they can carry out the required tasks safely and competently. The following should be considered: • accreditation of the courses, • the relevance to the tasks to be performed, • national competency standards or industry equivalent, • the course syllabus, • the facilities for training, • assessment criteria for the issue of certificates, • a linkage between in-school and on-the-job training, and • whether the training provider has a Quality Assurance system in place and

is listed in the National Register of quality training providers for utilities.

7.2.3 Employees in Training

Employees undergoing training may undertake the work, subject to: • it being safe to perform, and • they are under continuous and close supervision of a qualified and

experienced employee.

7.3 General Safety Provisions

7.3.1 Basic Safety Principles All HV electricity works shall be regarded as live until isolated, proved to be de-energised, earthed and short-circuited, and an Access Permit issued according to the Network Operator’s approved procedure. Alternatively approved live line working techniques shall be used. All LV electricity works shall be regarded as live until isolated and proved to be de-energised, in accordance with the Network Operator’s approved procedure, otherwise approved safe live working procedures shall be used.

7.3.2 Hazard Identification and Risk Assessment

All hazards shall be identified and the associated risks assessed, in writing, prior to working on or near any electricity works. The hazard identification and risk assessment system shall be regularly audited to ensure compliance.

7.3.3 Hazard Control Appropriate control measures shall be adopted for identified hazards, taking into consideration the associated risks.

NSW Department of Water and Energy, February 2009 Page 23 of 45

Code of Practice - Electricity transmission and distribution asset management

7.3.4 Minimum Safe Working Distances No part of a person’s body and no material or equipment not insulated for the voltage concerned must come closer than the following minimum safe working distances for live exposed electricity works specified in Table 4, unless specific procedures approved by the Network Operator, including fixing barriers or live working techniques, are utilised:

TABLE 4

Nominal Voltage (U) (Volts) Minimum Safe Working Distance (mm)

U < 1 000 500 1 000 < U < 11 000 700

11 000 < U < 66 000 1 000 66 000 < U < 132 000 1 500

132 000 < U < 220 000 2 500 220 000 < U < 330 000 3 000

U > 330 000 4 000

7.3.5 Correct Labelling and Recording of Electricity Works

All electricity works shall be clearly identified by labels, which shall be updated if any network alteration has taken place.

Temporary labelling and danger tags are required as a warning against inadvertent and unauthorised operation of electricity works. Records, diagrams, maps and the like shall be kept as to the location, type and installation details.

7.3.6 Hazardous Electrical Occurrences or Effects

The hazardous electrical occurrences or effects which can develop on or around electricity works are summarised under the following categories: • lightning, • induction, • transfer voltage, • voltage gradient, • line energising, and • neutral and earthing system currents. Precautions shall be taken to avoid danger from electrical occurrences or effects.

NSW Department of Water and Energy, February 2009 Page 24 of 45

Code of Practice - Electricity transmission and distribution asset management

7.3.7 Precautions for Energisation and Re-energisation of Electricity Works

Electricity works shall not be energised or re-energised unless:

• the employees are trained and authorised to carry out the energisation or

re-energisation of the electricity works, • all work on the electricity works is complete, • all equipment (including testing equipment), plant, tools and materials are

removed, • all earths, short-circuits and equipotential bonds, if used, are removed, • appropriate checks and tests are carried out to ensure safety, • precautions are taken to ensure all persons are clear of the electricity

works, and • all relevant Access Permits are cancelled.

Re-energisation of electricity works following an unplanned outage (protection operation) shall be carried out by trained and authorised employees in accordance with the Network Operator’s approved procedures.

Consideration shall be given to: • the geographic location of the apparatus, • the need for patrol and inspection, • the time delay between the outage and the proposed ‘try-back’, and • assessment of the associated risks, including any fire ban declarations.

No electricity works shall be manually re-energised following an unplanned outage during ‘total fire ban periods’ where the electricity works or part of the works to be re-energised is located within the ‘total fire ban’ area until patrol and inspection has confirmed the condition of the electricity works.

