Chap 1 final

-

Upload

neeraj-parmar -

Category

Education

-

view

728 -

download

1

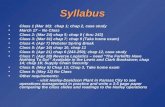

Transcript of Chap 1 final

MATERIAL SCIENCE &

ENGINEERING

Material science and engineering is an interdisciplinary field concerned with inventing new materials and improving previously known materials by developing deeper understanding of microstructure-composition-synthesis processing relationships.

Structure means description of arrangement of atoms.

Synthesis refers to how material are being made from naturally occurring or man made chemicals

Processesing refers to how material are shaped into useful component to cause changes in properties of different material.

In MATERIAL SCIENCE the emphasis is on underlying relation ships between synthesis and processesing, structure and properties of materials.

In MATERIALS ENGINEERING the focus is on how to translate or transform materials into useful devices or structures.

PERFORMANCE: What is Strength to density ratio? What is formability? How does this relate to the crash worthiness of the vehicle? What is the cost of fabrication? A COMPOSITION Iron Based ? Aluminium based? What alloying elements should be added? What quantities? B MICROSTRUCTURE: (a)What features of the structure limit the strength and formability? (b) What controls the strength? C SNYTHESIS & PROCESSESING (a)How can steel making be controlled so as to provide high level of

toughness and formability (b)How can aerodynamic car chassis be formed.

CERAMIC SUPERCONDUCTORS

SEMICONDUCTING POLYMERS

STEEL SHEETS USED FOR MANUFACTURE OF CAR CHASSIS

Material Scientist is concerned with steel sheet’s

(1)Composition (2) Strength (3)Weight (4)Energy absorbing properties (5)Malleability(formability)

MATERIAL SPECIFICATION Chemical composition Mechanical properties – Strength,

hardness (under various conditions: temperature, humidity, pressure)

Physical properties – density, optical, electrical, magnetic

Environmental – green, recycling

METALS & ALLOYS These materials are inorganic

substances that are composed of one or more metallic elements .

Eg:Fe,Ni,Cu,Al Non metallic elements as C,N may also

be included in metallic materials Metals have crystalline structure in

which atoms are arranged in orderly fashion

Many metals are strong and hard even at high temperature.

METALS

Ferrous MetalsCast ironsSteels

Super alloysIron-basedNickel-basedCobalt-based

Non-ferrous metalsAluminum and its

alloysCopper and its alloysMagnesium and its

alloysNickel and its alloysTitanium and its alloysZinc and its alloysLead & TinRefractory metalsPrecious metals

GENERAL PROPERTIES AND APPLICATIONS OF FERROUS ALLOYS

• Ferrous alloys are useful metals in terms of mechanical, physical and chemical properties.

• Alloys contain iron as their base metal.

• Carbon steels are least expensive of all metals while stainless steels is costly.

CARBON AND ALLOY STEELSCarbon steels• Classified as low, medium and high:1.Low-carbon steel or mild steel,

< 0.3%C, bolts, nuts and sheet plates.

2.Medium-carbon steel, 0.3% ~ 0.6%C, machinery, automotive and agricultural equipment.

3.High-carbon steel, > 0.60% C, springs, cutlery, cable.

CARBON AND ALLOY STEELSAlloy steels• Steels containing significant

amounts of alloying elements.• Structural-grade alloy steels used

for construction industries due to high strength.

• Other alloy steels are used for its strength, hardness, resistance to creep and fatigue, and toughness.

• It may heat treated to obtain the desired properties.

New and improved Ni-based,Fe-Ni-Co based SUPERALLOYS are available for use in high pressure turbine airfoils in aircraft gas turbines.

The term SUPER ALLOY is used because of their improved performance at elevated temperature of 5400Cand high stress levels

CERAMICS Ceramics are defined as inorganic

crystalline material. Advanced ceramics are made by

refining naturally occurring ceramics and other special processes.

CERAMICS Traditional ceramics

clays: kaolinitesilica: quartz, sandstonealuminasilicon carbide

New ceramicsoxide ceramics : aluminacarbides : silicon carbide, titanium carbide,

etc.nitrides : silicon nitride, boron nitiride, etc.

Advanced Ceramics are used in substrate that house computer chips,sensers and actuators,capacitors,wirless communication, spark plug,inductor,and electrical insulation.

They are used as barrier coating to protect the substrate in turbine engines.

Used in consumer product like paints, plastics and tires, and for industrial application as tiles for space shuttle, a catalyst support and oxygen sensors used in car.

Traditional Ceramics are used to make brick,table ware,sanitary ware,refractories and abrasives.

