Chrysler Wayne 62te Pg 60-76

-

Upload

erickramos -

Category

Documents

-

view

273 -

download

30

description

Transcript of Chrysler Wayne 62te Pg 60-76

-

Automatic Transmission Service Group

CHRYSLER 62TEP0733 THIRD GEAR RATIO/NEUTRAL CONDITION

COMPLAINT: After Overhaul, Chrysler and Dodge vehicles equipped with the 62TE may exhibit gear ratio error in third gear, P0733, then a neutral condition when coming to a stop. Clearing the code or recycling the ignition would get the same condition to happen again during the 2-3 upshift.

Figure 1

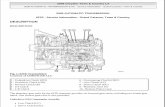

COMPONENT APPLICATION CHART

Gear Ratio3.2154.1272.8422.2841.5731.4521.0000.689

UnderdriveClutch

2-4Clutch

OverdriveClutch

ReverseClutch

Low-RevClutch

LowClutch

DirectClutch

Over-runSprag

Reverse1st Gear ON

ON ONONON ON

ON

ONON

ONON**

ON*

ON*

Hold

Hold

Hold

ONONONON ON

ONON

ONONON

ON

2nd Gear3rd Gear

4th Gear5th Gear6th Gear

4th Prime

Note: 3rd Gear is used for "Limp-in Mode". Note: 4th Prime is used on a 6-4 downshift only to avoid "Double Swap" shift. Note: * = Effective on coast only for engine braking. Note: ** = In OD 1st gear, ON at launch, Off at 150 RPM output speed. Always ON in Manual Low. Copyright 2012 ATSG

CAUSE: The cause may be, that during overhaul, the 2-4 piston retainer was swapped with that of a 41TE. Refer to Figure 2 and see that these piston retainers are identical in every way but the feed hole location. If the 41TE piston retainer is used on a 62TE, there will be no feed to the 2-4 Clutch which will also cause the neutral condition when it goes into limp mode. See the component application chart in Figure 1 and note the information at the bottom of the chart indicating that 3rd gear is failsafe. Note: 2011 Red Seminar book also has similar information in it pertaining to the same complaint but the cause is related to putting the 2-4 feed pipe in backwards.

To correct this condition use the 62TE 2-4 piston retainer. CORRECTION:

60 " 2 0 1 3 S E M I N A R I N F O R M A T I O N

-

Figure 2

1 2-4 CLUTCH PISTON RETAINER. 2 2-4 CLUTCH APPLY PISTON.

1

SLOT FOR THE LEGOF BELLVILLE SPRING

ALIGNED WITH THETAB ON RETAINER

2

62TE 41TE (604)

1 2-4 CLUTCH PISTON RETAINER. 2 2-4 CLUTCH APPLY PISTON.

1

SLOT FOR THE LEGOF BELLVILLE SPRING

ALIGNED WITH THETAB ON RETAINER

2

2-4 PISTON AND RETAINER

Feed Hole Feed Hole

" 2 0 1 3 S E M I N A R I N F O R M A T I O N

Automatic Transmission Service Group

61

-

Automatic Transmission Service Group

CHRYSLER 62TEENGINE STALL IN D OR DURING COAST-DOWN

COMPLAINT: Before or after Overhaul, Chrysler and Dodge vehicles equipped with the 62TE transaxle, may exhibit a complaint of an engine stall when the selector lever is placed in the Drive position or a complaint of a engine stumble and or a stalling condition when coasting to a stop.

CAUSE: The cause may be, that the Electronically Modulated Converter Clutch Variable Force Solenoid is mechanically stuck, causing the Torque Converter Clutch to be engaged, causing the engine stall. EMCC VFS Solenoid - is normally vented and is a variable force solenoid used to control the torque converter clutch application, release and the force with which it is applied or released. Refer to Figure 1 for a description of mechanical function and testing. Solenoid output pressure controls the position of the TCC Switch and TCC Control Valves as shown in the partial hydraulic circuit diagram in Figure 2.

