Centerm Expansion Project / South Shore Access Project ...€¦ · 2016-11-12 · November 2016...

Transcript of Centerm Expansion Project / South Shore Access Project ...€¦ · 2016-11-12 · November 2016...

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

Prepared by:

AECOM 3292 Production Way, Floor 4 604 444 6400 tel Burnaby, BC, Canada V5A 4R4 604 294 8597 fax www.aecom.com

November 2016 Project Number: 60476505 VFPA Project Number: 07-14 VPISD

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505

Distribution List

# Hard Copies PDF Required Association / Company Name

Revision History

Revision # Date Revised By: Revision Description

A 21Sept16 NB, GC Initial Draft

B 26Oct16 JN, NB Initial Draft

1 21Nov16 NB, JP Issued for Information

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

AECOM: 2015-04-13 © 2009-2015 AECOM Canada Ltd. All Rights Reserved. i 2016-11-23 Hazardous Materials Report_60476505

Statement of Qualifications and Limitations The attached Report (the “Report”) has been prepared by AECOM Canada Ltd. (“AECOM”) for the benefit of the Client (“Client”) in accordance with the agreement between AECOM and Client, including the scope of work detailed therein (the “Agreement”). The information, data, recommendations and conclusions contained in the Report (collectively, the “Information”): is subject to the scope, schedule, and other constraints and limitations in the Agreement and the qualifications

contained in the Report (the “Limitations”); represents AECOM’s professional judgement in light of the Limitations and industry standards for the preparation of

similar reports; may be based on information provided to AECOM which has not been independently verified; has not been updated since the date of issuance of the Report and its accuracy is limited to the time period and

circumstances in which it was collected, processed, made or issued; must be read as a whole and sections thereof should not be read out of such context; was prepared for the specific purposes described in the Report and the Agreement; and in the case of subsurface, environmental or geotechnical conditions, may be based on limited testing and on the

assumption that such conditions are uniform and not variable either geographically or over time. AECOM shall be entitled to rely upon the accuracy and completeness of information that was provided to it and has no obligation to update such information. AECOM accepts no responsibility for any events or circumstances that may have occurred since the date on which the Report was prepared and, in the case of subsurface, environmental or geotechnical conditions, is not responsible for any variability in such conditions, geographically or over time. AECOM agrees that the Report represents its professional judgement as described above and that the Information has been prepared for the specific purpose and use described in the Report and the Agreement, but AECOM makes no other representations, or any guarantees or warranties whatsoever, whether express or implied, with respect to the Report, the Information or any part thereof. Without in any way limiting the generality of the foregoing, any estimates or opinions regarding probable construction costs or construction schedule provided by AECOM represent AECOM’s professional judgement in light of its experience and the knowledge and information available to it at the time of preparation. Since AECOM has no control over market or economic conditions, prices for construction labour, equipment or materials or bidding procedures, AECOM, its directors, officers and employees are not able to, nor do they, make any representations, warranties or guarantees whatsoever, whether express or implied, with respect to such estimates or opinions, or their variance from actual construction costs or schedules, and accept no responsibility for any loss or damage arising therefrom or in any way related thereto. Persons relying on such estimates or opinions do so at their own risk. Except (1) as agreed to in writing by AECOM and Client; (2) as required by-law; or (3) to the extent used by governmental reviewing agencies for the purpose of obtaining permits or approvals, the Report and the Information may be used and relied upon only by Client. AECOM accepts no responsibility, and denies any liability whatsoever, to parties other than Client who may obtain access to the Report or the Information for any injury, loss or damage suffered by such parties arising from their use of, reliance upon, or decisions or actions based on the Report or any of the Information (“improper use of the Report”), except to the extent those parties have obtained the prior written consent of AECOM to use and rely upon the Report and the Information. Any injury, loss or damages arising from improper use of the Report shall be borne by the party making such use. This Statement of Qualifications and Limitations is attached to and forms part of the Report and any use of the Report is subject to the terms hereof.

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 ii

Quality Information

Report Prepared By:

Nadia Baker, BSc., RPBio

Environmental Assessment and Permitting Specialist

Gary Cheung, MASc., BASc., STS Area SH&E Manager

Kenneth Gauthier, B.Sc., P.Ag.

Environmental Scientist

James Neville, MEDes, RPBio Senior Scientist

Report Reviewed By: Giovanna (Joanne) Petrini, BA, LLB, MBA Associate Vice President Environment, BC and Yukon

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 iii

Executive Summary The Centerm Container Terminal (Centerm) is located in Vancouver Harbour on the south shore of Burrard Inlet, British Columbia (BC) (Figure 1-1). The proposed Project will result in the demolition or alteration of a number of on-site buildings. In addition, a portion of one off-site building (Canfisco) is expected to be demolished to facilitate the East Waterfront Road expansion. On the 22nd and 24th February 2016, an Asbestos Hazard Emergency Response Act (AHERA) accredited building inspector and an Environmental Scientist from AECOM performed the visual site assessment. The visual site assessment identified a number of hazardous materials on-site, including:

Asbestos-containing materials Lead-containing paint PCBs ODSs Mercury and other heavy metals Abandoned chemicals Silica Mould

Based on the initial findings, subsequent hazardous materials site survey and sampling was conducted by AECOM on 9th August and 12th September 2016. Suspected asbestos-containing materials and lead-containing paint were collected and submitted for laboratory analysis and came back negative. Potential sources of PCBs in electrical equipment (i.e., light ballasts), mercury switches, and ozone depleting substance refrigerants were identified.

Based on observations made during the Hazardous Building Materials Review, the following recommendations are provided:

1. As “hazardous materials” have been identified in the building, all identified “hazardous materials” affected by the upcoming work should be first removed prior to demolition of any affected part of the building. These specific requirements are outlined in the City of Vancouver’s Bulletin 2000-065 Hazardous Material Report Form (or any other requirements that may be included under the permit(s) that may be issued by the City), as well as in Section 20.112 of the OHSR.

2. Removal and/or handling of any hazardous materials should only be carried out in accordance with written safe work procedures and requirements of the OHSR, and other application regulatory requirements.

3. In the event that a suspect asbestos-containing material (not already identified by the surveys) is encountered during demolition work, representative samples of the material should be collected and submitted for laboratory analysis to verify the material’s asbestos content.

4. During the Detailed Site Survey some of the light ballasts in various buildings could not be inspected due to ongoing operations. There is potential for these light ballasts to contain PCBs depending on the age of the building and equipment, therefore, they will need to be investigated further prior to demolition of buildings.

