Clean Air Conditioners · Daikin’s clean air conditioners are specially designed to ... remote...

-

Upload

vuongthien -

Category

Documents

-

view

217 -

download

0

Transcript of Clean Air Conditioners · Daikin’s clean air conditioners are specially designed to ... remote...

1

Easily providing the high cleanliness environment required by various industries. Daikin’s clean air conditioners are specially designed to realize an environment of cleanness class 10,000 with little

construction.

These air conditioners easily realize a cleanliness-class environment and help create the atmospheric environment

of hospitals, food and beverage factories, electronics factories and other venues that require clean air.

Select the air flow system and installation method to match the usage environment and purpose of the room.

Two types of clean air conditioner are available – an integrated outlet unit model and a separate outlet unit model.

Furthermore, it is possible to configure the air flow system to ceiling intake or floor-level intake according to the panel selected.

This makes it possible to respond precisely to the layout and purpose of the room.

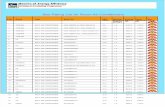

Model series

Integrated outlet unit model

Ceiling intake type

FBXYP45MA (Corresponding to 1.6HP) Decorative panel · · · · · · · · · · ·BYBP82D56CStandard HEPA filter · · · · · · · ·BAFHJ82A56[Quick navi] operation remote controller · · · · · · · · · · ·BRC1E62

FBXYP56MA (Corresponding to 2HP) Decorative panel · · · · · · · · · · ·BYBP82D56CStandard HEPA filter · · · · · · · ·BAFHJ82A56[Quick navi] operation remote controller · · · · · · · · · · ·BRC1E62

FBXYP71MA (Corresponding to 2.5HP) Decorative panel · · · · · · · · · · ·BYBP82D80CStandard HEPA filter · · · · · · · ·BAFHJ82A80[Quick navi] operation remote controller · · · · · · · · · · ·BRC1E62

Floor-level intake type

FBXYP45MA (Corresponding to 1.6HP) Decorative panel · · · · · · · · · · ·BYBP82D56WStandard HEPA filter · · · · · · · ·BAFHJ82A56[Quick navi] operation remote controller · · · · · · · · · · ·BRC1E62

FBXYP56MA (Corresponding to 2HP)Decorative panel · · · · · · · · · · ·BYBP82D56WStandard HEPA filter · · · · · · · ·BAFHJ82A56[Quick navi] operation remote controller · · · · · · · · · · ·BRC1E62

FBXYP71MA (Corresponding to 2.5HP) Decorative panel · · · · · · · · · · ·BYBP82D80WStandard HEPA filter · · · · · · · ·BAFHJ82A80[Quick navi] operation remote controller · · · · · · · · · · ·BRC1E62

Separate outlet unit model

Ceiling intake type

FBXYP71MAP (Corresponding to 2.5HP) Decorative panel · · · · · · · · · · ·BYBP82D80CPOutlet unit · · · · · · · · · · · · · · · · ·BAFJ82B80Standard HEPA filter · · · · · · · ·BAFHJ82A80[Quick navi] operation remote controller · · · · · · · · · · ·BRC1E62

Floor-level intake type

FBXYP71MAP (Corresponding to 2.5HP)Decorative panel · · · · · · · · · · ·BYBP82D80WPOutlet unit · · · · · · · · · · · · · · · · ·BAFJ82B80Standard HEPA filter · · · · · · · ·BAFHJ82A80[Quick navi] operation remote controller · · · · · · · · · · ·BRC1E62

2

Instances of installation by type (for a hospital)

The floor-level intake system prevents uncomfortable drafts with a low flow speed of 0.5 m/s.

The floor-level intake system has a low flow speed of 0.5 m/s, improving dust filtration and eliminating the feeling of drafts. Broadly air-conditions the room with a gentle air flow and creates a people-friendly environment.

Can be easily installed in existing buildings.

A simple structure makes it easy to realize a highly clean environment with the same installation work as for a typical air conditioner. Can be easily installed in new buildings, existing structures, and during refurbishments.

