CHAPTER 1

description

Transcript of CHAPTER 1

Introduction Chapter 1

CHAPTER 1

INTRODUCTIONThis chapter deals with the introduction about the basic processes involved in this

work, their definition, principle, working and schematics.

1.1 Metal Working

Metalworking is the process of working with metals to create individual parts,

assemblies, or large scale structures.

1.2 Metal Cutting

Metal cutting is a process in which chip is formed by a relative motion between the

tool and work piece. It is otherwise called metal removal process.

Figure1.1 Flow Chart for Metal Removal Process

1

Introduction Chapter 1

1.3 Turning Operation

Turning is the removal of metal from the outer diameter of a rotating cylindrical work

piece. Turning is used to reduce the diameter of the work piece, usually to a specified

dimension, and to produce a smooth finish on the metal. Often the work piece will be turned

so that adjacent sections have different diameters. Turning is the machining operation that

produces cylindrical parts. In its basic form, it can be defined as the machining of an external

surface:

1. With the work piece rotating.

2. With a single-point cutting tool, and

3. With the cutting tool feeding parallel to the axis of the work piece and at distance that

will remove the outer surface of the work.

Figure1.2 Turning Operation

1.3.1 Adjustable cutting factors in Turning

The three primary factors in any basic turning operation are speed, feed, and depth

of cut. Other factors such as kind of material and type of tool have a large influence, of

course, but these three are the ones the operator can change by adjusting the controls, right

at the machine.

Speed

Speed always refers to the spindle and the work piece. When it is stated in

revolutions per minute (rpm) it tells their rotating speed. But the important feature for a

particular turning operation is the surface speed, or the speed at which the work piece

material is moving past the cutting tool. It is simply the product of the rotating speed times

the circumference of the work piece before the cut is started. It is expressed in meter per

minute (m/min), and it refers only to the work piece. Every different diameter on a work piece

will have a different cutting speed, even though the rotating speed remains the same.

2

Introduction Chapter 1

Here, v is the cutting speed in turning, D is the initial diameter of the work piece in mm, and

N is the spindle speed in rpm.

Feed

Feed always refers to the cutting tool, and it is the rate at which the tool advances

along its cutting path. On most power-fed lathes, the feed rate is directly related to the

spindle speed and is expressed in mm (of tool advance) per revolution (of the spindle), or

mm/rev.

Depth of Cut

Depth of cut is practically self explanatory. It is the thickness of the layer being

removed (in a single pass) from the work piece or the distance from the uncut surface of the

work to the cut surface, expressed in mm. It is important to note, though, that the diameter of

the work piece is reduced by two times the depth of cut because this layer is being removed

from both sides of the work.

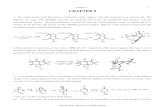

1.3.2 Cutting tool nomenclature

It is a systematic naming of the various parts and angles of a cutting tool.

Figure1.3 Cutting Tool nomenclature

Single point cutting tool nomenclature

1. The shank is that portion of the tool bit which is not ground to form cutting edges and

is rectangular in cross section.

3

Introduction Chapter 1

2. The face of the cutting tool is that surface against which the chip slides upward.

3. The flank of the tool is that surface which faces the work piece.

4. The heel of a single point cutting tool is the lowest portion of the side cutting edges.

5. The nose of the tool is the conjunction of the side and end cutting edge.

6. The base of the tool is the underside of the tool.

7. The rake is the slope of the top away from the cutting edge. The larger the rake

angle, larger the shear angle and subsequently the power and cutting force reduces.

8. Side rake indicates that the plane that forms the face or top of a tool has been

ground back at an angle sloping from the side cutting edge.

9. Back rake indicates that the plane which forms the face or top of a tool has been

ground back at an angle sloping from the nose.

10. The side clearance angle or side relief indicates that the plane that forms the flank

or side of a tool has been ground back at an angle sloping down from the side cutting

edge.

11. The edge clearance angle or end relief angle indicates that the nose or end of a tool

has been ground back at an angle sloping down from the end cutting edge.

