Co-Ti Substituted BaHex

-

Upload

basharat-ahmad -

Category

Documents

-

view

215 -

download

0

Transcript of Co-Ti Substituted BaHex

-

7/31/2019 Co-Ti Substituted BaHex

1/7

-

7/31/2019 Co-Ti Substituted BaHex

2/7

the hexaferrite family for high-frequency applica-

tion [9,10]; however, few investigations have been

made on M-type hexaferrite, especially those

sintered at temperatures below the melting pointof silver.

The M-type barium ferrite BaFe12O19 has strong

uniaxial magnetocrystalline anisotropy and is

usually used as permanent magnetic materials.

However, the strong uniaxial magnetocrystalline

anisotropy can be reduced by substitution of Fe3+

cations which distribute on five distinct crystal-

lographic sites. Different cations have been used to

substitute the Fe3+ to make the barium ferrite

suitable for magnetic recording and microwave

applications [1113]. The typical example is the

substitution of Fe3+ by Co2+ and Ti4+, which

undergoes a magnetic anisotropy change from

uniaxial to planar when the CoTi substitution

amount is 0.91.20 [14]. Complex permeability of

CoTi substituted barium ferrites have been

investigated by Autissier et al. using classical

ceramics method with sintering temperature

123012901C [15]. In this paper, the microstruc-

tures and high-frequency magnetic properties of

CoTi substituted barium ferrites prepared by

chemical coprecipitation and low-temperature

sintering with Bi2O3 doping are presented.

2. Experimental procedure

BaFe122xCoxTixO19 particles with different

target compositions were prepared by a modified

flux method which combines the chemical copre-

cipitation process and the synthesis from salt melts

[11,16]. An aqueous solution of the metal chlorides

containing Ba2+, Fe3+, Co2+ and Ti4+ in the

ratio required for the ferrite was stirred into anexcess of an aqueous solution of NaOH and

Na2CO3. All the reagents were of analytical grade.

A suspension containing intermediate precipitates

was formed during mixing. The product of

coprecipitation was filtered off, washed thor-

oughly, dried and mixed with NaCl. When heated

at 8109501C, ferrite particles crystallized from the

NaCl matrix. When the salts were dissolved in

water, BaFe122xCoxTixO19 particles were ob-

tained. The ferrite particles were then mixed with

an appropriate amount of Bi2O3. For electromag-

netic properties measurement, pellets (10 mm

diameter, 0.71.0 mm thickness) and toroidal

samples (20 mm outside diameter, 10 mm insidediameter, about 13 mm thickness) were pressed

and then sintered at 9001C and 9501C in air.

The identification of the crystalline phases for

ferrite particles was carried out by X-ray diffrac-

tion (XRD). To obtain detailed information on the

morphology, and to verify the size of the

BaFe122xCoxTixO19 particles, a set of micro-

graphs were taken by transition electron micro-

scope (TEM). Scanning electron microscope

(SEM) was used to observe the microstructures

of sintered ferrites. The high-frequency magnetic

properties were measured using an HP4291B RF

impedance/materials analyzer from 10 MHz to

1.8 GHz. The electrical resistivity of all ferrite

samples was determined with an HP4140B meter

using silver contacts.

3. Results and discussion

3.1. Structure and morphology

The XRD patterns of particle samples with CoTi substitution amount x 1:20 obtained by

chemical coprecipitation process and synthesis

from NaCl melts at different temperatures are

shown in Fig. 1. As can be seen, the only crystal-

line phase that can be detected by XRD is an M-

type hexaferrite for all particle samples, no other

phases were apparently detectable. With the

increase of heat-treatment temperature from

8101C to 9501C, the relative intensity increases

while peaks become sharper, indicating an increase

of particle size. The temperature of 8101

C, which isslightly higher than the melting point (8011C) of

NaCl, is much lower than (above 10001C) what is

needed for complete reaction in classical ceramics

method. Only the M-type hexaferrite phase

formed at 8101C was thought to be from the

contribution of liquid phase formation of NaCl

which could make the metal ions diffusing more

easily.

Fig. 2 shows the morphologies of BaFe9.6Co1.2-

Ti1.2O19 particles prepared at 8101C (a) and 9501C

C. Wang et al. / Journal of Magnetism and Magnetic Materials 257 (2003) 100106 101

-

7/31/2019 Co-Ti Substituted BaHex

3/7

(b) taken by TEM. It is clear that barium ferrite

particles are hexagonal platelet crystals, and high-

er temperature corresponds to larger average size

and more regular particle shape with a more

perfect crystalline phase. The particle sizes are

ranged in 40100 nm and 50200 nm for samples

prepared at 8101C and 9501C, respectively.

