CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling...

Transcript of CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling...

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

1/19

Improvements in Analyzing High-Speed Fuel/Air MixingProblems Using Scalar Fluctuation Modeling

S. Mattick * Combustion Research & Flow Technology, Inc. (CRAFT Tech)

Huntsville, ALPhone: 256-883-1905/Fax: 256-833-1967

Email: [email protected]

and

K.W. Brinckman , S.M. Dash , and Z. Liu ,Combustion Research & Flow Technology, Inc. (CRAFT Tech)

Pipersville, PA 18947Phone: 215-766-1520/Fax: 215-766-1524

A scalar fluctuation model (SFM) that solves partial differential equations forenergy/species variance and corresponding dissipation rates is presented, along with severalapplications to high-speed fuel/air mixing problems. The model is implemented in a k-epsilon turbulence model framework with unified compressibility and low Re extensions,specialized for high speed aero-propulsive flow applications. It is used to predict the spatialvariation of turbulent Prandtl and Schmidt numbers using time-scale relations, providingmore accurate and reliable solutions than those based on user-specified average-values. Overthe past several years, the authors and coworkers have systematically upgraded the SFM totreat flows of increasing complexity, using a building-block approach to ensure thatmodifications made to improve the analysis of more complex cases will not degrade themodel performance in analyzing fundamental cases. A GUI-driven building-block data base(BBDB) tool has been developed to facilitate the validation/calibration process, whichcontains the various data sets we are working with (experimental and LES) along with gridsand solution files, and scripts to take CFD output and put it into the format required tocompare with the data. This paper will describe the latest version of the SFM, itsapplication to select fundamental cases in the BBDB, and a detailed description of itsanalysis of the SCHOLAR fuel/air mixing/combustion data in which we have examined gridresolution sensitivities and compared results using the SFM with those using different valuesof constant turbulent Prandtl and Schmidt numbers.

I. INTRODUCTIONAccurate modeling of scalar transport, such as internal energy and species concentration, is needed to properly

predict the temperature and fuel/air distribution in high-speed aero-propulsive devices, and thus to predictcombustion efficiency and overall performance. The effect of turbulence plays a dominant role in scalar transportand is accounted for in a RANS framework through the application of a turbulent Prandtl ( Pr t ) and turbulentSchmidt ( Sct ) number for thermal and species mixing, respectively. It is now well recognized that the application ofconstant-average values of these numbers for complex flows is inadequate since: different values apply to differentvery basic flows (e.g., 0.7 is used for round jets, 0.9 is used for boundary layers); these numbers vary widely incomplex flows; and, the values differ with varying levels of compressibility in the flow. Turbulence predictions forhigh speed flows are complicated by compressibility effects which have a first-order influence on fundamental

* Research Scientist, 3313 Memorial Parkway South, Suite 108, Member AIAA. Senior Research Scientist, 6210 Kellers Church Rd., Member AIAA President & Chief Scientist, 6210 Kellers Church Rd., Associate Fellow AIAA. Research Scientist, 6210 Kellers Church Rd., Member AIAA

American Institute of Aeronautics and Astronautics1

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

2/19

mixing for basic (cold air/air) flows, and have an even more complex influence on flows with large densityvariations produced by differences in temperature and species molecular weights.

To address such issues, a scalar fluctuation model (SFM) has been developed and systematically extended toanalyze high-speed aero-propulsive flow problems such as those encountered in scramjets, as well as in a variety ofrelated mixing problems such as those associated with missile plumes and divert/control jets. Brinckman et al. 1 extended earlier methodology formulated for lower speed flows for deriving local values of turbulent Prandtlnumber in hot jets. Transport equations for both temperature and species mass-fraction variance were formulatedwhich incorporated both high-speed compressibility corrections and low Reynolds-number near-wall extensions.Various simulations were p er f ormed for basic fuel/air mixing problems and for problems with more complexgeometries. Brinckman et al. 2,3 and Calhoon et al. 4 presented extended methodology which is capable of modelinghigh-speed reacting flows. Validation cases were presented in Ref. [ 2],[3] and [ 4] which demonstrated goodagreement for both reacting and non-reacting flows. Brinckman et al. 3 showed model comparisons for a non-reacting high-speed fuel injector, and demonstrated the complex three-dime nsional variation in turbulent scalarmixing characteristics associated with these types of configurations. Ott et al. 5 showed additional predictions for anon-reacting angled fuel injector, including comparisons to LES predictions. With a scalar variance modelingcapability for variable Pr t and Sct in place and validated against several fundamental data sets, the current workseeks to: extend the approach used for validation using a new Building-Block Data Base (BBDB) tool; and, analyzemore complex 3D problems, such as the SCHOLAR combustor data, which typifies high-speed fuel injection andcombustion in a scramjet combustor type of environment.