� The ceiling intake type provides concentrated air conditioning centered directly under the outlet. Accordingly, please be aware of the following. • Sufficient heating my not be achieved near the floor or at locations far from the outlet. • In the case of utilization in a hospital, some patients may be susceptible to cool

drafts, so please ensure that they do not come directly under the outlet.

� Please make sure to use the floor-level intake type in the following kinds of locations. • Locations in which heating of the lower part or the entire room is

important. • Locations necessitating a particularly high cleanliness factor and

in which there are a lot of people. Attention

� Air flow distribution diagram (operating theatre)

3m

0

0.6

0.5

0.4

0.3

0.2

0.1

0

(m3/sec)

0 Operatingtable

Intake 3m 3m

Outlet

Intake

*Analysis of the floor-level intake type with the integrated outlet model.

*1. Cleanliness class. A scale expressing the cleanliness of air established by NASA (National Aeronautics and Space Administration). Class 10,000 represents a state of less than 10,000 minute particles of diameter under 0.5 µm per cubic foot.

For comparison, the cleanliness of a typical office is around class 1,000,000. *2. CCU (Cardiac Care Unit). A ward dedicated to the admission of patients with myocardial infarctions and other heart diseases. *3. ICU (Intensive Care Unit). A ward for the careful treatment and nursing of patients with serious illnesses, injuries, or recovering from operations.

Ceiling intake type(high speed contracted flow/high ceiling model)

Floor-level intake type(gentle wind distribution/high cleanness class model)

Construction work is simple and a ceiling installation is possible. Dust filtering and air-conditioning can be started immediately.

Easy to increase the cleanness and air-conditioning effect. A low flow speed prevents drying of the affected part and the experience of drafts.

100,000 to 10,000

Type

Features

Cleanness class*1

Wind speed

Blow method

Integrated outlet unit

model

Separate outlet unit

model

10,000

1.0m/s or higher 0.5m/s

Intake (sourced locally)

Outlet unit

Air conditioner Intake

(sourced locally)

� Concentrated air conditioning centered directly under the unit. � Easy installation.

� Somewhat concentrated air conditioning centered directly under the outlet. � Can air-condition irregularly shaped rooms.

� Total air conditioning with an emphasis on cleanliness.

� Total air conditioning with an emphasis on cleanliness. � Maintenance from a different room possible.

Applications: Surgery prep rooms, recovery rooms, nurse stations, etc

Applications: CCU*2, sterile rooms, etc

Applications: Operating theatres, delivery rooms, etc

Applications: Premature nurseries, newborn nurseries, ICU*3, etc

3

Providing each and every necessary function at a high standard.

Realizing cleanliness class 10,000 with an HEPA filter (sold separately).

Clean

The low pressure-loss standard HEPA filter (sold separately) demonstrates a superior dust filtering performance and easily accomplishes an air cleanliness of class 10,000.

The HEPA filter has a structure incorporating a pleated glass fiber filter medium, making it highly efficient and suitable for clean rooms etc.

* It may not be possible to maintain cleanliness in rooms with low air tightness. * An antibacterial HEPA filter (order item) which inhibits the propagation of filtered bacteria is also available. Cannot be used with the standard HEPA filter.

�Standard HEPA filter

Suppresses the propagation of bacteria in the duct with a proprietary mixed antibacterial powder coating.

Antibacterial

The filter implements an antibacterial treatment with a new coating combining a silver-based inorganic antibacterial material effective against germs and an organic antibacterial material that prevents mold. This enhances the antibacterial condition of the duct.

Antibacterial fiber used in the intake filter. An antibacterial type is also used for the HEPA filter. With a long-life filter employing mold-preventing antibacterial fiber near the intake, cleaning performance is increased even further. An antibacterial type (order item) made from a combination of antibacterial fibers that suppress the propagation of collected bacteria is also available.

* Please be aware that antibacterial products suppress the propagation of bacteria but do not have a sterilizing effect. Also, mold may grow in places where dust or soot accumulates.

* A material for which the registered safety was verified by Japanese chemicals and dangerous substances regulation law (Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture, etc) is used for the antibacterial material.

* Please make sure to carry out maintenance periodically (cleaning the air filter and washing the inside of the unit).

