Challenges for future mineral processing - Home...

Transcript of Challenges for future mineral processing - Home...

Challenges for future mineral processing

Energy, Water and Masses

Hermann Wotruba, Henning Knapp

Unit of Mineral Processing, RWTH Aachen University

Outline

Introduction

Energy consumption

Water consumption

Mass movement

• Processing of very fine (<20 µm) and ultra fine (<5 µm) particles

Conclusion

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 2

Introduction

Quality of mineral resources (in terms of grade, depth/accessibility

and complexity) is degrading ,

More material has to be extracted and processed to produce the

same amount of product

Per unit of product this results in

– more energy consumption

– more water consumption

– more mass movement and increased amount of tailings

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 3

System limits

The allocated energy and water consumption per unit of product depends on the system limits:

The whole process chain has to be considered

Mineral Processing is only one part of the process chain

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 4

Mineral Processing

Transport Mineral Processing

Mining Transport Mineral Processing Mining Transport Mineral Processing Tailings deposition

Exploration Mining Transport Mineral Processing Tailings deposition Consumables Exploration Mining Transport Mineral Processing Tailings deposition Consumables Water management

Exploration Mining Transport Mineral Processing Tailings deposition Consumables Water management Smelting/Refining etc.

Energy

Global energy consumption has risen and will be rising

Most of our energy is produced from fossil fuels (CO2)

Mining, Mineral processing and metallurgical processing consume a considerable amount of energy

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 6

Oil

Coal

Gas

Biomass Nuclear

Other renewables

0

2 000

4 000

6 000

8 000

10 000

12 000

14 000

16 000

18 000

1970 1980 1990 2000 2010 2020 2030

Mto

e

Source: Energy consumption

prognosis (IEA modelling

2006)

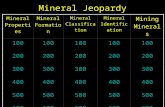

Average energy consumption by stage of production (Ore open pit) [KWh/1000t]

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 7

400 500 700 600

3500

5600

300 450 800

2800

9950

350 150

10450

1300

12000

9500 1800

1500 1500

27600

800

38850

Drilli

ng

Bla

sting

Exc

avation

Handlin

g

Tra

nsport

Tota

l w

aste

rock r

em

oval

Drilli

ng

Bla

sting

Exc

avation

Tra

nsport

Tota

l ore

exc

avation

Dew

ate

ring

Min

e s

upport

Tota

l m

inin

g

Cru

shin

g

Grindin

g

Oth

er

pro

cessin

g

Taili

ngs

Pro

cess w

ate

r

Oth

er

pla

nt

Tota

l m

ill /

concentr

ato

r opera

tio

ns

G &

A

Tota

l opera

tio

ns

KW

h/1

000t

Source: Benchmarking the Energy Consumption of Canadian Open Pit Mines, CIPEC, Canada, 2005, modified

Strategies to reduce energy consumption

Incremental improvements

– Improve unit processes (usually: “bigger is better”)

– Improve process control, online analysis and automation

– Reduce overgrinding

– Optimize mine-to-plant integration (e.g. intensified blasting as first crushing

step)

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 8

Strategies to reduce energy consumption

Step-change improvements

– Waste reduction by

• Selective mining

• Waste removal after primary crushing (e.g. by sensor-based sorting, gravity concentration)

– Improved comminution technology

• HPGR

• Vertical roller mill

• New fine grinding mills (Isa-mill, tower mill)

• Alternative fine grinding processes (e.g. shockwaves etc.)

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 9

Strategies to reduce energy consumption

Step-change improvements

– Coarse particle recovery

• Coarse flash flotation

• Step-wise milling and concentration

– Near-to-face processing

• Near-to-face pre-concentration

– Underground pre-concentration

• Satellite pre-concentration with central processing plant

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 10

Water

Global water consumption is increasing

Main increase is expected in

– Africa (+44 %)

– Asia (+43 %)

– South America (+38 %)

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 12

2000: 3900 km³ 2025: 5100 km³ (+31%)

(Data: Shiklomanov, I. A. und Rodda, J. C. (2003): World Water Resources at the Beginning of

the 21st Century)

Water in mineral processing

Washing and scrubbing

Medium for grinding and separation

– Wet screening

– Wet ball mill

– Wet gravity concentration

– Wet magnetic separation

– Flotation

– Leaching

Medium for transport (slurry)

Dust precipitation

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 13

Impacts of mineral processing on water

Chemical impacts

– Acidity/alkalinity

– Heavy metals (arsenic, mercury, etc.)