II. SFM TURBULENCE MODEL EQUATIONS

A. k- Turbulence Modeling FrameworkThe k- turbulence model used for aero-propulsive fl ows in the CRAFT CFD Navier-Stokes code is based on

the original model for free shear flows of Launder et al. 6 with enhancements incorporated by Papp and Dash 7 toaccount for compressibility effects in a unified manner, following concepts introduced by Sarkar and Zeman 8,9 along with other specialized extensions (e.g. vortex stretching, etc). The near-wall damping formulation of So et al. 10 is us ed with modifications that permit our application of the original Launder et al. 6 coefficients and not those of Soet al. 10 Details, plus model equations are provided in Ref. [ 2]. The scalar fluctuation model (SFM) employed in theCRAFT CFD code is based on extensions to the temperature variance model of Sommer et al. 11. It includes a two-equation species mixture fraction variance k f - f model used for obtaining the turbulent Schmidt number, and a two-equation energy variance k e- e model used for obtaining the turbulent Prandtl number, via time-scale relations.While the added expense of solving transport equations for both species and energy variance can be avoided if aconstant value of turbulent Lewis number is assumed,

t t

t

Pr Le

Sc= (1)

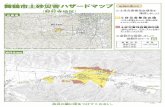

this assumption is not generally valid, and the Lewis number can vary significantly in many of the flows of interest.Figure 1 shows how the Schmidt number can vary in an angled (transverse) fuel injection flowfield. Prandtl numbervariations governed by temperature/internal energy gradients will be quite different and Lewis number variations inmost fuel injection flowfields are very substantive.

Figure 1. Schmidt Number variations in a Transverse Fuel Injection Flowfield with High-Speed ApproachFlow.

American Institute of Aeronautics and Astronautics2

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

3/19

B. Energy Variance EquationsThe energy variance k e- e formulation used to predict local values of turbulent Prandtl number has a production

source term for the energy variance k e = based on the gradient of the internal energy, e. Earlier versions hadused the gradient of temperature for the production term, but for chemically reacting flows, use of energy variance is

preferable 4. The transport equations for energy variance and its dissipation rate e are:

2

,

( )( ) 2ee e ek e j

u k k k e j t t t x x x x j j j

2 + = + +

(2)

2

,

( )( )1 2

3 4 5

j ee e

j j e j e

e ee

e

u et C C t d d t x x x k k

C P C C d k d d T k k k

e

j x

+ = + + +

+ + +

(3)

where the dissipation rate is defined as,

ek k

e e

x x

=

(4)

and the heat transfer time scale is,

,e

m ee

k k

= (5)

The compressibility correction used in the k- model 7 has the relation,

2 2 P P M P M k k 1 T k 2 T =

(6)

In this equation, P k is the production term in the transport equation for k and T M is the local turbulent Mach numberwith respect to the sound speed, c, la gged by a value of = 0.2, so that compressibility corrections do not initiateuntil this fluctuation level is exceeded 7. Thus,

22 / ,T M k c M max M , 0T T = = (7)

In Eqn. (3), T is a near-wall damping function included to capture low-Reynolds number behavior. Details ofthis term are provided in Ref. [ 1] for the temperature variance formulation. An analogous form is used for the energyvariance dissipation rate, with the scalar fluctuation time scale provided by the ratio k e / e. Constants used in the k e- e model, summarized in Table 1 , are consistent with those proposed by Sommer et al. 11 with the exception of ,k

and ,e , whose value of 1.0 has been found to provide better agreement with data. Wall thermal boundary

treatments using a wall-function approach 12 or a wall resolved approach 11 are both available.The turbulent Prandtl number with near-wall damping is given by

eT

e

C f k Pr

C f k

=

(8)

and the turbulent thermal diffusivity is calculated from,

,t

t T

vC f k

Pr m e = = (9)

where C = 0.14, which differs slightly from the value presented by Sommer et al. 11 to better simulate the turbulentPrandtl number for jet mixing problems. The coefficients C and f are related to the k- turbulence model and are