Fan

Intake filter (antibacterial fiber)

Intake panel (punched)

Sheet steel drain pan (antibacterial treated)

HEPA filter or antibacterial HEPA filter (order item)

Outlet panel (punched)

�Structural diagram

All models incorporate an industry-leading meticulous quiet design, operating at under 41dB.

Quiet

Operating noise is substantially reduced by employing a proprietary double-structure outlet filter chamber, sound absorbing heat insulation, and a low pressure-loss HEPA filter etc. All models emit under 41dB of noise. (38dB during low-power operation)

The outdoor unit also operates quietly. If set to night time quiet mode, the air conditioner becomes even quieter at night.

*Operating noise may be greater than these values in highly reflective locations.

Filter maintenance unnecessary for about five years. Under-surface access system for easy maintenance.

Labor-saving

The HEPA filter has an exceptionally long life, not requiring maintenance for about five years. Daikin has aimed to reduce maintenance work from various perspectives, including an under-surface access system that eliminates the necessity for service panels and an easily detachable fan and drip pan.

Precise operation and room temperature control. Operation is as easy as for an ordinary air conditioner. Control by distant/dual remote control operation possible. System is equipped with a self-diagnosis function that indicates the location and details in the event of a malfunction. Combine with a controller that can centrally control multiple air conditioners* to reduce total air conditioner management work in combination with other air conditioners.

� i-touch controller� Wired liquid crystal remote controller

*Individual control of up to 64 groups possible by central control.

*The maintenance period differs significantly according to the cleanliness of the room and operating time of the air conditioner.

Installation example (in a hospital facility)

· HEPA filter replacement

· Fan inspection

· Drip pan inspection · Pre-filter replacement

4

Providing each and every necessary function at a high standard.

Realizing cleanliness class 10,000 with an HEPA filter (sold separately).

Clean

The low pressure-loss standard HEPA filter (sold separately) demonstrates a superior dust filtering performance and easily accomplishes an air cleanliness of class 10,000.

The HEPA filter has a structure incorporating a pleated glass fiber filter medium, making it highly efficient and suitable for clean rooms etc.

* It may not be possible to maintain cleanliness in rooms with low air tightness. * An antibacterial HEPA filter (order item) which inhibits the propagation of filtered bacteria is also available. Cannot be used with the standard HEPA filter.

�Standard HEPA filter

Suppresses the propagation of bacteria in the duct with a proprietary mixed antibacterial powder coating.

Antibacterial

The filter implements an antibacterial treatment with a new coating combining a silver-based inorganic antibacterial material effective against germs and an organic antibacterial material that prevents mold. This enhances the antibacterial condition of the duct.

Antibacterial fiber used in the intake filter. An antibacterial type is also used for the HEPA filter. With a long-life filter employing mold-preventing antibacterial fiber near the intake, cleaning performance is increased even further. An antibacterial type (order item) made from a combination of antibacterial fibers that suppress the propagation of collected bacteria is also available.

* Please be aware that antibacterial products suppress the propagation of bacteria but do not have a sterilizing effect. Also, mold may grow in places where dust or soot accumulates.

* A material for which the registered safety was verified by Japanese chemicals and dangerous substances regulation law (Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture, etc) is used for the antibacterial material.

* Please make sure to carry out maintenance periodically (cleaning the air filter and washing the inside of the unit).

Fan

Intake filter (antibacterial fiber)

Intake panel (punched)

Sheet steel drain pan (antibacterial treated)

HEPA filter or antibacterial HEPA filter (order item)

Outlet panel (punched)

�Structural diagram

All models incorporate an industry-leading meticulous quiet design, operating at under 41dB.

Quiet

Operating noise is substantially reduced by employing a proprietary double-structure outlet filter chamber, sound absorbing heat insulation, and a low pressure-loss HEPA filter etc. All models emit under 41dB of noise. (38dB during low-power operation)

The outdoor unit also operates quietly. If set to night time quiet mode, the air conditioner becomes even quieter at night.

*Operating noise may be greater than these values in highly reflective locations.

Filter maintenance unnecessary for about five years. Under-surface access system for easy maintenance.