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 iv

Acronyms AHERA Asbestos Hazard Emergency Response Act

AST Aboveground Storage Tank

BC British Columbia

BCCDC BC Centre for Disease Control

BCSP Board Certified Safety Professional

CBL Container Berth Lunchroom

CEL Container East Lunchroom

CEP Centerm Expansion Project

CFF Container Foreman Facility

CEPA Canadian Environmental Protection Act

CMO Centennial Main Office

CYL Container Yard Lunchroom

DLC Demolition, Land Clearing, and Construction

DPWV DP World Vancouver

EMA British Columbia Environmental Management Act

EPA Environmental Protection Act

EPA Environmental Protection Agency

EPDM Ethylene Propylene Diene Terpolymer

ESA Environmental Site Assessment

HPA Hazardous Products Act

HUD Department of Housing and Urban Development

HWRBC Hazardous Waste Regulation (HWR)

LED Light-Emitting Diode

ODS Ozone-Depleting Substances

OHSR Occupational Health and Safety Regulation

PCB Polychlorinated Biphenyl

PLM polarized light microscopy

SLF Stevedoring Locker Facility

SSAP South Shore Access Project

SSF Site Service Facility

STS Safety Trained Supervisor

TCLP Toxicity Characteristic Leaching Procedure

USEPA United States Environmental Protection Agency

UST Underground Storage Tank

VFPA port authority

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 v

Table of Contents page

1. Introduction .................................................................................................................. 1-1

1.1 Location and Project Overview ......................................................................................... 1-1 1.2 Hazardous Materials Inventory ......................................................................................... 1-1 1.3 Hazardous Materials Inspections ..................................................................................... 1-2

2. Scope of Assessment .................................................................................................. 2-1

2.1 Visual Site Assessment .................................................................................................... 2-1 2.2 Detailed Site Survey ......................................................................................................... 2-1

3. Applicable Regulations ............................................................................................... 3-1

3.1 Occupational Health and Safety Regulation ..................................................................... 3-1 3.2 BC Hazardous Waste Regulation ..................................................................................... 3-1

4. Survey Limitations ....................................................................................................... 4-1

4.1 Visual Site Assessment .................................................................................................... 4-1 4.2 Detailed Site Survey ......................................................................................................... 4-1

5. Methods ........................................................................................................................ 5-1

5.1 Visual Site Assessment .................................................................................................... 5-1 5.2 Detailed Site Survey and Sample Collection .................................................................... 5-1

6. Visual Site Assessment ............................................................................................... 6-1

6.1 Canfisco Site Visit ............................................................................................................. 6-1 6.2 Centerm Site Visit ............................................................................................................. 6-3 6.3 Discussion and Observations ........................................................................................... 6-4

7. Detailed Site Survey .................................................................................................... 7-1

7.1 Main Gate Checker Shack and Gate Checker Shack ...................................................... 7-1 7.2 Reefer Towers .................................................................................................................. 7-4 7.3 Electrical Substation – Heatley Overpass Storage ........................................................... 7-4 7.4 Shed 3 .............................................................................................................................. 7-4 7.5 Britco Trailer (Inside Shed 3) ............................................................................................ 7-5 7.6 Heatley Avenue Overpass Storage .................................................................................. 7-5 7.7 Centennial Main Office ..................................................................................................... 7-6 7.8 Ballantyne Building - East ................................................................................................. 7-7 7.9 Ballantyne Building - East ................................................................................................. 7-7 7.10 Survey Summary .............................................................................................................. 7-8

8. Recommendations ....................................................................................................... 8-1

8.1 Recommendations for Handling Specific Hazardous Materials ........................................ 8-1 8.2 Demolition Plan ................................................................................................................ 8-3

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 vi

9. References .................................................................................................................... 9-1

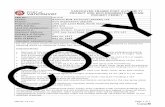

List of Figures Figure 1-1: Project Location within Burrard Inlet ................................................................................................... 1-3 Figure 1-2: Project Overview including Centennial Road Overpass ..................................................................... 1-4 Figure 6-1: Hazardous Materials Site Inspection Summary .................................................................................. 6-2 List of Tables Table 5-1: Asbestos Bulk Sampling Requirements .............................................................................................. 5-1 Table 6-1: Canfisco Building Details .................................................................................................................... 6-1 Table 6-2: Centerm Facilities Details ................................................................................................................... 6-3 Table 7-1: Asbestos-Containing Sample Collection Summary ............................................................................ 7-1 Table 7-2: Lead in Paint Sample Collection Summary (EMSL Results) .............................................................. 7-2 Table 7-3: Lead in Paint Sample Collection Summary ......................................................................................... 7-3 Table 7-4: Survey Summary ................................................................................................................................. 7-8 Appendices Appendix A – DP World Vancouver Material Safety Data Sheet Inventory Appendix B – Photolog – Visual Site Assessment Appendix C – Photolog – Detailed Site Survey Appendix D – Analytical Lab Results Appendix E – Hazardous Materials Field Survey Form - VFPA PER Guidelines – Demolition

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 1-1

1. Introduction

The Centerm Container Terminal (Centerm) on the south shore of Vancouver’s Inner Harbour is one of three primary container terminals in the Vancouver area. The Vancouver Fraser Port Authority (port authority) is proposing to concurrently deliver two projects (referred to collectively as “the proposed Project”) to increase goods movement through the south shore of Vancouver’s Inner Harbour: the Centerm Expansion Project (CEP), a set of improvements to Centerm to increase container handling capacity and accommodate larger vessels (Terminal improvements); and the South Shore Access Project (SSAP), which will improve the adjacent road and rail networks to accommodate the predicted increases in containerized goods movement (Off-Terminal improvements).

The Centerm Expansion Project Team (Project Team) consists of port authority staff and subject matter experts. The Project Team includes engineers, environmental scientists, project managers and communications and engagement specialists. The Project Team is working closely with DP World Vancouver (DPWV), the operator of Centerm, to deliver this project. The port authority intends to deliver the proposed Project under a single Design-Build (DB) contract by which the selected DB Contractor develops and constructs the final design of the proposed Project based on the performance requirements and details established by the Project Team.

This report was prepared by AECOM for the port authority to satisfy requirements of the Project and Environmental Review Process, and the Project Specific Requirements issued on 21 October 2016. This report describes investigations of legacy hazardous materials that warrant consideration and management during demolition, renovation, and reconstruction activities associated with upcoming upgrades to port authority facilities in Vancouver, British Columbia (BC). The Hazardous Materials Site Assessment consisted of both a Visual Site Assessment and a Detailed Site Survey.

1.1 Location and Project Overview

Centerm is located in Vancouver Harbour, along the south shore of Burrard Inlet (Figure 1-1 and Figure 1-2). Centerm falls under the jurisdiction of the port authority, which is responsible for the stewardship of federal port lands in and around Vancouver, its mandate being to facilitate Canada’s trade objectives and ensuring goods are moved safely while protecting the environment and considering local communities. DPWV, a container terminal operator and stevedore, has operated Centerm since 2006.

The proposed Project will include demolition or alteration of a number of on-site buildings. In addition, it is expected that a portion of one off-site building (Canfisco) will be demolished to facilitate the East Waterfront Road expansion.

1.2 Hazardous Materials Inventory

DPWV’s inventory of hazardous materials and associated Material Safety Data Sheet (MSDS) anticipated to be handled or stored on site during normal operations (not products in transit, but products used at the Terminal are included in Appendix A).

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 1-2

1.3 Hazardous Materials Inspections

Two types of inspections were conducted by qualified professionals from AECOM. The first inspection was a Visual Site Assessment undertaken to identify the types and locations of hazardous materials in areas to be affected by the proposed Project. The second inspection was a more detailed Site Survey of identified areas, and included collection of samples.

N

2016 / 06 / 21

2

1 : 100,000

0.5 1 3 4 km0

Figure 1-1

vancouver

PLAN

Scale 1:5000

1 : 5000

10025 50 150 200 m0

Figure 1-2

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 1-5

The Visual Survey was conducted on February 22 and 24, 2106 by Ken Gauthier, an AECOM environmental scientist who is also a building inspector accredited under the Asbestos Hazard Emergency Response Act (AHERA). The US Environmental Protection Agency (USEPA) AHERA certification is accepted by WorkSafeBC as qualification for those conducting hazardous materials assessments. The objective of that survey was to identify areas where hazardous materials could potentially be encountered during demolition and to assess the need for further investigation.

The Detailed Site Survey was conducted on August 9 and September 12, 2016, by Gary Cheung, AECOM’s Area Safety Health and Environment Manager, who is a Board Certified Safety Professional (BCSP) with STS certification. His experience, education and STS designation is recognized by WorkSafeBC as AHERA certification equivalent. The objective of that survey was to examine more closely areas of interest identified during the Visual Survey, and to sample materials to enable assessment of potential hazards they pose.