The microstructures and morphologies of sin-

tered barium ferrites were studied by SEM. Fig. 3shows the micrographs of samples sintered at

9001C for 5 h with CoTi substitution amount x

1:20: As can be seen, the microstructure of a

sample sintered with Bi2O3 addition (b) is very

different from that without Bi2O3 (a), although

both the sintered samples were based on the same

ferrite particles obtained at 9501C for 2h. When

sintered without Bi2O3 addition, sample (a) is

composed of small grains with little porosity,

indicating little change of particle size compared

with the original barium ferrite particles. Whereas

the sample (b) that sintered with 2 wt% Bi2O3doping is composed of much larger grains with a

grain size distribution of 16 mm. The more and

larger pores were formed due to the irregular

alignment of larger hexagonal platelets. Effects of

temperatures for barium ferrite particles fabrica-

tion on microstructures of sintered samples canalso be concluded from (b)(d) micrographs in

Fig. 3. It can be seen that higher particle fabrica-

tion temperature produced larger size grain and

more regular grain shape when sintered at 9001C

for 5 h with the same amount of Bi2O3 addition.

3.2. High-frequency magnetic properties

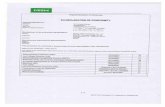

To investigate the effect of Bi2O3 content on the

high-frequency magnetic properties of CoTi

substituted barium ferrites, ceramic samples wereprepared by mixing the CoTi substituted barium

ferrite particles which were fabricated at 9501C for

2 h, with various amount of Bi2O3 and sintered at

9501C for 5 h. The CoTi substitution amount was

x 1:20 for all samples. Fig. 4 depicts the

frequency dependence of complex permeability of

sintered ferrites, where m0 is the real part and m00 is

the imaginary part. Results revealed the tendency

of an increase in initial permeability with the Bi2O3content. For instance, the sample without Bi2O3

20 30 40 50 60 70

0

20

40

60

80

100BaFe12 O1927-1029

2 (Degrees)

Intensity(%)

950 Cx2h

900 Cx2h

850 Cx2h

810 Cx2h

Intensity(Arb.

Units)

Fig. 1. XRD patterns of CoTi substituted barium ferrite

particles fabricated at different temperatures.

Fig. 2. TEM micrographs of the barium ferrite particles

fabricated at 8101C (a) and 9501C (b).

C. Wang et al. / Journal of Magnetism and Magnetic Materials 257 (2003) 100106102

-

7/31/2019 Co-Ti Substituted BaHex

4/7

has a permeability m0 of about 6; however, sample

with 2 wt% Bi2O3 content has a permeability m0 of

above 14 in a wide frequency range. Increasing the

Bi2O3 content from 2 to 5 wt%, there is a littleenhancement of both m0 and m00: Comparing with

the frequency of about 1 GHz for a sample without

Bi2O3, permeability m0 of samples with Bi2O3

doping starts to decrease from 400 to 500 MHz.

Permeability m00 has a maximum value at about

1 GHz for samples with Bi2O3 doping and above

1.8 GHz which is out of the measurement range for

a sample without Bi2O3 doping. This behavior

indicates a decreasing effect of Bi2O3 doping on

cut-off frequency while the permeability m0 can be

improved effectively in lower frequency rangebelow the magnetic resonant frequency.

Fig. 5 shows the effect of particles fabricating

temperature on high-frequency magnetic proper-

ties of CoTi substituted barium ferrites sintered

at 9001C for 5 h with CoTi substitution x 1:20

and Bi2O3 content of 2 wt%. Obviously, the

magnetic properties are promoted significantly by

using the barium particles fabricated at higher

temperature. The value of initial permeability m0

rises from 8 (for 8101C) to 12.5 (for 9501C). The

frequency where m0 has the maximum value shifts

lower when the temperature for particles fabrica-

tion increases. The permeability m00 has little

change in the frequency region below 100 MHz,but has a larger value corresponding to larger

magnetic loss in relative higher frequency region of

3001000 MHz with increasing the particles fabri-

cation temperature.