Labor-saving

The HEPA filter has an exceptionally long life, not requiring maintenance for about five years. Daikin has aimed to reduce maintenance work from various perspectives, including an under-surface access system that eliminates the necessity for service panels and an easily detachable fan and drip pan.

Precise operation and room temperature control. Operation is as easy as for an ordinary air conditioner. Control by distant/dual remote control operation possible. System is equipped with a self-diagnosis function that indicates the location and details in the event of a malfunction. Combine with a controller that can centrally control multiple air conditioners* to reduce total air conditioner management work in combination with other air conditioners.

� i-touch controller� Wired liquid crystal remote controller

*Individual control of up to 64 groups possible by central control.

*The maintenance period differs significantly according to the cleanliness of the room and operating time of the air conditioner.

Installation example (in a hospital facility)

· HEPA filter replacement

· Fan inspection

· Drip pan inspection · Pre-filter replacement

5

Clean air conditioner

Easily realizing the clean environment of cleanliness class 10,000 required in ICUs, newborn nurseries and other medical facilities and medical/food factories.

FBXYP-MA(P)P45/56/71

HEPA filter sold separately

Order product

Two types available according to the application. Possible to select the air flow system and installation method in accordance with the usage environment and purpose of the room.

“Floor-level intake type” A clean air flow spreads throughout the whole room.

“Ceiling intake type” Provides concentrated air conditioning focused directly under the outlet and creates a clean zone. * Integrated outlet and separate outlet unit models are available for each type.

�A HEPA filter of dust filtering efficiency 99.97% realizes an air cleanliness of class 10,000*. (count method 0.3 μm) * Cleanness class. A scale expressing the cleanliness of air established by NASA (National Aeronautics and Space Administration). Class 10,000 represents a state of under 10,000 minute particles of diameter under 0.5 μm per cubic foot. For comparison, the cleanliness of a typical office is around class 1,000,000.

The propagation of bacteria in the duct is suppressed by a new coating combining a silver-based inorganic antibacterial material effective against germs and an organic antibacterial material that prevents mold. This inhibits the growth of mold in the air conditioner and keeps the duct hygienic.

�Possible to incorporate an antibacterial HEPA filter employing antibacterial fiber in the outlet filter (modified product).

�The floor-level intake system prevents uncomfortable drafts with a low flow speed of 0.5 m/s.

�Industry-leading meticulous quiet design. (Operation noise under 41dB for all models)

�Filter maintenance is unnecessary for about five years*. Employs an under-surface access system for easy maintenance.

* 5 years (12500 hours) 8 hours/day x 26 days/month x 12 months/year x 5 years Conditions: Room dust concentration: Class 10,000

Outside air intake volume: 20% of rated air flow Outside dust concentration: Class 1,000,000

Easy installation in existing structures with the same installation work as for a typical air conditioner.

Package type also available.

Intake

Intake

Fan

Intake filter (antibacterial fiber)

Intake panel (punched)

Sheet steel drain pan (antibacterial treated)

HEPA filter (sold separately) or antibacterial HEPA filter (modified product)

Outlet panel (punched)

�Outline drawing (units: mm)

Integrated outlet unit model

�Ceiling intake type

�Floor-level intake type

Type

P45/56

P71

A

820

1120

B

860

1120

C

1115

1415

D

1150

1450

E

1000

1300

F

960

1260

G

930

1230

H

900

1200

K

1050

1350

J

5×150=750

5×200=1000

Type

P45/56

P71

A

918

1218

B

1115

1415

C

1150

1450

D

1000

1300

E

960

1260

F

930

1230

G

900

1200

J

1050

1350

H

5×150=750

5×200=1000

1. Heat insulating material (polyethylene foam) is affixed to the inside of the outlet panel. 2. This is the distance between the ceiling and the end face of the main unit plate. (Not the distance between the

ceiling and the seal material.)3. In the case of drawing in air through the fresh air intake, install a damper linked with the indoor unit fan in the duct

and ensure that the air intake is cut off when the fan is stopped. It is possible for the taken-in air to flow backwards through inlet filter and for the dust deposited in the filter to be returned to the room.