12. The end cutting edge angle indicates that the plane which forms the end of a tool

has been ground back at an angle sloping from the nose to the side of the shank.

13.The side cutting edge angle indicates that the plane which forms the flank or side

for a tool has been ground back at an angle to the side of a shank.

1.4 Grinding Operation

Grinding is an abrasive machining process that uses a grinding wheel as the cutting

tool against which the work piece is forced. The relative motion between the work piece and

the grinding wheel leads to the removal of material from the work piece in the form of chips.

Grinding practice is a large and diverse area of manufacturing and tool making. It can

produce very fine finishes and very accurate dimensions. It is usually better suited to the

machining of very hard materials like hardened steels. Grinding is a subset of cutting, as

grinding is a true metal cutting process. Each grain of the abrasive wheel functions as a

microscopic single-point cutting edge and shears a tiny chip from the material. But the size

of the chips produced by grinding process is very small when to those chips which are

produced by conventional methods.

4

Introduction Chapter 1

Figure 1.4 Grinding Operation

1.4.1 Adjustable cutting factors in Grinding

The success of any grinding operation depends on the proper selection of various

operating conditions like wheel speed, work speed, depth of cut, transverse feed, etc.

Wheel speed

Wheel speed is the speed at which the grinding wheel rotates. If the wheel speed is

increased, the size of the chips removed by a single abrasive grain is reduced. This reduces

the wear of the wheel. Hence it is better to operate at higher wheel speeds. However, this is

limited by the allowable speeds at which the wheel can be worked, as well as the power and

the rigidity of grinding machine. Normally, the grinding wheel speed ranges from 20 to 40

m/s. The wheel speed also depends upon the type of grinding operation and the bond of the

grinding wheel. For example, resinoid bonded wheels can be generally used at higher

peripheral speeds than vitrified bond wheels.

Work speed

Work speed is the speed at which the work piece traverses across the wheel face or

rotates around between the centers. It is expressed in rpm. If the work speed is high, the

wheel wear is increased but the heat produced is reduced. On the other hand, if the work

speed is low, wheel wear decreases but more heat is produced. The ratio of wheel speed to

work speed is of much importance and it should be maintained at the proper value. Micro

cracks will be produced if more heat is generated.

5

Introduction Chapter 1

Depth of cut

It is the thickness of the layer being removed (in a single pass) from the work piece

or the distance from the uncut surface of the work to the cut surface, expressed in mm. It is

important to note, though, that the diameter of work piece is reduced by two times the depth

of cut because this layer is being removed from both sides of the work.

Number of passes

The grinding process can be done in two ways. They are single stage and multi-pass

grinding. The single stage of grinding process gives the surface of work piece not smooth

but when done with the multi-pass grinding at certain depth of cut and number of passes, the

surface roughness can be improved.

Figure 1.5 Grinding Parameters

1.4.2 Factors affecting surface finish in Grinding Operation

One of the main considerations in the choice of grinding process is the required

surface finish. There are any factors which contribute to the surface finish among which

some are discussed below.

6

Introduction Chapter 1

Spark out

It is has been found that surface finish is inversely proportional to the depth of cut in

grinding i.e. low depth of cut results in a finish and vice versa. Therefore the obvious way to

improve surface finish is to reduce the depth of cut to a minimum value. However, in

practice, the machine tool feed mechanisms cannot give very low in feed owing to various

design constraints. This can be encountered by the process of spark out.

Cutting parameters

Surface finish is influenced by the other cutting parameters. The surface finish can

also be improved by reducing the job speed (rotation speed in outer diameter grinding and

reciprocating speed in surface grinding) and reducing the traverse feed (table traverse in

outer diameter grinding and cross feed in surface grinding).

Cutting fluids

The influence of cutting fluids on surface finish is relatively small. Generally, fluids

with greater lubricating action impart a better finish. The main point is to ensure proper

filtration of the fluid because suspended particles of abrasive and metal can cause deep

scratches. Isolated scratch marks are a sure sign of dirty fluid. The remedy in such cases is

to clean the tank and use magnetic separators at regular intervals.

