CHAPTER VIII SPECTROPHTOMETRIC AND HIGH...

Transcript of CHAPTER VIII SPECTROPHTOMETRIC AND HIGH...

CHAPTER VIII

SPECTROPHTOMETRIC AND HIGH PERFORMANCE LIQUID

CHROMATOGRAPHIC ASSAY OF ETAMSYLATE

312

Section 8.0

DRUG PROFILE AND LITERATURE SURVEY 8.0.1 DRUG PROFILE

Etamsylate (ETM), chemically known as 2, 5-dihydroxy benzene sulphonic

acid with ethylethanamine [1], is a haemostatic drug. Its empirical formula is

C10H17NO5S with a molecular weight of 263.3. The structural formula is:

H3C HN CH2

S

OH

OO

ETM is a white crystalline powder. It is highly soluble in water, freely soluble

in methanol, soluble in anhydrous ethanol and practically insoluble in methylene

chloride [2].

ETM promotes angioprotective and proaggregant action. It stimulates

thrombocytopoesis and their release from bone marrow [3]. It is believed to work by

increasing capillary endothelial resistance and promoting platelet adhesion. ETM is

used in the treatment of capillary hemorrhage, hematemesis, hemopthsis, malena,

hematuria, epistaxis, menorrhagia and post partum hemorrhage [4].

The assay of drug is listed in the monograph of British Pharmacopoeia [2]

and the procedure recommends potentiometric titration of ETM with cerium(IV)

sulphate.

313

8.0.2 LITERATURE SURVEY OF METHODS FOR ETAMSYLATE

8.0.2.1 Titrimetric Methods

The literature survey revealed that no titrimetric assay except BP method has

ever been reported for ETM.

8.0.2.2 Visible Spectrophotometric Methods

Many visible spectrophotometric methods based on different reaction schemes

are found in the literature for the assay of ETM in pharmaceuticals [5-10].

8.0.2.3 UV-spectrophotometric methods Three UV-spectrophotometric methods [11-13] have been reported for the

determination of ETM in either single or combined tablet dosage form. Gard et al.,

[11] have developed a method in which the absorbance was measured at 305 nm. The

Beer Lambert's law is obeyed for ETM in the range of 10-60 µg ml-1. Anju Goyal et

al., [12] have developed two methods for the determination of ETM in combined

tablet with mefenamic acid. The first method involves solving of simultaneous

equation using 287.6 nm and 313.2 nm as two wavelengths. Second method is based

on two wavelength calculation. Two wavelengths selected for estimation of ETM

were 274.4 nm and 301.2 nm. Roshan et al., [13] have developed a method for

estimation of ETM in combined tablet dosage form with tranexamic acid.

8.0.2.4 Chromatographic methods

Three HPLC [14-16] and four HPTLC [14,17-19] methods are found in the

literature for the determination of ETM in pharmaceuticals.

8.0.2.4 Other methods

Biamperimetry [20], chemiluminescence spectrometry [21-23] and flow injection potentiometry [24] have also been reported for the assay of ETM in pharmaceuticals. None of the reported UV-spectrophotometric methods [11-13] is stability indicating. The two reported methods [12,13] are applicable for combined dosage forms. Further, the published HPLC methods [14-16] deal with assay, but are not stability-indicating assays. Realizing the importance of stability-indicating assays, the author has developed one UV-spectrophotometric and one HPLC methods for ETM in pharmaceuticals and the methods are stability-indicating. The details of method development and validation are presented in this chapter.

314

Section 8.1

DEVELOPMENT AND VALIDATION OF STABILITY INDICATING UV-

SPECTROPHOTOMETRIC METHOD FOR THE DETERMINATION OF

ETHAMSYLATE IN PHARMACEUTICALS.

8.1.1 INTRODUCTION

The importance and applications of UV-spectrophotometry in pharmaceutical

analysis as well as the degradation profile under different conditions as recommended

by the International Conference on Harmonization (ICH) guidelines are described in

Section 3.3.1.

Since none of the published UV-spectrophotometric methods [11-13] is

stability-indicating, the author has developed an UV-spectrophotometric method for

ETM in bulk drug and in tablets. The method entails measuring the absorbance of the

drug solution in 0.1 M HCl at 300 nm. The technique has been used to study the

behavior of ETM towards various stress conditions as well. The details are compiled

in this Section 8.1.

8.1.2 EXPERIMENTAL

8.1.2.1 Apparatus

The Spectrophotometric measurements were carried out using the same

instrument described in Section 3.2

8.1.2.2 Materials

All chemicals used were of analytical reagent grade. Doubly-distilled water

was used to prepare solutions wherever required. Hydrogen peroxide (H2O2),

hydrochloric acid (HCl) and sodium hydroxide (NaOH) were purchased from Merck

(Mumbai, India).

Hydrochloric acid (HCl, 2M): Prepared by diluting concentrated acid (Merck,

Mumbai, India) with water.