4. In the case of an installation in an operating theatre etc where an air conditioner malfunction may have serious consequences, please build in redundancy with two or more outside units.

5. Please do not place things that must not become wet under the indoor unit. Condensation may fall in the case of humidity of 80%, in the case the drainage outlet is blocked, or in the case the air filter is dirty.

6. This is the height excluding the screws for securing the outlet panel on the surface (height: 10 mm).

Notes)

1. The back inlet companion flange is attached to the panel (BYBP82D56W or BYBP82D80W). 2. This is the distance between the ceiling and the end face of the main unit plate. (Not the distance between the ceiling

and the seal material.)3. In the case of drawing in air through the fresh air intake, install a damper linked with the indoor unit fan in the duct

and ensure that the air intake is cut off when the fan is stopped. It is possible for the taken-in air to flow backwards through inlet filter and for the dust deposited in the filter to be returned to the room.

4. In the case of an installation in an operating theatre etc where an air conditioner malfunction may have serious consequences, please build in redundancy with two or more outside units.

5. Please do not place things that must not become wet under the indoor unit. Condensation may fall in the case of humidity of 80%, in the case the drainage outlet is blocked, or in the case the air filter is dirty.

Notes)

In the case of introducing outside air, please install a damper linked with the indoor unit fan. Please contact our customer service center about damper precautions and linkage methods. Attention

In the case of introducing outside air, please install a damper linked with the indoor unit fan. Please contact our customer service center about damper precautions and linkage methods. Attention

10

(A)

CB

(Cei

ling

aper

ture

)

1490 (Center of outlet panel) Diffusion punching

1840 (Ceiling aperture) 1880

(45)(45)

(45)(560)

(45)

7 811

ø210 hole (note 3) (fresh air intake)

ø226 P.C.D

188

210

4-M4 countersink (cyclotomic)

View on arrow A

(Not

e 2)

J9

D500 or more 54

50

39

2 200

280

31

220

3

44

E

G (Square hole)H

F

16-ø7 hole

310

340

492

10 6570

505 o

r mor

e

(Mou

ntin

g se

rvic

e sp

ace)

(Main

unit

mou

nting

dim

ensio

ns) 1

2(Sq

uare

hole)

(Mounting service space)

13 12

�This diagram is based on the FBXYP45/56MA.

�This diagram is based on the FBXYP45/56MA.

B(A)

DC

(Cei

ling

aper

ture

)

1575 (Centered on outlet) 240 (Centered on inlet)

Outlet punching Inlet punching

1840 (Ceiling aperture) 1880

(280) (300)

7 11 9 812

345

435

1788

730 917 66

Hangingbolt

480426414

23275

465

3 1 2

ø210 hole (note 3) (fresh air intake)

ø226 P.C.D

188

210

4-M4 countersink (cyclotomic)

View on arrow A

E500 or more54

50

39

2 200

280

31

220

3

44

F

H (Square hole) J

K

G

16-ø7 hole

310

340

492

10(N

ote

6) 2

7

(Not

e 2)

70

505

or m

ore

(Mou

ntin

g se

rvic

e sp

ace)

(Main

unit

mou

nting

dim

ensio

ns) 1

2(S

quar

e ho

le)

(Mounting service space)

14

10

13

� Liquid pipe connection � Gas pipe connection � Drain pipe connection � Power connection � Junction wiring connection � Outlet panel � HEPA filter � Inlet � L.L. filter � Electrical components box � Shield plate � Panel frame � Back shield plate � Main unit seal material

� Liquid piping connection � Gas piping connection � Drain pipe connection � Power connection � Junction wiring connection � Outlet panel � HEPA filter � Inspection panel � Electrical components box � Shield plate � Panel frame � Back shield plate � Main unit seal material

730 917 66

345

435

1788

Hangingbolt

480426414

23275

46

5

3 1 2

6

�Outline drawing (units: mm)

Separate outlet unit model

1. Please use a dedicated HEPA unit for the outlet filter unit. 2. This is the distance between the ceiling and the end face of the main unit plate. (Not the distance between the ceiling and the seal

material.)3. In the case of drawing in air through the fresh air intake, install a damper linked with the indoor unit fan in the duct and ensure that

the air intake is cut off when the fan is stopped. It is possible for the taken-in air to flow backwards through inlet filter and for the dust deposited in the filter to be returned to the room.