To correct this condition, replace the EMCC Solenoid. Refer to Figure 3 for the location. Note: There is much confusion in the Chrysler/Dodge parts system and OE printed repair information pertaining to the location and name of the EMCC Solenoid. Figure 3 shows that there are two Variable Force Solenoids, one located in the Solenoid Body, which is used for Line Pressure Control. The other, located at the top of the valve body, which is the EMCC Variable Force Solenoid, and used for TCC application. Early OE information doesnt label either of the two solenoids as a EMCC Solenoid, and in some instances labeled the EMCC as the VLP Sensor. This confusion has caused shops to purchase the Solenoid Body thinking that the EMCC Solenoid is included and it is not, which results in the same problem when the vehicle is put back together.

CORRECTION:

SERVICE INFORMATION:

EMCC VARIABLE FORCE SOLENOID(Chrysler part#).................................5169313AA

62 " 2 0 1 3 S E M I N A R I N F O R M A T I O N

-

Figure 1

ELECTRONICALLY MODULATED CONVERTER CLUTCH VARIABLE FORCE SOLENOID

The EMCC Solenoid is a Normally Vented Solenoid. When the Solenoid is OFF, Solenoid Feedfrom the Manual Valve Drive position, is blocked at the bottom of the solenoid. When the

Solenoid is ON, Solenoid feed is connected to the TCC Switch and Control Valve, whichregulate the application of the Torque Converter Clutch.

OFF ON

Solenoid FeedFrom Manual

Valve D Blocked

Solenoid Outputto TCC Valves

Vented to Exhaust

Solenoid Outputto TCC ValvesConnected toSolenoid Feed

Solenoid FeedFrom Manual

Valve D Open

Resistance value5 ohms

" 2 0 1 3 S E M I N A R I N F O R M A T I O N

Automatic Transmission Service Group

63

-

DRIVE FIRST GEAR EMCC SOLENOID STUCK ON

PT PT PT PT PT PT

DCLCLR 2-4 UD OD

LR SWITCH VALVEPT

REV

TORQUE CONVERTER

COOLER

CENTERLINELUBE

TCC SWITCH VALVE

PTPT

UD LUBE

EMCC SOL

PUMPLPS

TCC REG VALVE

DIFFERENTIAL LUBE

FILTER PR REG VALVE

PRESSURE TRANSDUCER

MANUAL VALVE

RESERVOIR VENT

VENT RESERVOIR

LC DR

R-L/RPND-L/R

UD OD

ODPS

L/RPS

LCPS

DRPS

SOLENOIDSWITCHVALVE

2/4PS

LC SWITCH VALVE

BLOCKERVALVE

TCC CONTROL VALVE

LINE PRESSURE (D) COOLER FLOW TCC APPLY DRIBBLER LUBE SUCTION EMCC SOLENOID LP SOLENOID0-1000-3015-400-530-8035-11035-135

D

The Electronic Modulated Converter Clutch Variable Force Solenoid is fed from the Drive position of the Manual Valve. Normal EMCC Solenoid operation begins after the 2-3 shift.

If the EMCC Solenoid is partially stuck, it may allow Solenoid Feed to be connectedto the TCC Control valves causing the Torque Converter to be applied during the Drive

engagement and/or during coast-down to a stop.

TCC APPLY PSI

Automatic Transmission Service Group

Figure 2

64 " 2 0 1 3 S E M I N A R I N F O R M A T I O N

-

EMCC VFS(TCC) Solenoid

Solenoid BodyAssembly

Chrysler calls it a Solenoid Module

Line PressureSensor

Figure 3

SOLENOID LOCATIONS

" 2 0 1 3 S E M I N A R I N F O R M A T I O N

Automatic Transmission Service Group

VFS SolenoidLine Pressure

Part of Solenoid Body/Module

65

-

Automatic Transmission Service Group

CHRYSLER 62TEMULTIPLE GEAR RATIO ERRORS

COMPLAINT:

CAUSE:

CORRECTION:

The cause may be, that during installation of the transmission, the Transfer shaft speed sensor and the Output Speed sensor connectors were cross connected, as shown in Figure 2. Note that the connectors for all three of the sensors are identical, it will be necessary to verify wire color to ensure the right connector is connected to the right sensor. Another possibility may be that during overhaul the Rear Planetary was replaced with one from a 41TE transmission. See Figure 3 and note that the reluctor for the 62TE has 48 teeth and the 41TE has 24. This will cause problems with ratio calculation by the PCM.Description: The 62TE is equipped with three speed sensors and their locations are shown in Figures 1 and 2.With a total of three speed sensors, the 62TE can monitor three different ratios. One is the ratio check of the Input Shaft Speed Sensor (Nt) versus the Output Shaft Speed Sensor (No). This measures the overall transmission ratio. A second ratio check is made between the Input Shaft Speed Sensor (Nt) and the Transfer Shaft Speed Sensor (Nc), which checks the main transmission centerline ratio. A third ratio check is made between the Transfer Shaft Speed Sensor (Nc) and the Output Shaft Speed Sensor (No), which checks the underdrive centerline ratio. The control logic is to continuously check the three ratios while in gear. Should any of the three ratios fall outside of the programmed parameters, due to clutch slippage or clutch failure for a given period of time, the transmission is intelligently put into 3rd gear failsafe.

After Overhaul, Chrysler and Dodge vehicles equipped with the 62TE may exhibit gear ratio errors and erratic shifts, accompanied with limp mode. The Diagnostic trouble codes include P0731, P0732, P0733, P0734, P0735 and P0736 , which are gear ratio errors for all gears.

To correct this condition, refer to Figures 1 and 2 to ensure that the correct connectors are connected to the correct sensors and ensure that the correct Rear Planetary has been installed, as shown in Figure 3.

66 " 2 0 1 3 S E M I N A R I N F O R M A T I O N

-

Copyright 2013 ATSG

OEE DLF RAR

USY

EL ON

T K

6D2

60

T PK

0 88

1

0 51 6

91 3

A A

P

7

173

AA

1A

02

73

A8

68

61

01

86

63

63

7P

SPEED SENSOR LOCATIONS AND GEAR RATIOS

Input ShaftSpeed Sensor

Output ShaftSpeed Sensor

Transfer ShaftSpeed Sensor

Gear Ratio3.2154.1272.8422.2841.5731.4521.0000.689

Reverse1st Gear2nd Gear3rd Gear

4th Gear5th Gear6th Gear

4th Prime

Figure 1

" 2 0 1 3 S E M I N A R I N F O R M A T I O N

Automatic Transmission Service Group

67

-

Transfer Shaft Speed Sensor (TSS)

Output Shaft Speed Sensor (OSS)

The TSS is a two wire magnetic pickup device that generates AC signals as rotation of the rear planetary carrier occurs.

The Output Speed Sensor (OSS) has been relocated to the underdrive centerline side of the case, and reads output shaft speed from the output planetary carrier assembly. The OSS is a two wire magnetic pickup device that generates AC signals as rotation of the output planetary carrier occurs..

5 AA54

8.6

9 0AA3

8.6

5 A54 A

8.6

INPUT SHAFT SPEED SENSOR

OUTPUT SHAFT SPEED SENSOR

TRANSFER SHAFT SPEED SENSOR

SPEED SENSOR HARNESS CONNECTORS

INPUT TRANSFER OUTPUT

1 2

Dk

Gre

en/V

iole

t

Dk

Gre

en/O

rang

e

1 2

Dk

Gre

en/V

iole

t

Dk

Gre

en/L

t Gre

en

1 2

Dk

Gre

en/V

iole

t

Dk

Gre

en/B

rown

1 = Speed Sensor Signal 2 = Speed Sensor Ground Note: Wire colors shown are for 2009 Grand Caravan 3.8L.

Actual Resistance1590 Ohms @ 72F

Actual Resistance1590 Ohms @ 72F

Actual Resistance1424 Ohms @ 72F

Input Shaft Speed Sensor (ISS) The ISS is a two wire magnetic pickup device that generates AC signals as rotation of the input clutch housing occurs.

Automatic Transmission Service Group

Note: The Speed Sensor Harness connectors as shown above are identical.It will be necessary to verify the correct location with a wire diagram with

wire color information

INPUT-OUTPUT AND TRANSFER SHAFT SPEED SENSOR DESCRIPTION

Figure 2

68 " 2 0 1 3 S E M I N A R I N F O R M A T I O N

-

62TE 41TE (604)

48 ToothTransfer Speed

Reluctor

24 ToothOutput Speed

Reluctor

REAR PLANETARY

Figure 3

" 2 0 1 3 S E M I N A R I N F O R M A T I O N

Automatic Transmission Service Group

These Planetarys DO NOT interchange

69

-

NO REVERSECOMPLAINT: Vehicle comes into the shop for repairs due to a severe slip in reverse or no move condition in

reverse. In some cases, upon disassembly the cause is not readily identified and the unit is rebuilt without correcting the problem. Obviously the transmission is installed into the vehicle exhibiting the original no reverse complaint.

