Chapter 4 Treatment processes and systemsonsite.tennessee.edu/EPA Decentralized CD... · 15-03-1997...

Transcript of Chapter 4 Treatment processes and systemsonsite.tennessee.edu/EPA Decentralized CD... · 15-03-1997...

USEPA Onsite Wastewater Treatment Systems Manual (Click Here to Return to Bookmarks Page) 4-1

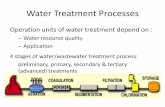

Chapter 4: Treatment Processes and Systems

4.1 IntroductionThis chapter contains information on individualonsite/decentralized treatment technologies or unitprocesses. Information on typical application,design, construction, operation, maintenance, cost,and pollutant removal effectiveness is provided formost classes of treatment units and their relatedprocesses. This information is intended to be usedin the preliminary selection of a system of treat-ment unit processes that can be assembled toachieve predetermined pollutant discharge concen-trations or other specific performance require-ments. Complete design specifications for unitprocesses and complete systems are not included inthe manual because of the number of processes andprocess combinations and the wide variability intheir application and operation under various siteconditions. Designers and others who require moredetailed technical information are referred to suchsources.

Chapter 4 is presented in two main sections. Thefirst section contains information about conven-tional (soil-based or subsurface wastewater infiltra-tion) systems, referred to as SWISs in this docu-ment. Both gravity-driven and mechanized SWISsare covered in this section of chapter 4. The secondsection contains a general introduction to sandfilters (including other media), and a series of factsheets on treatment technologies, alternativesystems (e.g., fixed-film and suspended growthsystems, evapotranspiration systems, and otherapplications), and special issues pertaining to thedesign, operation, and maintenance of onsitewastewater treatment systems (OWTSs). This

Chapter 4Treatment processes and systems

approach was used because the conventional systemis the most economical and practical system typethat can meet performance requirements in manyapplications.

The first section is further organized to provideinformation about the major components of aconventional system. Given the emphasis in thismanual on the design boundary (performance-based) approach to system design, this section wasstructured to lead the reader through a discussion ofsystem components by working backwards fromthe point of discharge to the receiving environmentto the point of discharge from the home or otherfacility served by the onsite system. Under thisapproach, soil infiltration issues are discussed first,the distribution piping to the infiltration systemincluding graveless sytems is addressed next, andmatters related to the most common preliminarytreatment device, the septic tank, are covered last.

The fact sheets in the second section of this chapterdescribe treatment technologies and discuss specialissues that might affect system design, perfor-mance, operation, and maintenance. These treat-ment technologies are often preceded by a septictank and can include a subsurface wastewaterinfiltration system. Some treatment technologiesmay be substituted for part or all of the conven-tional system, though nearly all alternative ap-proaches include a septic tank for each facilitybeing served. Fact sheets are provided for the morewidely used and successful treatment technologies,such as sand filters and aerobic treatment units.

4.1 Introduction

4.2 Conventional systems and treatment options

4.3 Subsurface wastewater infiltration

4.4 Design considerations

4.5 Construction management and contingency options

4.6 Septic tanks

4.7 Sand/media filters

4.8 Aerobic Treatment Units

Chapter 4: Treatment Processes and Systems

4-2 USEPA Onsite Wastewater Treatment Systems Manual

The component descriptions provided in thischapter are intended to assist the reader in screen-ing components and technologies for specificapplications. Chapter 5 presents a strategy andprocedures that can be used to screen and selectappropriate treatment trains and their componentsfor specific receiver sites. The reader should reviewchapter 5 before selecting system components.

4.2 Conventional systems andtreatment options

The three primary components of a conventionalsystem (figure 4-1) are the soil, the subsurfacewastewater infiltration system (SWIS; also called aleach field or infiltration trench), and the septictank. The SWIS is the interface between theengineered system components and the receivingground water environment. It is important to notethat the performance of conventional systems reliesprimarily on treatment of the wastewater effluentin the soil horizon(s) below the dispersal andinfiltration components of the SWIS. Informationon SWIS siting, hydraulic and mass loadings,design and geometry, distribution methods, andconstruction considerations is included in thischapter. The other major component of a conven-tional system, the septic tank, is characterized bydescribing its many functions in an OWTS.

Treatment options include physical, chemical, andbiological processes. Use of these options isdetermined by site-specific needs. Table 4-1 lists

common onsite treatment processes and methodsthat may be used alone or in combination toassemble a treatment train capable of meetingestablished performance requirements. Specialissues that might need to be addressed in OWTSdesign include treatment of high-strength wastes(e.g., biochemical oxygen demand and grease fromschools and restaurants), mitigation of impactsfrom home water softeners and garbage disposals,management of holding tanks, and additives (seerelated fact sheets).

4.3 Subsurface wastewaterinfiltration

Subsurface wastewater infiltration systems (SWISs)are the most commonly used systems for thetreatment and dispersal of onsite wastewater.Infiltrative surfaces are located in permeable,unsaturated natural soil or imported fill material sowastewater can infiltrate and percolate through theunderlying soil to the ground water. As the waste-water infiltrates and percolates through the soil, itis treated through a variety of physical, chemical,and biochemical processes and reactions.

Many different designs and configurations are used,but all incorporate soil infiltrative surfaces that arelocated in buried excavations (figure 4-1). Theprimary infiltrative surface is the bottom of theexcavation, but the sidewalls also may be used forinfiltration. Perforated pipe is installed to distributethe wastewater over the infiltration surface. A porous

Figure 4-1. Conventional subsurface wastewater infiltration system

USEPA Onsite Wastewater Treatment Systems Manual 4-3

Chapter 4: Treatment Processes and Systems

Table 4-1. Commonly used treatment processes and optional treatment methods

Chapter 4: Treatment Processes and Systems

4-4 USEPA Onsite Wastewater Treatment Systems Manual

medium, typically gravel or crushed rock, is placedin the excavation below and around the distributionpiping to support the pipe and spread the localizedflow from the distribution pipes across the excavationcavity. Other gravelless or “aggregate-free” systemcomponents may be substituted. The porousmedium maintains the structure of the excavation,exposes the applied wastewater to more infiltrativesurface, and provides storage space for the waste-water within its void fractions (interstitial spaces,typically 30 to 40 percent of the volume) during peakflows with gravity systems. A permeable geotextilefabric or other suitable material is laid over the porousmedium before the excavation is backfilled to preventthe introduction of backfill material into the porousmedium. Natural soil is typically used for backfilling,and the surface of the backfill is usually slightlymounded and seeded with grass.

Subsurface wastewater infiltration systems provideboth dispersal and treatment of the applied waste-water. Wastewater is transported from the infiltrationsystem through three zones (see chapter 3). Two ofthese zones, the infiltration zone and vadose zone, actas fixed-film bioreactors. The infiltration zone, whichis only a few centimeters thick, is the most biologi-cally active zone and is often referred to as the“biomat.” Carbonaceous material in the wastewater isquickly degraded in this zone, and nitrification occursimmediately below this zone if sufficient oxygen ispresent. Free or combined forms of oxygen in the soilmust satisfy the oxygen demand generated by themicroorganisms degrading the materials. If sufficientoxygen is not present, the metabolic processes of themicroorganisms can be reduced or halted and bothtreatment and infiltration of the wastewater will beadversely affected (Otis, 1985). The vadose (unsatur-ated) zone provides a significant pathway for oxygendiffusion to reaerate the infiltration zone (Otis, 1997,Siegrist et al., 1986). Also, it is the zone where mostsorption reactions occur because the negative moisturepotential in the unsaturated zone causes percolatingwater to flow into the finer pores of the soil, resultingin greater contact with the soil surfaces. Finally, muchof the phosphorus and pathogen removal occurs inthis zone (Robertson and Harman, 1999; Robertson etal., 1998; Rose et al., 1999; Yates and Yates, 1988).

4.3.1 SWIS designs

There are several different designs for SWISs.They include trenches, beds, seepage pits, at-grade

systems, and mounds. SWIS applications differ intheir geometry and location in the soil profile.Trenches have a large length-to-width ratio, whilebeds have a wide, rectangular or square geometry.Seepage pits are deep, circular excavations that relyalmost completely on sidewall infiltration. Seepagepits are no longer permitted in many jurisdictionsbecause their depth and relatively small horizontalprofile create a greater point-source pollutantloading potential to ground water than othergeometries. Because of these shortcomings, seepagepits are not recommended in this manual.