4. In the case of an installation in an operating theatre etc where an air conditioner malfunction may have serious consequences, please build in redundancy with two or more outside units.

5. Please do not place things that must not become wet under the indoor unit. Condensation may fall in the case of humidity of 80%, in the case the drainage outlet is blocked, or in the case the air filter is dirty.

Notes)

�Ceiling intake type In the case of introducing outside air, please install a damper linked with the indoor unit fan. Please contact our customer service center about damper precautions and linkage methods. Attention

7×150=1050

40

1080 (Square hole) 1110

150

190

220

(Squ

are h

ole)

20-ø8 hole

View on arrow A

12

ø210 hole (note 3) (Fresh air intake)

ø226 P.C.D25

188

210

4-M4 countersink (cyclotomic)

1078

Hangingbolt

480426414

232

435

345

75

2×65

=130

4 5

3 1 2

917 66

240 (Centered on inlet)

(112

0)

1450

1415

(Cei

ling

aper

ture

)

1130 (Ceiling aperture) 1170

(300)

Inlet punching

10 97 8

16×

65=

1040

40-ø4.7hole

1300500 or more 54

50

392 200

280

312

203

44 1260

1200 (Square hole) 5×200=1000

1230

16-ø7hole

310

340

492

1070

505

or m

ore

(Mou

ntin

g se

rvic

e sp

ace)

(Mai

n un

it m

ount

ing

dim

ensi

ons)

12

(Not

e 2)

(Squ

are h

ole)

(Mounting service space)

13 11

13506

1. Heat insulating material (polyethylene foam) is affixed to the inside of the outlet panel.

2. This is the distance between the ceiling and the end face of the main unit plate. (Not the distance between the ceiling and the seal material.)

3. This is the height excluding the screws for securing the outlet panel on the surface (height: 10 mm).

Notes)

�Outlet unit (Ceiling intake type)

�Outlet unit (Floor-level intake type)

(112

0)

790750 (Ceiling aperture)

16×

65=

1040

40-ø4.7 hole

View on arrow A

1350

1450

345 40 220

492

10

505

or m

ore

(Mou

nting

servi

ce sp

ace)

(Squar

e hole

)

190

150

1415

(Cei

ling

aper

ture

)

(280)

700

20-ø8 hole

Hanging bolt

480

7×150=10501080 (Square hole)

1110

1300

3

1

550

2 4

2×65

=130

27 (N

ote

3)

12 (M

ain un

it mou

nting

dime

nsion

s)

(Not

e 2)

5

� Outlet panel � HEPA filter � Ceiling shield

decorative frame � Companion flange � Main unit seal material

�Floor-level intake type

1. Please use a dedicated HEPA unit for the outlet filter unit.2. This is the distance between the ceiling and the end face of the main unit plate. (Not the distance between the ceiling and the seal

material.)3. The back inlet companion flange is attached to the panel (BYBP82D56WP). 4. In the case of drawing in air through the fresh air intake, install a damper linked with the indoor unit fan in the duct and ensure that

the air intake is cut off when the fan is stopped. It is possible for the taken-in air to flow backwards through inlet filter and for the dust deposited in the filter to be returned to the room.

5. In the case of an installation in an operating theatre etc where an air conditioner malfunction may have serious consequences, please build in redundancy with two or more outside units.

6. Please do not place things that must not become wet under the indoor unit. Condensation may fall in the case of humidity of 80%, in the case the drainage outlet is blocked, or in the case the air filter is dirty.