Hydrogen peroxide (H2O2, 5% v/v): Prepared by diluting 9 ml of the commercially

available 30% reagent to 50 ml with water in a volumetric flask.

Sodium hydroxide solution (NaOH, 2M): Prepared by dissolving required amount

of the pellets in water.

315

Standard drug solution

Pharmaceutical grade ETM (purity 99.67 %) was kindly provided by Biocon

India Ltd., Bangalore, India, and was used as received. Standard drug solution (100

µg ml-1 ETM) was prepared by dissolving accurately weighed 10 mg of pure drug in

0.1 M HCl in a 100 ml standard flask.

8.1.2.3 General procedures

Preparation of calibration curve

Varying aliquots (0.0, 0.5, 1.0, 3.0, 5.0, and 7.0 of 100 µg ml-1) of working

standard solution corresponding to 5.0 – 70.0 µg ml-1 ETM were taken in a series of

10 ml calibration flasks and volume was made up to the mark with 0.1 M HCl. The

absorbance of each solution was measured at 300 nm vs 0.1 M HCl.

A calibration curve was plotted and the concentration of the unknown was read

from the calibration graph or computed from the regression equation derived using

Beer’s law data.

Procedure for tablets

Tablets, Dicynene-250 (Dr. Reddy’s Lab. Ltd., India) and K. Stat-250

(Mercury Lab. Ltd., India) containing ETM were purchased from local commercial

sources.

Twenty tablets from each brand were weighed and crushed into a fine powder.

An amount of tablet powder equivalent to 100 mg of ETM was transferred into a 100

ml volumetric flask. The content was shaken well with about 60 ml of 0.1 M HCl for

20 min. The content was diluted to the mark with the same solvent. It was filtered

using Whatman No 42 filter paper. First 10 ml portion of the filtrate was discarded

and a subsequent portion was diluted to get a working concentration of 100 µg ml-1.

A suitable aliquot was subjected to analysis as described above.

Forced degradation study (Stability study)

A 2 ml aliquot of the standard 100 µg ml-1 ETM was taken (in triplicate) in a

10 ml volumetric flask and mixed with 5 ml of 2M HCl (acid hydrolysis) or 2M

NaOH (alkaline hydrolysis) or 5% H2O2 (oxidative degradation) and boiled for 2 h at

80 °C in a hot water bath. The solution was cooled to room temperature neutralized

appropriately and diluted to the mark with 0.1 M HCl. In thermal degradation, solid

316

drug was kept in Petri dish in oven at 100 °C for 24 h. After cooling to room

temperature, 10 mg of ETM was weighed and transferred to a 100 ml volumetric

flask, dissolved in and diluted up to the mark with 0.1 N HCl. For UV degradation

study, the stock solutions of the drug (100 µg ml-1) was exposed to UV radiation of

wavelength 254 nm and of 1.2K flux intensity for 48 h in a UV chamber. Finally, the

absorbance of all the resulting solutions (20 µg ml-1 in ETM) obtained from acid and

alkaline hydrolysis, oxidative degradation, thermal and UV degradation of ETM, was

measured at 300 nm against 0.1 M HCl.

8.1.3 RESULTS AND DISCUSSION

8.1.3.1 Spectral characteristics

ETM dissolved in 0.1 M HCl showed maximum absorbance at 300 nm, and at

this wavelength blank solution (0.1 M HCl) had insignificant absorbance as shown by

the absorption spectrum in Figure. 8.1.1.

The absorbance spectra of ETM after subjecting to forced degradation were

separately recorded for 20 µg ml-1 solution and are presented in Figure 8.1.2. From

the individual spectra (Figure 8.1.2 a-e) it is apparent that the drug undergoes slight

degradation under acidic conditions, extensive degradation under basic conditions as

shown by two peaks, and also under oxidizing conditions. The drug remained

unaffected under thermal and photolytic stress-conditions as shown by the data in

Table 8.1.0.

Figure 8.1.1 Absorption spectrum

317

(a)

(b)

(c)

(d)

318

(e)

Figure 8.1.2 UV-spectra obtained after:

(a) acid,(b) base, (c) thermal, (d) photo and (e) peroxide degradation

Table 8.1.1 Results of degradation study

Degradation condition % Assay* Observation Control sample 99.8 Not applicable Acid hydrolysis (2M HCl, 80°C, 2 hours)

92.3 Slightly degraded

Base hydrolysis (2M NaOH , 80°C, 2 hours)

137.1 Degraded

Oxidation (5% H2O2, 80°C, 2 hours)

- Extensively degraded (Undetectable)

Thermal (105°C, 3 hours)

100.0 No degradation observed

Photolytic (1.2 million lux hours)

99.1 No degradation observed

* Percentage against standard ETM.