Infiltration surfaces may be created in natural soilor imported fill material. Most traditional systemsare constructed below ground surface in naturalsoil. In some instances, a restrictive horizon abovea more permeable horizon may be removed and theexcavation filled with suitable porous material inwhich to construct the infiltration surface (Hinsonet al., 1994). Infiltration surfaces may be con-structed at the ground surface (“at-grades”) orelevated in imported fill material above the naturalsoil surface (“mounds”). An important differencebetween infiltration surfaces constructed in naturalsoil and those constructed in fill material is that asecondary infiltrative surface (which must beconsidered in design) is created at the fill/naturalsoil interface. Despite the differences between thetypes of SWISs, the mechanisms of treatment anddispersal are similar.

4.3.2 Typical applications

Subsurface wastewater infiltration systems arepassive, effective, and inexpensive treatmentsystems because the assimilative capacity of manysoils can transform and recycle most pollutantsfound in domestic and commercial wastewaters.SWISs are the treatment method of choice in rural,unsewered areas. Where point discharges to surfacewaters are not permitted, SWISs offer an alterna-tive if ground water is not closely interconnectedwith surface water. Soil characteristics, lot size, andthe proximity of sensitive water resources affect theuse of SWISs. Table 4-2 presents characteristics fortypical SWIS applications and suggests applicationsto avoid. Local codes should be consulted forspecial requirements, restrictions, and otherrelevant information.

USEPA Onsite Wastewater Treatment Systems Manual 4-5

Chapter 4: Treatment Processes and Systems

4.3.3 Typical performance

Results from numerous studies have shown thatSWISs achieve high removal rates for most waste-water pollutants of concern (see chapter 3) with thenotable exception of nitrogen. Biochemical oxygendemand, suspended solids, fecal indicators, andsurfactants are effectively removed within 2 to 5feet of unsaturated, aerobic soil (figure 4-2).Phosphorus and metals are removed throughadsorption, ion exchange, and precipitation reac-tions. However, the retention capacity of the soil isfinite and varies with soil mineralogy, organiccontent, pH, redox potential, and cation exchangecapacity. The fate of viruses and toxic organiccompounds has not been well documented (Tomsonet al., 1984). Field and laboratory studies suggestthat the soil is quite effective in removing viruses,but some types of viruses apparently are able toleach from SWISs to the ground water. Fine-textured soils, low hydraulic loadings, aerobicsubsoils, and high temperatures favor destruction ofviruses and toxic organics. The most significantdocumented threats to ground water quality from

SWISs are nitrates. Wastewater nitrogen is nearlycompletely nitrified below properly operatingSWISs. Because nitrate is highly soluble andenvironments favoring denitrification in subsoil arelimited, little removal occurs (see chapter 3).Chlorides also leach readily to ground waterbecause they, too, are highly soluble and arenonreactive in soil.

Figure 4-2. Lateral view of conventional SWIS-based system

Source: Bouma, 1975.

aAvoid when possible.Source: Adapted from WEF, 1990.

Table 4-2. Characteristics of typical SWIS applications

Chapter 4: Treatment Processes and Systems

4-6 USEPA Onsite Wastewater Treatment Systems Manual

Dispersion of SWIS percolate in the ground wateris often minimal because most ground water flow islaminar. The percolate can remain for severalhundred feet as a distinct plume in which the soluteconcentrations remain above ambient ground waterconcentrations (Robertson et al., 1989, Shaw andTuryk, 1994). The plume descends in the groundwater as the ground water is recharged from thesurface, but the amount of dispersion of the plumecan be variable. Thus, drinking water wells somedistance from a SWIS can be threatened if they aredirectly in the path of a percolate plume.

4.4 Design considerations

Onsite wastewater treatment system designs varyaccording to the site and wastewater characteristicsencountered. However, all designs should strive toincorporate the following features to achievesatisfactory long-term performance:

• Shallow placement of the infiltration surface(< 2 feet below final grade)

• Organic loading comparable to that of septictank effluent at its recommended hydraulicloading rate

• Trench orientation parallel to surface contours

• Narrow trenches (< 3 feet wide)

• Timed dosing with peak flow storage

• Uniform application of wastewater over theinfiltration surface

• Multiple cells to provide periodic resting,standby capacity, and space for future repairs orreplacement

Based on the site characteristics, compromises toideal system designs are necessary. However, thedesigner should attempt to include as many of theabove features as possible to ensure optimal long-term performance and minimal impact on publichealth and environmental quality.

4.4.1 Placement of the infiltrationsurface

Placement of a SWIS infiltration surface may bebelow, at, or above the existing ground surface (inan in-ground trench, at grade, or elevated in a

mound system). Actual placement relative to theoriginal soil profile at the site is determined bydesired separation from a limiting condition(figure 4-3). Treatment by removal of additionalpollutants during movement through soils and thepotential for excessive ground water mounding willcontrol the minimum separation distance from alimiting condition. The depth below final grade isaffected by subsoil reaeration potential. Maximumdelivery of oxygen to the infiltration zone is mostlikely when soil components are shallow andnarrow and have separated infiltration areas.(Erickson and Tyler, 2001).

4.4.2 Separation distance from alimiting condition

Placement of the infiltration surface in the soilprofile is determined by both treatment and hy-draulic performance requirements. Adequateseparation between the infiltration surface and anysaturated zone or hydraulically restrictive horizonwithin the soil profile (secondary design boundaryas defined in section 5.3.1) must be maintained toachieve acceptable pollutant removals, sustainaerobic conditions in the subsoil, and provide anadequate hydraulic gradient across the infiltrationzone. Treatment needs (performance requirements)establish the minimum separation distance, but thepotential for ground water mounding or theavailability of more permeable soil may make itadvantageous to increase the separation distance byraising the infiltration surface in the soil profile.

Most current onsite wastewater system codesrequire minimum separation distances of at least 18inches from the seasonally high water table orsaturated zone irrespective of soil characteristics.Generally, 2- to 4-foot separation distances haveproven to be adequate in removing most fecalcoliforms in septic tank effluent (Ayres Associates,1993). However, studies have shown that theapplied effluent quality, hydraulic loading rates,and wastewater distribution methods can affect theunsaturated soil depth necessary to achieve accept-able wastewater pollutant removals. A few studieshave shown that separation distances of 12 to 18inches are sufficient to achieve good fecal coliformremoval if the wastewater receives additionalpretreatment prior to soil application (Converse andTyler, 1998a, 1998b; Duncan et al., 1994). How-ever, when effluents with lower organic and

USEPA Onsite Wastewater Treatment Systems Manual 4-7

Chapter 4: Treatment Processes and Systems

oxygen-demanding content are applied to theinfiltration surface at greater hydraulic loadingrates than those typically used for septic tankeffluents (during extended periods of peak flow),treatment efficiency can be lost (Converse andTyler, 1998b, Siegrist et al., 2000).

Reducing the hydraulic loading rate or providinguniform distribution of the septic tank effluent hasbeen shown to reduce the needed separationdistance (Bomblat et al., 1994; Converse and Tyler,1998a; Otis, 1985; Siegrist et al., 2000; Simon andReneau, 1987). Reducing both the daily andinstantaneous hydraulic loading rates and providinguniform distribution over the infiltration surfacecan help maintain lower soil moisture levels.Lower soil moisture results in longer wastewaterretention times in the soil and causes the wastewa-ter to flow though the smaller soil pores in theunsaturated zone, both of which enhance treatmentand can reduce the necessary separation distance.

Based only on hydraulics, certain soils requiredifferent vertical separation distances from ground

water to avoid hydrologic interference with theinfiltration rate. From a treatment standpoint,required separation distances are affected by dosingpattern, loading rate, temperature, and soil charac-teristics. Uniform, frequent dosing (more than 12times/day) in coarser soils maximizes the effective-ness of biological, chemical, and physical treatmentmechanisms. To offset inadequate vertical separa-tion, a system designer can raise the infiltrationsurface in an at-grade system or incorporate amound in the design. If the restrictive horizon is ahigh water table and the soil is porous, the watertable can be lowered through the use of drainagetile or a curtain drain if the site has sufficient reliefto promote surface discharge from the tile piping.For flat terrain with porous soils, a commercialsystem has been developed and is being field tested.It lowers the water table with air pressure, therebyavoiding any aesthetic concerns associated with araised mound on the site. Another option usedwhere the terrain is flat and wet is pumped drain-age surrounding the OWTS (or throughout thesubdivision) to lower the seasonal high water tableand enhance aerobic conditions beneath the

Figure 4-3. Suggested subsurface infiltration system design versus depth (below the original ground surface) to alimiting condition

Source: Otis, 2001.