American Institute of Aeronautics and Astronautics3

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

4/19

discussed in Ref. [ 7]. For the nearwall damping function, f , following Abe et al. 13 , we use the Kolmogorovvelocity scale u = ( )

1/4 to define a wall distance y* = u y/ , which can be applied in both attached and detachedflows. The expression for the near-wall damping function f used in the current fluctuating-scalar model is

*2

11/4

/1t

C y A f f eT Re

+ = +

(10)

Use of the internal energy as a basis for this model removes the chemical source terms from the transportequations that appear for the temperature-based formulatio n. This model has also been formulated so that it reducesexactly to the nonreacting formulation of Brinckman et al. 1 when the fluid mixture specific heats are constant. Themodel predicts both low and high speed flows using a single set of calibration coefficients. For reacting flowsimulations using a pdf-based model, the required temperature fluctuations may then be extracted from k e asdescribed by Calhoon and Kenzakowski 14.

Table 1. Scalar Variable Model Constants

Cd1 Cd2 Cd3 Cd4 Cd5 C1 A+ k,e ,e

2.0 0.0 0.72 2.2 0.8 0.1 45 1.0 1.0

C. Mixture Fraction Variance EquationsTransport equations for the mixture-fraction variance k f = and its dissipation rate f are similar to the

energy variance model, except that the source term on the k f equation is based on the mixture fraction f , where f isgenerally taken to be the effective dilution ratio of an inert species (e.g., f =1 in the unmixed fuel jet and f =0 in thesurrounding airstream). The mixture fraction variance equations are given as:

2

,

( )( )2

f f f t f

j j k f j j

u k k k D f j D Dt t x x x x

2 + = + +

(11)

2

,

( )( )1 2

3 4 5

f f f

j j f j f

f f

f f

u D f j t D D C C t d d t x x x k k

C P C C

d k d d f k k k

f

j x

+ = + + +

+ + +

(12)

where f is tracked as a conserved scalar. In non-reacting problems, the mass fraction of an individual species behaves as a conserved scalar, and a mixture fraction can be derived by normalizing one of the species massfractions. This approach provides computational efficiency by eliminating the need to solve an additional transportequation for mixture fraction. In reacting problems, the same approach can be used with any inert species, as itsmass must be conserved. In the absence of an inert species, an additional transport equation for the mixture fractionitself must be solved to assure that the variance k f is based on a conserved scalar (see Ref. [ 2]).

Here, the dissipation rate is defined as

f k k

f f D

x x

=

(13)

and the mass transfer time scale, based on the turbulent velocity and species mixing time scales, is

, f

m f f

k k

= (14)

The turbulent mass diffusivity is calculated from:

,t

t t

D C f k Sc

m f = = (15)

American Institute of Aeronautics and Astronautics4

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

5/19

and the turbulent Schmidt number with near-wall damping is:

f t

f

C f k Sc

C f k

= (16)

where the model parameters C , C , f and f are as described earlier for the energy variance model. The model

constants for the mixture fraction variance are those used in the energy variance model as given in Table 1 .

III. Building-Block Data Base (BBDB) ToolIn calibrating and validating the SFM, a building-block approach is now being used where we start with very

basic cases and work our way forward analyzing cases of increasing complexity. If we need to add corrections ormodify the SFM for more complex cases to get good agreement with data, we have to go back to the more basiccases and rerun them to ensure that the changes made do not degrade the earlier comparisons. This can be a verytime-consuming and tedious process, which we have now expedited by constructing a GUI-driven BBDB tool. Thistool has the basic features summarized in Table 2 below, with some of the cases we have included shown in Table 3 .Figures 3 and 4 show case descriptions, which summarize some of the cases included in the BBDB. For each case,we have the data (experimental or LES) in line plot format and scripts for the CFD solution files that provide directgraphical comparisons with the data withno user intervention. Several cases can

be run sequentially, so that after onemakes some modifications to the SFM, asequence of runs can be performedovernight with the comparisons availablein the morning, plotted as per the scriptsset up for each case. The BBDB tool hasalso proven useful in comparing resultsof different codes and we have beendeveloping code-specific interfaceroutines to facilitate making suchcomparisons. Once we have completedinstallation of the BBDB on a dedicatedweb-site, outside users will be able touse it as well, as shown schematically inFigure 2.