Notes)

In the case of introducing outside air, please install a damper linked with the indoor unit fan. Please contact our customer service center about damper precautions and linkage methods. Attention

505

or m

ore

917 66

1078

Hangingbolt

480426414

232

435

345

75

2×65

=130

4 5

3 1 2

ø210 hole (note 4) (Fresh air intake)

ø226 P.C.D25

188

210

4-M4 countersink (cyclotomic)

16×

65=

1040

40-ø4.7hole

1450

1415

(C

eilin

g ap

ertu

re)

1130 (Ceiling aperture) 1170

9 8

7×150=1050

401080 (Square hole)

1110

150

190

220

(Squ

are h

ole)

20-ø8 hole

View on arrow A

11

1300500 or more 54

50

392 200

280

312

203

44 1260

1200 (Square hole) 5×200=1000

1230

16-ø7 hole

310

340

492

1070

(Mou

ntin

g se

rvic

e sp

ace)

(Mai

n un

it m

ount

ing

dim

ensi

ons)

12

(Not

e 2)

(Squ

are

hole)

(Mounting service space)

12 10

1350

1. This is the distance between the ceiling and the end face of the main unit plate. (Not the distance between the ceiling and the seal material.)

Notes)

� Outlet panel � HEPA filter � Ceiling shield

decorative frame � Companion flange � Main unit seal material

790750 (Ceiling aperture)

16×

65=

1040

40-ø4.7 hole

View on arrow A

1350

1450

(121

8)(4

5)

345 40 220

492

10

505

or m

ore

(Mou

nting

servi

ce sp

ace)

(Squar

e hole

)

190

150

1415

(Cei

ling

aper

ture

)

700

20-ø8 hole

Hanging bolt

7×150=10501080 (Square hole)

1110

1300

3

550

(594) (45)

(45)

(45)2 4

2×65

=130

65(M

ain un

it mou

nting

dime

nsion

s) 12

51

(Not

e 1)

� Liquid piping connection � Gas piping connection � Drain pipe connection � Power connection � Junction wiring connection � Electrical components box � Shield plate

� Inlet � L.L. filter � Panel frame � Back shield plate � Outlet companion flange � Main unit seal material

� Liquid piping connection � Gas piping connection � Drain pipe connection � Power connection � Junction wiring connection � Electrical components box � Shield plate

� Inspection panel � Panel frame � Back shield plate � Outlet companion flange � Main unit seal material

Standard specifications (50/60Hz)Type Integrated outlet unit model Separate outlet unit model

Model name Indoor unit FBXYP45MA FBXYP56MA FBXYP71MA FBXYP71MAP

Outlet unit Integrated with the indoor unit BAFJ82B80

Power Single phase 200V (power supply also necessary for the indoor unit) 50/60 Hz

Cooling capacity *1 kW 4.5 5.6 7.1

Heating capacity *2 kW 5.0 6.3 8.0

Rated power consumption

When cooling *1 W 220/280 330/350 423/479

When heating *2 W 220/280 330/350 423/479

Intake filter efficiency *3 70% by gravimetric method

Outlet HEPA filter efficiency *4 99.97% by DOP method *7

Unit weight kg 140 *5 170 *5 100 *8

Fan Motor output x number of units W 135×1 165×1

Air flow (strong – weak) m3/min 19−16/18−15 24−19/22.5−17.5

Operation noise (strong – weak) *6 dB 41−38

Outlet unit weight kg — 70 *5

Pipe connections

Liquid pipe/gas pipe (øC1220T) mm 6.4/12.7 flare 9.5/15.9 flare

Drain pipe PT1B male screw *1 JIS B 8616 condition (indoor: 27°C DB/19°C WB, outside air: 35°C DB), pipe connection 7.5 m (equivalent length), height 0 m. *2 JIS B 8616 condition (indoor: 20°C DB, outside air: 7°C DB/6°C WB), pipe connection 7.5 m (equivalent length), height 0 m. *3 An intake air filter is only attached to the ceiling intake type. *4 HEPA filter sold separately. *5 Weight including HEPA filter and panel. *6 Anechoic chamber conversion value under JIS B 8616 test conditions. Value usually increases slightly in practice due to surrounding conditions. *7 The clean air conditioner does not support DOP testing (leak test) based on GMP standards (Standards for Manufacturing Control and Quality Control for Medical Devices ) due to slight leakage at time of

product installation. *8 Weight including panel.