8.1.3.2 Method validation

Linearity, sensitivity, limits of detection and quantification

A linear correlation was found between absorbance at max and concentration of

ETM (Figure 8.1.3). The slope (b), intercept (a) and correlation coefficient (r) for

each system were evaluated by using the method of least squares optical

characteristics such as Beer’s law limits, molar absorptivity and Sandell sensitivity

values are presented in Table 8.1.2. The limits of detection (LOD) and quantitation

(LOQ) are also calculated according to ICH guidelines [25] and these data are

presented in Table 8.1.2.

319

Figure 8.1.3 Calibration curve

Table 8.1.2 Sensitivity and regression parameters

Parameter Proposed method max, nm 300 Beer’s law limits (µg ml-1) 5.0-70.0 Molar absorptivity (l mol-1 cm-1) 4.33×103 Sandell sensitivity (µg cm-2) 0.0608 Limit of detection (µg ml-1) 0.40 Limit of quantification (µg ml-1) 1.21 Regression equation, Y Intercept,(a)

0.0020

Slope,(b) 0.0164 Correlation coefficient (r) 0.9999 Standard deviation of intercept (Sa) 0.00241 Standard deviation of slope (Sb) 0.00005

Limit of determination as the weight in µg ml-1of solution, which corresponds to an absorbance of A = 0.001 measured in a cuvette of cross-sectional area 1 cm2 and l = 1 cm. *Y=a + bX, Where Y is the absorbance, X is concentration in µg ml-1, a is intercept, b is slope. Precision and accuracy

To check the precision and accuracy of the proposed methods, the assays

described under “general procedures” were repeated seven times within the day

(intra-day precision) and five times on five different days (inter-day precision). These

assays were performed for three levels of analyte. The RSD values were ≤0.68%

(intra-day) and ≤ 0.84% (inter-day) indicating high precision of the methods. The

accuracy of the methods was evaluated as percentage relative error, RE (%), between

the measured mean concentrations and taken concentrations for ETM. RE (%) values

of ≤1.77% demonstrate the high accuracy of the proposed methods. The results of this

study are summarized in Table 8.1.3.

0

0.5

1

0 10 20 30 40 50 60 70

Abso

rban

ce

Conventration of ETM, µg ml-1

320

Table 8.1.3 Results of intra-day and inter-day accuracy and precision study

Ruggedness

Method ruggedness was demonstrated by determination of ETM at three

different concentrations. The analysis was performed by four different analysts, and

also with three different cuvettes by a single analyst. The intermediate precision,

expressed as percent RSD, which is a measure of ruggedness, was within the

acceptable limits as shown in the Table 8.1.3.

Table 8.1.3 Results of ruggedness study expressed as intermediate precision (%RSD)

Selectivity

A placebo blank was prepared by mixing 20 mg talk, 20 mg starch, 15 mg

acacia, 20 mg methyl cellulose, 30 mg sodium citrate, 25 mg magnesium stearate, 25

mg sodium alginate and homogenizing. A 20 mg portion was weighed and solution

prepared as ‘described under tablets’ and then subjected to analysis. The absorbance

of the placebo solution in each case was almost equal to the absorbance of the blank

which revealed no interference. To assess the role of the inactive ingredients on the

assay of ETM, a synthetic mixture was separately prepared by adding 10 mg of ETM

to 20 mg of the placebo mentioned above. The drug was extracted and solution

prepared as described under the general ‘Procedure for tablets’. The solution was

analyzed by following the recommended procedure. The percentage recovery was

ETM taken (µg ml-1)

Intra-day (n = 5) Inter-day (n = 5)

ETM founda

(µg ml-1)

%RSDb %REc ETM founda

(µg ml-1)

%RSDb

%REc

10.00 10.14 0.42 1.38 10.18 0.68 1.77

30.00 30.12 0.53 0.40 30.17 0.46 0.56 50.00 49.98 0.68 0.04 50.15 0.84 0.31

a. Mean value of five determinations; b. Relative standard deviation (%); c. Relative error (%).

ETM taken,

µg ml-1

Method ruggedness Inter-analysts

RSD, % (n = 4)

Inter-cuvettes RSD, % (n = 4)

10.00 1.07 1.19 20.00 0.91 1.04 30.00 0.86 1.12

321

99.67±1.94. This unequivocally demonstrated the non-interference of the inactive

ingredients in the assay of ETM.

Application to tablets

The proposed methods were applied to the quantification of ETM in

commercial tablets. The results were compared with those of official method [2]. The

BP method involves cerimetric titration of the drug in H2SO4 medium with

potentiometric end point detection. The assay was performed for two brands of tablets

containing 250 mg of active ingredient (K-Stat-250; Dicynene-250) as described

earlier. Statistical analysis of the results did not detect any significant difference

between the performance of the proposed methods and reference method with respect

to accuracy and precision as revealed by the Student’s t-value and variance ratio F-

value. The results of this study are presented in Table 8.1.4.