Table 2. Building Block Data Base (BBDB) Tool

Tool kit / data base provides: user-friendly / web-based environment for accessing and using validation case files detailed description of validation case files with available experimental or LES data solution files ( using various turbulence models, etc) grid file restart file and instructions on how to restart (code specific) current solution file: case specific processing (scripts)

- utilities to format data files for direct comparison Data organized in a Building-Block manner

automated run sequencing is available so we can repeat a series of most relevant cases to see how a modeling change impacts comparisons with data and earlier solutions

Figure 2. Schematic of Web-based BBDB System used for SFM

Validation.

American Institute of Aeronautics and Astronautics5

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

6/19

Table 3. Select SFM Validation Data Sets and GUI Driven Data Retrieval

Figure 3. Beach Hydrogen/Air Coaxial Reacting JetData Set.

Figure 4. SCHOLAR Angled Fuel InjectionCombustion Data Set.

American Institute of Aeronautics and Astronautics6

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

7/19

IV. Fundamental Case Studies

A. Compressibility-Effects Air/Air StudiesThe effects of compressibility on jet mixing problems are quite significant, and can be illustrated by the

comparisons shown below for a round, Mach 2 jet into still air (Seiner 15), and for a transverse jet exhausting into asupersonic approach flow with boundary layer (Spaid and Zukoski 16). Including the unified compressibility

correction of Reference [ 7] into the k- turbulence model reduces the rate of jet decay, and increases the extent of thetransverse jet induced separation bubble, in agreement with the data, as shown in Figures 5 and 6 below.

Figure 5. Analysis of Seiner Mach 2 Jet into StillAir with and w/o Compressibility-Correction (CC).

Figure 6. Analysis of Spaid and Zukoski Transverse JetData with and w/o CC

B. Low Speed vs. High Speed Hot, Round Jet BehaviorOur studies using SFM have indicated fundamental differences in the behavior of subsonic ( Figure 7 a) and

supersonic ( Figure 7 b) hot jets. For hot subsonic jets, the velocity and temperature fluctuations behave in similarmanner as their intensities asymptote toward the same level after the mixing reaches the axis (as confirmed bycomparisons with data sets such as those of Lockwood and Moneib 17). In contrast for supersonic jets, the velocityfluctuations on the centerline asymptote, but the temperature fluctuations peak and then decay. The SFM predictedtrends are confirmed by comparisons with an LES calculation for the supersonic jet in Figure 7 b.

(a). Hot Subsonic Jet (b). Hot Supersonic JetFigure 7. Low Speed vs. High Speed Hot, Round Jet Behavior, Fluctuation Intensity

American Institute of Aeronautics and Astronautics7

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

8/19

C. Scalar Fluctuation Differences in Variable Density Subsonic and Supersonic Round JetsAs shown in the comparisons below (Figure 8)

performed using SFM, for subsonic jets with the samedensity ratio (produced by either temperature ormolecular weight), the temperature and speciesfluctuations are identical. This should be contrastedwith the behavior in supersonic jets where it is seenthat temperature fluctuation levels are significantlyhigher than species fluctuation levels, and they peakand decay rather than flattening after the mixingreaches the axis. This difference in behaviorexemplifies how compressibility affects scalarfluctuations, and modeling this behavior properly is amatter of on-going research, as we look to analyzemore challenging supersonic flows, with shocks andother complexities.

Figure 8. Subsonic and Supersonic Variable DensityRatio Jets.

V. Basic Fuel / Air Mixing and Combustion Studies

A. Beach/Evans Coaxial H 2 /Air Jet StudyIn the experiment of Evans et al. 18, a Mach 2 hydrogen jet is exhausted into a co-axial stream of vitiated air at

Mach 1.9. This is a basic coaxial H 2/air high-speed jet mixing and combustion case with no geometric complexities.The jet issues from a nozzle with inner diameter d = 0.6525 cm and outer diameter d o = 0.9525 cm. A schematic ofthe experimental apparatus and flow conditions for the inner and outer jets is provided in Figure 3 . The case wasanalyzed using a basic H/O reaction mechanism (7 species/8 reactions) with both the Prandtl and Schmidt numbers

prescribed ( Pr t = Sct = 0.7), and using the SFM model. Figure 9 (a) and (b) show the predicted variation of H 2 alongthe jet centerline, and a profile of H 2O at a location about 22 diameters downstream of the nozzle exit plane. The

predicted contours of Pr t and Sct for this case are shown in Figure 10 and do not vary significantly, with valuesranging from about 0.55 - 0.75 in the developed jet. Using averaged values of 0.7 appears to do an adequate job forthis basic case.