7.3.8 First-aid

Appropriate first-aid facilities shall be readily available for use in the event of injury to any employee.

7.3.9 Protective Clothing

Clothing shall be worn which gives appropriate protection to the head, body, arms, hands, legs and feet when working on or near electricity works.

NSW Department of Water and Energy, February 2009 Page 25 of 45

Code of Practice - Electricity transmission and distribution asset management

7.3.10 Work in Confined Spaces Work in a confined space shall be carried out in accordance with the Network Operator’s approved procedures, and shall consider the following:

• an assessment of the hazards involved, • authorisation for an employee to enter the confined space, • an atmospheric check of the confined space before entry, and • continual monitoring of the atmosphere while the confined space is

occupied, and • a suitable rescue procedure.

7.4 Operating Work

All operating work shall be in accordance with the Network Operator’s approved procedures which shall ensure:

• the safety of employees, • the safety of the public, and • the correct operation of the electricity works.

7.5 Access Permits

A Network Operator shall ensure that there is an approved procedure for the issuing of access permits. An access permit shall:

• be issued and/or cancelled by an authorised person, • only give access for work on electricity works which are safe to work on, • only authorise work to begin when all employees are aware of:

◊ the electricity works to be worked on, ◊ the conditions under which the permit is issued (including any

special precautions), and ◊ the existence of any remaining electrical hazards; and

• be cancelled after the work to which it relates has been completed.

NSW Department of Water and Energy, February 2009 Page 26 of 45

Code of Practice - Electricity transmission and distribution asset management

7.6 Work on Low Voltage Electricity Works

Work on LV electricity works, whether under live or de-energised conditions, shall be in accordance with the Network Operator’s approved procedure.

7.6.1 De-energised LV Electricity Works

Work on de-energised LV electricity works shall be carried out in accordance with the Network Operator’s approved procedure, with due regard to the following: • isolating the electricity works, • taking precautions to ensure the electricity works remains de-energised, • proving the electricity works is de-energised, • clearly identifying the electricity works, • defining the safe work area where appropriate, and • taking additional precautions such as earthing and short-circuiting of

electricity works and/or live working procedures where hazardous induced voltages are likely to occur.

7.6.2 Live LV Electricity Works

Work on live LV electricity works shall be carried out in accordance with the Network Operator’s approved procedure, with due regard to the following: • that the electricity works has been identified as LV, • that suitable precautions have been taken to avoid inadvertent contact

with other live conductors or earth, and • that the employee is trained in the safe execution of the work.

7.7 Work on High Voltage Electricity Works

7.7.1 De-energised HV Electricity Works

Work on de-energised HV electricity works shall be carried out in accordance with the Network Operator’s approved procedure, with due regard to the following: • isolating the electricity works, • taking precautions to ensure the electricity works remain de-energised, • proving the electricity works are de-energised, • earthing and short-circuiting the electricity works, except for periods where

testing is in progress, • defining the safe work area where appropriate and the issue of an Access

Permit.

NSW Department of Water and Energy, February 2009 Page 27 of 45

Code of Practice - Electricity transmission and distribution asset management

7.7.2 Live HV Electricity Works

Work on live HV electricity works shall be carried out in accordance with the Network Operator’s approved procedure, with due regard to the following:

• that the employees are trained in the safe execution of the work, • that all members of the working team are currently qualified, • that the Network Operator’s approved procedures are adhered to, and • that the required minimum safe approach and working distances are

maintained. The minimum approach distances for work on live HV electricity works are detailed in Table 5 below. These shall be observed, except where a procedure approved by the Network Operator is adopted for work directly on exposed conductors.

