Centrifugal feeders - Gruber...Centrifugal feeders A centrifugal feeder ensures you speedy as -...

Transcript of Centrifugal feeders - Gruber...Centrifugal feeders A centrifugal feeder ensures you speedy as -...

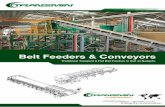

Centrifugal feeders

� �� A centrifugal feeder ensures you speedy as-sembly. The centrifugal feeder of Gruber can handle up to three millions in 24 hours.

� �� Avoid wear on the components: with the aid of centrifugal force, Gruber’s centrifugal feeders ensure that your pieces are not damaged du-ring alignment.

� �� A centrifugal feeder emits minimal noise and is thus good for your working environment.

�� Gruber has developed a system that is suitable for all component sizes. Choose from bowls with 350 mm, 500 mm or 850 mm diameter.

Manage your components in a centrifugal feeder from Gruber

A centrifugal feeder from Gruber ensures that your components are sorted and oriented quickly and correctly before they are used in your automated assembly line.

�� Stepless speed regulation on the centrifugal feeder plate and bowl ensures you optimal sorting conditions.

�� With a centrifugal feeder from Gruber, you are guaranteed speedy changeover to another similar component.

Get a free test

Contact Gruber if you have a component you would like to have oriented better, quicker and with greater care. Send us 30 - 40 samples. We will then perform a test with our laboratory feeds and send you a report with recommendations for improvements.

A centrifugal feeder from Gruber A/S ensures that your components are sorted and oriented quickly and correctly before they are used in your automated assembly line.

GRUBER

Ole Rømersvej 32DK-6100 Haderslev

+45 - 7452 9392

Please call Poul Bek from gruber at +45 2687 2200, if you have a componentyou would like to have oriented better, quicker and with greater care.