(a). H2 variation along jet Centerline (b). H

2O profile at x/d ~ 22

Figure 9. Beach/Evans Coaxial H 2 /Air Jet, Comparison of Predictions to Data.

American Institute of Aeronautics and Astronautics8

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

9/19

(a). Turbulent Prandtl Number (b). Turbulent Schmidt NumberFigure 10. Prandtl and Schmidt number variations for Beach/Evans Jet.

Figure 11. Schematic of experimental set-upfor the Burrows and Kurkov 19 combustor.

B. Burrows and Kurkov H 2 Slot Jet Ducted Mixing and Combustion StudyThis experiment consisted of sonic hydrogen injection

through a backward facing step into a Mach 2.44 vitiated air(or with N 2 in the non-combusting case) stream. Figure 11

presents a schematic of the experimental set-up. The flowconditions for this case are summarized in Table 4 . Contoursof Prandtl, Schmidt and Lewis number are shown in Figure12. For the mixing case, the variations are seen to be modest,and the analysis of this case with constant values has beenshown to be adequate. For the combusting case, note the

pronounced change in these transport parameters at theignition location which has led to markedly improvedcomparisons with the data (see Refs. [ 2]-[4]). The response ofthe SFM to the changes in turbulence produced by heat release due to combustion is an extremely promising featureof this model and has led to improvements in comparisons with data for several case, including the SCHOLAR datato be discussed below.

Mixing Experiment Combustion Experiment

Figure 12. Burrows & Kurkov Study Contours of Pr t , Sc t and Le t.

American Institute of Aeronautics and Astronautics9

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

10/19

Table 4. Vitiated air and fuel exit conditions for Burrows and Kurkov 19 experiment.Vitiated Air Hydrogen

Static Pressure 101.325 kPa 101.325 kPaStatic Temperature 1270 K 242 KMach Number 2.44 1.0H2 mass fraction 0.0 1.0

O2 mass fraction 0.258 0.0 N2 mass fraction 0.486 0.0H2O mass fraction 0.256 0.0

VI. Analysis of SCHOLAR Data

A. OverviewThe SCHOLAR data set (see Figure 4 ) is intended to validate CFD models in an environment which typifies that

in a scramjet combustor, with flush/angled injectors. The 3D SCHOLAR angled fuel injector mixing andcombustion experiments were conducted at NASA Langley Research Center Ref. [ 20-21], providing data for CFDmodel validation, including mean temperature, wall pressure, and species measurements. These data sets are usefulfor analyzing the capabilities of the SFM to capture turbulent mixing effects in more complex flows involvinghydrogen injection into three-dimensional cross-flows. Data was obtained at 4 stream-wise planes downstream of

the injector, with the X-location of each stream-wise plane provided in Table 5 .

Table 5. X-location of planes.Plane X-location

3 274.2 mm5 426.6 mm6 777.0 mm7 1234.2 mm

Computational analyses by Rodriguez and Cutler 22 showed sensitivity to boundary conditions includingtemperature, species composition, and inflow turbulence parameters. They found their solutions to be most sensitiveto the values used for Pr t and Sct , and concluded that it is unlikely that constant values for these parameters can becalibrated to be valid for a wide range of flows. They suggested that the use of models providing for variable Pr t and Sct values are necessary to properly simulate the SCHOLAR combustion experiment. Keistler et al. 23 proposeda model for variable Pr t and Sct based on enthalpy and concentration variances, which they used to analyze theSCHOLAR combustor experiment but comparisons with the data have not shown overall consistency.

Our analysis predicts variable Pr t and Sct using the SFM formulation, which includes compressibilitycorrections. The facility nozzle from the upstream heater was modeled to provide inflow boundary conditions formean and turbulence quantities, to the test section. Near-wall modeling was used for no-slip walls, along with aconstant wall temperature. Early analyses considered the effect of wall temperature and it was found to have alimited impact on results. This correlates well with the results of Ref. [ 22], which showed a minor effect from thetemperature of the wall.

B. Grid SensitivityA systematic approach was used to model the

SCHOLAR experiment. Three levels of grid refinement

were performed, denoted as Grid A, Grid B, and Grid Cfor subsequent levels of refinement. A representativeview of Grid C in the vicinity near the injector is

provided in Figure 13. This domain was decomposedinto an isolator section upstream of the injector, theinjector section containing the angled fuel injector, and adownstream combustor section. The injector nozzle wasincluded in a block that extended into the duct. Griddimensions are shown in Table 6 . The large increase ininjector nozzle grid points was primarily directed at

American Institute of Aeronautics and Astronautics10

Figure 13. Schematic of SCHOLAR grid nearinjector ( every other grid point shown), Plane 5 (X =

426.6mm) shown for reference.