TABLE 5

Nominal Voltage (U) (Volts) Minimum Approach Distance (mm)U < 33 000 500

33 000 < U < 66 000 700 66 000 < U < 132 000 1 200

132 000 < U < 220 000 1 700 220 000 < U < 330 000 2 200 330 000 < U < 500 000 2 600

7.8 Work on Overhead Lines

In addition to the other requirements of this Code it is necessary to:

• identify the overhead line at the point where the work is carried out, • check the soundness of poles or structures, and the employee shall not

ascend a pole or structure which is found to have suffered deterioration or damage to a degree which may cause it to collapse,

• prevent the line in the course of erection from becoming energised, and • safeguard employees against hazardous electrical occurrences or effects.

NSW Department of Water and Energy, February 2009 Page 28 of 45

Code of Practice - Electricity transmission and distribution asset management

7.9 Work on Underground Cables

Work on or near underground cables shall be in accordance with the Network Operator’s approved procedures.

7.9.1 Cable identification Work shall not commence on any cable unless it has been:

• identified by a method approved by the Network Operator, • in the case of a low voltage cable, identified as low voltage, and • in the case of a high voltage cable, proved to be de-energised by a

method approved by the Network Operator.

7.9.2 Precautions for Work on or Near Cables

The following precautions shall be taken before working on or near cables: • Identify and safeguard against the electrical hazards that are present on

the site. These can include, but are not limited to, live electricity works, induced voltages and transfer potentials and the potential for faults on adjacent cables and joints.

• Identify and safeguard against the physical hazards that are present on the site. These can include, but are not limited to, lack of ventilation or suitable lighting, dangerous gases, confined working environment, high temperatures, traffic hazards and other services.

• An employee shall not physically handle a high voltage cable while it is live unless it is completely surrounded by an earthed sheath or screen, or both, and precautions are taken, where necessary, to avoid danger from induced voltages and transferred earth potentials.

• An employee shall not physically handle a cable, whether sheathed or screened or not, if its condition is suspect or doubtful unless the cable is proved to be de-energised.

• When excavating in the vicinity of live cables an approved safe working procedure shall be used.

NSW Department of Water and Energy, February 2009 Page 29 of 45

Code of Practice - Electricity transmission and distribution asset management

7.10 Access into Substations

An employee shall not enter an area in an electrical station where there are live exposed high voltage conductors unless the employee:

• is authorised to enter that area, or • is accompanied by a person who is authorised to enter that area, or • has been specifically instructed by an authorised person as to the area

that can be entered, the dangers that exist and the precautions that must be observed.

7.11 Work in Substations

Work in substations shall be in accordance with the Network Operator’s approved procedures.

7.12 Tools and Safety Equipment

The employer shall ensure that appropriate tools and safety equipment are used:

• All tools and safety equipment shall be periodically inspected and tested

to ensure their safety for use. • The employee shall use the appropriate tools and safety equipment

provided by the employer. • The employee shall inspect tools and safety equipment to check their

serviceability before use. • Any defective tools or safety equipment shall be withdrawn from service. • The employee shall not use any suspected defective tool or equipment.

NSW Department of Water and Energy, February 2009 Page 30 of 45

Code of Practice - Electricity transmission and distribution asset management

Appendix: Acts, Regulations, Australian Standards, Codes and Guides relating to the Design, Construction, Maintenance and Safe Electrical Operation and Work Practices for Transmission & Distribution Systems

SECTION A: STANDARDS, CODES AND GUIDES RELATING TO OVERHEAD LINES AND SERVICES The standards and publications listed below (and any associated amendments) are relevant to this Code but do not necessarily represent all the standards that may need to be consulted in meeting the requirements of this Code. The publication dates for the reference documents listed below are correct at the time of publication of this Code, however they should be checked before use to ensure that they are still the most current and appropriate issue, and that all associated amendments are considered. Conductors Conductors - Bare overhead - Hard-drawn copper AS 1746 - 1991 Conductors - Bare overhead - aluminium and aluminium alloy