CHARACTERISTICS 1. Due to presence of porosity(small

holes) ceramics do not conduct heat well and must be heated to very high temperature before melting

2.Ceramics are strong and hard but also very brittle

3. Fine powders of ceramics are prepared and then converted to useful shapes.

GLASS Glass products

window glasscontainers light bulb glass laboratory glassglass fibersoptical glass

Glass ceramics - polycrystalline structure

Glasses are Amorphous materials which do not have regular periodic arrangement of atoms

Fiber optic system uses optical fiber based on high purity silica glass.

Glasses can be thermally treated (tempered ) to make them stronger.

Forming glasses and nucleating(forming)small crystal within them by special thermal process creates material that are known as GLASS CERAMICS”

ZERODUR is the glass ceramic material that is used for making mirror substrate for large telescope.

POLYMERS They are inorganic materials Processed by Polymeraistaion Properties:

1. Good thermal insulation 2.Good electrical resistivity 3.Lower strenth but high strength to weight

ratio. 4. Not suitable for high temperature application 5.Good corrosion resistance Application:

Bullet proof vests ,compact disc,and liquid crystal displays

POLYMERS Thermoplastics - reversible in phase by

heating and cooling. Solid phase at room temperature and liquid phase at elevated temperature.

Thermosets - irreversible in phase by heating and cooling. Change to liquid phase when heated, then follow with an irreversible exothermic chemical reaction. Remain in solid phase subsequently.

Elastomers - Rubbers

THERMOPLASTICSAcetalsAcrylics - PMMAAcrylonitrile-Butadiene-Styrene - ABSCellulosicsFluoropolymers - PTFE , TeflonPolyamides (PA) - Nylons, KevlarPolysters - PETPolyethylene (PE) - HDPE, LDPEPolypropylene (PP)Polystyrene (PS)Polyvinyl chloride (PVC)

THERMOSETS Amino resins Epoxies Phenolics Polyesters Polyurethanes Silicones

ELASTOMERS Natural rubber Synthetic rubbers

butadiene rubberbutyl rubberchloroprene rubberethylene-propylene rubber isoprene rubbernitrile rubberpolyurethanessiliconesstyrene-butadiene rubber thermoplastic elastomers

SEMICONDUCTORS Si,Ge and gallium arsenide based

semiconductors such as those used in computers and electronics are part of Electronic materials.

The electrical conductivity of semiconductors is material is between metal conductor and ceramic insulator.

In some semiconductor the level of conductivity can be controlled to enable electronic devices such as transistor, diodes etc that are used to build integrated circuits.

Thin films of semiconducting materials are also made by specialization processes.

COMPOSITES Main idea in developing COMPOSITE is to

blend the properties of different material These are formed from two or more

materials, producing properties not found in single material.

Concrete, plywood and fiberglass are example of composite material

Fiberglass is obtained by dispersing glass fibers in polymer matrix. Fiber make it stiffer without increasing density.

PROPERTIES With composite we can produce

structure: 1. Light Weight 2. strong 3. ductile 4.high temperature resistant 5. Shock resistant Advanced Aircraft and aerospace

vehicles rely heavily on composites as carbon fiber reinforced composites

CLASSIFICATION OF COMPOSITE MATERIALS

Metal Matrix Composites

Ceramic Matrix Composites

Polymer Matrix Composites

COMPOSITE MATERIALS Metal Matrix Composites (MMC)

Mixture of ceramics and metals reinforced by strong, high-stiffness fibers

Ceramic Matrix Composites (CMC)Ceramics such as aluminum oxide and silicon

carbide embedded with fibers for improved properties, especially high temperature applications.

Polymer Matrix Composites (PMC)Thermosets or thermoplastics mixed with fiber

reinforcement or powder.

COMPOSITE MATERIALS

1D fibre

Woven fabric

Random fibre

37

Table 1.1 Representative examples, applications, and properties for each

category of materials

Example of Applications Properties

Metals and Alloys Gray cast iron Automobile engine blocks Castable, machinable,

vibration dampingCeramics and Glasses SiO2-Na2O-CaO Window glass Optically transparent, thermally insulatingPolymers Polyethylene Food packaging Easily formed into thin,

flexible, airtight film

38

Example of Applications Properties

Semiconductors Silicon Transistors and integrated Unique electrical

circuits behavior

Composites Carbide cutting tools for High hardness, yet Tungsten carbide machining good shock resistance-cobalt (WC-Co)

Table 1.1 Continued

39

© 2003 B

rooks/Cole P

ublishing / Thom

son Learning™

Figure 1.4 Representative strengths of various categories of materials