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

11/19

better resolving the nozzle wall boundary layer and turbulence production, with the intent of improving early jetcore mixing predictions.

Table 6. Scholar Grid Dimensions.Grid A Grid B Grid C

Duct Block 245x95x33 305x113x41

565x145x65

Isolator(black) 209x145x65 Injector(green) 173x145x65Combustor(purple) 201x145x65

Injector Nozzle Block 134,976 cells 449,196 cells 1,258,353 cellsTotal Cells 868,928 1,811,116 6,456,177

Figure 14. SCHOLAR mixing experiment, Wallpressure grid sensitivity.

Mixing and combustion cases were considered for allthree grids using SFM. Comparisons of lower wall pressurefor the three grids (Figure 14) for the mixing case primarilyshow a sharpening of the peaks, particularly downstream ofinjection. The general peak locations, however, are basicallythe same. Comparisons of results to contours developed fromexperimental data are shown in Figure 15 and indicate thatgrid refinement helps to better capture the radial extent of themixing, but the jet core mixing is being somewhat under

predicted. A three-fold increase in mesh points from Grid Bto Grid C did not significantly improve the core mixing

prediction. This type of trend has been noted in compa risonsto other data sets involving transverse fuel injectors 24 andwork is ongoing to understand the model performance inthese mixing configurations.

(a) mean temperature

(b) mole fraction N 2 Figure 15. SCHOLAR mixing experiment, Comparison of CRAFT predictions to measured data at Plane 5,

grid sensitivity.

American Institute of Aeronautics and Astronautics11

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

12/19

Wall pressure comparisons to data for all three grids for the combustion case are shown in Figure 16 .Substantial improvement is noted in going from Grid A to Grid C downstream of x = 400mm. Grid A was verycoarse stream-wise in this section due to the long combustor, which caused a much more diffusive flow-field thanthat of the more refined grids. Contours of mean temperature shown in Figure 17 indicate combustion in Grid Astarting to take place well upstream of the other two grids. However, the amount of combustion taking place ismuch less, which coincides with the wall pressure result. The combustion onset location along the top wall for GridB and Grid C are in similar locations, providing some consistency in the results. Figure 18 shows mean temperatureand N2 mole fraction contours compared to measured data for all three grids. As in the mixing case, the core jetmixing is under-predicted, even with the substantial increase in the number of grid points. More combustionappears to be taking place on Planes 6 and 7 of Grid C compared to the experiment, but the overall contours providea better match to data than the coarser grids. These results clearly r eveal an improved match to data with gridrefinement going from Grid A to Grid C. However, grid convergence 25 has yet to be realized. Work is progressingon a formal method of grid convergence, which will be employed in further analyses of this experiment 26.

(a) lower wall (b) upper wallFigure 16. SCHOLAR combustion experiment, Wall pressure grid sensitivity.

Figure 17. SCHOLAR combustion experiment, Temperature grid sensitivity.

American Institute of Aeronautics and Astronautics12

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

13/19

(a) Mean temperature

(b) mole fraction N 2 Figure 18. SCHOLAR combustion experiment, grid-sensitivity comparison.

American Institute of Aeronautics and Astronautics13

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

14/19

Figure 19. SCHOLAR mixing experiment, wallpressure predictions vs. data.

C. SCHOLAR Supersonic Mixing ExperimentHaving established sensitivities to grid resolution, we

now focus on SFM model comparisons versus those withconstant Pr t and Sct , with all calculations performed onGrid C. The CRAFT CFD code was used to performthree-dimensional simulations of this experiment, takingadvantage of planar symmetry on the fuel injectorcenterline to reduce the computational expense of thesimulation. The symmetry assumption is consistent withtraditional RANS-based approaches to modelingsymmetrically placed multiple fuel injector arrangements,and is reasonable for the current comparisons, based on areview of the experimental data provided in Ref. [ 20]-[21].Lower wall pressure predicted with CRAFT CFD usingvariable and constant values of Pr t and Sct equal to 0.9 iscompared to measured data from the SCHOLAR mixingexperiment in Figure 19. There is good overall agreementwith the data except for the early peak pressures, which appear to be due to shocks upstream of the injector. Thesemissed shocks also seem to cause the curves to be shifted downstream of the data. Geometry refinement was

performed to include the upstream facility nozzle to try to capture these shocks, but the two peaks upstream of x =200mm could not be reproduced in wor k to date. The same inconsistency to experimental data was observed insimulations documented by Danehy et al. 20, suggesting that there may be some physical feature in the experimentalfacility that is not being included in relatively simple isolator models. Sensitivity analyses and model refinementsare being considered which may reveal the source of this discrepancy with the data, and its impact on jet mixing.