Chapter 4: Treatment Processes and Systems

4-8 USEPA Onsite Wastewater Treatment Systems Manual

drainfield. These systems must be properly oper-ated by certified operators and managed by a publicmanagement entity since maintenance of off-lotportions of the drainage network will influenceperformance of the SWIS.

The hydraulic capacity of the site or the hydraulicconductivity of the soil may increase the minimumacceptable separation distance determined bytreatment needs. The soil below the infiltrationsurface must be capable of accepting and transmit-ting the wastewater to maintain the desired unsatur-ated separation distance at the design hydraulicloading rate to the SWIS. The separation distancenecessary for satisfactory hydraulic performance isa function of the permeability of the underlyingsoil, the depth to the limiting condition, thethickness of the saturated zone, the percentage ofrocks in the soil, and the hydraulic gradient.Ground water mounding analyses may be necessaryto assess the potential for the saturated zone to riseand encroach upon the minimum acceptableseparation distance (see section 5.4). Raising theinfiltration surface can increase the hydrauliccapacity of the site by accommodating moremounding. If the underlying soil is more slowlypermeable than soil horizons higher in the profile,it might be advantageous to raise the infiltrationsurface into the more permeable horizon wherehigher hydraulic loading rates are possible (Hooveret al., 1991; Weymann et al., 1998). A shallowinfiltration system covered with fill or an at-gradesystem can be used if the natural soil has a shallowpermeable soil horizon (Converse et al., 1990;Penninger, and Hoover, 1998). If more permeablehorizons do not exist, a mound system constructedof suitable sand fill (figure 4-4) can provide morepermeable material in which to place the infiltra-tion surface.

4.4.3 Depth of the infiltration surface

The depth of the infiltration surface is an importantconsideration in maintaining adequate subsoilaeration and frost protection in cold climates. Themaximum depth should be limited to no more than3 to 4 feet below final grade to adequately reaeratethe soil and satisfy the daily oxygen demand of theapplied wastewater. The infiltrative surface depthshould be less in slowly permeable soils or soilswith higher ambient moisture. Placement belowthis depth to take advantage of more permeable

soils should be resisted because reaeration of thesoil below the infiltration surface will be limited.In cold climates, a minimum depth of 1 to 2 feetmay be necessary to protect against freezing.Porous fill material can be used to provide thenecessary cover even with an elevated (at-grade ormound) system if it is necessary to place theinfiltration surface higher.

4.4.4 Subsurface drainage

Soils with shallow saturated zones sometimes canbe drained to allow the infiltration surface to beplaced in the natural soil. Curtain drains, verticaldrains, underdrains, and mechanically assistedcommercial systems can be used to drain shallowwater tables or perched saturated zones. Of thethree, curtain drains are most often used in onsitewastewater systems to any great extent. They canbe used effectively to remove water that is perchedover a slowly permeable horizon on a sloping site.However, poorly drained soils often indicate othersoil and site limitations that improved drainagealone will not overcome, so the use of drainageenhancements must be carefully considered. Anysloping site that is subject to frequent inundationduring prolonged rainfall should be considered acandidate for upslope curtain drains to maintainunsaturated conditions in the vadose zone.

Curtain drains are installed upslope of the SWIS tointercept the permanent and perched ground waterflowing through the site over a restrictive horizon.Perforated pipe is laid in the bottom of upslopetrenches excavated into the restrictive horizon. Adurable, porous medium is placed around thepiping and up to a level above the estimatedseasonally high saturated zone. The porous mediumintercepts the ground water and conveys it to thedrainage pipe (figure 4-5). To provide an outfallfor the drain, one or both ends of the pipe areextended downslope to a point where it interceptsthe ground surface. When drainage enhancementsare used, the outlet and boundary conditions mustbe carefully evaluated to protect local waterquality.

The drain should avoid capture of the SWISpercolate plume and ground water infiltrating frombelow the SWIS or near the end of the drain. Aseparation distance between the SWIS and the drainthat is sufficient to prevent percolate from the

USEPA Onsite Wastewater Treatment Systems Manual 4-9

Chapter 4: Treatment Processes and Systems

SWIS from entering the drain should be main-tained. The vertical distance between the bottom ofthe SWIS and the drain and soil permeabilitycharacteristics should determine this distance. Asthe vertical distance increases and the permeabilitydecreases, the necessary separation distance in-creases. A 10-foot separation is used for mostapplications. Also, if both ends of the drain cannotbe extended to the ground surface, the upslope endshould be extended some distance along the surfacecontour beyond the end of the SWIS. If not done,

ground water that seeps around the end of the draincan render the drain ineffective. Similar cautionsshould be observed when designing and locatingoutlet locations for commercial systems on flatsites.

The design of a curtain drain is based on thepermeability of the soil in the saturated zone, thesize of the area upslope of the SWIS that contrib-utes water to the saturated zone, the gradient of thedrainage pipe, and a suitable outlet configuration.

Figure 4-4. Raising the infiltration surface with a typical mound system.

CurtainDrain

FillMaterial

PerchedWaterTable Gravel Filled

Above HighWater Table

Drainage Pipe

Impermeable Layer

AbsorptionTrenches

Fill

Figure 4-5. Schematic of curtain drain constructionSource: USEPA, 1980

Source: ASAE, Converse and Tyler, 1998b.

Chapter 4: Treatment Processes and Systems

4-10 USEPA Onsite Wastewater Treatment Systems Manual

If the saturated hydraulic conductivity is low andthe drainable porosity (the percentage of pore spacedrained when the soil is at field capacity) is small,even effectively designed curtain drains might havelimited effect on soil wetness conditions. Penningeret al. (1998) illustrated this at a site with a siltyclay loam soil at field capacity that became com-pletely re-saturated with as little as 1-inch ofprecipitation. Figure 4-6 provides a useful designchart that considers most of these parameters. Forfurther design guidance, refer to the U.S. Depart-ment of Agriculture’s Drainage of AgriculturalLand (USDA, 1973).

4.4.5 Sizing of the infiltration surface

The minimum acceptable infiltration surface area isa function of the maximum anticipated dailywastewater volume to be applied and the maximuminstantaneous and daily mass loading limitations ofthe infiltration surface (see chapter 5). Both thebottom and sidewall area of the SWIS excavationcan be infiltration surfaces; however, if the sidewallis to be an active infiltration surface, the bottomsurface must pond. If continuous ponding of theinfiltration surface persists, the infiltration zonewill become anaerobic, resulting in loss of hydrau-lic capacity. Loss of the bottom surface for infiltra-tion will cause the ponding depth to increase overtime as the sidewall also clogs (Bouma, 1975; Keyset al., 1998; Otis, 1977). If allowed to continue,

hydraulic failure of the system is probable. There-fore, including sidewall area as an active infiltra-tion surface in design should be avoided. Ifsidewall areas are included, provisions should bemade in the design to enable removal of the pondedsystem from service periodically to allow thesystem to drain and the biomat to oxidize naturally.

Design flowAn accurate estimation of the design flow is criticalto infiltration surface sizing. For existing buildingswhere significant changes in use are not expected,water service metering will provide good estimatesfor design. It is best to obtain several weeks ofmetered daily flows to estimate daily average andpeak flows. For new construction, water usemetering is not possible and thus waste flowprojections must be made based on similar estab-lishments. Tables of “typical” water use or waste-water flows for different water use fixtures, usagepatterns, and building uses are available (seesection 3.3.1). Incorporated into these guidelinesare varying factors of safety. As a result, the use ofthese guides typically provides conservatively highestimates of maximum peak flows that may occuronly occasionally. It is critical that the designerrecognizes the conservativeness of these guides andhow they can be appropriately adjusted because oftheir impacts on the design and, ultimately, perfor-mance of the system.

Curtain drain designCurtain drain designCurtain drain designCurtain drain designCurtain drain design

Curtain drain design (see preceding figures) is dependent on the size of the contributing drainage area, theamount of water that must be removed, the soil’s hydraulic properties, and the available slope of the site.

The contributing drainage area is estimated by outlining the capture zone on a topographic map of the site.Drainage boundaries are determined by extending flow lines perpendicular to the topographic contours upslopefrom the drain to natural divides (e.g., ridge tops) or natural or man-made “no-flow” boundaries (e.g., rockoutcrops, major roads). The amount of water that must be removed is an estimate of the volume of precipitationthat would be absorbed by the soil after a rainfall event. This is called the drainage coefficient, which is expressedas the depth of water to be removed over a specified period of time, typically 24 hours. Soil structure, texture,bulk density, slope, and vegetated cover all affect the volume of water to be drained.