The CoTi substitution dependence of complex

permeability is given in Fig. 6. Samples were

sintered at 9001C for 5h with Bi2O3 content of

2 wt%, and barium particles used were prepared at

9501C for 2 h. As it shows, the magnetic resonant

frequency has been greatly affected by the CoTi

substitution. With the increase of CoTi substitu-tion amount, the permeability m0 decreases and the

magnetic resonant frequency increases. Barium

ferrites with initial permeability m0 > 10 and

magnetic resonant frequency >1 GHz could be

obtained when the CoTi substitution amount was

x 1:2021:30:

It is known that the permeability of a poly-

crystalline ferrite can be described as the super-

position of two different magnetizing mechanisms:

spin rotation and domain wall motion [17]. Globus

Fig. 3. SEM micrographs of barium ferrites sintered at 9001C for 5 h without Bi2O3 doping with particles fabrication temperature

9501C (a); with 2 wt% Bi2O3 and particles fabrication temperature 9501C (b); with 2 wt% Bi2O3 and particles fabrication temperature

8501C (c); with 2 wt% Bi2O3 and particles fabrication temperature 8101C (d).

C. Wang et al. / Journal of Magnetism and Magnetic Materials 257 (2003) 100106 103

-

7/31/2019 Co-Ti Substituted BaHex

5/7

suggested that the domain wall motion was

affected by the grain size and could be enhanced

with the increase of grain size [18]. Comparing the

magnetic properties with the microstructures

indicated in Fig. 3, it manifests that the increase

in initial permeability is closely correlated to thedensification and grain size of sintered ferrites. In

case of ferrites composed with small grains, the

relatively larger volume fraction of grain boundary

and defects, where domain wall pinning could

occur, would decrease the contribution of domain

wall motion. In addition, small grains would make

magnetization decreased due to the existence of

spin canting layer [19], which also could increase

the effective magnetic anisotropy field. On the

contrary, since the melting temperature of Bi2O3 is

8251C, when samples with Bi2O3 doping were

sintered at above 9001C, higher density could be

obtained through particle re-arrangement, solu-

tion re-precipitation and solid skeleton processes

by formation of the Bi2O3 liquid phase [20]. An

increase in sintered density of ferrites not onlycauses the reduction of the demagnetizing field due

to pores but also raises the spin rotational

contribution, which in turn increases the perme-

ability [21]. Also, as the grain size was increased

with Bi2O3 doping, the multi-domain grains

appeared which could result in higher permeability

values due to the domain wall motion [22]. The

CoTi substitution dependence of high-frequency

magnetic properties was mainly due to the change

of the magnetocrystalline anisotropy field, which is

1E7 1E8 1E9

0

4

8

12

16

20

'

Frequency (Hz)

Bi2O3 wt%0 23 45

1E7 1E8 1E9

0

4

8

12

16

20

"

Frequency (Hz)

Bi2O3 wt%

02345

Fig. 4. Effect of Bi2O3 content on the complex permeability.

1E7 1E8 1E9

0

2

4

6

8

10

12

14

16

'

Frequency (Hz)

950 C

850 C

810 C

1E7 1E8 1E9

0

2

4

6

8

10

12

14

16

"

Frequency(Hz)

950 C

850 C

810 C

Fig. 5. Effect of magnetic particles fabrication temperature on

the complex permeability.

C. Wang et al. / Journal of Magnetism and Magnetic Materials 257 (2003) 100106104

-

7/31/2019 Co-Ti Substituted BaHex

6/7

in proportion to the magnetic resonant frequency.

In addition, the electrical resistivity for all sintered

samples was measured using silver contacts, and

was found to be above 108O cm. This high

electrical resistivity could reduce the eddy current

losses in the high-frequency range. All the electro-

magnetic behaviors of CoTi substituted barium

ferrites showed the potential to be used for MLCIsor multi-layer chip beads (MLCBs) in the hyper-

frequency range.

4. Summary

CoTi substituted barium ferrites Ba-

Fe122xCoxTixO19 were prepared by chemical

coprecipitation and low-temperature sintering

with Bi2O3 doping, their microstructures and

high-frequency magnetic properties were investi-

gated. Experimental results showed that CoTi

substituted barium ferrite particles with average

size range 40200 nm could be obtained whenheated in NaCl matrix at 8109501C, and high

temperature for barium ferrite particles fabrication

resulted in high permeability for sintered barium

ferrites. High-frequency magnetic properties could

be improved obviously with Bi2O3 doping. The

initial permeability m0 > 14 of sintered ferrites

could be obtained with Bi2O3 content varying

from 2 to 5 wt% compared with m0 6 without

Bi2O3 doping when sintered at 9501C for 5 h .