AS 1531 - 1991

Conductors - Bare overhead - aluminium and aluminium alloy - steel reinforced

AS 3607 - 1989

Steel conductors and stays - Bare overhead : Galvanised AS 1222.1 - 1992

Steel conductors and stays - Bare overhead: Aluminium clad AS 1222.2 - 1992 Galvanised steel wire strand AS 2841 - 1986 Insulated Cables Approval and test specification - Electric Cables - elastomer insulated - For working voltages up to and including 0.6/1kV

AS 3116 - 1996

Approval and test specification - Electric Cables -Thermoplastic insulated - For working voltages up to and including 0.6/1kV

AS 3147 - 1992

Approval and test specification - Electric Cables neutral screened - For working voltages up to and including 0.6/1kV

AS 3155 - 1995

Electric cables - XLPE insulated - Aerial bundled - For working voltages up to and including 0.6/1kV

AS 3560 - 1991

Mechanical fittings for low voltage aerial bundled cables AS 3766 - 1990 Electric cables - Aerial bundled - Polymeric insulated voltage 6.35/11(12) kV and 12.7/22 (24) kV - Metallic screened

AS 3599.1 - 1988

Electric cables - Aerial bundled - Polymeric insulated - voltage 6.35/11 (12) kV and 12.7/22 (24) kV - Non-metallic screened

AS 3599.2 - 1991

Conductors - Covered overhead - For working voltages 6.35/11 kV up to and including 19/33kV

AS 3675 - 1993

NSW Department of Water and Energy, February 2009 Page 31 of 45

Code of Practice - Electricity transmission and distribution asset management

Insulators Guidelines for the design and maintenance of overhead distribution and transmission lines

ESAA C(b)1 - 1991

Selection Insulators - Ceramic or Glass - Station Post for Indoor and Outdoor use - Voltages Greater than 1000 V AC - Characteristics

AS 4398.1 - 1996

Insulators - Ceramic or Glass - Station Post for Indoor and Outdoor use - Voltages Greater than 1000 V AC - Tests

AS 4398.2 - 1996

Insulators - Porcelain and glass for overhead power lines, voltages greater than 1000V a.c.: Test methods

AS 2947.1 - 1989

Insulators - Porcelain and glass for overhead power lines, voltages greater than 1000V a.c.: Characteristics

AS 2947.2 - 1989

Insulators - Porcelain and glass for overhead power lines, voltages greater than 1000V a.c.: Couplings

AS 2947.3 - 1995

Insulators - Porcelain and glass, pin and shackle type - Voltages not exceeding 1000V a.c.

AS 3608 - 1989

Insulators - Porcelain stay type - Voltages greater than 1000V a.c.

AS 3609 - 1989

Insulators - Ceramic or glass - Station post for indoor and outdoor use - Voltages greater than 1000V a.c. : Characteristics

AS 4398.1 - 1996

Insulators - Ceramic or glass - Station post for indoor and outdoor use - Voltages greater than 1000V a.c. : Tests

AS 4398.2 - 1996

Insulator and Conductor Fittings Insulator and conductor fittings for overhead power lines : Performance and general requirements

AS 1154.1 - 1985

Insulator and conductor fittings for overhead power lines : Dimensions

AS 1154.2 - 1985

Insulator and conductor fittings for overhead power lines : Performance and general requirements for helical fittings

AS 1154.3 - 1985

Connectors - Insulation piercing - For 0.6/1 kV aerial bundled cables

AS 4396(INT) - 1996

NSW Department of Water and Energy, February 2009 Page 32 of 45

Code of Practice - Electricity transmission and distribution asset management

Thermal Limits Guidelines for the design and maintenance of overhead distribution and transmission lines

ESAA C(b)1 - 1991

Thermal limits Current rating of bare overhead line conductors ESAA D(b)5 - 1988 Short Circuit Capacity Guidelines for the design and maintenance of overhead distribution and transmission lines Fault ratings

ESAA C(b)1 - 1991

Mechanical Loading Conditions Guidelines for the design and maintenance of overhead distribution and transmission lines

Mechanical Loading Conditions ESAA C(b)1 - 1991 Minimum design loads on structures (known as the SAA Loading Code) Dead and live loads and load combinations