The slope of the drain can be determined after the upslope depth of the drain invert and the outfall invert areestablished. These can be estimated from the topographic map of the site. The contributing drainage area, watervolume to be removed, and slope of the drain are estimated. Figure 4-6 can be used to determine the draindiameter. For example, the diameter of a curtain drain that will drain an area upslope of 50 acres with a drainagecoefficient of ¾ inch on a slope of 5 percent would be 8 inches (see figure). At 0.5 percent, the necessary draindiameter would be 12 inches.

USEPA Onsite Wastewater Treatment Systems Manual 4-11

Chapter 4: Treatment Processes and Systems

DRAINAGE CHART FOR

CORRUGATED PLASTIC DRAINAGE TUBING

GRADE IN CENTIMETERS PER METER

0.05 0.1 0.2 0.3 0.4 0.5 1.0 2.0 3.0 5.04.0 101009080807060

50

40

30

20

15

10

5

4

3

2

1.5

1.0

0.8

0.6

0.4

0.3

0.15

0.3

0.2

0.10

0.060.05 0.1 0.2 0.3 0.4 0.5 1.0 2.0 3.0 4.0 5.0 10

GRADE IN FEET PER 100 FEET

Space between lines is the range of drain

capacity for the size shown between lines

V= velocity in feet per second

n=0.015

DIS

CH

AR

GE

INC

UB

ICF

EE

TP

ER

SE

CO

ND

ACRES

DRAINED

5000

6000

4500

4000

3500

3000

2500

2000

1500

1200

1000900

800

700

600

500450

400

350

300

250

200180160

140

120

100

9080

70

60

504540

35

30

25

20

15

10

98

7

6

5

4

4

4

4

5

5

510

10

10

15

15

15

20

20

20

25

25

25

30

30

30

35

35

35

40

40

40

45

45

45

50

50

50

60

60

60

70

70

70

80

80

80

90

90

90

100

100

100

120

120

120

140

140

140

160

160

160

180

180

200

200

200

250

250

250

300

300

300

350

350

350

400

400

400

450

450

450

500

500

500

600

600

600

700

700

700

800

800

800

900

900

900

1000

1000

1000

1200

1200

1200

1500

1500

1500

2000

2000

2000

2500

2500

3000

3000

3500

40004500

3

3

3

2

2

1”3”8

1”2

3”4

DRAINAGE

COEFFICIENT

30”

24”

20”

18”

16”

14”

12”

10”

8”

6”

5”

4”

V=

2

V=

1

V=

1.4

V=

3

V=

4

V=

5

V=

6

V=

8

V=

10

V=

15

180

Figure 4-6. Capacity chart for subsurface drains

Source: USDA, 1973.

Chapter 4: Treatment Processes and Systems

4-12 USEPA Onsite Wastewater Treatment Systems Manual

Table 4-3. Suggested hydraulic and organic loading rates for sizing infiltration surfaces

Source: Adapted from Tyler, 2000.

Infiltration surface loading limitationsInfiltration surface hydraulic loading design ratesare a function of soil morphology, wastewaterstrength, and SWIS design configuration. Hydrau-lic loadings are traditionally used to size infiltrationsurfaces for domestic septic tank effluent. In thepast, soil percolation tests determined acceptablehydraulic loading rates. Codes provided tables thatcorrelated percolation test results to the necessaryinfiltration surface areas for different classes ofsoils. Most states have supplemented this approachwith soil morphologic descriptions. Morphologicfeatures of the soil, particularly structure, texture,and consistence, are better predictors of the soil’shydraulic capacity than percolation tests (Brown etal., 1994; Gross et al., 1998; Kleiss and Hoover,

1986; Simon and Reneau, 1987; Tyler et al., 1991;Tyler and Converse, 1994). Although soil textureanalysis supplemented the percolation test in moststates by the mid-1990s, soil structure has onlyrecently been included in infiltrative surface sizingtables (table 4-3). Consistence, a measure of howwell soils form shapes and stick to other objects, isan important consideration for many slowlypermeable soil horizons. Expansive clay soils thatbecome extremely firm when moist and very stickyor plastic when wet (exhibiting firm or extremelyfirm consistence) are not well suited for SWISs.

Not all soil conditions are represented in table 4-3,which is a generic guide to the effects of soilproperties on the performance of SWISs. Also

USEPA Onsite Wastewater Treatment Systems Manual 4-13

Chapter 4: Treatment Processes and Systems

available are many other state and local guides thatinclude loadings for soils specific to local geomor-phology. North Carolina, for example, uses thelong-term acceptance rate (LTAR) for soil load-ings, which is the volume of wastewater that can beapplied to a square foot of soil each day over anindefinite period of time such that the effluentfrom the onsite system is absorbed and properlytreated (North Carolina DEHNR, 1996). In theNorth Carolina rules, LTAR and loading rate valuesare the same.

Increasingly, organic loading is being used to sizeinfiltration surfaces. Based on current understand-ing of the mechanisms of SWIS operation, organicloadings and the reaeration potential of the subsoilto meet the applied oxygen demand are criticalconsiderations in successful SWIS design. Anaero-bic conditions are created when the applied oxygendemand exceeds what the soil is able to supply bydiffusion through the vadose zone (Otis, 1985,1997; Siegrist et al., 1986). The facultative andanaerobic microorganisms that are able to thrive inthis environment are less efficient in degrading thewaste materials. The accumulating waste materialsand the metabolic by-products cause soil cloggingand loss of infiltrative capacity.

Further, higher forms of soil fauna that would helpbreak up the biomat (e.g., worms, insects, non-wetland plants) and would be attracted to thecarbon and nutrient-rich infiltration zone arerepelled by the anoxic or anaerobic environment. Ifwastewater application continues without ampletime to satisfy the oxygen demand, hydraulicfailure due to soil clogging occurs. Numerousstudies have shown that wastewaters with low BODconcentrations (e.g., < 50 mg/L) can be applied tosoils at rates 2 to 16 times the typical hydraulicloading rate for domestic septic tank effluent (Jonesand Taylor, 1965; Laak, 1970, 1986; Louden et al.,1998; Otis, 1985; Siegrist and Boyle, 1987; Tylerand Converse, 1994).

The comparatively higher hydraulic loadings thathighly treated wastewater (highly treated in termsof TSS, ammonium-nitrogen, and BOD) maypermit should be considered carefully because theresulting rapid flow through the soil may allowdeep penetration of pathogens (Converse and Tyler,1998a, 1998b; Siegrist et al., 2000; Siegrist andVan Cuyk, 2001b; Tyler and Converse, 1994). Thetrench length perpendicular to ground water

movement (footprint) should remain the same tominimize system impacts on the aquifer.

Unfortunately, well-tested organic loading rates forvarious classes of soils and SWIS design configura-tions have not been developed. Most organicloading rates have been derived directly from thehydraulic loadings typically used in SWIS designby assuming a BOD5 concentration (see box andtable 4-3). The derived organic loading rates alsoincorporate the implicit factor of safety found inthe hydraulic loading rates. Organic loadings doappear to have less impact on slowly permeablesoils because the resistance of the biomat that formsat the infiltrative surface presents less resistance toinfiltration of the wastewater than the soil itself(Bouma, 1975). For a further discussion of SWISperformance under various environmental condi-tions, see Siegrist and Van Cuyk, 2001b.

Constituent mass loadingsConstituent mass loadings may be a concern withrespect to water quality. For example, to use thesoil’s capacity to adsorb and retain phosphoruswhen systems are located near sensitive surfacewaters, a phosphorus loading rate based on the soiladsorption capacity might be selected as thecontrolling rate of wastewater application to theinfiltration surface to maximize phosphorusremoval. Placement of the effluent distributionpiping high in the soil profile can promote greaterphosphorus removal because the permeability ofmedium- and fine-textured soils tends to decreasewith depth and because the translocation of alumi-num and iron—which react with phosphorus toform insoluble compounds retained in the soilmatrix—occurs in some sandy soils, with themaximum accumulation usually above 45 cm(Mokma et al., 2001). Many lakes are surroundedby sandy soils with a low phosphorus adsorptioncapacity. If effluent distribution systems areinstalled below 45 cm in these sandy soils, lessphosphorus will be removed from the percolatingeffluent. In the case of a soluble constituent ofconcern such as nitrate-nitrogen, a designer mightdecide to reduce the mass of nitrate per unit ofapplication area. This would have the effect ofincreasing the size of the SWIS footprint, therebyreducing the potential concentration of nitrate inthe ground water immediately surrounding theSWIS (Otis, 2001).