Results from predictions using both variable and constant values of Pr t and Sct equal to 0.9 are compared formean temperature and nitrogen mole fraction at a streamwise plane corresponding to x 427mm. As with the wall

pressure, the contours of mean temperature and nitrogen mole fraction between variable and constant Pr t and Sct inFigure 20 are very similar. Contours of local Pr t and Sct are shown in Figure 21 , exhibiting a range of Pr t and Sct from 0.8 to 1.0 in the jet region, indicating that a constant value of 0.9 is an appropriate choice in the downstreammixing region.

Figure 22 shows CRAFT predictions using variable Pr t and Sct compared to the measured data. The generalshape of the jet region is similar between the two, but the extent of jet core mixing is larger in the data. Asmentioned earlier, this discrepancy with data does not seem to be related to grid resolution. While use of constant

values of Pr t and Sc t for the mixing case has a minimal effect compared to use of the SFM, it has a significant effecton comparisons to data for the combusting case, as will be discussed.

(a) mean temperature (b) mole fraction N 2 Figure 20. SCHOLAR mixing experiment, Comparison of CRAFT predictions for variable and constant Pr t

and Sc t.

American Institute of Aeronautics and Astronautics14

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

15/19

(a) turbulent Prandtl number (b) turbulent Schmidt numberFigure 21. SCHOLAR mixing experiment, Predicted Pr t and Sc t.

(a) mean temperature (b) mole fraction N 2 Figure 22. SCHOLAR mixing experiment, Comparison of CRAFT predictions with measured data.

D. SCHOLAR Supersonic Combustion ExperimentComparisons of res ults predicted with CRAFT CFD for Grid C (using the extended chemistry mechanism and

rates of Conaire, et al. 25) are made along the symmetry-plane for wall pressure and at four stream-wise planes forcontours of mean temperature and N 2 mole fraction. Figure 23 compares predicted and measured wall pressurealong the upper and lower combustor walls. Three cases are shown in this figure: one using variable Pr t and Sc t; andthe other using a constant Pr t equal to 0.9 and Lewis ( Let ) numbers of 1.0 ( Sct = 0.9) and 2.0 ( Sct = 0.45). TheSCHOLAR mixing predictions presented above suggested that constant values of Pr t = 0.9 and Sct = 0.9 would bereasonable values for analysis of the SCHOLAR combustion problem, since the results between the two were verysimilar. For the reacting case, however, predicted wall pressure compared to measured data in Figure 23 shows amarked difference between the two cases. Here, the Le t =1.0 case overpredicts fuel/air mixing with the ignition pointsomewhat upstream of the data. The Le t =2.0 case grossly overpredicts fuel/air mixing, with the onset of ignition wellupstream of that indicated by the data. The variable Pr t /Sc t prediction appears to capture the ignition point in much

better agreement with the data, based on the location of the peak pressure spike.

(a) lower wall (b) upper wallFigure 23. SCHOLAR combustion experiment, wall pressure predictions vs. data.

American Institute of Aeronautics and Astronautics15

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

16/19

Figure 24 shows contours of temperature, Pr t , H2O/H 2 mole fraction, and Sct on the symmetry plane for thevariable Pr t /Sc t case. Along this plane, the combustion begins at both walls near the same X-location, whichcorrelates to the largest peak in the pressure plots shown in Figure 23 . The changes in Pr t correspond to sharptemperature gradients near where the fuel enters the duct and where combustion begins. Pr t is greater than 1.0 inthese locations, but is closer to 0.7 near the center of the fuel jet. The plots of H 2O and Sct reveal Sct values greaterthan 0.9 that appear to delay ignition, as was seen in the wall pressure comparison. These figures reveal a continualvariation in Pr

t and Sc

t values as the flow evolves downstream. Figure 25 shows Pr

t and Sc

t values at the

experimental stream-wise planes, with a variation seen throughout the width of the duct. Contours of Le t in Figure26 reveal the deviation from 1.0 throughout the flow field.