Table 8.1.4 Results of analysis of tablets by the proposed methods.

*Mean value of five determinations. Recovery study

To further assess the accuracy of the methods, recovery experiments were

performed by applying the standard-addition technique. The test was done by spiking

the pre-analyzed tablet powder with pure ETM at three different levels (50, 100 and

150 % of the content present in the tablet powder (taken) and the total was found by

the proposed method. Each test was repeated three times. The recovery percentage

values ranged between 99.03 and 101.9% with relative standard deviation in the range

0.88-1.73%. Closeness of the results to 100% showed the fairly good accuracy of the

methods. The results are shown in Table 8.1.5.

Tablet brand name Label claim, mg/tablet

Found* (Percent of label claim ±SD) Reference method Proposed method

K-Stat 250

250

100.8 ± 0.64

99.56 ± 1.01 t= 2.32 F= 2.49

Dicynene 250

250

101.3 ± 0.85

101.7 ± 1.25 t= 0.59 F= 2.16

322

Table .8.1.5 Results of recovery study by standard addition method.

*Mean value of three determinations.

Tablets studied

ETM in

tablet, µg ml-1

Pure ETM added, µg ml-1

Total found, µg ml-1

Pure ETM recovered*, Percent±SD

K-Stat - 250

19.90

19.90

19.90

10.0

20.0

30.0

30.09

40.16

49.96

101.9 ±1.73

101.3±1.53

100.2±1.23

Dicynene - 250

20.34

20.34

20.34

10.0

20.0

30.0

30.42

40.72

50.05

100.8 ±1.27

101.9±0.93

99.03±0.88

323

Section 8.2

DEVELOPMENT AND VALIDATION OF HPLC METHOD FOR THE DETERMINATION OF ETHAMSYLATE IN TABLETS AND ITS

STABILITY STUDY 8.2.1 INTRODUCTION

From the literature survey presented in Section 8.0.2.3 it is clear that none of

the published HPLC methods [14-16] is stability-indicating. Driven by the need for a

stability-indicating HPLC method, the author has developed and validated one HPLC

method for ETM, which is stability-indicating. The details are presented in this

Section 8.2.

8.2.2 EXPERIMENTAL

8.2.2.1 Chemicals and Reagents

HPLC grade acetonitrile was purchased from Merck Ltd., Mumbai, India, and ortho

phosphoric acids were from Rankem-India. Doubly distilled (Milli-Q) water was used

throughout the investigation. 0.45µm nylon membrane filter (Millipore, Milford, MA,

USA) was used.

The mobile phase was prepared by mixing 0.2 % ortho phosphoric acid and

methanol in the ratio 65:35. The pH of the mobile phase solution was 2.8 and the

same was used as the diluent.

A standard stock solution of ETM (1000 µg ml-1) was prepared in diluent

working standard solutions in the range, 10-300 µg ml-1 were prepared by dilution of

the stock solution with the diluent.

HCl (1M), NaOH (1M) and H2O2 (5%) solutions required for degradation

study were prepared as described in the previous chapters.

8.2.2.2 HPLC instrumentation and chromatographic conditions

HPLC analysis was performed with a Waters HPLC system equipped with

Alliances 2695 series low pressure quaternary gradient pump, a programmable

variable wavelength UV-visible detector and autosampler. Data were collected and

processed using Waters Empower 2 software.

Chromatographic separation was achieved on a Symmetry C8 (100×4.6 mm,

3.5u) column. The flow rate of the mobile phase 1.0 ml min-1; and UV-detection was

324

performed at 225 nm. Before use, the mobile phase was filtered through 0.45 µm

filter. The column temperature was maintained at 25 °C.

8.2.2.3 General procedure for the calibration graph

Working standard solutions (10-300 µg ml-1 ETM) were injected

automatically onto the column in triplicate and the chromatograms were recorded.

The calibration graph was prepared by plotting the mean peak area versus

concentration of ETM in µg ml-1. Use of standard graph or regression equation

derived using mean peak area-concentration data allowed the calculation of unknown

concentration.

Procedure for tablets

A quantity of tablet powder equivalent to 100 mg of ETM was weighed

accurately into a 100 ml calibrated flask, 50 ml of diluent solution added and was

sonicated for 20 min to complete dissolution of the ETM, and the solution was then

diluted to the mark with the diluent and mixed well. A small portion of the tablet

solution (say 10 ml) was withdrawn and filtered through a 0.45 µm filter to ensure the

absence of particulate matter. The filtrate was appropriately diluted with the diluent

before injection onto the column.