Chapter 4: Treatment Processes and Systems

4-14 USEPA Onsite Wastewater Treatment Systems Manual

4.4.6 Geometry, orientation, andconfiguration of the infiltrationsurface

The geometry, orientation, and configuration of theinfiltration surface are critical design factors thataffect the performance of SWISs. They are impor-tant for promoting subsoil aeration, maintaining anacceptable separation distance from a saturatedzone or restrictive horizon, and facilitating con-struction. Table 4-4 lists the design considerationsdiscussed in this section.

GeometryThe width and length of the infiltration surface areimportant design considerations to improve perfor-mance and limit impacts on the receiving environ-ment. Trenches, beds, and seepage pits (or drywells) are traditionally used geometries. Seepagepits can be effective for wastewater dispersal, butthey provide little treatment because they extenddeep into the soil profile, where oxygen transferand treatment are limited and the separationdistance to ground water is reduced. They are notrecommended for onsite wastewater treatment andare not included as an option in this manual.

Width

Infiltration surface clogging and the resulting lossof infiltrative capacity are less where the infiltra-tion surface is narrow. This appears to occurbecause reaeration of the soil below a narrowinfiltration surface is more rapid. The dominantpathway for oxygen transport to the subsoil appearsto be diffusion through the soil surrounding theinfiltration surface (figure 4-7). The unsaturatedzone below a wide surface quickly becomesanaerobic because the rates of oxygen diffusion aretoo low to meet the oxygen demands of biota andorganics on the infiltration surface. (Otis, 1985;Siegrist et al., 1986). Therefore, trenches performbetter than beds. Typical trench widths range from1 to 4 feet. Narrower trenches are preferred, butsoil conditions and construction techniques mightlimit how narrow a trench can be constructed. Onsloping sites, narrow trenches are a necessitybecause in keeping the infiltration surface level, theuphill side of the trench bottom might be excavatedinto a less suitable soil horizon. Wider trenchinfiltration surfaces have been successful in at-grade systems and mounds probably because theengineered fill material and elevation above thenatural grade promote better reaeration of the fill.

Factors of safety in infiltration surface sizingFactors of safety in infiltration surface sizingFactors of safety in infiltration surface sizingFactors of safety in infiltration surface sizingFactors of safety in infiltration surface sizingSizing of onsite wastewater systems for single-family homes is typically based on the estimated peak daily flowand the “long term acceptance rate” of the soil for septic tank effluent. In most states, the design flow is based onthe number of bedrooms in the house. A daily flow of 150 gallons is commonly assumed for each bedroom. Thisdaily flow per bedroom assumes two people per bedroom that generate 75 gpd each. Bedrooms, rather thancurrent occupancy, are used for the basis of SWIS design because the number of occupants in the house canchange.

Using this typical estimating procedure, a three-bedroom home would have a design flow of 150 gpd/bedroom x 3bedrooms or 450 gpd. However, the actual daily average flow could be much less. Based on the 1990 census, theaverage home is occupied by 2.8 persons. Each person in the United States generates 45 to 70 gpd of domesticwastewater. Assuming these averages, the average daily flow would be 125 to 195 gpd or 28 to 44 percent of thedesign flow, respectively. Therefore, the design flow includes an implicit factor of safety of 2.3 to 3.6. Of course,this factor of safety varies inversely with the home occupancy and water use.

Unfortunately, the factors of safety implicitly built into the flow estimates are seldom recognized. This isparticularly true in the case of the design hydraulic loading rates, which were derived from existing SWISs. Inmost codes, the hydraulic loading rates for sand are about 1.0 to 1.25 gpd/ft2. Because these hydraulic loadingrates assume daily flows of 150 gpd per bedroom, they are overestimated by a factor of 2.3 to 3.6. Fortunately,these two assumptions largely cancel each other out in residential applications, but the suggested hydraulicloading rates often are used to size commercial systems and systems for schools and similar facilities, where theratios between design flows and actual daily flows are closer to 1.0. This situation, combined with a lack of usefulinformation on allowable organic loading rates, has resulted in failures, particularly for larger systems whereactual flow approximates design.

USEPA Onsite Wastewater Treatment Systems Manual 4-15

Chapter 4: Treatment Processes and Systems

However, infiltration bed surface widths of greaterthan 10 feet are not recommended because oxygentransfer and clogging problems can occur (Con-verse and Tyler, 2000; Converse et al., 1990).

LengthThe trench length is important where downslopelinear loadings are critical, ground water qualityimpacts are a concern, or the potential for ground

water mounding exists. In many jurisdictions,trench lengths have been limited to 100 feet. Thisrestriction appeared in early codes written forgravity distribution systems and exists as an artifactwith little or no practical basis when pressuredistribution is used. Trench lengths longer than 100feet might be necessary to minimize ground waterimpacts and to permit proper wastewater drainagefrom the site. Long trenches can be used to reducethe linear loadings on a site by spreading the

Comparing hydraulic and organic mass loadings for a restaurant wastewaterComparing hydraulic and organic mass loadings for a restaurant wastewaterComparing hydraulic and organic mass loadings for a restaurant wastewaterComparing hydraulic and organic mass loadings for a restaurant wastewaterComparing hydraulic and organic mass loadings for a restaurant wastewater

Infiltration surface sizing traditionally has been based on the daily hydraulic load determined through experienceto be acceptable for the soil characteristics. This approach to sizing fails to account for changes in appliedwastewater strength. Since soil clogging has been shown to be dependent on applied wastewater strength, itmight be more appropriate to size infiltration surfaces based on organic mass loadings.

To illustrate the impact of the different sizing methods, sizing computations for a restaurant are compared. Aseptic tank is used for pretreatment prior to application to the SWIS. The SWIS is to be constructed in a sandyloam with a moderate, subangular blocky structure. The suggested hydraulic loading rate for domestic septic tankeffluent on this soil is 0.6 gpd/ft2 (table 4-3). The restaurant septic tank effluent has the following characteristics:

BOD5

800 mg/L

TSS 200 mg/L

Average daily flow 600 gpd

Infiltration area based on hydraulic loading:Infiltration area based on hydraulic loading:Infiltration area based on hydraulic loading:Infiltration area based on hydraulic loading:Infiltration area based on hydraulic loading:

Area = 600 gpd/0.6 gpd/ft2 = 1,000 ft2

Infiltration area based on organic loading:Infiltration area based on organic loading:Infiltration area based on organic loading:Infiltration area based on organic loading:Infiltration area based on organic loading:

At the design infiltration rate of 0.6 gpd/ft2 recommended for domestic septic tank effluent, the equivalent organicloading is (assuming a septic tank BOD

5 effluent concentration of 150 mg/L)

Organic Loading = 150 mg/L x 0.6 gpd/ft2 x (8.34 lb/mg/L x 10-6 gal)

= 7.5 x 10-4 lb BOD5/ft2-d

Assuming 7.5 x 10-4 lb BOD5/ft2-d as the design organic loading rate,

Area = (800 mg-BOD5/L x 600 gpd x 8.34 lbs/mg/L x 10-6 gal)

(7.5 x 10-4 lb BOD5/ft2-d)

= 4.0 lb BOD5/d = 5337 ft2 (a 540% increase)

(7.5 x 10-4 lb BOD5/ft2-d)

Impact of a 40% water use reduction on infiltration area sizingImpact of a 40% water use reduction on infiltration area sizingImpact of a 40% water use reduction on infiltration area sizingImpact of a 40% water use reduction on infiltration area sizingImpact of a 40% water use reduction on infiltration area sizing

Based on hydraulic loading,

Area = (1 – 0.4) x 600 gpd = 600 ft2

0.6 gpd/ft2

Based on organic loading (note the concentration of BOD5 increases with water conservation but the mass of

BOD5

discharged does not change),

Area = (800 mg-BOD5/L x 600 gpd) x (8.34 lb/mg/L x 10-6 gal)

[(1 – 0.4) x 600 gpd] x (7.5 x 10-4 lb BOD5/ft2-d)

= 4.0 lb BOD5/d = 5337 ft2 (an 890% increase)

(7.5 x 10-4 lb BOD5/ft2-d)

Chapter 4: Treatment Processes and Systems

4-16 USEPA Onsite Wastewater Treatment Systems Manual

Figure 4-7. Pathway of subsoil reaeration

Source: Ayres Associates, 2000

Table 4-4. Geometry, orientation, and configuration considerations for SWISs

USEPA Onsite Wastewater Treatment Systems Manual 4-17

Chapter 4: Treatment Processes and Systems

wastewater loading parallel to and farther along thesurface contour. With current distribution/dosingtechnology, materials, and construction methods,trench lengths need be limited only by what ispractical or feasible on a given site. Also, use ofstandard trench lengths, e.g., X feet of trench/BR,is discouraged because it restricts the design optionsto optimize performance for a given site condition.