– Reagents (acids, cyanides, organics)

– Radioactivity

– Oxygen content

Physical impacts

– Turbidity/siltation

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 14

Typical environmental impacts of mining on water resources

Demand for local water sources

– River water

– Lake water

– Ground water

– Captured rain water

– Sea water

Discharge of contaminants into ground water

Depression of ground water table

Erosion of unprotected surfaces – increased sediment load in streams

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 15

Water cleaning generates costs

Sedimentation

Filtration

Neutralization

Cyanide oxidation/destruction

Heavy metal precipitation

Storage and pumping

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 16

Strategies to reduce water consumption

Online analysis, automation and process control

Dry processing

– Dry gravity separation

• Dry jigging

• Dry fluidized bed separation

• Dry shaking table

– Dry magnetic separation

– Electrostatic separation

– Sensor-based sorting

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 17

Sensor-based

sorting Screen

Mill

Primary

crusher

Secondary

crusher

Product Waste

ROM

Flotation

Coarse waste to:

• Dump

• (underground) backfill

• Market (as construction

material) Fine

Quantity and quality of process water

About 3-4 parts of water per part of solids

Quality of process water depends on processing method (flotation and leaching have a high impact)

Processes without the use of reagents are preferable

– Wet gravity concentration

– Wet magnetic separation

If possible, non-toxic and degradable reagents should be used

Long term behavior of many process chemicals are not fully understood (e.g. flocculants)

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 18

Masses

Mining and mineral processing requires movement of large quantities of masses

Ratio between ore and waste depends on the mining method

– Underground 1:1 or better

– Surface from 1:1 to 1:10

Percentage of usable material in ROM depends on mineral and deposit

– Close to 100 % for coal

– Less than 1 ppm for gold in open pit

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 20

Masses

Non usable material from mineral extraction:

– Overburden and waste rock

– Mineral processing tailings

Mass movement for copper, iron and gold (without overburden/waste)

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 21

Commodity World Production 2007

Mio. t

World Production 2011

Mio. t

Increase 2007-2011

%

Mass ore 2011

Mio. t

Copper (metal) 15.5 16.1 4 1610 (at 1% Cu)

Gold (metal) 0.00235 0.00266 13 887 (at 3g/t Au)

Iron 1070 1390 20 2940

Source: USGS

Quality of masses

Not only quantity but also quality of masses influences the environmental impact

– Particle size (coarse waste vs. flotation tailings)

– Physical and chemical activation (leaching, bacterial activity…)

– Acid generation potential

– Heavy metal potential

– Mechanical stability

The quality of masses is influenced by their nature and by the process

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 22

Strategies to reduce mass movement

Similar to water and energy reduction

– Selective mining

– Transition from open pit to underground

– Waste removal prior to milling and concentration

– Coarse particle concentration

– Near-to-face processing

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 23

Processing of very fine and ultra fine particles

Due to increasingly complex mineralogy, processing of very fine (<20 µm) and ultra fine particles (<5 µm) becomes more and more important (Source: R. Sivamohan, 1989)

Necessary liberation requires fine grinding and separation at small particle sizes

Technologies allowing a reliable separation at <20 µm have to be developed/improved

– Ultra fine flotation

– Ultra fine gravity separation

– Ultra fine magnetic separation

– Selective flocculation

– Carrier flotation

– New dry ultra fine particle separation (electrostatic, etc.)

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 24

Relation of energy, water and masses in mineral processing

Energy consumption, water consumption and mass movement are related

Any measure to reduce mass movement reduces

– Energy consumption

– Water consumption

– Environmental impacts

– Costs

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 25

Mass movement

Environmental impact

Water consumption

Energy consumption

Summary & Conclusion I

Energy is the major cost factor for mineral processing

– High energy prices lead to high commodity prices

High commodity prices are affordable for developed countries but are harmful for poor countries

– Increasing imparity between rich and poor countries

Social acceptance (“social license”) of mineral processing strongly depends on environmental impacts (water, energy…)

Mineral extraction, mineral processing and mineral refinement (smelting, etc.) have to be considered as one process chain

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 26

Summary & Conclusion III

Processing of fine particles (<20 µm) will become increasingly important

Reduction of moved and treated masses reduces energy and water consumption

Some low-grade deposits cannot be exploited with todays technologies

Increased water and energy efficiency can turn reserves into resources

European equipment manufacturing companies are world leader in mayor fields

– Energy efficient fine and ultra fine grinding

– Sensor-based sorting

– Dry separation processes

December 17, 2014 PROMETIA Scientific Seminar, Marcoule, France

Henning Knapp 27

![Mineral Oil Manual - [Mineral Oil Manual]](https://static.fdocuments.us/doc/165x107/62101977efe0c144cb43a59a/mineral-oil-manual-mineral-oil-manual.jpg)

![Additive Manufacturing of 1018 Steel: Process …sffsymposium.engr.utexas.edu/sites/default/files/2014-029-Knapp.pdf · components that can be used in load-bearing components [1].](https://static.fdocuments.us/doc/165x107/5b72e07f7f8b9a95348d7860/additive-manufacturing-of-1018-steel-process-components-that-can-be-used-in.jpg)