Stress study

All stress decomposition studies were performed at an initial drug

concentration of 200 µg ml-1 in mobile phase. Acid hydrolysis was performed in 1 M

HCl at 80 °C for 2 h. The study in alkaline condition was carried out in 1 M NaOH at

80 °C for 2 h. For study in neutral condition, drug dissolved in water was heated at 80

°C for 2 h. Oxidative studies were carried out at 80 °C in 5% hydrogen peroxide for 2

h. For photolytic degradation studies, pure drug in solid state was exposed to 1.2

million flux hours in a photo stability chamber. Additionally, the drug powder was

exposed to dry heat at 105 °C for 3 h. Samples were withdrawn at appropriate time,

cooled and neutralized by adding base or acid and subjected to HPLC analysis after

suitable dilution or preparing solution of appropriate concentration in the diluent.

325

8.2.3 RESULTS AND DISCUSSION

8.2.3.1 Method development and optimization

Chromatographic parameters were preliminarily optimized to develop the

present method. In the present case, a symmetry C8 column maintained at 25 °C was

used for method development. The mobile phase, 0.2 % ortho phosphoric acid and

methanol in the ratio 65:35 (v/v), at a flow rate of 1.0 ml min-1 was selected, after

several preliminary investigatory chromatography runs. Under the experimental

conditions described, the peak was well-defined and free from tailing (Figure 8.2.1)

with a retention time of ≈3.78 min.

Figure 8.2.1 Typical chromatogram recorded for 200 µg ml-1ETM under the

optimized conditions. Stability studies

ETM was found to be more stable under photolytic (1.2 million flux hours),

thermal (105 0C for 3 hours) hydrolytic (aqueous, 80 0C for 2 hours), in solid state,

stress conditions. The drug was found to be sensitive to acid, base and oxidative stress

conditions. The chromatograms obtained for ETM after subjecting to degradation are

presented in Figure 8.2.2. Assay study was carried out by the comparison with the

peak area of ETM sample without degradation (Table 8.2.1).

3.78

6

AU

0.00

0.05

0.10

0.15

0.20

0.25

0.30

Minutes0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00

326

(a)

(b)

(c)

Eth

amsy

late

- 4.

452

AU

0.00

0.05

0.10

0.15

0.20

0.25

Minutes0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00

AU

-0.04

-0.02

0.00

0.02

0.04

0.06

0.08

0.10

Minutes0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00

Eth

amsy

late

- 4.

517

AU

-0.10

0.00

0.10

0.20

0.30

0.40

0.50

Minutes0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00

327

(d)

(e)

(f)

Figure 8.2.2 Chromatograms obtained for ETM after subjecting to stress studies by: (a) acid (b) base (c) oxidative (d)hydrolytic, (e) thermal and (f) photo degradation.

Eth

amsy

late

- 3.

779

AU-0.10

0.00

0.10

0.20

0.30

0.40

0.50

Minutes0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00

Eth

amsy

late

- 3.

783

AU

-0.10

0.00

0.10

0.20

0.30

0.40

0.50

Minutes0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00

Eth

amsy

late

- 3.

787

AU

-0.10

0.00

0.10

0.20

0.30

0.40

0.50

Minutes0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00

328

Table 8.2.1 Results of degradation study

Degradation condition % Assay* Observation

Control sample 99.7 Not applicable Acid hydrolysis (1N HCl , 80°C, 2 hours)

70.6 Degradation observed

Base hydrolysis (1N NaOH , 80°C, 2 hours)

- Extensively degraded (Undetectable)

Oxidation (5% H2O2 , 80°C, 2 hours)

44.1 Extensively degraded

Water hydrolysis (water , 80°C, 2 hours)

97.1 No degradation observed

Thermal (105°C, 3 hours) 94.1 No degradation observed

Photolytic (1.2 million lux hours) 97.1 No degradation observed

* Percentage against standard OFX

8.4.3.2 Method validation

Linearity

Linearity was studied by preparing standard solutions of different

concentrations from 10 to 300 µg ml-1, plotting a graph of mean peak area against

concentration and determining the linearity by least-square regression. The calibration

plot was linear over the concentration range 10 - 300 µg ml-1 (n= 7) (Fig 8.2.3). The

regression equation in the form Y = a +bX was obtained, where Y is the mean peak

area, X is the concentration of ETM in µg ml-1, a is intercept (5774.54) and b is the

slope (11897.98) of the calibration line with mean regression coefficient (r) of

0.9994.

Figure 8.2.3 Calibration curve

0

1000000

2000000

3000000

4000000

0 100 200 300

Area

Concentration of ETM µg ml-1

329

Specificity

The specificity of an analytical method may be defined as the ability to

unequivocally determine the analyte in the presence of additional components such as

impurities, degradation products and matrix [26-28]. The specificity was evaluated by

injecting the analytical placebo and it was found that the signal measured was caused

only by the analyte. A solution of analytical placebo (containing all the tablet

excipients except ETM) was prepared according to procedure described in Section

8.1 using diluent as extracting solvent and injected onto the column. The resulting

chromatogram is shown in Figure 8.2.4. To identify the interference by the inactive

ingredients, a mixture of inactive ingredients (placebo) and pure ETM was prepared

using diluent by following the procedure described in Section 8.1 and its solution

after filtration and appropriate dilution was chromatographed. The chromatogram did

not show any additional peaks (Figure 8.2.5) which confirmed the specificity of the

method. This was further demonstrated by the absence of additional peak in the

chromatogram of tablet extract (Figure 8.2.6). In addition, the slope of the calibration

graph for standards was compared with that prepared from tablet solutions. It was

found that there was no significant difference between the slopes, which indicated

that the excipients did not interfere with ETM.