HeightThe height of the sidewall is determined primarilyby the type of porous medium used in the system,the depth of the medium needed to encase thedistribution piping, and/or storage requirements forpeak flows. Because the sidewall is not included asan active infiltration surface in sizing the infiltra-tion area, the height of the sidewall can be mini-mized to keep the infiltration surface high in thesoil profile. A height of 6 inches is usually suffi-cient for most porous aggregate applications. Useof a gravelless system requires a separate analysisto determine the height based on whether it is anaggregate-free (empty chamber) design or one thatsubstitutes a lightweight aggregate for washedgravel or crushed stone.

OrientationOrientation of the infiltration surface(s) becomesan important consideration on sloping sites, siteswith shallow soils over a restrictive horizon orsaturated zone, and small or irregularly shaped lots.The long axes of trenches should be alignedparallel to the ground surface contours to reducelinear contour hydraulic loadings and ground watermounding potential. In some cases, ground wateror restrictive horizon contours may differ fromsurface contours because of surface grading or thesoil’s morphological history. Where this occurs,consideration should be given to aligning thetrenches with the contours of the limiting conditionrather than those of the surface. Extending thetrenches perpendicular to the ground water gradientreduces the mass loadings per unit area by creatinga “line” source rather than a “point” source alongthe contour. However, the designer must recognizethat the depth of the trenches and the soil horizonin which the infiltration surface is placed will varyacross the system. Any adverse impacts this mighthave on system performance should be mitigatedthrough design adjustments.

ConfigurationThe spacing of multiple trenches constructedparallel to one another is determined by the soilcharacteristics and the method of construction. Thesidewall-to-sidewall spacing must be sufficient toenable construction without damage to the adjacenttrenches. Only in very tight soils will normallyused spacings be inadequate because of high soilwetness and capillary fringe effects, which canlimit oxygen transfer. It is important to note thatthe sum of the hydraulic loadings to one or moretrenches or beds per each unit of contour length(when projected downslope) must not exceed theestimated maximum contour loading for the site.Also, the finer (tighter) the soil, the greater thetrench spacing should be to provide sufficientoxygen transfer. Quantitative data are lacking, butCamp (1985) reported a lateral impact of morethan 2.0 meters in a clay soil.

Given the advantages of lightweight gravellesssystems in terms of potentially reduced damage tothe site’s hydraulic capacity, parallel trenches mayphysically be placed closer together, but thedownslope hydraulic capacity of the site and thenatural oxygen diffusion capacity of the soil cannotbe exceeded.

4.4.7 Wastewater distribution onto theinfiltration surface

The method and pattern of wastewater distributionin a subsurface infiltration system are importantdesign elements. Uniform distribution aids inmaintaining unsaturated flow below the infiltrationsurface, which results in wastewater retention timesin the soil that are sufficiently long to effecttreatment and promote subsoil reaeration. Uniformdistribution design also results in more completeutilization of the infiltration surface.

Gravity flow and dosing are the two most com-monly used distribution methods. For each method,various network designs are used (table 4-5).Gravity flow is the most commonly used methodbecause it is simple and inexpensive. This methoddischarges effluent from the septic tank or otherpretreatment tank directly to the infiltration surfaceas incoming wastewater displaces it from thetank(s). It is characterized by the term “trickleflow” because the effluent is slowly dischargedover much of the day. Typically, tank discharges

Chapter 4: Treatment Processes and Systems

4-18 USEPA Onsite Wastewater Treatment Systems Manual

are too low to flow throughout the distributionnetwork. Thus, distribution is unequal and local-ized overloading of the infiltration surface occurswith concomitant poor treatment and soil clogging(Bouma, 1975; McGauhey and Winneberger, 1964;Otis, 1985; Robeck et al., 1964).

Dosing, on the other hand, accumulates the waste-water effluent in a dose tank from which the wateris periodically discharged under pressure in “doses”to the infiltration system by a pump or siphon. Thepretreated wastewater is allowed to accumulate inthe dose tank and is discharged when a predeter-mined water level, water volume, or elapsed time isreached. The dose volumes and discharge rates areusually such that much of the distribution networkis filled, resulting in more uniform distributionover the infiltration surface. Dosing outperformsgravity-flow systems because distribution is moreuniform. In addition, the periods between dosesprovide opportunities for the subsoil to drain andreaerate before the next dose (Bouma et al., 1974;Hargett et al., 1982; Otis et al., 1977). However,which method is most appropriate depends on thespecific application.

Gravity flow

Gravity flow can be used where there is a sufficientelevation difference between the outlet of thepretreatment tank and the SWIS to allow flow toand through the SWIS by gravity. Gravity flowsystems are simple and inexpensive to construct but

are the least efficient method of distribution.Distribution is very uneven over the infiltrationsurface, resulting in localized overloading (Con-verse, 1974; McGauhey and Winneberger, 1964;Otis et al., 1978; University of Wisconsin, 1978).Until a biomat forms on the infiltration surface toslow the rate of infiltration, the wastewater resi-dence time in the soil might be too short to effectgood treatment. As the biomat continues to form onthe overloaded areas, the soil surface becomesclogged, forcing wastewater effluent to flowthrough the porous medium of the trench until itreaches an unclogged infiltration surface. Thisphenomenon, known as “progressive clogging,”occurs until the entire infiltration surface is pondedand the sidewalls become the more active infiltra-tion surfaces. Without extended periods of little orno flow to allow the surface to dry, hydraulicfailure becomes imminent. Although inefficient,these systems can work well for seasonal homeswith intermittent use or for households with lowoccupancies. Seasonal use of SWISs allows theinfiltration surface to dry and the biomat to oxi-dize, which rejuvenates the infiltration capacity.Low occupancies result in mass loadings of waste-water constituents that are lower and less likely toexceed the soil’s capacity to completely treat theeffluent.

Perforated pipe

Four-inch-diameter perforated plastic pipe is themost commonly used distribution piping for

Table 4-5. Distribution methods and applications.

USEPA Onsite Wastewater Treatment Systems Manual 4-19

Chapter 4: Treatment Processes and Systems

gravity flow systems. The piping is generallysmooth-walled rigid polyvinyl chloride (PVC), orflexible corrugated polyethylene (PE) or acryloni-trile-butadiene-styrene (ABS). One or two rows ofholes or slots spaced 12 inches apart are cut into thepipe wall. Typically, the piping is laid level ingravel (figure 4-1) with the holes or slots at thebottom (ASTM, undated). One distribution line isused per trench. In bed systems, multiple lines areinstalled 3 to 6 feet apart.

Distribution box

Distribution boxes are used to divide the wastewa-ter effluent flow among multiple distribution lines.They are shallow, flat bottomed, watertight struc-tures with a single inlet and individual outletsprovided at the same elevation for each distributionline. An above-grade cover allows access to theinside of the box. The “d-box” must be laid levelon a sound, frost-proof footing to divide the flowevenly among the outlets. Uneven settlement orfrost heaving results in unequal flow to the laterallines because the outlet hole elevations cease to belevel. If this occurs, adjustments must be made toreestablish equal division of flow. Several devicescan be used. Adjustable weirs that can level theoutlet inverts and maintain the same length of weirper outlet are one option. Other options includedesigns that allow for leveling of the entire box(figure 4-8). The box can also be used to takeindividual trenches out of service by blocking theoutlet to the distribution lateral or raising the outletweir above the weir elevations for the other outlets.Because of the inevitable movement of d-boxes,their use has been discouraged for many years(USPHS, 1957). However, under a managed caresystem with regular adjustment, the d-box isacceptable.

Serial relief line

Serial relief lines distribute wastewater to a seriesof trenches constructed on a sloping site. Ratherthan dividing the flow equally among all trenchesas with a distribution box, the uppermost trench isloaded until completely flooded before the next(lower) trench receives effluent. Similarly, thattrench is loaded until flooded before dischargeoccurs to the next trench, and so on. This methodof loading is accomplished by installing “relieflines” between successive trenches (figure 4-9).