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 2-1

2. Scope of Assessment

2.1 Visual Site Assessment

The scope of the Visual Site Assessment consisted of:

Review of any available reports on suspect areas Walkthrough of the Canfisco building (off-site) boiler room to inspect suspect hazardous building materials Walkthrough of the Centerm facility to inspect suspect hazardous building materials in on-site buildings subject

to demolition or relocation on-site (Section 4.1) Complete visual assessments of the following buildings: Ballantyne Building – East Ballantyne Building – West

Preparation of this report, and recommendations for: Additional hazardous material surveys and sampling of suspect building materials Materials handling and disposal

Hazardous materials included in the Visual Site Assessment were:

Asbestos-Containing Materials Lead-Containing Paint Polychlorinated Biphenyls (PCBs) Ozone-Depleting Substances Mercury and Other Heavy Metals Above-ground storage tanks and underground storage tanks (ASTs/USTs) Abandoned Chemicals Silica Mould Radon Sources

2.2 Detailed Site Survey

The scope of the Detailed Site Survey consisted of:

Inspection of buildings and areas to be affected by CEP to identify potential hazardous materials sources Main gate and pre gate checker shack Shed 3 Britco Trailer located inside Shed 3 Reefer towers Heatley overpass storage Electrical substation – adjacent to Heatley overpass storage

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 2-2

Centennial Main Office Ballantyne Building – West (exterior only, as interior was not accessible) Ballantyne Building – East (exterior only, as interior was not accessible)

Sampling of suspected asbestos-containing materials and lead-containing paints for further laboratory analysis Inspection of equipment (where not in service) for PCBs, mercury switches, and ozone depleting substances Laboratory analysis of samples Quantification of suspected asbestos-containing materials and lead-containing paints Preparation of this report on the investigation

Hazardous materials included in the Detailed Site Survey were:

Asbestos-Containing Materials Lead-Containing Paint Polychlorinated Biphenyls (PCBs) Ozone-Depleting Substances Mercury and Other Heavy Metals Above-ground storage tanks and underground storage tanks (ASTs/USTs) Abandoned Chemicals Silica Mould Radon

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 3-1

3. Applicable Regulations

3.1 Occupational Health and Safety Regulation

WorkSafeBC Sections 6.0 – 6.12

WorkSafeBC’s Occupational Health and Safety Regulation (OHSR), Sections 6.0 to 6.12, stipulates requirements for identification of asbestos in the workplace, risk assessment, and asbestos management program.

WorkSafeBC Sections 6.59 – 6.69

WorkSafeBC’s OHSR, Sections 6.59 to 6.69, stipulates requirements for identification of lead and lead-containing paints and coatings in the workplace, and an exposure control plan.

WorkSafeBC Section 20.112

WorkSafeBC OASR Section 20.112 stipulates the requirement that, before work begins on demolition or salvage of machinery, equipment, a building, or a structure, or the renovation of a building or structure, all employers responsible for that work, and the owner, ensure that a qualified person inspects the machinery, equipment, building, or structure, and the worksite, to identify the hazardous materials, if any.

3.2 BC Hazardous Waste Regulation

The BC Hazardous Waste Regulation (HWR) classifies substances as hazardous waste if they contain leachable contaminants at concentrations in excess of a specified maximum, their total concentrations are in excess of a specified maximum, or they are a listed type of waste. Additional disposal options are available for hydrocarbon-contaminated soils with concentrations less than the benzene, toluene, ethylbenzene, xylenes, and total oil standards listed in Section 41.1 of the HWR. The Toxicity Characteristic Leaching Procedure, USEPA Method 1311, is employed to assess contaminant leachability. Materials for which contaminants are detected in the leachate at concentrations exceeding the leachate quality standards specified in Table 1 of HWR Schedule 4 are considered to be leachable toxic wastes and, hence, hazardous wastes. Schedule 7 of the HWR lists substances considered to be hazardous wastes. Hazardous wastes defined by total concentrations include PCB waste, waste containing dioxins, tetrachloroethylene, or polycyclic aromatic hydrocarbons, waste oil, and waste asbestos. Hazardous waste is also defined in Section 1 (Interpretation) of the HWR. Hazardous waste must be handled, stored, and disposed of in accordance with the HWR.

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 4-1

4. Survey Limitations

4.1 Visual Site Assessment

The Visual Site Assessment consisted of room-by-room, area-by-area visual assessments that were conducted in a non-intrusive manner. No samples of suspected hazardous building materials were collected at that time. No wall or ceiling cavities, carpets, floor tiles, ceiling tiles, roofing materials, insulating materials, or other building materials requiring a more intrusive approach were examined at the time of the assessment.

The majority of the roofs were either inaccessible or of limited access due to fall arrest restrictions (e.g., working from a ladder without fall protection). Also, the majority of the smaller office and storage rooms on both floors of the Ballantyne buildings, Shed 3 north and south end rooms, and electrical rooms outside of the Centennial Main Office (CMO) were inaccessible at the time of the survey.

4.2 Detailed Site Survey

The Detailed Site Survey was limited to accessible areas. The majority of the roofs were either inaccessible or of limited access due to fall arrest restrictions (e.g., working from a ladder without fall protection). Confined spaces were not inspected, due to health and safety precautions.

AECOM personnel were escorted during the Detailed Site Survey by the DPWV Facility Manager and, as a result, AECOM personnel had access only to available areas and only at the time of the visit. AECOM personnel were instructed by the DPWV Facility Manager that no sampling of building materials could take place in areas that were currently occupied, such as the Centennial Main Office, due to the potential disturbance to staff. AECOM personnel did not have access to the Ballantyne East or West buildings, as the DPWV Facility Manager has no access to these buildings, described as port authority property.

Where sampling was not possible, visual surveys were conducted to assess and quantify building materials and condition. Extensive interviews with the DPWV Facility Manager were conducted to ascertain the age of construction of these buildings, including renovation dates, building materials used, and condition of the materials.

Site surveying and sampling consisted of a room-by-room, area-by-area, and system-by-system approach. Wherever possible in unoccupied areas, sampling was conducted in inconspicuous areas, such as behind door frames, or hidden corners of the floor surface. Building materials were visually assessed for hazardous materials. Field documentation included the types of building materials identified, whether they are hazardous or non-hazardous, and the condition of the building materials at the time of the survey. Similar to the initial Visual Site Assessment, all roofs, electrical rooms outside of the Centennial Main Office, and the Ballantyne Buildings were inaccessible at the time of the survey.

The company practices and details described herein rely on information supplied by others, such as local, provincial, and federal agencies and site personnel. No attempt has been made to independently verify the accuracy of such information, unless specifically noted.

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 5-1

5. Methods

5.1 Visual Site Assessment

The Visual Site Assessments were conducted room-by-room and area-by-area, and in a non-intrusive manner. The purpose of the visual assessment was to identify potential site locations that may contain hazardous materials.

A summary of the buildings and structures assessed during the site visits is provided on Figure 6-1. Site photographs are provided in Appendix B.

5.2 Detailed Site Survey and Sample Collection

5.2.1 Asbestos Containing Materials

Materials suspected to contain asbestos observed within the surveyed area were sampled in accordance with requirements of WorkSafeBC and industry standards, summarized in Table 5-1.