AS 1170.1 1989

Wind loads AS 1170.2 - 1989 Snow loads AS 1170.3 - 1990 Minimum design loads on structures - Commentary (Supplement to AS 1170.3 - 1990)

AS 1170.3 Supp 1 -1990

Earthquake loads AS 1170.4 - 1993 Earthquake loads - Commentary (Supplement to AS 1170.4 - 1993)

AS 1170.4 Supp 1 - 1993

Conductor Tensions Guidelines for the design and maintenance of overhead distribution and transmission lines

General ESAA C(b)1 - 1991 Calculations ESAA C(b)1 - 1991 Structures and Footings Guidelines for the design and maintenance of overhead distribution and transmission lines

ESAA C(b)1 - 1991

General Methods of testing soils for engineering purposes AS 1289 Series Piling - Design and installation AS 2159 - 1995 Piling - Design and installation - Guidelines (Supplement to AS 2159 - 1995)

AS 2159 Supp 1 - 1996

SAA Timber Structures Code : Design methods

AS 1720.1 - 1988

Timber properties AS 1720.2 - 1990 Timber - Poles for overhead lines AS 2209 - 1994 Timber - Classification into strength groups AS 2878 - 1986 Design of steel lattice towers and masts AS 3995 - 1994 Steel structures AS 4100 - 1990 Concrete structures (and supplement) AS 3600 - 1994 (and

Supp1 - 1994) Concrete Poles for Overhead Line and Street Lighting AS 4065 -1992 Lighting Poles and Bracket Arms - Preferred Dimensions AS 1798 - 1992 Clearances From Ground Guidelines for the design and maintenance of overhead distribution and transmission lines

ESAA C(b)1 - 1991

NSW Department of Water and Energy, February 2009 Page 33 of 45

Code of Practice - Electricity transmission and distribution asset management

Clearances From Structures Guidelines for the design and maintenance of overhead distribution and transmission lines

ESAA C(b)1 - 1991 and “Code of Practice for Service and Installation Rules”

Spacing of Conductors Guidelines for the design and maintenance of overhead distribution and transmission lines Clearances

ESAA C(b)1-1991

Marking of Conductors Air Navigation - Cables and their supporting structures - Mapping and marking : Permanent marking of overhead cables and their supporting structures

AS 3891.1 - 1991

Air Navigation - Cables and their supporting structures - Mapping and marking : Marking of overhead cables for low level flying

AS 3891.2 - 1992

Services The New South Wales Service and Installation Rules 1996 Joint Use of Power Poles ESAA Model Agreement between an Electricity Supply Utility and a Communication Cable Owner

ESAA Publication

Joint use of Poles : The placement on poles of power lines and paired cable telecommunications lines

HB87 - 1997 (CJC 1)

Maintenance Guidelines for the design and maintenance of overhead distribution and transmission lines

ESAA C(b)1 - 1991

Guide to tree planting and maintaining safety clearances near power lines

ISSC3

Guide to the prevention of unauthorised access EC7 Guide to the inspection, assessment and preservation of wood poles

EC8

Guide to the aerial inspection and patrol of overhead lines EC10 Guidelines for the management of electricity easements EC20 Procedures for ESI risk management EC21 Guidelines for the development of electricity systems: community and environmental considerations

EC22

Voltage Levels Standard Voltages - Alternating (50Hz) and direct AS 2926 - 1987 Risk Management Risk Management AS 4360 - 1995

NSW Department of Water and Energy, February 2009 Page 34 of 45

Code of Practice - Electricity transmission and distribution asset management

SECTION B: STANDARDS, CODES AND GUIDES RELATING TO CABLES AND SERVICES The standards and publications listed below (and any associated amendments) are relevant to this Code but do not necessarily represent all the standards that may need to be consulted in meeting the requirements of this Code. The publication dates for the reference documents listed below are correct at the time of publication of this Code, however they should be checked before use to ensure that they are still the most current and appropriate issue, and that all associated amendments are considered. High Voltage Cables Electric cables - Polymeric insulated For working voltages 1.9/3.3 (3.6) kV up to and including 19/33 (36) kV