CAUSE: When an application chart is used to diagnose the no reverse complaint, it is noticed that three elements need to apply to complete a reverse gear; the reverse clutch, the low/reverse clutch and the low clutch (Figure 1). At first glance the low clutch seems to be used in other forward gears and since all forward gears are operational the low clutch is not considered. This may prevent a thorough inspection of the low clutch located on the centerline shaft. Additionally, since the low/reverse clutch is used for first and reverse, this too is not seriously considered. As a result, the reverse clutch appears to be the most likely candidate and great effort goes into locating a problem with its operation yet none is found. This has lead some technicians to change the entire UD/OD/Rev. clutch housing assembly along with a solenoid and valve body assembly as a solution but the desired result is not achieved.

The cause is a problem with the low clutch. Although it is used in some forward gears, it is only applied during certain driving conditions. The overrunning sprag is the primary holding device to complete first, third and fourth gears. The low clutch is applied when additional holding capacity is required as well as for engine breaking. This low clutch housing drum is known to crack or blow out the 0.020" air bleed capsule (# 202 in Figure 2). Some of these orifices were not properly staked into place. When it works its way out of the bore it causes a large enough leak to prevent the clutch from applying or burning it.

CORRECTION: If the screened orifice capsule is located and is not damaged, it can be reused if staked back in properly. If it's damaged, you will need to fabricate one to save the housing as this orifice is not sold separately.

Finding a good used low clutch housing is not easy either as this is the housing with the Direct Clutch sealing rings on it. The rings wear into the housing enlarging their grooves. When this occurs, instead of having a nice first to second shift it either flares or goes to neutral. Since this is a common problem, good used housings can be difficult to locate. Brand new from the dealer now come fully loaded for approximately $360.00 dollars.

One word of caution, on a few occasions technicians have accidently placed the valve body gaskets on backwards (Figure 3). A line pressure check indicates that line pressure is good in park and neutral, but low in drive and reverse. This will cause the vehicle to have delayed engagements and it will slip badly in all gears. Figure 4 shows the correct placement of the gaskets. Figure 5 shows a break out view of all the valve body parts and placements.

CVI Information: CVI's are not listed in the Chrysler Group LLC's DealerCONNECT program. This information is not given to aftermarket scan companies either. Should this information ever be released, inside sources have provided these following figures: U/D 30-602/4 30-60L/R 30-60O/D 50-130L/C 18D/C 24-48

62TE

Automatic Transmission Service Group

70 " 2 0 1 3 S E M I N A R I N F O R M A T I O N

-

COMPONENT APPLICATION CHART

Gear Ratio3.2154.1272.8422.2841.5731.4521.0000.689

UnderdriveClutch

2-4Clutch

OverdriveClutch

ReverseClutch

Low-RevClutch

LowClutch

DirectClutch

Over-runSprag

Reverse1st Gear ON

ON ONONON ON

ON

ONON

ONON**

ON*

ON*

Hold

Hold

Hold

ONONONON ON

ONON

ONONON

ON

2nd Gear3rd Gear

4th Gear5th Gear6th Gear

4th Prime

Note: 3rd Gear is used for "Limp-in Mode". Note: 4th Prime is used on a 6-4 downshift only to avoid "Double Swap" shift. Note: * = Effective on coast only for engine braking. Note: ** = In OD 1st gear, ON at launch, Off at 150 RPM output speed. Always ON in Manual Low.

