Ch 4 Plc Lecure

Transcript of Ch 4 Plc Lecure

-

8/8/2019 Ch 4 Plc Lecure

1/30

Programmable Logic Controllers

-

8/8/2019 Ch 4 Plc Lecure

2/30

Objectives

Define PLC.

Explain where the PLC came from.

Explain why their use is valuable.

Explain where they are used.

Detail what PLCs can do.

Explain how PLCs know what they aresupposed to do.

-

8/8/2019 Ch 4 Plc Lecure

3/30

What Is

aProgrammable Controller?

Aprogrammable logic controller, usually

called a PLC orprogrammable controller,is a solid-state, digital, industrial computer.

Simply, a programmable controller is acomputer, much like a desktoppersonalcomputer.

A PLC is an industrially hardenedcomputer.

-

8/8/2019 Ch 4 Plc Lecure

4/30

Where Did thePLC Come From?

In the 1960s, electromechanical relays,

timers, counters, and sequencers were thestandard.

Many control panels contained hundredsof these devices and a mile or more ofwire.

-

8/8/2019 Ch 4 Plc Lecure

5/30

Where Did thePLC Come From?

Reliability was low and maintenance costs

were high. Cost was high to modify or upgrade control

panels.

In 1968 the General Motors Hydramaticdivision specified a device that wouldbecome what we know today as theprogrammable logic controller.

-

8/8/2019 Ch 4 Plc Lecure

6/30

Early PLCs

Only relay replacers

Did not have timers or counters

No sequencer instructions

No math instructions

No data manipulation instructions

-

8/8/2019 Ch 4 Plc Lecure

7/30

Why a PLC?

Easily changeable

Programmable

Reliable

Smaller

Fast switching

-

8/8/2019 Ch 4 Plc Lecure

8/30

Why a PLC?

Able to withstand harsh factory

environment Consumes less power

Easier to troubleshoot

Easy to install

-

8/8/2019 Ch 4 Plc Lecure

9/30

Why Use a PLC?

The question why use a PLC? should

really be rephrased to why automate? The PLC is the tool that provides the control

for the automated process.

-

8/8/2019 Ch 4 Plc Lecure

10/30

Automating Helps aManufacturing Facility

Gain complete control of the

manufacturing process Achieve consistency

Improve quality and accuracy

Work in difficult or hazardousenvironments

Increase productivity

-

8/8/2019 Ch 4 Plc Lecure

11/30

Automating Helps aManufacturing Facility

Shorten lead time to market

Lower cost of quality, scrap, and rework Offer greaterproduct variety

Allow a quick changeover from one

product to another

Control inventory

-

8/8/2019 Ch 4 Plc Lecure

12/30

A PLC Upon First Glance

A black box with wires bringing signals in

and other wires sending signals out Some sort of magic being done inside that

somehow decides when field devicesshould be turned on or off

-

8/8/2019 Ch 4 Plc Lecure

13/30

-

8/8/2019 Ch 4 Plc Lecure

14/30

What Makes a PLC Work?

The heart of any computer is the

microprocessor. The microprocessor, also called the processor

or central processing unit (CPU), supervisessystem control through the userprogram.

-

8/8/2019 Ch 4 Plc Lecure

15/30

What Makes a PLC Work?

The processor reads input signals and

follows the instructions that theprogrammer has stored in the PLCsmemory.

-

8/8/2019 Ch 4 Plc Lecure

16/30

What Makes a PLC Work?

As a result of the solved program, the PLC

writes information to outputs, or field-controlled devices, to turn them on or off.

When the PLC is running and following theprograms instructions, this is called

solving the userprogram.

The PLC is running or in RUNMODE.

-

8/8/2019 Ch 4 Plc Lecure

17/30

What Makes a PLC Work?

The userprogram (ladderprogram) is the

list of instructions that tells the PLC what todo.

The library of instructions available to thePLC is called the instruction set.

The instruction set determines how muchflexibility the programmer has.

-

8/8/2019 Ch 4 Plc Lecure

18/30

Common PLC Inputs

Pushbuttons

Selector switches Limit switches and level switches

Proximity sensors

Photo switches

Relay contacts

Motor starter contacts

-

8/8/2019 Ch 4 Plc Lecure

19/30

An Overview ofa PLC System

-

8/8/2019 Ch 4 Plc Lecure

20/30

An Overview ofaPLC System

Incoming signals, or inputs, interact with

instructions in the userprogram to help thePLC determine when an input instruction iseither true or false.

-

8/8/2019 Ch 4 Plc Lecure

21/30

vantages o L : Use of s/w programming instead of hardware & wires

to control the i/o devices. Amount of wiring is cut-

down by 80%.

Faster scan time: Operational time of PLC is very fastas compare to Relays. The speed of PLC logic

operation is determine by scan time, which is a matterof millisecond.

Intelligent I/Os & high speed counters.

Supervisory control & ASCII message handlingcapability.

Reliability & Maintainability: PLC has very high

reliability rate & hence control system maintenancecost is low and downtime is minimal.

-

8/8/2019 Ch 4 Plc Lecure

22/30

Flexibility :- Flexibility in programming &reprogramming in plant. Also flexibility in control

technique. i.e. the control equipment can be easilyreconfigured to accommodate required change inprocess online.

Ability to communicate with computer system in

plant.

COST :- PLC can scan digital & analog inputsthrough relevant sensors. It can execute the logic

w.r.t. the scanned inputs, take necessary decision andsend it to digital / analog outputs. It can also performtimer, counter, sequencer, PID , and other controlfunctions. The cost of all this is much less than a

conventional DATA Logger !!

-

8/8/2019 Ch 4 Plc Lecure

23/30

Versatility :- The ability to combine discrete (Digital)& Analog logic is a powerful tool for the ControlEngineers. Control of critical start-up parameters, such

as temperature and pressure, can be precisely pre-programmed for each start-up step.

As one common device (PLC) performs multiple

functions in a Plant, fewer spare parts are needed.

Programmable troubleshooting aids reduces downtime.

The software consist of LAD, which is similar to relay

logic, so even technician can maintain the plant.

-

8/8/2019 Ch 4 Plc Lecure

24/30

Expandability :- As a process changes, it is inevitablethat changes will be needed or any expansion, theseusually require more outputs.

A PLC can easily change the sequence of processthrough software and also accommodates theadditional I/Os without requiring changes in the

existing wiring ( due to modular design).

If a PID loop is to be added, no panel rework isnecessary; only the wiring of new points and some re-

programming to incorporate them is required. Rugged Construction - Can operate in Extremely harsh

field conditions.

Small in physical Size.

-

8/8/2019 Ch 4 Plc Lecure

25/30

-

8/8/2019 Ch 4 Plc Lecure

26/30

Limitations OfPLC People reluctance to change( New technology): It is

difficult to change mind set of people to newtechnology.

Environmental Considerations: Certain processenvironments, such as high heat, vibrations, noise level,interference with electronic devices limit the use ofPLC.

Fixed circuit operation: If circuit in operation is never

altered, a fixed control system might be less costly thanPLC. The PLC is most effective when periodic changesin operation are made.

-

8/8/2019 Ch 4 Plc Lecure

27/30

-

8/8/2019 Ch 4 Plc Lecure

28/30

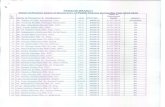

COMPARISION BETWEEN A PLC AND PCCOMPARISION BETWEEN A PLC AND PC

-

8/8/2019 Ch 4 Plc Lecure

29/30

-

8/8/2019 Ch 4 Plc Lecure

30/30

APPLICATIONSAPPLICATIONS