Ch4 Fused Deposition Modelling Systems

-

Upload

ben-george -

Category

Documents

-

view

70 -

download

0

description

Transcript of Ch4 Fused Deposition Modelling Systems

7/15/2019 Ch4 Fused Deposition Modelling Systems

http://slidepdf.com/reader/full/ch4-fused-deposition-modelling-systems 1/14

CH4 FUSED DEPOSITION

MODELLING SYSTEMS

7/15/2019 Ch4 Fused Deposition Modelling Systems

http://slidepdf.com/reader/full/ch4-fused-deposition-modelling-systems 2/14

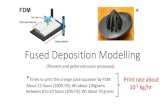

The FDM process was developed in 1988 by S.Crump whofounded Stratasys the following year. Since then the

company has produced more than 1000 systems. The firstproduct ,the 3D MODELER, was introduced by thecompany in 1922.

The FDM process works by extruding a thermoplasticmaterial and depositing it layer-by-layer fusing it to the layerbeneath it, to form a 3D model. FDM creates functionalprototypes using a variety of engineering materials like ABS,and polycarbonate.

7/15/2019 Ch4 Fused Deposition Modelling Systems

http://slidepdf.com/reader/full/ch4-fused-deposition-modelling-systems 3/14

7/15/2019 Ch4 Fused Deposition Modelling Systems

http://slidepdf.com/reader/full/ch4-fused-deposition-modelling-systems 4/14

7/15/2019 Ch4 Fused Deposition Modelling Systems

http://slidepdf.com/reader/full/ch4-fused-deposition-modelling-systems 5/14

PROCESS

Step 1 : The Preparation

FDM begins with a 3D CAD file that is oriented in theappropriate orientation for building the part. The data is thenmathematically sliced into 2D cross-sections (layers) along the Z-axis.Step 2 : The Build

The nozzle is heated to melt the plastic filament and is mountedto a mechanical stage which can be moved in both horizontaland vertical directions. As the nozzle is moved over the table inthe required geometry, it deposits a thin bead of extruded plasticto form each layer and create a two-dimensional cross section of the model.

7/15/2019 Ch4 Fused Deposition Modelling Systems

http://slidepdf.com/reader/full/ch4-fused-deposition-modelling-systems 6/14

PROCESS

The plastic hardens immediately after being squirted from thenozzle and bonds to the layer below. The platform then descends

where the next layer is extruded upon the previous. Thiscontinues until the model is completed. The entire system is

contained within a chamber which is held at a temperature justbelow the melting point of the plastic.

Step 3 : The Completion

Once all the layers are drawn and the model is complete, themodel is then removed from the platform, and the supportstructures are removed from the part.

7/15/2019 Ch4 Fused Deposition Modelling Systems

http://slidepdf.com/reader/full/ch4-fused-deposition-modelling-systems 7/14

PROCESS PARAMETERS

FDM 2000 FDM 3000 FDM 8000 Quantum

Build size

mm

254 x 254 x 254 254 x 254 x 406 457 x 457 x 609 600 x 500 x 600

Accuracy mm

+/- 0.127 +/- 0.127 +/- 0.127-0.254 +/- 0.127

Size mm 660x 914 x1067

660 x 1067 x914

1486 x 1905 x1003

2235 x 1981 x1118

7/15/2019 Ch4 Fused Deposition Modelling Systems

http://slidepdf.com/reader/full/ch4-fused-deposition-modelling-systems 8/14

PROCESS PARAMETERS Weight

Kg

160 160 392 1134

Powerrequirements

220-240 VAC

50/60 Hz10A singlephase

208-240 VAC

50/60 Hz10A singlephase

220-240 VAC

50/60 Hz10A singlephase

208-240 VAC

50/60 Hz10A singlephase

Materials ABS (white)

Investmentcasting wax

Elastomer

ABS (white)

Investmentcasting wax

Elastomer

ABS ABS

Layer width 0.254 to 2.54mm

0.254 to 2.54mm

0.254 to 2.54mm

0.38 to 0.51

Layerthickness

0.05 to 0.762mm

0.05 to 0.762mm

0.05 to 0.762mm

0.18 to 0.25mm

7/15/2019 Ch4 Fused Deposition Modelling Systems

http://slidepdf.com/reader/full/ch4-fused-deposition-modelling-systems 9/14

ADVANTAGES

True desktop manufacturing system that can be run in officeenvironment. There is no worry of exposure to toxic fume andchemicals.

The process is clean, simple, easy to operate and produces no waste

Fast building for bottle like structure or hollow parts Material is supplied in spool form which is easy to handle and

can be changed in minute Materials used are very cost effective, typical parts cost under

US$20 A good variety of material is available including colour ABS and

Medical ABS, investment casting wax and elastomer Mid range performance/cost RP system and is the best selling

RP system in 1995

7/15/2019 Ch4 Fused Deposition Modelling Systems

http://slidepdf.com/reader/full/ch4-fused-deposition-modelling-systems 10/14

DISADVANTAGES

Accuracy is relatively low and is difficult to buildparts with complicated details

Poor strength in vertical direction

Slow for building a mass part

7/15/2019 Ch4 Fused Deposition Modelling Systems

http://slidepdf.com/reader/full/ch4-fused-deposition-modelling-systems 11/14

APPLICATIONS

It does not need laser systems, uses relatively inexpensive binders, and is easy to changematerials.

The main difficulties are in controlling temperature within the growing part, the need toprovide support structures for the growing model

The accuracy which is limited to the nozzlediameter.

7/15/2019 Ch4 Fused Deposition Modelling Systems

http://slidepdf.com/reader/full/ch4-fused-deposition-modelling-systems 12/14

APPLICATIONS

Limited number of prototypes needed (1-10) Concept Models Functional testing Si3N4 components with good mechanical properties and

microstructure were produced with a filament containing 55 vol% of the ceramic. After FDM, green parts were densified by hotpressing and gave four point bend strengths similar to that of hotisostatic pressed parts.

A fine scaled piezoelectric composite structure can be made

consisting of PZT and polymer. The piezoelectric properties of the composite are similar or superior to conventionally processed PZT composites.

Composites with controlled composition distribution and a variety of microstructures can be made by combining filamentsof different compositions.

7/15/2019 Ch4 Fused Deposition Modelling Systems

http://slidepdf.com/reader/full/ch4-fused-deposition-modelling-systems 13/14

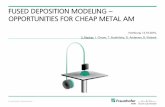

Rapid Manufacturing Jigs and Fixtures with FDMRapid prototyping has become a standard practice in productdevelopment. At the BMW AG plant in Regensburg, Germany, FDM

(fused deposition modeling) continues to be an important component in vehicle design prototyping. But moving beyond prototyping, BMW isextending the application of FDM to other areas and functions,including rapid manufacturing.

Rapid Manufacturing at

BMW

“BMW has determined that the FDM process can be an alternative to

the conventional metal-cutting manufacturing methods like milling,turning, and boring.”