Copyright 2013 ATSG

Figure 1

" 2 0 1 3 S E M I N A R I N F O R M A T I O N

Automatic Transmission Service Group

71

-

186 UNDERDRIVE CENTER SHAFT. 187 CENTER SHAFT, WHITE, SCARF-CUT SEALING RINGS (3 REQ). 188 "SPLIT" CAGED NEEDLE BEARING ASSEMBLY (LARGE). 189 CENTER SHAFT, GREEN, SCARF-CUT SEALING RING. 191 UNDERDRIVE CENTER SHAFT ORIFICED CUP PLUG. 201 LOW CLUTCH HOUSING ASSEMBLY. 202 LOW CLUTCH HOUSING SCREEN/ORIFICE. 203 LOW CLUTCH BONDED APPLY PISTON. 204 LOW CLUTCH PISTON "BELLVILLE" RETURN SPRING. 205 LOW CLUTCH "BELLVILLE" RETURN SPRING SNAP RING. 208 LOW CLUTCH BACKING PLATE. 209 LOW CLUTCH BACKING PLATE "SELECTIVE" SNAP RING. 217 DIRECT CLUTCH HOOK-JOINT SEALING RINGS (2 REQUIRED). 218 DIRECT CLUTCH HOUSING. 219 DIRECT CLUTCH BONDED APPLY PISTON. 220 DIRECT CLUTCH PISTON RETURN SPRING. 221 DIRECT RETURN SPRING RETAINER AND BALANCE PISTON. 222 DIRECT CLUTCH RETURN SPRING RETAINER SNAP RING.

186189

188

201

208209218219

220

221

222

217

203204

205

202

191

187

UNDERDRIVE COMPOUNDER ASSEMBLY EXPLODED VIEW

Copyright 2013 ATSG

Figure 2Automatic Transmission Service Group

72 " 2 0 1 3 S E M I N A R I N F O R M A T I O N

-

32 0

100 0

3

D -2F

78AA

5065

09

D -2F

78AA

505

096

Copyright 2013 ATSG

Figure 3

Automatic Transmission Service Group

INCORRECT PLACEMENT OF VALVE BODY GASKETS

74 " 2 0 1 3 S E M I N A R I N F O R M A T I O N

-

Copyright 2013 ATSG

23 1

00

0 03

D -2F

7805A

A

0596

D -2F

8075A

A

0596

Figure 4

Automatic Transmission Service Group

CORRECT PLACEMENT OF VALVE BODY GASKETS

" 2 0 1 3 S E M I N A R I N F O R M A T I O N 75

-

COMPLETE VALVE BODY EXPLODED VIEW

300

301

302 303

304

305

306

307

318

308

309

317

310

311

312

313

314

315

316

300 SOLENOID BODY ASSEMBLY (SERVICED AS ASSEMBLY ONLY). 301 SOLENOID BODY SCREEN/GASKET. 302 VALVE BODY SUPPORT PLATE. 303 VALVE BODY SUPPORT PLATE SCREWS (5 REQUIRED). 304 SUPPORT PLATE TO OUTER SPACER PLATE GASKET. 305 VALVE BODY OUTER SPACER PLATE. 306. VALVE BODY ASSEMBLY. 307 VALVE BODY INNER SPACER PLATE. 308 VALVE BODY INNER SPACER PLATE TO CASE GASKET. 309 VALVE BODY TRANSFER PLATE. 310 LINE PRESSURE SENSOR "O" RING. 311 LINE PRESSURE SENSOR ASSEMBLY. 312 LINE PRESSURE SENSOR RETAINING BOLTS (2 REQUIRED).

Figure 5Copyright 2013 ATSG

319

313 EMCC (TCC) SOLENOID RETAINING BOLT. 314 EMCC (TCC) SOLENOID ASSEMBLY. 315 EMCC (TCC) SOLENOID LARGE "O" RING. 316 EMCC (TCC) SOLENOID SMALL "O" RING. 317 TRANSFER PLATE TO SOLENOID BODY BOLTS (14 REQUIRED). 318 REMOVABLE TORLON (TAN) CHECK BALLS. (3 OR 4 REQUIRED, MODEL SENSITIVE) 319 SOLENOID BODY TO SIDE COVER SEAL.

Automatic Transmission Service Group

76 " 2 0 1 3 S E M I N A R I N F O R M A T I O N

![03/14/18 · Additionally, Wayne allegedly gifted a new pickup truck valued at $31,890 to Ducheneaux and a 2006 Chrysler 300 to Daughters. [¶7.] That summer, Wayne also penned four](https://static.fdocuments.us/doc/165x107/5f271042bd5b8a48e719b0c2/031418-additionally-wayne-allegedly-gifted-a-new-pickup-truck-valued-at-31890.jpg)