*In the case of an installation in an operating theatre etc where an air conditioner malfunction may have serious consequences, please build in redundancy with two or more outside units.

Clean air conditioner: FBXYP-MA (P)Type Integrated outlet unit model Separate outlet unit model

Model name FBXYP45MA · 56MA FBXYP71MA FBXYP71MAP

Outlet unit model name — BAFJ82B80

Operation control

Operation remote controller

Wired liquid crystal BRC1E62

Wireless liquid crystal Separate light receiver type BRC4L1

Intelligent touch manager DCM601A1

FilterStandard HEPA filter (Note 1) BAFHJ82A56 BAFHJ82A80

Antibacterial HEPA filter (Note 1) (Note 2) NAFJ82A56B NAFJ82A80B

PanelCeiling intake type BYBP82D56C BYBP82D80C BYBP82D80CP

Floor-level intake type BYBP82D56W BYBP82D80W BYBP82D80WP

Outside air intake duct flange KDFJ82A80 3,800 yen

(Note 1) The standard HEPA filter and the antibacterial HEPA filter cannot be used together. (Note 2) The antibacterial HEPA filter is a modified product.

• In the case a high cleanliness and air conditioning at the floor level is important, please deploy the <Floor-level inlet type>.

• In the case of drawing in air through the fresh air intake, the taken-in air may flow backwards through inlet filter and the dust deposited in the filter may be returned to the room. Accordingly, please install a damper linked with the indoor unit fan in the duct and ensure that the air intake is cut off when the fan is stopped.

• The entry of gas disinfectant into the air conditioner may cause a malfunction, so please turn off the air conditioner and cover the inlet and outlet with vinyl sheeting etc when sterilizing operating theatres etc in which the air conditioner is installed in medical institutions.

• The clean air conditioner does not support DOP testing (leak test) based on GMP standards (Standards for Manufacturing Control and Quality Control for Medical Devices).

Clean air conditioners

Zonename

Clean areaA

Clean areaB

Facility name Minimum outside air volume ventilation frequency (times/h)

Maternity room

5

4

3

2Special medical ward

�Outside air intake volume (Table 1)

�1989: According to the Healthcare Engineering Association of Japan’s “Design and Management Guidelines for Hospital Air Conditioner Facilities.”

�Please procure a fan filer unit (fan + HEPA filter). Also, please make sure to ensure the minimum necessary air volume QS with the air conditioner and the fan filer unit.

Airborne particles

Diameter(µm or more)

Cumulative particle count (particles/ft3)

�Minimum circulated air volume ventilation frequency: 30 times/h (Table 2) <For a general operating theatre>

�According to the NASA (National Aeronautics and Space Administration) Standard NHB5340,.2.

Clean room class

Viable biological particlecount (particles/ft3)

Pressure difference (mmAq)

By air turbulence method

10,000 0.5 10,000 (350/ ) 0.5 (0.0176/ ) 1.27 Over 20 times

Outline of simple clean air conditioner model selection at a medical institution

Minimum outdoor intake volume QF (m3/h) = room volume (m3) x minimum outside air ventilation frequency (times/h)

Calculate the outside air intake volume.

Calculate the necessary air volume.

Calculate the air-conditioning load. Please calculate taking into account the outside air intake volume.

Select the model capacity. Model required by air-conditioning load calculation: X, model required by minimum necessary air volume calculation: Y

Minimum necessary air volume QS (m3/h) = room volume (m3) x minimum circulated air volume ventilation frequency (times/h)

· X>Y: Select model X. · X=Y: Select either X or Y.

· X<Y: Select model Y, or model X + fan filter unit*

1

2

3

4

Installation and handling precautions

Operating theatre Surgery prep room Pantry Wound irradiation chamber Emergency operating theatreNeonatal intensive care unit (NICU) Clean corridor Aseptic dispensing pharmacy Hand washing stationPre-sterilized room of the central materials store

Premature nursery Some areas of the surgery section Recovery room Operation locker room ICU Special laboratory Outpatient surgery Some areas of the central materials store Dialysis room

• Items marked in the option list are handled by Daikin Industries, Ltd. All others are handled by O.K. KIZAI CO., LTD.