Table 5-1: Asbestos Bulk Sampling Requirements

Type of Material Size of Area of Homogeneous Material

Surfacing material, including without limitation material that is applied to surfaces by spraying, by troweling or otherwise, such as acoustical plaster on ceilings and fireproofing materials on structural members

<90 m2 (<968 ft2)

>90 m2 but <450 m2 (>968 ft2 but < 4843 ft2)

>450 m2 (> 4843 ft2)

Thermal insulation, except as described in item 3 Any size

Thermal insulation patch <2 linear metres or 0.5 m2 (<6 linear feet or 5 ft2)

Other material Any size

As described in WorkSafeBC Section 6, if laboratory analysis establishes that a bulk sample contains 0.5% or more asbestos by dry weight, it is not necessary to analyze bulk material samples that were collected from the same area as the homogenous material, as the entire area of homogenous material from which the bulk material sample was taken is deemed to be asbestos-containing material.

Where applicable, the suspected asbestos-containing materials were collected and submitted for laboratory analysis. In some cases, sampling of homogeneous materials was not necessary, based on visual inspection; however, these materials were documented and quantified throughout the building.

One sample suspected to contain asbestos was collected and sent to the NVLAP accredited laboratory, EMSL Analytical Inc., located at 2755 Slough Street, Mississauga, Ontario. Preliminary identification was made using polarized light microscopy (PLM), and presence and type of asbestos was confirmed by dispersion staining optical microscopy. This analytical procedure follows the USEPA Test Method EPA/600/R-93/116 Method (Equivalent to NIOSH 9002) for the Determination of Asbestos in Bulk Building Materials.

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 5-2

5.2.2 Lead in Paint

Samples were collected at selected locations from various building surfaces that were accessible. Sampling was not necessarily representative of all existing paint applications, as our judgement of the homogeneity of the existing materials was based on exposed paint applications. In addition, sampling was restricted to predominant paint applications (i.e., paint colours).

A total of two samples suspected to contain lead in paint were collected and submitted to the AIHA ELPAT #196142 accredited laboratory, EMSL Analytical Inc., located at 2755 Slough Street, Mississauga, Ontario, for laboratory analysis to confirm lead in paint. The analytical procedure follows USEPA method SW-846 7000B, Flame Atomic Absorption Spectroscopy.

Lead sampling and laboratory analysis meets Environmental Protection Act (EPA) Requirements and conducted in accordance to WorkSafeBC requirements and industry practice standards.

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 6-1

6. Visual Site Assessment

A summary of the buildings and structures assessed during the site visits is provided on Figure 6-1. Site photographs are provided in Appendix B.

6.1 Canfisco Site Visit

Canfisco is a fully integrated fish processing warehouse located at the foot of Gore Avenue. It is anticipated that the boiler room will be partially demolished to facilitate the East Waterfront Road expansion.

On February 22, 2016, AECOM staff conducted a site visit at the Canfisco building. At the time of the assessment, the extent of the demolition required for safe execution of the East Waterfront Road expansion (demolishing the entire boiler room or only a few feet off the south wall) was being determined. Two boilers in the Canfisco building were expected to be decommissioned; however, it was not known whether the boilers would have to be removed and disposed of and replaced, or reused. A brief summary of the building details is provided in Table 6-1. The location of the building is depicted on Figure 1-1, and photographs are provided in Appendix A.

Table 6-1: Canfisco Building Details

Building Name Description Year Built General Construction Details

Canadian Fishing Company (Canfisco)

Boiler room in fish processing warehouse

Began in 1906, extended fish dock in 1910. Rebuilt in 1917

after a fire (Kalman et al. 2012)

Masonry concrete cinder blocks, steel beam columns,

and wood

Dat

e: 2

6/10

/201

6 1:

06:2

5 P

MP

ath:

P:\6

0476

505\

900-

Wor

k\92

0-92

9 (G

IS)\2

016-

02-2

9-H

azar

dous

Mat

eria

ls\F

ig1-

2016

-02-

29-H

azar

dous

Mat

eria

l-604

7650

5-00

2.m

xd

SuperiorPropane

Tank

Container BerthLunchroom (CBL)

ScaleKiosk

Pre-OutgateChecker

Shack

MainGate

Canopy

Main GateCheckerShack

Container YardLunchroom (CYL)

ContainerForeman

Facility (CFF)

CentennialMain Office

(CMO)

ContainerCentennial

Guardhouse (CCG)

Heatley OverpassHeatley

OverpassStorage

Superior Propane TankContainer EastLunchroom (CEL)

Shed 3South End Rooms

Ballantyne CruiseBuilding - West

BallantyneCruise

Building - East

StevedoringLockerFacility (SLF)

Shed 3North

End Rooms

Shed 3

Fuel Kiosk(A/G diesel andgasoline asts)

SuperiorPropaneTank

Canfisco(BoilerRoom)

Shed 3Britco Trailer

!>!>

!>

!>

!> !>

!>!>

!>!>!>

!>!>

!>

!>

!> !>

!>

!>

!>!>!>

!>

!>

ReeferTowers

492500

492500

493000

493000

493500

493500

494000

494000

5459

000

5459

000

5459

500

5459

500

LEGEND!> Hazardous Materials Site

Hazardous Materials Area

THIS

DR

AW

ING

HA

S B

EE

N P

RE

PAR

ED

FO

R T

HE

US

E O

F A

EC

OM

'S C

LIE

NT

AN

D M

AY

NO

T B

E U

SE

D, R

EP

RO

DU

CE

D, O

R R

ELI

ED

UP

ON

BY

TH

IRD

PA

RT

IES

, EX

CE

PT

AS

AG

RE

ED

BY

AE

CO

M A

ND

ITS

CLI

EN

T, A

S R

EQ

UIR

ED

BY

LA

W O

R F

OR

US

E B

Y G

OV

ER

NM

EN

TAL

RE

VIE

WIN

G A

GE

NC

IES

.A

EC

OM

AC

CE

PT

S N

O R

ES

PO

NS

IBIL

ITY,

AN

D D

EN

IES

AN

Y L

IAB

ILIT

Y W

HAT

SO

EV

ER

, TO

AN

Y P

AR

TY

TH

AT

MO

DIF

IES

TH

IS D

RA

WIN

G W

ITH

OU

T A

EC

OM

'S E

XP

RE

SS

WR

ITT

EN

CO

NS

EN

T, D

O N

OT

SC

ALE

TH

IS D

OC

UM

EN

T. A

LL M

EA

SU

RE

ME

NT

MU

ST

BE

OB

TAIN

ED

FR

OM

STA

TE

D D

IME

NS

ION

S.

1:4,000

0 50 100m

FOR INFORMATIONAND REVIEW

2016/05/05

1:4,000 Figure 6-1

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 6-3

6.2 Centerm Site Visit

On February 24, 2016, AECOM met with DPWV’s Facility Manager and conducted a visual site assessment of the buildings expected to be demolished or relocated as a result of the proposed Project. The Facility Manager had been an employee of DPWV for over 20 years and actively involved with the facility renovations and, therefore, was able to provide information pertaining to the approximate age and construction details of the buildings and any subsequent renovations. All buildings were assessed at the time and a brief summary of the building details are included in Table 6-21. Locations of the buildings are shown on Figure 6-1 and photographs are provided in Appendix B.

Table 6-2: Centerm Facilities Details

Building Name Description Year Built (according to DPWV Facility Manager)

General Construction Details

Centennial Main Office (CMO)

Three level operations building with rooftop balcony. Two inaccessible electrical rooms outside, north side of CMO.