AS 1429.1 - 1993

Electric cables - Impregnated paper insulated - working voltages up to and including 33 kV

AS 1026 - 1992

Electric Cables - for underground residential distribution systems AS 4026 - 1992 Extruded solid dielectric - 1 kV to 30 kV IEC 502 - 1994 Tests for solid electric cables 30 kV to 150 kV IEC 840 - 1988 Low Voltage Cables Conductors in insulated electric cables and flexible cords AS 1125 - 1993 Concentric wire neutral cable - XLPE insulated - for electricity supply for working voltages of 0.6/1 kV

AS 1178 - 1986

Approval and test specification - Electric cables - Elastomer insulated - for working voltages up to and including 0.6/1 kV

AS 3116 - 1996

Approval and test specification - Electric cables - Thermoplastic insulated - for working voltages up to and including 0.6/1kV

AS 3147 - 1992

Approval and test specification - Electric cables - Neutral screened - For working voltages up to and including 0.6/1kV

AS 3155 - 1995

Electric Cables - for underground residential distribution systems AS 4026 - 1992 High Voltage Cable Accessories High voltage Cable Joints ANSI/IEEE 48 - 1990 High Voltage Cable Terminations ANSI/IEEE 404 - 1994 Separable insul. connectors for power distribution systems >1 kV AS 2629 - 1983 Continuous Cable Ratings Calculations methods IEC 287 - 1982 Electrical installations - Selection of cables Cables for alternating voltages up to and including 0.6/1 kV

AS 3008.1 - 1989

Short Circuit Currents Calculation of Short Circuit Currents IEC 949 - 1988 Installation ESAA Guide to the Installation of Underground Cables C(b)2 - 1989 ESAA Guide to the Use of Separable Connectors D(b)30 - 1983 Maintenance ESAA Guide for the Maintenance of High Voltage Paper Oil Insulated cables and Accessories

D(b)31 - 1989

Voltage Levels Standard Voltages - Alternating (50 Hz) and direct AS 2926 - 1987 Risk Management Risk Management AS 4360 - 1995

NSW Department of Water and Energy, February 2009 Page 35 of 45

Code of Practice - Electricity transmission and distribution asset management

SECTION C: STANDARDS, CODES AND GUIDES RELATING TO SUBSTATIONS The standards and publications listed below (and any associated amendments) are relevant to this Code but do not necessarily represent all the standards that may need to be consulted in meeting the requirements of this Code. The publication dates for the reference documents listed below are correct at the time of publication of this Code, however they should be checked before use to ensure that they are still the most current and appropriate issue, and that all associated amendments are considered. Electrical Design Switchgear assemblies and ancillary equipment for alternating voltages above 1kV

AS 2067 - 1984

Circuit Breakers and Ancillary Equipment Degrees of protection provided by enclosures for electrical equipment (IP code) (and two supplements)

AS 1939 - 1990 (and Supp1 - 1990, Supp2 - 1990)

High voltage a.c. switchgear and control gear - Circuit breakers for rated voltages above 1000 V

AS 2006 - 1986

Switchgear Assemblies and Ancillary Equipment High voltage a.c. switchgear and control gear - Switches and switch-disconnectors For rated voltages above 1 kV and less than 52 kV

AS 1025.1 - 1984

For rated voltages 52 kV and above AS 1025.2 - 1989 High voltage a.c. switchgear and control gear - Disconnectors (isolators) and earthing switches

AS 1306 - 1985

High voltage a.c. switchgear and control gear - switch-fuse combinations

AS 2024 - 1991

High voltage a.c. switchgear and control gear - Common requirements

AS 2650 - 1986

A. C. metal enclosed switchgear and control gear for rated voltages above 1kV and up to and including 72.5 kV

AS 2086 - 1995

A. C. insulation-enclosed switchgear and control gear for rated voltages above 1kV and up to and including 38 kV

AS 2264 - 1995

Switchgear assemblies and ancillary equipment for alternating voltages above 1 kV