Barium ferrites with initial permeability m0 > 10;

magnetic resonant frequency >1 GHz were ob-

tained when it was sintered at 9001C with 2 wt%

Bi2O3 doping in the CoTi substitution of 1.20

1.30. The electrical resistivity of all sintered ferrite

samples was above 108O cm.

Acknowledgements

This work was supported by the High Tech-

nology Research and Development Project of

Peoples Republic of China (Grant No.

2001AA320502).

References

[1] H.M. Sung, C.J. Chen, W.S. Ko, H.C. Lin, IEEE Trans.

Magn. 30 (1994) 4906.

[2] H.G. Zhang, L.T. Li, Z.W. Ma, J. Zhou, Z.X. Yue,

Z.L. Gui, J. Magn. Magn. Mater. 218 (2000) 67.

[3] K. Hirota, T. Aoyama, S. Enomoto, M. Yoshinaka,

O. Yamaguchi, J. Magn. Magn. Mater. 205 (1999) 283.

[4] J. Smit, H.P.J. Wijn, Ferrites, Philips Technical Library,

Eindhoven, 1959, p. 285.[5] P. Allegri, D. Autissier, T. Taffary, Key Eng. Mater.

132136 (1997) 1424.

[6] R.C. Pullar, S.G. Appleton, A.K. Bhattacharya, J. Mater.

Sci. Lett. 17 (1998) 973.

[7] J.L. Snoek, Physica 14 (1948) 207.

[8] M. Sugimoto, in: E.P. Wohlfarth (Ed.), Ferromagnetic

Materials, Vol. 3, 1982, p. 394.

[9] I.G. Chen, S.H. Hsu, Y.H. Chang, J. Appl. Phys. 87 (2000)

6247.

[10] O. Sakaguchi, T. Kagotani, D. Book, H. Nakamura, S.

Sugimoto, M. Okada, M. Homma, Mater. Trans. JIM 37

(1996) 878.

1E7 1E8 1E9

0

2

4

6

8

1012

14

16

18

'

Frequency (Hz)

x = 1.20

x = 1.25

x = 1.30

1E7 1E8 1E9

0

2

4

6

8

10

12

14

16

18

"

Frequency (Hz)

x = 1.20

x = 1.25

x = 1.30

Fig. 6. CoTi substitution dependence of complex permeability.

C. Wang et al. / Journal of Magnetism and Magnetic Materials 257 (2003) 100106 105

-

7/31/2019 Co-Ti Substituted BaHex

7/7

[11] Z. Yang, H.X. Zeng, M.L. Yan, S.L. Geng, J. Magn. Soc.

Jpn. 13S1 (1989) 363.

[12] T. Fujiwara, IEEE Trans. Magn. 21 (1985) 1480.

[13] H. Kojima, in: E.P. Wohlfarth (Ed.), Ferromagneric

Materials, Vol. 3, 1982, p. 305.[14] D.J. de Bitetto, J. Appl. Phys. 35 (1964) 3482.

[15] D. Autissier, A. Podembski, C. Jacquiod, J. Phys. IV 7

(1997) 409.

[16] C.S. Wang, F.L. Wei, M. Lu, D.H. Han, Z. Yang,

J. Magn. Magn. Mater. 183 (1998) 241.

[17] J.P. Bouchaud, P.G. Zerah, J. Appl. Phys. 67 (1990) 5512.

[18] A. Globus, J. Phys. Suppl. C1(ICF-3) (1977) 1.

[19] X. Batlle, X. Obradors, M. Medarde, J. Rodriguez-

Carvajal, M. Pernet, M. Vallet-Regi, J. Magn. Magn.

Mater. 124 (1993) 228.[20] S.F. Wang, Y.R. Wang, T.C.K. Yang, C.F. Chen, C.A.

Lu, C.Y. Huang, J. Magn. Magn. Mater. 220 (2000) 129.

[21] J.J. Shrotri, S.D. Kulkarni, C.E. Deshpande, S.K. Date,

Mater. Chem. Phys. 59 (1999) 1.

[22] T. Nakamura, J. Magn. Magn. Mater. 168 (1997) 265.

C. Wang et al. / Journal of Magnetism and Magnetic Materials 257 (2003) 100106106