Built in 2002; third floor was added in 2006

Drywall, wood stud with steel cladding (exterior). Floors were Q deck with concrete

Container Centennial Guardhouse (CCG)

Small modular security building

West room built in 2001, east room built in 2008

Drywall, wood stud with steel cladding (exterior)

Container Foreman Facility (CFF)

Small L-shaped modular building

Built in 2006 Vinyl wall boards, wood stud with steel cladding (exterior)

Container Yard Lunchroom (CYL)

Small modular building (formerly the CFO)

Built in 2000-2001; renovated in 2008

Drywall, wood stud with steel cladding (exterior)

Container Berth Lunchroom (CBL)

Two-level modular building with accessible roof (formerly dispatch building in maintenance area)

Built in 1997, relocated and renovated in 2006

Vinyl wall boards, wood stud with steel cladding (exterior), and EPDM roof

Stevedoring Locker Facility (SLF)

Two-level modular building consisting of three portables. Adjacent sprinkler room.

Built in 1994 Vinyl wall, with suspect wood stud with aluminum cladding (different modular design from other on-site buildings)

Shed 3 Large open concept warehouse

Built in 1992 Steel beam columns and concrete with steel cladding

Shed 3 (north/south end rooms with bathrooms)

Unknown – could not access any of these rooms

Assumed to be 1992 (same as Shed 3)

Masonry cinder block walls

Ballantyne Cruise Building – West building (851 Centennial)

Both the west and east buildings are connected and were previously the former Ballantyne Cruise Terminal

West building built in 1994 Drywall, concrete cast walls, steel beam columns and joists; steel cladding on roof

Ballantyne Cruise Building – East building (Shed 1)

Both the west and east buildings are connected and were previously the former Ballantyne Cruise Terminal

Built in 1923; renovated in 1995 to create the east berth and west berth

Drywall, concrete cast walls, and concrete columns

1 DP World’s Facility Manager provided access to all of the areas in Table 6-2 with the exception of the two Ballantyne Cruise Buildings (east and west), where AECOM’s project manager provided limited access.

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 6-4

Building Name Description Year Built (according to DPWV Facility Manager)

General Construction Details

Heatley Avenue Overpass Storage

Three connecting storage buildings (west, centre, and east), situated under the Heatley Avenue Overpass loop. Two inaccessible electrical rooms on north side of CMO

Heatley Avenue Overpass built in the 1960s. Unsure whether the storage rooms were built at the same time. Only renovations were electrical panels in 2001/02.

Masonry cinder block walls and concrete floor. Concrete ceiling is the Heatley Avenue Overpass

Main Gate Checker Shack Small operations shack for cargo inspections

Built in October 1988 (identified on tag). Was relocated across the facility in 2001.

Vinyl wallboards, steel stud, and wood frame

Pre-Outgate Checker Shack Unable to visually inspect – speculate same building materials as Main Gate Checker Shack

Assumed to be built in 1988, same as the Main Gate Checker Shack

According to DPWV’s Facility Manager assumed to be the same as the Main Gate Checker Shack (same building construction)

Main Gate Canopy Canopy covering 12 lanes for incoming trucks awaiting container pickup

Built in 2000-2001 Steel beam columns and steel cladding

Reefer Towers (11 in total) Galvanized steel structures designed for holding refrigerated containers

Seven built in 2001, four built in 2006

According to building code is considered a building, although entire structure is galvanized steel with no walls (open concept)

Scale Kiosk Small modular shack for weighing containers on yard scale

Built in 2001 (formerly electrical room on Shed 1 roof); relocated in 2012

Vinyl wall boards, wood stud with steel cladding (exterior). Yard scale appeared to be made of steel

Fuel Kiosk Small modular shack accompanied by a 3,800 litre (L) gasoline AST and a 22,700 L diesel AST

Built in 2006 No wallboards, steel stud and wood frame, and EPDM roof

Container East Lunchroom (CEL)

As per DPWV’s Facility Manager’s request, not inspected because they are rentals and will be returned to supplier. Not discussed any further.

Not applicable; however, assumed to be similar to the other modular buildings on-site

Assumed same construction details as the other modular buildings

6.3 Discussion and Observations

6.3.1 Asbestos-Containing Materials

Use of friable asbestos-containing materials (ACMs) was discontinued in 1978, and non-friable ACM was phased out in the early- to mid-1980s. As a result, ACMs are mostly found in pre-1990 building materials, in components that include drywall joint compounds, mastics, floor and ceiling tiles, boiler gaskets, piping and thermal insulation, fireproofing materials, concrete, and vermiculite insulation.

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 6-5

The majority of the inspected buildings were built post-1990 of similar modular construction, and many of the buildings had already been subject to renovations within the last 10 to 15 years; however, during AECOM’s site visit there were a few areas where suspected ACMs may be present, including:

• In the Canfisco building (built in 1906 and rebuilt in 1917 after a fire), suspect ACMs were assumed to be present in boiler gaskets, pipe elbow insulations, masonry blocks, brick mortar, electrical panels, plaster, floor leveling compound, window caulking, and pipe penetration insulation. AECOM did not have access to Canfisco building at the time of site survey.

• The Main gate checker shack and pre-gate checker shack (1988) were observed to be identical in building construction and contains identical building materials. Furthermore, it was confirmed by DPWV Facility Manager that the construction date of the two buildings were built in 1988. Inside both gate checker shacks contained the identical 12 x 12 inch blue colored vinyl floor tiles. A sample was collected and submitted for laboratory analysis. Based on laboratory analysis, the blue coloured 12x12 inch vinyl floor tiles were confirmed not to contain asbestos. Meanwhile, AECOM did not have access to the roof to sample roofing materials, more importantly, due the nature of sampling requirement for roofing materials – roof sampling will cause leaks into an existing occupied space.

• In the Main gate checker shack and pre-gate checker shack, two (2) types of paint were identified. A blue colored paint was identified on the door, and a sample of the blue paint was collected and submitted for laboratory analysis. Based on laboratory analysis, the lead paint content identified in the blue color paint was below the EPA/HUD guideline of 0.05% of lead content by dry weight. Furthermore, the blue color paint was confirmed by DPWV Facility Manager that the paint of that the particular colour is used throughout the entire facility. Outside the main gate checker shack and pre-gate checker shack, the shacks are constructed on top of foundation I-beams, a sample of the orange paint on the I-beam was collected and submitted for laboratory analysis. Based on laboratory analysis, the lead paint content identified in the orange colored paint was well above the EPA/HUD guideline of 0.05% of lead content by dry weight. As a result, the demolition method of the orange paint must meet WorkSafeBC Part 6 – 6.60 Lead Exposure Control requirements. Removal of Lead containing paint and coating must be completed in accordance to WorkSafeBC’s publication – Lead-Containing Paint and Coating – Preventing Exposure in the Construction Industry or equivalent industry standard practice.

• Construction dates of the Heatley Avenue Overpass Storage are currently unknown; however, the Heatley Avenue Overpass was built in the 1960s. Assuming the storage rooms were constructed in the early 1990s2. Based on visual survey, the Heatley Avenue Overpass Storage is comprised of concrete cinder blocks and wooden frames. The ground was asphalt paved. Suspected ACMs were present in the building materials. Some of these suspect ACMs include masonry blocks, mortar, floor leveling compounds, drywall joint compound, and pipe and other insulations.

• Shed 3 was constructed in 1992, and the associated north and south end rooms were assumed to be constructed at this same time. No suspected ACMs were observed in Shed 3; however, observations were limited to the ground surface. AECOM was unable to access the north and south end rooms; these rooms are considered to contain hazardous building materials until assessed.

• The Stevedoring Locker Facility (1994) is not expected to contain ACMs; however, as this was the only modular building that did not resemble the others on-site, this building should be assessed prior to demolition. A locked sprinkler room was located adjacent to the Stevedoring Locker Facility.