AS 2067 - 1984

Degrees of protection provided by enclosures for electrical equipment (IP code) (and two supplements)

AS 1939 - 1990 (and Supp1 - 1990, Supp2 - 1990)

Insulating oil for transformers and switchgear (IEC 296) AS 1767 - 1975

NSW Department of Water and Energy, February 2009 Page 36 of 45

Code of Practice - Electricity transmission and distribution asset management

Control Equipment Low voltage switch gear and control gear : General rules

AS 3947.1 - 1993

Switches, disconnectors, switch disconnectors and fuse combination units

AS 3947.3 - 1994

Switches, disconnectors, switch disconnectors and fuse combination units - Supplement 1: Fuse-switch disconnectors for use with aerial bundled cables

AS 3947.3 Supp 1 - 1995

Contactors and motor starters - Electromechanical contactors and motor starters

AS 3947.4.1 - 1995

Control circuit devices and switching elements -Electromechanical control circuit devices

AS 3947.5.1 - 1995

Control circuit devices and switching elements - Proximity switches

AS 3947.5.2 - 1995

Insulating Panels Sheets and Boards for electrical purposes

Classification and general requirements AS 1795.1 - 1983 Dimension of switchboard panels AS 1795.2 - 1983 Power Transformer Power Transformers : General requirements (IEC 76-1)

AS 2374.1 - 1982

Temperature rise (IEC 76-2) AS 2374.2 - 1982 Insulation Levels and dielectric tests - General requirements (IEC 76-3)

AS 2374.3.0 - 1982

Insulation Levels and dielectric tests - External clearances in air (IEC 76-3-1: 1987)

AS 2374.3.1 - 1982

Tappings and connections (IEC 76-4) AS 2374.4 - 1982 Ability to withstand short circuit (IEC 76-5) AS 2374.5 - 1982 Determination of transformer and reactor sound levels (IEC 551:1987)

AS 2374.6 - 1994

Guide to the selection and use of Power Transformers AS 2421 - 1981 Dry-type power transformers AS 2735 - 1984 Loading guide for dry-type power transformers AS 3953 - 1996 Transformers for use on single wire earth return distribution systems

AS 2558 - 1982

Insulating oil for transformers and switchgear (IEC 296) AS 1767 - 1975

NSW Department of Water and Energy, February 2009 Page 37 of 45

Code of Practice - Electricity transmission and distribution asset management

Bushings Bushings for alternating voltages above 1000 V AS 1265 - 1990 Surge Arresters Surge Arresters (diverters): Silicon carbide type for a.c. systems

AS 1307.1 - 1986

Metal oxide surge arresters without gaps for a.c. systems AS 1307.2 - 1996 Batteries Stationary batteries - Lead-acid: Vented type (based on and including the full text of IEC 896.1)

AS 4029.1 - 1994

Valve regulated sealed type AS 4029.2 - 1992 Pure lead positive pasted plate type AS 4029.3 - 1993 Insulation Co-ordination Insulation Co-ordination: Definitions, principles and rules AS 1824.1 - 1995 Application Guide AS 1824.2 - 1985 Insulation co- ordination within LV systems: Principles, requirements and tests

IEC 664.1 - 1992

Safety Clearances Degrees of protection provided by enclosures for electrical equipment (IP code)(and two supplements)

AS 1939 - 1990 (and Supp1 - 1990, Supp2 - 1990)

Switchgear assemblies and ancillary equipment for alternating voltages above 1 kV

AS 2067 - 1984

Buildings and Enclosures Australian Building Code of Australia 1990 Fixed platforms, walkways, stairways and ladders - Design construction and installation

AS 1657 - 1992

The use of mechanical ventilation and air conditioning in buildings Fire and smoke control

AS 1668.1 - 1991