Dressing

Dressing is the conditioning of the wheel surface which ensures that grit cutting

edges are exposed from the bond and thus able to penetrate into the work piece material.

Therefore dressing produces micro-geometry. The structure of the micro-geometry of the

grinding wheel determines the cutting ability of a wheel with a given composition. Wheel

wear in dressing is substantially more than the wheel wear in grinding. This results in

reduced wheel life.

Truing

Truing is the process of regenerating the required geometry on the grinding wheel,

whether the geometry is a special form of flat profile. Therefore truing produces the macro-

geometry of the wheel. Generally, truing is done after dressing. Truing is also done on a new

conventional wheel to ensure its concentricity with specified mounting system.

1.5 Optimization – introduction

In mathematics, computer science and economics, optimization, or mathematical

programming, refer to choosing the best element from some set of available alternatives.

In the simplest case, this means solving problems in which one seeks to minimize or

maximize a real function by systematically choosing the values of real or integer variables

7

Introduction Chapter 1

from within an allowed set, this formulation, using a scalar, real- valued objective function, is

probably the simplest example; the generalization of optimization theory and techniques to

other formulations comprises a large values of some objective function given a defined

domain, including a variety of different types of objective functions and different types of

domains.

1.5.1 Taguchi method

Taguchi methods are statistical methods developed by Genichi Taguchi to improve

the quality of manufactured goods, and more recently also applied to, engineering,

biotechnology, marketing and advertising, professional statisticians have welcomed the

goals and improvements brought about by Taguchi methods, particularly by Taguchi’s

development of designs for studying variation, but have criticized the inefficiency of some of

Taguchi’s proposals.

1.5.2 Off- line quality control

Taguchi’s rule for manufacturing

Taguchi realize that the best opportunity to eliminate variation is during the design of a

product and its manufacturing process. Consequently, he developed a strategy for quality

engineering that can be used in both contexts. The process has three stages:

1. System design

2. Parameter design

3. Tolerance design

1. System design

This is design at the conceptual level, involving creativity and innovation.

2. Parameter design

Once the concept is established, the nominal values of the various dimensions and

design parameters need to be set, the detailed design phase of conventional engineering.

Taguchi’s radical insight was that the exact choice of values required is under specified by

the performance requirements of the system. In many circumstances, this allows the

parameters to be chosen so as to minimize the effects on performance arising from variation

in manufacture, environment and cumulative damage.

3. Tolerance design

With a successfully completed parameters design, and an understanding of the effect

that the various parameters have on performance, resources can be focused on reducing

and controlling variation in the critical few dimensions.

8

Introduction Chapter 1

1.5.3 DESIGN OF EXPERIMENTS

In general usage, design of experiments(DOE)or experimental design is the design

of any information- gathering exercises where variation is present, whether under the full

control of the experimenter or not. However, the statistics, these terms are usually used for

controlled experiments. Other types of study, and their design, are discussed in the articles

on opinion polls and statistical surveys (which are types of observational study), natural

experiments and quasi- experiments (for example, quasi- experimental design).

In the design of experiments, the experimenter is often interested in the effect of some

process or intervention(the “treatment”)on some objects(the “experimental units”),which may

be the people, parts of people, groups of people, plants, animals, materials, etc. Design of

experiments is thus a discipline that has broad application across all the natural and social

sciences.

1.6 Surface roughness

Surface roughness is an important measure of product quality since it greatly

influences the performance of mechanical parts as well as production cost. Surface

roughness has an impact on the mechanical properties like fatigue behavior, corrosion

resistance, creep life, etc. It also affects other functional attributes of parts like friction, wear,

light reflection, heat transmission, lubrication, electrical conductivity, etc. Upon close

examination of the surface of a piece of metal, it can be found that it generally consists of

several layers.