Figure 4-8. Distribution box with adjustable weir outlets

Figure 4-9. Serial relief line distribution network and installationdetail

Source: USEPA, 1980.

Source: Ayres Associates.

Chapter 4: Treatment Processes and Systems

4-20 USEPA Onsite Wastewater Treatment Systems Manual

The relief lines are simple overflow lines thatconnect one trench to the adjacent lower trench.They are solid-wall pipes that connect the crown ofthe upper trench distribution pipe with the distribu-tion pipe in the lower trench. Successive relief linesare separated by 5 to 10 feet to avoid short-circuiting. This method of distribution makes fullhydraulic use of all bottom and sidewall infiltrationsurfaces, creates the maximum hydrostatic headover the infiltration surfaces to force the water intothe surrounding soil, and eliminates the problem ofdividing flows evenly among independent trenches.However, because continuous ponding of theinfiltration surfaces is necessary for the system tofunction, the trenches suffer hydraulic failure morerapidly and progressively because the infiltrationsurfaces cannot regenerate their infiltrative capacity.

Drop box

Drop box distribution systems function similarly torelief line systems except that drop boxes are usedin place of the relief lines. Drop boxes are installedfor each trench. They are connected in manifolds totrenches above and below (figure 4-10). The outletinvert can be placed near the top of each trench toforce the trench to fill completely before it dis-charges to the next trench if a serial distributionmode of operation is desired. Solid-wall pipe isused between the boxes.

The advantage of this method over serial relieflines is that individual trenches can be taken out ofservice by attaching 90 degree ells to the outletsthat rise above the invert of the manifold connec-tion to the next trench drop box. It is easier to addadditional trenches to a drop box system than to aserial relief line network. Also, the drop boxsystem may be operated as an alternating trenchsystem by using the 90 degree ells on unused lines.With this and the serial distribution system, thedesigner must carefully evaluate the downslopecapacity of the site to ensure that it will not beoverloaded when the entire system or specifictrench combinations are functioning.

Gravelless wastewater dispersal systemsGravelless systems have been widely used. Theytake many forms, including open-bottomed cham-bers, fabric-wrapped pipe, and synthetic materialssuch as expanded polystyrene foam chips (fig-

ure 4-11). Some gravelless drain field systems uselarge-diameter corrugated plastic tubing coveredwith permeable nylon filter fabric not surroundedby gravel or rock. The area of fabric in contactwith the soil provides the surface for the septic tankeffluent to infiltrate the soil. The pipe is a mini-mum of 10 to 12 inches (25.4 to 30.5 centimeters)in diameter covered with spun bonded nylon filterfabric to distribute water around the pipe. The pipeis placed in a 12- to 24-inch (30.5- to 61-centime-ter)-wide trench. These systems can be installed inareas with steep slopes with small equipment and inhand-dug trenches where conventional gravelsystems would not be possible.

Reduced sizing of the infiltration surface is oftenpromoted as another advantage of the gravellesssystem. This is based primarily on the premise thatgravelless systems do not “mask” the infiltrationsurface as gravel does where the gravel is in directcontact with the soil. Proponents of this theoryclaim that an infiltration surface area reduction of50 percent is warranted. However, these reductionsare not based on scientific evidence though theyhave been codified in some jurisdictions (Amersonet al., 1991; Anderson et al., 1985; Carlile andOsborne, 1982; Effert and Cashell, 1987). Al-though gravel masking might occur in porousmedium applications, reducing the infiltrationsurface area for gravelless systems increases theBOD mass loading to the available infiltrationsurface. Many soils might not be able to supportthe higher organic loading and, as a result, moresevere soil clogging and greater penetration ofpollutants into the vadose zone and ground watercan occur (University of Wisconsin, 1978), negat-ing the benefits of the gravelless surface.

A similar approach must be taken with any con-taminant in the pretreatment system effluent thatmust be removed before it reaches ground water ornearby surface waters. A 50 percent reduction ininfiltrative surface area will likely result in lessremoval of BOD, pathogens, and other contami-nants in the vadose zone and increase the presenceand concentrations of contaminants in effluentplumes. The relatively confined travel path of aplume provides fewer adsorption sites for removalof adsorbable contaminants (e.g., metals, phospho-rus, toxic organics). Because any potential reduc-tions in infiltrative surface area must be analyzed ina similar comprehensive fashion, the use of

USEPA Onsite Wastewater Treatment Systems Manual 4-21

Chapter 4: Treatment Processes and Systems

Figure 4-10. Drop box distribution network

Source: National Small Flows Clearinghouse.

Figure 4-11. Various gravelless systems

Source: USEPA, 1980

Chapter 4: Treatment Processes and Systems

4-22 USEPA Onsite Wastewater Treatment Systems Manual

gravelless medium should be treated similarly topotential reductions from increased pretreatmentand better distribution and dosing concepts.

Despite the cautions stated above, the overallinherent value of lightweight gravelless systemsshould not be ignored, especially in areas wheregravel is expensive and at sites that have soils thatare susceptible to smearing or other structuraldamage during construction due to the impacts ofheavy machinery on the site. In all applicationswhere gravel is used (see SWIS Media in thefollowing section), it must be properly graded andwashed. Improperly washed gravel can contributefines and other material that can plug voids in theinfiltrative surface and reduce hydraulic capability.Gravel that is embedded into clay or fine soilsduring placement can have the same effect.

Leaching chambers

A leaching chamber is a wastewater treatmentsystem that consists of trenches or beds and one ormore distribution pipes or open-bottomed plasticchambers. Leaching chambers have two keyfunctions: to disperse the effluent from septic tanksand to distribute this effluent throughout thetrenches. A typical leaching chamber consists ofseveral high-density polyethylene injection-moldedarch-shaped chamber segments. A typical chamberhas an average inside width of 15 to 40 inches (38to 102 centimeters) and an overall length of 6 to 8feet (1.8 to 2.4 meters). The chamber segments areusually 1-foot high, with wide slotted sidewalls.Depending on the drain field size requirements, oneor more chambers are typically connected to forman underground drain field network.

Typical leaching chambers (figure 4-12) aregravelless systems that have drain field chamberswith no bottoms and plastic chamber sidewalls,available in a variety of shapes and sizes. Use ofthese systems sometimes decreases overall drainfield costs and may reduce the number of trees thatmust be removed from the drain field lot.

Millions of leaching chamber sysems have beeninstalled in the 50 states, Canada, and overseas.About 750,000 chamber systems have been installedover the past 15 years. Currently, a high percentageof new construction applications use lightweightplastic leaching chambers for new wastewatertreatment systems in states like Colorado, Idaho,North Carolina, Georgia, Florida, and Oregon. Thegravel aggregate traditionally used in drain fieldscan have large quantities of mineral fines that alsoclog or block soil pores. Use of leaching chambersavoids this problem. Recent research sponsored bymanufacturers shows promising results to supportreduction in sizing of drain fields through the useof leaching chambers without increased hydraulicand pollutant penetration failures (Colorado Schoolof Mines, 2001; Siegrist and Vancuyk, 2001a, 2001b).These studies should be continued to eventually yieldrational guidelines for proper sizing of these systemsbased on the type of pretreatment effluent to bereceived (septic tank effluent, effluent from filtersor aerobic treatment units, etc.), as well as differentsoil types and hydrogeological conditions. Manystates offer drain field sizing reduction allowanceswhen leaching chambers are used instead ofconventional gravel drain fields.

Because leaching chamber systems can be installedwithout heavy equipment, they are easy to install

Figure 4-12. Placement of leaching chambers in typical application

Source: Hoover et al., 1996.

USEPA Onsite Wastewater Treatment Systems Manual 4-23

Chapter 4: Treatment Processes and Systems

and repair. These high-capacity, open-bottom drainfield systems can provide greater storage thanconventional gravel systems and can be used inareas appropriate for gravel aggregate drain fields.Leaching systems can operate independently andrequire little day-to-day maintenance. Theirmaintenance requirements are comparable to thoseof aggregate trench systems.

The lightweight chamber segments available on themarket stack together compactly for efficienttransport. Some chambers interlock with ribswithout fasteners, cutting installation time bymore than 50 percent reused and conventionalgravel/pipe systems. Such systems can be reusedand relocated if the site owner decides to buildon another drain field site. A key disadvantage ofleaching chambers compared to gravel drainfields is that they can be more expensive if alow-cost source of gravel is readily available.