Figure 8.2.4 Placebo chromatogram

AU

-0.10

0.00

0.10

0.20

0.30

0.40

0.50

Minutes0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00

330

Figure 8.2.5 Synthetic mixture chromatogram (ETM, 200 µg ml-1)

Figure 8.2.6 Tablet extract chromatogram (ETM, 200 µg ml-1) Detection and quantification limits (LOD and LOQ)

The LOD and LOQ were calculated using signal-to-noise ratio method [26-

28]. LOD and LOQ were found to be 0.5 µg ml-1 and 2.0 µg ml-1, respectively. These

values indicate that the method is suitable for detection and quantification of EPR

over a wide range of concentrations.

Precision

The precision of the method was evaluated in terms of intermediate precision

(intra-day and inter-day). Solutions of three different concentrations of ETM were

analyzed in seven replicates during the same day (intra-day precision) and five

consecutive days (inter-day precision). Within each series, every solution was

injected in triplicate. The RSD values of intra-day studies (<0.85 %) showed that the

precision of the method was excellent. The results of this study are given in Table

3.78

6

AU0.00

0.05

0.10

0.15

0.20

0.25

0.30

Minutes0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00

Eth

amsy

late

- 3.

779

AU

-0.10

0.00

0.10

0.20

0.30

0.40

0.50

Minutes0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00

331

8.2.2. The inter-day precision was equally good with the RSD values ≤ 1.01% (Table

8.2.2).

Accuracy

Accuracy was evaluated as percentage relative error (RE, %) between the

measured mean concentrations and taken concentrations. The results obtained for

three different concentrations are shown in Table 8.2.2 from which the accuracy is

<0.89%. The accuracy was also assessed by analyzing the synthetic mixture (prepared

by adding accurately weighed amount of ETM to the placebo), and the calculated

percent recovery of ETM was found to be 101.58 ± 1.73 % (n = 5) indicating that the

common tablet excipients like talc, starch, gum acacia, lactose, hydroxyl methyl

cellulose, sodium alginate, and magnesium stearate did not interfere in the assay.

Table 8.2.2 Intra-day and inter-day accuracy and precision

ETM injected µg ml-1

Intra-day accuracy and precision Inter-day accuracy and precision

ETM founda, µg ml-1

RE(%) RSDb (%)

RSDc (%)

ETM founda, µg ml-1

RE(%) RSDb (%)

RSDc (%)

150 148.84 0.78 0.58 0.27 148.67 0.89 0.96 0.25 200 201.63 0.82 0.43 0.34 201.47 0.74 0.72 0.22 250 248.63 0.55 0.85 0.29 248.47 0.61 1.01 0.28

aMean value of seven determinations. bbased on peak area; cbased on retention time. Robustness and ruggedness

The robustness of the method was investigated by making small deliberate

changes in the chromatographic conditions. The chromatographic conditions varied

were flow rate (0.9, 1.0 and 1.1 ml) and temperature (24, 25 and 26 °C). There was no

significant change in the retention time (Rt) when the flow rate or temperature was

changed slightly. The values of RSD (Table 8.2.3) indicate that the method is robust.

The ruggedness of the method was assessed by comparison of the results for

the assay of ETM performed by three analysts in the same laboratory. The % RSD did

not exceed 1.8% indicating the ruggedness of the method.

332

Table 8.2.3 Results of robustness study (ETM concentration, 200 µg ml-1, n=3)

Chromatographic Conditions Alteration

Peak area precision Retention time precision

Mean area ± SD RSD,% Mean Rt ± SD

RSD, %

Mobile phase

flow rate (ml min-1)

0.9 2376816 ± 44208.78 1.86 3.786 ± 0.02 0.53

1.0 2375845 ± 21382.61 0.90 3.779 ± 0.01 0.26

1.1 2367768 ± 34332.64 1.45 3.783 ± 0.03 0.79

Column

temperature (°C)

24 2381831 ± 11194.61 0.47 3.787 ± 0.01 0.26

25 2373506 ± 24209.76 1.02 3.785 ± 0.03 0.79

26 2380811 ± 33331.35 1.40 3.775 ± 0.02 0.53

Solution stability

To demonstrate the stability of standard solutions and tablet sample solutions

during analysis, they were analysed over a period of 24 h. The results showed that for

both the solutions, the RT and peak area of ETM remained almost unchanged (RSD

<0.12% and 0.28%, respectively) and no significant degradation was observed during

this period, suggesting that both the solutions were stable for at least 24 h, which was

sufficient for the whole analytical process.