Figure.1.6 Surface Structure

9

Introduction Chapter 1

1.6.1 Surface form deviations

Outermost layers of all machined surfaces display a great number of both macro

geometrical and micro-geometrical deviations from the ideal geometrical surface. Surface

roughness refers to deviation from the nominal surface of the third up to sixth order. Order of

deviation is defined in international standards. First and second-order deviations refer to

form, i.e. flatness, circularity, etc. and to waviness, respectively, and are due to machine tool

errors, deformation of the work piece, erroneous setups and clamping, vibration and work

piece material in-homogeneities. Third and fourth-order deviations refer to periodic grooves,

and to cracks and dilapidations, which are connected to the shape and condition of the

cutting edges, chip formation and process kinematics. Fifth and sixth-order deviations refer

to work piece material structure, which is connected to physical-chemical mechanisms acting

on a grain and lattice scale (slip, diffusion, oxidation, residual stress, etc.). Different order

deviations are superimposed and form the surface roughness profile (Figure 1.7).

Figure 1.7 Surface Deviation

10

Introduction Chapter 1

The principal elements of surfaces are discussed below:

a. Surface: The surface of an object is the boundary which separates that object from

another substance. Its shape and extent are usually defined by a drawing or

descriptive specifications.

b. Profile: It is the contour of any specified section through a surface.

c. Roughness: It is defined as closely spaced, irregular deviations on a scale smaller

than that of waviness. Roughness may be superimposed on waviness. Roughness is

expressed in terms of its height, its width, and its distance on the surface along which

it is measured.

d. Waviness: It is a recurrent deviation from a flat surface, much like waves on the

surface of water. It is measured and described in terms of the space between

adjacent crests of the waves (waviness width) and height between the crests and

valleys of the waves (waviness height). Waviness can be caused by,

I. Deflections of tools, dies, or the work piece,

II. Forces or temperature sufficient to cause warping,

III. Uneven lubrication,

IV. Vibration, or

V. Any periodic mechanical or thermal variations in the system during

VI. Manufacturing operations.

Figure 1.8 Surface Characteristics

e. Flaws: Flaws, or defects, are random irregularities, such as scratches, cracks, holes,

depressions, seams, tears, or inclusions as shown in Figure 1.8

f. Lay: Lay, or directionality, is the direction of the predominant surface pattern and is

usually visible to the naked eye.

11

Introduction Chapter 1

1.6.2 Factors affecting the surface finish

Whenever two machined surfaces come in contact with one another the quality of the

mating parts plays an important role in the performance and wear of the mating parts. The

height, shape, arrangement and direction of these surface irregularities on the work piece

depend upon a number of factors such as:

A. The machining variables which include

a. Cutting speed

b. Feed, and

c. Depth of cut.

B. The tool geometry some geometric factors which affect achieved surface finish

include:

a. Nose radius

b. Rake angle

c. Side cutting edge angle, and

d. Cutting edge.

C. Work piece and tool material combination and their mechanical properties

D. Quality and type of the machine tool used,

E. Auxiliary tooling, and lubricant used, and

F. Vibrations between the work piece, machine tool and cutting tool.

1.6.3 Measurement of surface roughness

Inspection and assessment of surface roughness of machined work pieces can be

carried out by means of different measurement techniques. These methods can be ranked

into the following classes

Direct measurement methods

Direct methods assess surface finish by means of stylus type devices.

Measurements are obtained using a stylus drawn along the surface to be measured. The

stylus motion perpendicular to the surface is registered. This registered profile is then used

to calculate the roughness parameters. This method requires interruption of the machine

process, and the sharp diamond stylus can make micro-scratches on surfaces.

12

Introduction Chapter 1

Figure 1.9 Stylus Equipment

Figure

1.10 Arithmetic Mean Roughness

1.7 Fish bone diagram for surface roughness

13

Introduction Chapter 1

14

![Chapter 01: Relational Databases - static.packt-cdn.com · Chapter 01: Relational Databases. Chapter 1 [ 2 ] Chapter 1 [ 3 ] Chapter 1 [ 4 ] Chapter 1 [ 5 ] Chapter 02: PostgreSQL](https://static.fdocuments.us/doc/165x107/5e1e7793cab1f72f70306c15/chapter-01-relational-databases-chapter-01-relational-databases-chapter-1-.jpg)