Figure 24. SCHOLAR combustion experiment, symmetry plane contours; temperature, Pr t, H 2O and H 2 mole fraction, and Sc t.

American Institute of Aeronautics and Astronautics16

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

17/19

(a) Turbulent Prandtl Number (b) Turbulent Schmidt NumberFigure 25. SCHOLAR combustion experiment, Predicted Pr t and Sc t plotted with mean temperature and

mixture fraction, respectively.

Figure 26. SCHOLAR combustion experiment, contours of Le t.

Unlike the mixing problem where constant global values of Pr t and Sc t were adequate to provide a reasonablematch to the measured data, in the reacting problem these parameters respond more vigorously to sharptemperature and species gradients in the vicinity of the flame. This result shows the difficulty of selecting constantvalues of Pr t and Sc t which are adequate over the entire domain, for more complex problems, and suggests that theirchoice is not intuitive based on the observed behavior of simpler unit problems.

American Institute of Aeronautics and Astronautics17

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

18/19

Comparisons of predicted to measured contours of mean temperature and nitrogen mole fraction are shown inFigure 27 for the variable Pr t /Sc t , Let = 1.0 ( Pr t =0.9, Sct =0.9), and Le t = 2.0 ( Pr t =0.9, Sct =0.45) cases. Meantemperature contours for the variable case show much better comparisons with the data in early portions of thefuel/air mixing region, with the Le t = 1.0 case (marked for Sct =0.9) and Le t = 2.0 case (marked for Sct =0.45)showing burning to occur prematurely. The constant Pr t /Sc t cases shown in Figure 27 capture the same behaviorseen in wall pressure, where high combustion temperatures are occurring far upstream compared to the data.Downstream, the comparisons of the CFD calculations are more reasonable.

(a) mean temperature (b) nitrogen mole fractionFigure 27. SCHOLAR combustion experiment, comparison of variable and constant Pr t and Sc t

predictions to measured data.

VII. Concluding RemarksThe current status of the SFM was summarized and a building block data base (BBDB) tool for systematic

validation was introduced. Varied basic studies were presented showing the markedly different behavior of scalarfluctuations in low speed vs. high speed flows, where compressibility-effects introduce complexities into themodeling. For very basic, non-reacting cases, selection of appropriate values of Pr t and Sc t can produce adequateresults, but the values to use are not always intuitive. For complex flows, and particular for flows with combustion,

Pr t and Sc t vary substantially and no constant values are appropriate. We have shown that Pr t and Sc t changesignificantly in flame zones (Burrows and Kurkov and SCHOLAR data) with the changes predicted by the SFM

providing substantive improvements in analyzing complex/combusting data sets. Modeling the effect ofcompressibility on scalar fluctuations is a matter of on-going research, particularly as we get into more challengingsupersonic flows with shocks and other complexities.

AcknowledgmentsSubstantive portions of this effort were performed under an AFRL funded SBIR effort monitored by D. Risha.

References1 Brinckman, K.W., Kenzakowski, D.C., and Dash, S.M., Progress in Practical Scalar Fluctuation Modeling for High-Speed

Aeropropulsive Flows, AIAA Paper No. AIAA-2005-0508, 43 rd Aerospace Sciences Meeting and Exhibit, Reno, NV,Jan. 10-13, 2005.

2 Brinckman, K. W., Calhoon, W.H., Jr., and Dash, S.M., Scalar Fluctuation Modeling for High-Speed AeropropulsiveFlows, AIAA Journal , Vol. 45, No. 5, pp 1036-1046, May 2007.

3 Brinckman, K.W., Calhoon, W.H., Jr., Mattick, S., Tomes, J. and Dash, S.M.., Scalar Variance Model Validation for High-Speed Variable Composition Flows AIAA Paper No. AIAA-2006-0715, 44 th Aerospace Sciences Meeting and Exhibit,Reno, NV, Jan. 9-12, 2006.

4 Calhoon, W.H., Jr., Brinckman, K.W., Tomes, J., Mattick, S. and Dash, S.M.., Scalar Fluctuation and Transport Modelingfor Application to High Speed Reacting Flows AIAA Paper No. AIAA-2006-1452, 44 th Aerospace Sciences Meeting andExhibit, Reno, NV, Jan. 9-12, 2006.

American Institute of Aeronautics and Astronautics18

-

8/10/2019 CFD Improvements in Analyzing High Speed FuelAir Mixing Problems Using Scalar Fluctuation Modeling 2008-0768

19/19