Application to tablets

The developed method was applied to the determination of ETM in two

brands of tablets containing ETM in one strength (250 mg per tablet) which were

available in the local market. Quantification was performed using the regression

equation. The results obtained are presented in Table 8.2.4 and are in fair agreement

with the label claim. The same tablet powder used for assay by the proposed method

was used for assay by the official method [2]. The BP method involves cerimetric

titration of the drug in H2SO4 medium with potentiometric end point detection. The

results were compared statistically by applying the Student’s t-test for accuracy and

F-test for precision. As shown by the results compiled in Table 8.2.4, the calculated t-

test and F-values did not exceed the tabulated values of 2.77 and 6.39 for four degrees

333

of freedom at the 95% confidence level, suggesting that the proposed method and the

reference method do not differ significantly with respect to accuracy and precision.

Table 8.2.4 Results of assay of tablets by the proposed method and comparison with

reference method

*Mean value of five determinations Figure in the parenthesis are the tabulated values for four degrees of freedom at 95% confidence level. Recovery studies

Pre-analyzed tablet powder was spiked with pure ETM at three different

concentration levels and the total was found by the proposed method. Each

determination was repeated three times. The recovery of pure drug added was

quantitative (Table 8.2.5) and revealed that co-formulated substances did not

interfere in the determination.

Table 8.2.5 Results of recovery study by standard-addition procedure

Tablet studied

ETM in tablet µg ml-1

Pure ETM added, µg ml-1

Total found, µg ml-1

Pure ETM recovered*,

(Percent ± SD)

K-Stat** 250 99.21 99.21 99.21

50.0 100.0 150.0

148.18 201.01 247.79

97.94 ± 0.59 101.8 ± 0.82 99.10 ± 0.63

Dicynene*** 250

100.9 100.9 100.9

50.0 100.0 150.0

150.41 202.98 252.25

99.02 ± 1.13 102.1 ± 0.47 100.9 ± 0.33

* Mean value of three experiments.

Tablet brand name

Nominal amount,

mg

Found* (Percent of label claim ± SD)

Reference method Proposed method

Student’s t-value (2.77)

F-value (6.39)

K-Stat250 250 100.8 ± 0.64 99.21±1.13 2.39 3.12

Dicynene

250

250 101.3±0.85 100.9±1.79 0.65 3.07

334

Section 8.3

SUMMARY AND CONCLUSIONS-Assessment of the methods

The major advantage of the developed UV-spectrophotometric method is that

it can be applied to assay of ETM in single dosage forms whereas the published

methods [10-13] are applicable to combined dosage forms. Additionally, the method

is stability-indicating whereas the earlier ones [10-13] are not. The method is simpler

interms of medium employed and ease of performance since the previously reported

methods are either derivative or absorbance difference procedures. The method is

reasonably sensitive with a linear range of 5-70 µg ml-1 and ɛ value of 4.33×103 l mol

cm-1. The method looks highly precise with intra-day RSD (%) values < 1%.

As can be seen from Table 8.2.6, compared to published HPLC methods [14-

16], the present method with a linear dynamic range of 10-300 µg ml-1 and LOD of

0.5 µg ml-1 looks more suitable for routine analysis since it is stability-indicating, and

none of the published methods [14-16] is stability- indicating. With RE and RSD

values within 1%, the developed HPLC method is highly accurate and precise besides

being robust and rugged (RSD%, < 2 %). The specificity of the method was fully

demonstrated by the absence of any peak in the placebo blank chromatogram and any

additional peak in the tablet extract/synthetic mixture chromatograms. Thus, both the

methods offer themselves as advantageous alternatives to existing methods for routine

use in quality control and method development laboratories of pharmaceutical

industries.

One UV-spectrophotometric and one HPLC methods which are stability-

indicating were developed for ETM and validated as per the current ICH guidelines.

The performance characteristics of the published and the proposed HPLC methods

are presented in the Table 8.2.6 below.

335

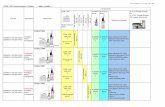

Table 8.2.6 Performance characteristics of the published and proposed methods for

ETM

Sl.

No.

Chromatographic condition Linear

range

(µg ml-1)

LOD

(µg ml-1)

Remarks Ref

1 Kromasil C18 column, H2O-CH3OH

(50:50) mobile phase at 0.6 ml min-

1 with UV-detection at 305 nm.

10-100 - Narrow linear

range, not

stability-indicating

14

2 C18 column, methanol: acetontrile:

acetate buffer pH 2.8 (60:30:10) as

mobile phase, at a flow rate of 1.0

ml min -1 and UV-detection at 290

nm

0.5-100 - Not stability

indicating, uses a

three-component

buffer.