• The Ballantyne Cruise Building – East was originally constructed in 1923 and renovated in 1995. As-builts from the renovations were provided; however, no previous asbestos inventory reports were supplied by the port authority. Although this building has undergone extensive renovation, is it unknown whether previously identified ACMs were completely abated or possibly left in place. This building should be assumed to contain ACMs until additional documentation is provided stating all ACMs were abated and/or an inventory of known ACMs within the building is provided.

2 Although the Heatley Avenue Overpass was built in the 1960s, the building materials of the storage rooms resembled the building

materials in the Shed 3 end rooms, which were assumed to be constructed in 1992. https://www2.worksafebc.com/publications/OHSRegulation/GuidelinePart20.asp?ReportID=35098

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 6-6

• During the site visit, DPWV’s Facility Manager advised AECOM of a 12-inch layer of known asbestosphalt located under the Reefer Towers. DPWV’s Facility Manager had mentioned similar facts during the URS Phase 1 Environmental Site Assessment (ESA). He stated a 2.5 centimetre thick layer of asbestosphalt was encountered at the northern part of Shed 3, where the asbestosphalt was removed, mixed in a 1 to 4 ratio with concrete, and re-used in place (URS 2008).

6.3.2 Lead-Containing Paint

As of October 2010, Health Canada, through the Hazardous Products Act Surface Coating Materials Regulation section 4(1), amended the amount of lead in new surface coating materials from 600 milligrams per kilogram (mg/kg) to 90 mg/kg. More than 90 mg/kg (0.009%) lead in surface coating materials (i.e., metal touch-up or anticorrosive material) may be used in industrial applications providing that an appropriate marking or labelling identifying the health hazards associating with the “lead-containing” material is present on the product.

Lead-based paints may be found in buildings constructed between 1950 and 1980 and are likely to be present in buildings built before the mid-1950s. Since the 1950s, the use of lead has been more common in exterior paint than interior paint. Given the age of the buildings and the date of recent renovations, lead-containing paints are not likely present in the majority of the buildings assessed. During the site visit, DPWV’s Facility Manager stated that all the modular buildings on-site that had undergone recent renovations had used latex-based paints purchased from General Paint and were not thought to be lead containing3. During AECOM's site visit, suspect lead-containing paints were identified in the following buildings and areas:

• Suspected lead-containing paint was identified in the Canfisco boiler room. Several colors of paint were observed on both the interior and exterior walls and on the boilers. On both the interior and exterior walls the paint was in poor condition and peeling. A Canfisco employee mentioned the interior walls in the boiler room had been repainted. It is assumed the recent paint was painted over the pre-existing paint.

• Suspected lead-containing paint is present in the Heatley Avenue Overpass Storage units.

For the majority of the modular buildings (i.e., Centennial Main Office, Container Foreman Facility, Container Yard Lunchroom, etc.), as renovations were completed in the past 10 to 15 years using latex-based paint, lead-containing paints are not expected to be present on the interior walls.

6.3.3 Polychlorinated Biphenyls (PCBs)

The PCB Regulations were introduced by CEPA in 1999 and was created to control activities regarding the use and disposal of PCBs, in addition to limiting PCBs from being released into the environment. Transformers, fluorescent light ballasts, and other electrical equipment manufactured prior to 1978 or 1979 may contain PCBs4. Although some PCB-containing equipment remains in use, the manufacturing, processing, importing, and offering for sale of PCBs have been prohibited in Canada since 1977.

Due to the presence of employees in the buildings, fall arrest restrictions (inaccessible due to height), and because many of the fluorescent lighting systems remained operational at the time of the assessment, detailed inspection of the fluorescent light ballasts could not be made. According to DPWV’s Facility Manager, electrical equipment and 3 According to information provided in Health Canada’s Lead Information Package, in homes built after 1980, there is little need for concern

about lead levels in interior paints. All post 1992 consumer paint produced in Canada for indoor use is virtually lead free. http://www.hc-sc.gc.ca/ewh-semt/contaminants/lead-plomb/asked_questions-questions_posees-eng.php 4 According to information presented in the Environment Canada’s publication (Identification of Lamp Ballasts Containing PCBs), most ballast

manufacturers (e.g., Sola Canada, Philips Lighting, Magnatek Universal Manufacturing, Advance Ballasts, Canadian General Electric) stopped producing PCB-containing ballasts (and capacitors) in 1979 or 1980.

http://www.facilities.ualberta.ca/en/Planning_Project_Delivery/Hazardous_Materials/~/media/facilities/Documents/SafetyDocuments/ID-LampBallastsContainingPCBsReport-EPS2CC2Aug1991.pdf

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 6-7

fluorescent lights currently present at the site were new when installed in the late 1990s and early 2000s (URS 2008). Given the ages of the buildings assessed and the recent renovations (including the Ballantyne Cruise Building – East), the electrical equipment and the ballasts currently used on-site are not likely to be PCB-containing. During AECOM's site visit, the following buildings were identified as suspect PCB containing:

• The Canfisco boiler room and Heatley Avenue Overpass Storage contains suspected PCB-containing fluorescent light ballasts and electrical equipment.

• Three pad-mounted transformers were present outside the Centennial Main Office, CFO, and Berth 4 trailers. All transformers appeared in good condition with no evidence of spills or leaks. Based on the years of installation, the presence of PCB-containing electrical equipment is not anticipated (URS 2008). These were not identified during the site visit, and the presence of transformers across the site should be reconfirmed.

• The Ballantyne Cruise Building – East was heavily renovated in the 1990s and is not expected to contain PCB-containing materials. Given the age of this building, PCBs should not be ruled out until further visual confirmation.

6.3.4 Ozone-Depleting Substances

The Ozone Depleting Substance and Other Halocarbon Regulations were introduced under the Environmental Management Act (EMA) in 1998 and were designed to regulate and minimize the release of ozone-depleting substances (ODS) into the environment. In addition, the regulations outline the methods to be used to install, remove, service, repair, or decommission products containing an ODS and their halocarbon alternatives. The Federal Halocarbon Regulations, introduced under CEPA in 2003, control the use and handling of halocarbons (including ODSs) in refrigeration, air-conditioning (A/C), fire-extinguishing, and solvent systems that are on federal lands.

Generally, ODSs (e.g., refrigerant associated with building cooling system) were assumed to be present in the majority of buildings containing A/C units. Large rooftop-mounted A/C units were identified in most of the modular buildings, ranging anywhere from one unit in the Container Centennial Guardhouse to six large units in the Centennial Main Office. The SLF contained a small window-mounted A/C unit and other buildings were suspected to contain similar smaller A/C units. In addition, various coolers, refrigerators, and freezers were generally present in the lunchrooms of each building.

Refrigerated containers stored on-site are maintained by Highway Refrigeration and Thermal King. DPWV’s Facility Manager had previously confirmed that no maintenance activities, including draining or refilling of refrigerants, are conducted on-site (URS 2008).

A halon fire suppression system had been previously identified in the IT room of the Centennial Main Office during the Phase I ESA (URS 2008). During the site walkover, DPWV’s Facility Manager stated this fire suppression system was suspected to be halon free. On closer examination it was suspected to be Novec 1230 (acceptable substitute) based on the manufacturer. A second dry fire suppression system was identified in the Container Yard Lunchroom server room. Upon closer examination, this fire system appeared to be an FM-200 system, which is halon free.

6.3.5 Mercury and Other Heavy Metals

The Products Containing Mercury Regulations were introduced under the CEPA in 1999 and were designed to reduce the risks posed by releases of mercury to the environment by prohibiting the manufacture and import of products containing mercury or any of its compounds (in some cases limiting the mercury content). The Recycling

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 6-8

Regulations were introduced by the EMA in 2004 (updated in 2014) and include general regulations relating to recycling of toxic materials including lead-acid batteries5.