Porous media should be placed along the chambersidewall area to a minimum compacted height of8 inches above the trench bottom. Additional backfillis placed to a minimum compacted height of 6 to12inches above the chamber, depending on the chamberstrength. Individual chamber trench bottoms shouldbe leveled in all directions and follow the contour ofthe ground surface elevation without any dams orother water stops. The manufacturer’s installationinstructions should be followed, and systems shouldbe installed by an authorized contractor.

Dosed flow distributionDosed-flow distribution systems are a significantimprovement over gravity-flow distribution systems.The design of dosed-flow systems (figure 4-13)includes both the distribution network and thedosing equipment (see table 4-6). Dosing achievesbetter distribution of the wastewater effluent overthe infiltration surface than gravity flow systems andprovides intervals between doses when no wastewateris applied. As a result, dosed-flow systems reduce therate of soil clogging, more effectively maintainunsaturated conditions in the subsoil (to effect goodtreatment through extended residence times andincreased reaeration potential), and provide a meansto manage wastewater effluent applications to theinfiltration system (Hargett et al., 1982). They can beused in any application and should be the method ofchoice. Unfortunately, they are commonly perceivedto be less desirable because they add a mechanical

Table 4-6. Dosing methods and devices.

Source: National Small Flows Clearinghouse

Figure 4-13. Typical pressurized distribution system layout

Chapter 4: Treatment Processes and Systems

4-24 USEPA Onsite Wastewater Treatment Systems Manual

component to an otherwise “passive” system andadd cost because of the dosing equipment. Theimproved performance of dosed-flow systems overgravity flow systems should outweigh these perceiveddisadvantages, especially when a managemententity is in place. It must be noted, however, that ifdosed infiltration systems are allowed to pond, theadvantages of dosing are lost because the bottominfiltration surface is continuously inundated andno longer allowed to rest and reaerate. Therefore,there is no value in using dosed-flow distribution inSWISs designed to operate ponded, such as systemsthat include sidewall area as an active infiltrationsurface or those using serial relief lines.

Perforated pipe

Four-inch perforated pipe networks (with orwithout d-boxes or pressure manifolds) that receivedosed-flow applications are designed no differentlythan gravity-flow systems. Many of the advantagesof dosing are lost in such networks, however,because the distribution is only slightly better thanthat of gravity-flow systems (Converse, 1974).

Pressure manifold

A pressure manifold consists of a large-diameterpipe tapped with small outlet pipes that dischargeto gravity laterals (figure 4-14). A pump pressur-izes the manifold, which has a selected diameter toensure that pressure inside the manifold is the sameat each outlet. This method of flow division ismore accurate and consistent than a distributionbox, but it has the same shortcoming since flowafter the manifold is by gravity along each distribu-

tion lateral. Its most common application is todivide flow among multiple trenches constructed atdifferent elevations on a sloping site.

Table 4-7 can be used to size a pressure manifoldfor different applications (see sidebar). This table wasdeveloped by Berkowitz (1985) to size the manifolddiameter based on the spacing between pressure lateraltaps, the lateral tap diameter, and the number oflateral taps. The hydraulic computations made todevelop the table set a maximum flow differentialbetween laterals of 5 percent. The dosing rate isdetermined by calculating the flow in a single lateraltap assuming 1 to 4 feet of head at the manifoldoutlets and multiplying the result by the number oflateral taps. The Hazen-Williams equation for pipeflow can be used to make this calculation.

Pressure distribution is typically constructed ofSchedule 40 PVC pipe (figure 4-15). The lateraltaps are joined by tees. They also can be attachedby tapping (threading) the manifold pipe, but themanifold pipe must be Schedule 80 to provide athicker pipe wall for successful tapping. Valves oneach pressure tap are recommended to enable eachline to be taken out of service as needed by closingthe appropriate valve. This allows an opportunityto manage, rest, or repair individual lines. Toprevent freezing, the manifold can be drained backto the dose tank after each dose. If this is done, thevolume of water that will drain from the manifoldand forcemain must be added to the dose volume toachieve the desired dose.

Rigid pipe pressure network

Rigid pipe pressure distribution networks are usedto provide relatively uniform distribution of

Figure 4-14. Pressure manifold detail

USEPA Onsite Wastewater Treatment Systems Manual 4-25

Chapter 4: Treatment Processes and Systems

Figure 4-15. Horizontal design for pressure distribution

Source: Washington Department of Health, 1998.

wastewater effluent over the entire infiltrationsurface simultaneously during each dose. They arewell suited for all dosed systems. Because theydeliver the same volume of wastewater effluent perlinear length of lateral, they can be used to dosemultiple trenches of unequal length. Although rigidpipe pressure networks can be designed to deliverequal volumes to trenches at different elevations(Mote, 1984; Mote et al., 1981; Otis, 1982), thesesituations should be avoided. Uniform distributionis achieved only when the network is fully pressur-ized. During filling and draining of the network,

the distribution lateral at the lowest elevationreceives more water. This disparity increases withincreasing dosing frequency. As an alternative onsloping sites, the SWIS could be divided intomultiple cells, with the laterals in each cell at thesame elevation. If this is not possible, otherdistribution designs should be considered.

The networks consist of solid PVC pipe manifoldsthat supply water to a series of smaller perforatedPVC laterals (figure 4-16). The laterals are de-signed to discharge nearly equal volumes of

Table 4-7. Pressure manifold sizing

Source: Adapted from Berkowitz, 1985.

Chapter 4: Treatment Processes and Systems

4-26 USEPA Onsite Wastewater Treatment Systems Manual

wastewater from each orifice in the network whenfully pressurized. This is accomplished by main-taining a uniform pressure throughout the networkduring dosing. The manifolds and laterals are sizedrelative to the selected orifice size and spacing toachieve uniform pressure. A manual flushingmechanism should be included to enable periodicflushing of slimes and other solids that accumulatein the laterals.

Design of dosed flow systems

A simplified method of network design has beendeveloped (Otis, 1982). Lateral and manifoldsizing is determined using a series of graphs andtables after the designer has selected the desiredorifice size and spacing and the distal pressure inthe network (typically 1 to 2 feet of head). Thesegraphs and tables were derived by calculating thechange in flow and pressure at each orifice betweenthe distal and proximal ends of the network. Themethod is meant to result in discharge rates fromthe first and last orifices that differ by no morethan 10 percent in any lateral and 15 percent acrossthe entire network. However, subsequent testing offield installations indicated that the design modeloverestimates the maximum lateral length by asmuch as 25 percent (Converse and Otis, 1982).Therefore, if the graphs and tables are used, themaximum lateral length for any given orifice sizeand spacing should not exceed 80 percent of themaximum design length suggested by the lateralsizing graphs. In lieu of using the graphs andtables, a spreadsheet could be written using theequations presented and adjusting the orificedischarge coefficient.

Pressure manifold designPressure manifold designPressure manifold designPressure manifold designPressure manifold designA SWIS consisting of 12 trenches of equal length is to be constructed on a slope. To divide the septic tankeffluent equally among the 12 trenches, a pressure manifold is to be used. The lateral taps are to be spaced 6inches apart on one side of the manifold.

Table 4-7 can be used to size the manifold. Looking down the series of columns under the Single-sided manifold,up to sixteen ½-inch taps could be made to a 4-inch manifold. Therefore, a 4-inch manifold would be acceptable. If¾- or 1-inch taps were used, a 6-inch manifold would be necessary.

Using the orifice equation, the flow from each lateral tap can be estimated by assuming an operating pressure inthe manifold:

Q = Ca(2gh)2

where Q is the lateral discharge rate, C is a dimensionless coefficient that varies with the characteristics of theorifice (0.6 for a sharp-edged orifice), a is the area of the orifice, g is the acceleration due to gravity, and h is theoperating pressure within the manifold. In English units using a 0.6 orifice coefficient, this equation becomes

Q = 11.79 d2hd1/2

where Q is the discharge rate in gallons per minute, d is the orifice diameter in inches, and h is the operatingpressure in feet of water.

Assuming ½-inch taps with a operating pressure of 3 feet of water, the discharge rate from each outlet is

Q = 11.79 (½)2 31/2 = 5.1 gpm

Thus, the pump must be capable of delivering 12 x 5.1 gpm or approximately 60 gpm against an operatingpressure of 3 feet of water plus the static lift and friction losses incurred in the forcemain to the pressuremanifold.

Septic TankPumping (Dosing)

Chamber

EffluentPump

Small DiameterPressure Distribution

Cleanout

Figure 4-16. Rigid pipe pressure distribution networks with flushingcleanouts

USEPA Onsite Wastewater Treatment Systems Manual 4-27

Chapter 4: Treatment Processes and Systems