15

3 Luna C8 column (48:52),

acetontrile: water pH 2.5 (60:40) as

mobile phase at a flow rate of 1.0

ml min-1 and UV-detection at 300

nm.

50-250 - Not stability

indicating, narrow

linear range.

16

5 Symmetry C8 column, 0.2 %

phosphoric acid and methanol

(65:35) as mobile phase at flow

rate of 1 ml min-1 and UV-

detection at 225 nm.

10-300 0.5 Stability

indicating, wide

linear range and

sensitive.

Present

work

336

REFERENCES

1. The Merck Index –An encyclopedia of chemicals, drugs and biologicals, 11th

edn., Merck and company, USA,1989, p.3757

2. British Pharmacopeia. Vol I & II Her Majesty’s Stationery office, London,

2009, p 1357.

3. http://en.wikipedia.org/wiki/Etamsylate

4. Martindale – The complete drug reference, 33rd edn., pharmaceutical press,

London, 2002, p. 732

5. K. Chitra, K. Sujatha, I. Rabia Ahmed, K. Shalini, B. Lakshmi Priya, S. S.

Varghese, Indian J. Pharm. Sci., 2005, 67, 98.

6. B.S. Kuchekar, V.S. Randive, A.P. Chaudhari, S.B. Bhise, Ind. J. Pharm. Sci.,

2003, 65, 184.

7. S. Elazaay Marwa, A. Shalaby, M.N. Elbolkiny, M. Khalil Hawa, Scientia

Pharmaceutica, 2004, 72, 73.

8. S. Elazaay Marwa, A. Shalaby, M.N. Elbolkiny, M. Khalil Hawa, Scientia

Pharmaceutica, 2003, 71, 211.

9. Y. El-Shabrawy, N. Elenany, K.M. Salem, IL Farmaco, 2004, 59, 803.

10. N. El-Enany, F. Belal, M. Rizk, J. AOAC Int., 2007, 90, 679.

11. G. Garg, S. Swarnalatha, S. Saraf, Ind. J. Pharm. Sci., 2007, 69, 279.

12. A. Goyal, I. Singhvi, Ind. J. Pharm. Sci., 2008, 70, 108.

13. R. Issarani, K.K. Vankar, D.K. Nayak, Int. J. ChemTech Res., 2010, 2, 74.

14. N. Kaul, H. Agrawal, A. Kakad, S.R. Dhaneshwar, B. Patil, Anal. Chim. Acta,

2005, 536, 49.

15. P. Nagaraju, K. Krishnachaithanya, V.D.N. Srinivas, S.V.N. Padma, Asian J.

Research Chem., 2008, 1, 88.

16. J. Yogini, T. Gokul, S. Sanjay, J. Liq. Chromatogr. Relat. Technol., 2007, 30,

1115.

17. J. Yogini, T. Gokul, S. Sanjay, J. Liq. Chromatogr. Relat. Technol., 2005, 18,

380.

337

18. J. Yogini, T. Gokul, S. Sanjay, J. Planar Chromatogr., 2005, 18, 460.

19. J. Yogini, T. Gokul, S. Sanjay, J. Planar Chromatogr., 2005, 18, 380.

20. C. Jia-Quan, S. Jun-Feng, C. Liang-Feng, Microchemical Journal, 2005, 80,

65.

21. F. Yang, C. Zhang, W.R.G. Baeyens, X. Zhang, J. Pharm. Biomed. Anal.,

2002, 30, 473.

22. C. Zhang, J. Huang, M. Feng, Z. Zhang, Anal. Lett., 1998, 31, 1917.

23. J. Du, Y. Li, Y. Tang, J. Lu, Anal. Lett., 2002, 35, 463.

24. S.S.M. Hassan, R.M. El-Bahnasawy, N.M. Rizk, Microchim. Acta, 1997, 126,

217.

25. International Conference On Harmonisation of Technical Requirements for

Registration of Pharmaceuticals for Human Use, ICH Harmonised Tripartite

Guideline, Validation of Analytical Procedures: Text and Methodology Q2(R

1), Complementary Guideline on Methodology dated 06 November 1996,

incorporated in November 2005, London.

26. M. Zeaiter, J.M. Roger, V.B. Maurel, D.N. Rutledge. Trends. Anal. Chem.,

2004, 23, 157.

27. M. Mulholland, Trends. Anal. Chem., 1988, 7, 383.

28. G.A. Shabir, J. Chromatogr. A., 2003, 987, 57.

![Antioxidant Cerium Oxide Nanoparticles in Biology and … · Antioxidant Cerium Oxide Nanoparticles in Biology ... dermal burn cream (Flammacerium) [5] ... Antioxidant Cerium Oxide](https://static.fdocuments.us/doc/165x107/5ade477c7f8b9ae1408e286b/antioxidant-cerium-oxide-nanoparticles-in-biology-and-cerium-oxide-nanoparticles.jpg)