No mercury thermostats or lead batteries were observed at the time of the visit. Fluorescent light tubes, which are known to contain small amounts of mercury (approximately 20 mg per fluorescent light tube), were assumed to be present throughout all the buildings in the light ballasts.

6.3.6 ASTs/USTs

The Canadian Council of Ministers of the Environment Environmental Code of Practice for Aboveground and Underground Storage Tank (AST/UST) Systems Containing Petroleum and Allied Petroleum Products, updated in 2013, was created to provide technical requirements for registration and approval of storage tank systems, design and installation, monitoring and leak detection, upgrading of existing systems, operations and maintenance, and decommissioning of storage tank systems. The Storage Tank Systems for Petroleum Products and Allied Petroleum Products Regulations were introduced under CEPA in 2008 with the main objective of preventing soil and groundwater contamination from storage tank systems located on federal and aboriginal lands.

The Canadian Propane Association outlines the regulations related to the storage, transportation, and safe handling and use of propane. The two major regulatory agencies involved include the Canadian Standards Association B149 Series and Transportation of Dangerous Goods Act.

The Fuel Kiosk Area, located on the northwest side of the Site Service Facility, contained one gasoline AST (3,800 L), and a second diesel AST (22,700 L). The two ASTs are anticipated to be moved once alternative provision is provided elsewhere on the Site.

No evidence of USTs was observed during the 2016 site visit and DPWV’s Facility Manager had previously confirmed none were present (URS 2008).

Three propane ASTs were identified on-site and prior to demolition/relocation activities, DPWV’s Facility Manager stated these propane ASTs would be returned to the supplier, Superior Propane. Propane ASTs were identified near the Centennial Main Office (1,000 US gallons), CBL (1,000 US gallons), and Fuel Kiosk area (1,000 US gallons).

6.3.7 Abandoned Chemicals

A variety of controlled products were identified during the 2016 site visit. Typically, all the modular buildings at the Centerm facility contained janitorial rooms containing standard household and cleaning products typically associated with this type of space.

Off-site at the Canfisco building, several chemicals in various quantities were identified with poor housekeeping conditions. MSDSs were requested at the time of the visit; however, none were provided. Many of these chemicals appeared abandoned and/or improperly labelled, including, but not limited to, bags and containers of caustic soda micropearls (sodium hydroxide), Scalex DS-410 (catalyzed suplhite and organic ions), Scalex LPP-63 (polymer phosphate), monolithic refractory, and a small wall-mounted chemical testing kit (silver nitrate, sulfuric acid, and titration solution were observed).

5 The Ministry has worked with the lead-acid battery sector to develop news bulletins describing when batteries become hazardous

waste and how to register, transport, store, and dispose of used or spent batteries The bulletins confirm that when used or spent batteries are collected they are subject to the Hazardous Waste Regulation, unless the batteries are transported from the original user directly to an original manufacturer or supplier of new batteries. http://www2.gov.bc.ca/gov/content/environment/waste-management/recycling/product-stewardship/lead-acid-batteries

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 6-9

6.3.8 Silica

The OHSR has an occupational exposure limit of 0.025 milligrams per cubic metre (mg/m3), which is the maximum amount of crystalline silica to which workers may be exposed during an 8-hour work shift. Crystalline silica is also classified as a human carcinogen, and exposures must be kept as low as reasonably achievable. Although not considered a hazardous material, exposure control plans are required per OHSRs. Given the nature of this project, it is assumed that silica will be encountered during much of the demolition work.

6.3.9 Mould

Section 4.79 in the OHSR contains guidelines related to mould and indoor air quality and states the presence of mould should be suspected if there is visible moisture on building surfaces or if there has been water damage.

No visible mould growth was observed at the time of the 2016 visit with the exception of a few water-damaged ceiling tiles on the second floor of the Container Berth Lunchroom, thought to be caused by A/C condensation.

6.3.10 Radon

In 2009, WorkSafeBC in association with the BC Centre for Disease Control (BCCDC) produced a report entitled Radon in British Columbia Workplaces (Copes 2009). The report presents the findings of a radon concentration study across BC. In the study, the nearest study area to the subject property is Vancouver/Lower Mainland where 138 homes were surveyed. The survey found the average main floor radon concentration of 18 Becquerels per cubic metre (Bq/m3) (200 Bq/m3 is the action level specified for corrective action in the Health Canada Guideline for Radon in Dwellings).

BCCDC derived a Radon in BC Work Places map and according to the map, average radon concentrations in Vancouver are on the lower end of the scale (less than 50 Bq/m3). It is important to note that even this mapping does not guarantee high or low radon levels. The mapping is used as more of a guideline regarding the average radon concentrations expected in a Vancouver property. Radon is not expected to be a concern at the site.

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 7-1

7. Detailed Site Survey

7.1 Main Gate Checker Shack and Gate Checker Shack

DPWV has 2 gate checker shacks (main and secondary) as located at the Centerm terminal, Vancouver, BC. Based on the conversation with site representative, these 2 shacks were constructed in the mid 1990’s with minor renovation over the past 10 years. Majority of the building materials were observed in good condition. Site photographs are provided in Appendix C. Suspected asbestos-containing materials were collected and sampled on 9th August 2016.

7.1.1 Asbestos-Containing Materials

On 9th August 2016, AECOM representative, Gary Cheung, Area Safety, Health and Environmental was on site to conduct a hazardous material survey. Suspected asbestos-containing materials were collected and submitted for laboratory analysis.

Only 2 building materials, vinyl floor tile and exterior wall texture coat, were collected for analysis. Upon laboratory analysis, the samples did not to contain asbestos. Results summary of the samples that were collected are presented in the following Table 7-1. The Laboratory Analytical Report is presented in Appendix D.

The following summary table presents the laboratory results of the samples, as well as the location and the description of the material.

Table 7-1: Asbestos-Containing Sample Collection Summary

Sample No. Location Material Asbestos Content1

SK1-VFT-01 Main Gate Checker Shack - Floor 12x12 Vinyl Floor Tile None detected

SK1 – WP – 01 Main Gate Checker Shack – Exterior Wall Wall Panel Texture Coate None detected

NOTE: 1. The Occupational Health & Safety Regulation (OHSR) defines an asbestos-containing material (ACM) as any manufactured article or other

material which contains 1% or more asbestos by weight at the time of manufacture, or which contains 1% or more asbestos as determined in the National Institute for Occupational Safety and Health Manual of Analytical Methods, Method 9002, Issue 2 (microscopy, stereo and polarized light, with dispersion staining) or other method acceptable to the Board.

7.1.1.1 12x12 Vinyl Floor Tile

One (1) blue coloured 12"x12" vinyl floor tile (sample ID: SK1-VFT-01) was collected and subsequently submitted to accredited asbestos laboratory for laboratory analysis. Based on laboratory analysis, it is confirmed not to contain asbestos. Furthermore, the blue coloured 12"x12" vinyl floor tiles were confirmed by DPWV Representative that these floor tiles were purchased and used through DPWV Facilities. As a result, it is determined and confirmed that all blue coloured 12"x12" vinyl floor tiles are not asbestos-containing materials. Based on laboratory analysis and visual inspection; all blue colored 12"x12" vinyl floor tiles within the Centennial Main Office building are the same as the sample. The condition of the material was observed to be in good condition.

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 7-2

7.1.1.2 Exterior Wall Texture Coat

One beige coloured wall texture panel (sample ID: SK1-WP-01) was collected at the main gate checker shack and subsequently submitted to accredited asbestos laboratory for analysis. Based on laboratory analysis, it was confirmed not to contain asbestos. The wall panel was found in both the main gate and pre-gate checker shack. The two shacks appeared to be identical and, according to DPWV Representative, the exterior wall texture panel was installed in mid 1990s. Based on the visual inspections and the sample, it could be assumed that both the main gate and the pre-gate checker shacks do not contain asbestos. The material was observed to be in good condition.

7.1.2 Lead-Containing Paint

As of May 2005, Health Canada, through the HPA Surface Coating Materials Regulations, limits the amount of lead in new surface coating materials to not exceed 600 mg/kg (0.06%). More than 600 mg/kg lead in surface coating materials (e.g., metal touch-up or anticorrosive material) may be used in industrial applications providing that an appropriate marking or label identifying the health hazards associating with the “lead-containing” material is present on the product. The US EPA defines “lead-containing” (lead-based) paint as “Any paint, varnish, shellac, or other coating that contains lead equal to or greater than 1.0 mg/cm² as measured by x-ray fluorescence detector or laboratory analysis, or 0.5% by weight (5,000 µg/g, 5,000 ppm, or 5,000 mg/kg) by laboratory analysis”. For the purpose of this project, any paint sample that contains lead content of 0.5% or greater has been considered lead-containing paint.

At the time of site visit on 9 August 2016, two paint samples were collected and were submitted to EMSL for analysis for lead content. Upon receiving the report from EMSL, one sample was indicated to be lead containing, and another sample was deemed to be of insufficient amount to reach the reporting limit. As a result, resampling of the material is required for submission to a laboratory for analysis.

Based on sampling, SK1-LP-02 has lead content of 4.3% by dry weight, which exceeded the EPA/HUD (0.05% by dry weight) and Health Canada requirement (0.06% by dry weight).

A summary of the EMSL analytical results (including locations of the collected samples) is presented in Table 7-2. The Laboratory Analytical Report is presented in Appendix D.

Table 7-2: Lead in Paint Sample Collection Summary (EMSL Results)

Sample No. Sampled Location Description Lead Content Comment

SK1-LP-01 Main Gate Checker Shack - Exterior door

Blue 0.024% Below EPA/HUD guidelines of 0.05% lead by weight; Insufficient amount of sample to reach reporting limit.

SK1-LP-02 Main Gate Checker Shack - Exterior I-Beam (foundation)

Red/Orange 4.3% Above EPA/HUD guidelines of 0.05% lead by weight

1. In the absence of a Canadian regulatory limit for lead-containing paint, the American regulatory limit of 0.5% lead by weight is applied, stipulated by the Environmental Protection Agency/Department of Housing and Urban Development (EPA/HUD) guidelines.

2. Due to the limitation of the testing instrument used by EMSL, a minimal of 50mg of lead-paint samples was required to conduct lead paint content analysis.

Due to the interpretation and the insufficient amount of information provided by the lab, it was suggested for AECOM to return to the site to collect additional sampling of the exterior door at the main gate checker shack. On September 12th, AECOM returned to the Main Gate Checker Shack to collect lead paint sample and subsequently submitted for laboratory analysis. Based on laboratory analysis, the blue exterior door at the main gate checker shack is confirmed to have lead paint less than the EPA/HUD requirement (0.05% by dry weight) and Health

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 7-3

Canada requirement (0.06% by dry weight) (Table 7-3). The Laboratory Analytical Report is presented in Appendix D.

It should be noted that, based on discussion with DPWV Representative that all building materials painted blue are the same as the blue paint sampled on September 12th 2016. Therefore, all colored blue paint (same as sample) are determined to be non-lead based paint.

Table 7-3: Lead in Paint Sample Collection Summary

Sample No Sampled Location Description Lead Content Comment

SK1-LP-01 (resample)

Main Gate Checker Shack - Exterior door Blue <0.009% Below EPA/HUD guidelines of

0.05% lead by weight

7.1.3 Polychlorinated Biphenyls

Light ballasts were observed to be present in various locations at the Main/Pre-Gate Checker Shack. To inspect and determine the presence of PCBs, AECOM would require removing the outer housing of the light fixture to inspect the ballast following the Environment Canada requirement. However, at the time of the site visit, a majority of the work areas were occupied with workers. Moreover, there were some areas where additional safety precautions would be required before inspecting the light ballast (e.g., working at heights, ladder access, and temporary turning off the lights), which at the time AECOM was not prepared for. Finally, all fluorescent lighting systems remained operational at the time of the inspection; detailed inspection of the fluorescent light ballasts could not be made without turning off, and lockout/tagout in selected areas.

It should be noted that, given the age of the Main/Pre-Gate Checker Shack (i.e., 1990s – 2000s construction), the ballasts currently in use are not likely to contain PCBs. According to the Environment Canada publication Identification of Lamp Ballasts Containing PCBs, most ballast manufacturers (e.g., Sola Canada, Philips Lighting, Magnatek Universal Manufacturing, Advance Ballasts, Canadian General Electric) stopped producing PCB-containing ballasts (and capacitors) in 1979 or 1980.

It is recommended that, prior to any demolition or disposal of the light ballast, at minimum, light ballasts should be inspected to ensure they are treated and disposed of properly.

7.1.4 Mercury Thermostats

At the time of site visit, no thermostats with mercury-containing switches were observed in the Main/Pre Gate Checker Shack. However, fluorescent light tubes, which are known to contain small amounts of mercury (approximately 20 mg per fluorescent light tube), were observed throughout the Main/Pre Gate Checker Shack.

7.1.5 Ozone Depleting Substances

Ozone depleting substances (ODS) (e.g., refrigerants associated with building cooling systems) were not observed or known to be present in the building. However, various coolers, refrigerators and freezers belonging to concessions are present in the building. At the time of site visit, AECOM observed refrigerators and freezers throughout the Terminal.

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 7-4

7.2 Reefer Towers

Asbestos Containing Materials

No suspected asbestos containing materials present.

Lead Containing Paint

No suspected asbestos containing materials present.

Polychlorinated Biphenyls

No suspected PCBs present.

Mercury

No suspected Mercury or mercury thermostats switches present.

Ozone Depleting Substance

No suspected ODS present.

7.3 Electrical Substation – Heatley Overpass Storage

Asbestos Containing Materials

No suspected asbestos containing materials present.

Lead Containing Paint

No suspected lead containing paint present.

Polychroinated Biphenyls

No suspected PCBs present.

Mercury

No suspected Mercury or mercury thermostats switches present.

Ozone Depleting Substance

No suspected ODS present.

7.4 Shed 3

Asbestos Containing Materials

No suspected asbestos containing materials present.

Lead Containing Paint

No suspected lead containing paint present.

Vancouver Fraser Port Authority

Centerm Expansion Project / South Shore Access Project Hazardous Materials Site Assessment

2016-11-23 Hazardous Materials Report_60476505 7-5

Polychlorinated Biphenyls

No suspected PCBs present.

Mercury

No suspected Mercury or mercury thermostats switches present.

Ozone Depleting Substance

No suspected ODS present.

7.5 Britco Trailer (Inside Shed 3)

Site photographs are provided in Appendix C.

Asbestos Containing Materials

No suspected asbestos containing materials present.

Lead Containing Paint

No suspected lead containing paint present.

Polychlorinated Biphenyls

No suspected PCBs present.

Mercury

No suspected Mercury or mercury thermostats switches present.

Ozone Depleting Substance

No suspected ODS present.

7.6 Heatley Avenue Overpass Storage

Asbestos Containing Materials

No suspected asbestos containing materials present.

Lead Containing Paint

No suspected lead containing paint present.

Polychlorinated Biphenyls