CATALOGUE - Fisher Metfishermet.com/fmlcat01.pdfOur mission at Fisher Metrology is to provide top...

Transcript of CATALOGUE - Fisher Metfishermet.com/fmlcat01.pdfOur mission at Fisher Metrology is to provide top...

C A TA L O G U EC A TA L O G U E

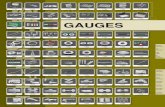

Our mission at Fisher Metrology is to provide top quality gauges, at competitive prices with the best delivery possible. We represent,and purchase products from premier gaugemakers in the U.S.A. and the European Community. We have visited most of our suppliers'plants and toured their manufacturing facilities and calibration rooms to assess their capabilities. Improvements in the level ofcertification to ISO 17025 (Guide 25) or ISO 9000 are evident. Fisher Metrology has recently implemented ISO 9002 and our QualitySystem Manual is complete.

We have selected our most popular gauge product lines and present them in detail with applicable technical data and illustrations. Wealso represent Alameda Thread Gages, Flexbar Machine, Van Keuren, R.L. Schmitt, Kentucky Gages, Swanson Tool, Piccadilly Precision,Kolb & Baumann, Tru-Thread, Tesa, Southern Gage, Huron Gage Blanks and Threads, Inc.

Our new computer system has greatly enhanced our order entry, purchasing and invoicing capabilities and allows quick access to allrecords. We have added email, a 1-800 fax line and completed our website to make our company more accessible to customers locallyand across Canada.

Service is our #1 priority and customer satisfaction is achieved through:

•• PPEERRSSOONNAALL AANNDD PPRROOMMPPTT RREEPPLLIIEESS TTOO AALLLL EENNQQUUIIRRIIEESS•• KKNNOOWWLLEEDDGGEEAABBLLEE,, EEXXPPEERRIIEENNCCEEDD AANNDD FFRRIIEENNDDLLYY SSTTAAFFFF•• SSUUPPPPLLYYIINNGG TTOOPP QQUUAALLIITTYY CCEERRTTIIFFIIEEDD GGAAUUGGEESS AANNDD IINNSSTTRRUUMMEENNTTSS•• AATTTTEENNTTIIOONN TTOO DDEETTAAIILL AANNDD FFRREEEE TTEECCHHNNIICCAALL AASSSSIISSTTAANNCCEE•• EEXXTTRRAA EEFFFFOORRTT OONN PPRREEMMIIUUMM SSEERRVVIICCEE FFOORR RRUUSSHH OORRDDEERRSS•• SSPPEECCIIAALL PPRRIICCIINNGG FFOORR HHIIGGHH VVOOLLUUMMEE CCOORRPPOORRAATTEE AACCCCOOUUNNTTSS•• SSAAMMEE DDAAYY SSHHIIPPMMEENNTT OOFF SSTTOOCCKK IITTEEMMSS OORRDDEERREEDD BBYY 11::3300PPMM•• QQUUAALLIIFFIIEEDD DDEEAALLEERRSS IINN OONNTTAARRIIOO,, QQUUEEBBEECC AANNDD MMAANNIITTOOBBAA

Give us a call and fax or email your enquiries. We would like an opportunity to quote your gauge requirements and show you what wecan do for your company.

T.R. (Tom) FisherGeneral Manager

2288 Dumfries Rd. RR#2Cambridge, ON, N1R 5S3Tel: 519-620-2044Fax: 519-620-1723Toll Free Fax: 1-800-210-6846Email: [email protected]: www.fishermet.com

Table of Contents

Unified Thread Plug Gauges Pg 2 - 4

Unified Thread Ring Gauges Pg 5 - 7

Unified Thread Setting Plugs Pg 5 - 7

Metric Thread Plug Gauges Pg 8 - 10

Metric Thread Rings and Setting Plugs Pg 8,9,11

Pipe Thread Plugs and Rings Pg 12

Hole Location Plugs and Calipers Pg 13

Vermont Gage Pin Sets and Members Pg 14

Vermont Gage Reversible Plugs Pg 15

Taperlock, Trilock, and Progressive Plugs Pg 16

Ring Gauges, Master Discs, and Snap Gauges Pg 17

Spline Ring Gauges and Plug Gauges Pg 18,19

Dyer/Schwenk Indicating Plug Pg 20

Subito Bore Gauge Sets Pg 21

Dyer 747 Measuring Table Pg 22

Dyer I.D. Calipers Pg 23

Mueller Gages Pg 24,25

Mahr Precision Instruments Pg 26 - 28

Barcor Chamfer Gages Pg 29

Opus Carbide Gauge Blocks Pg 30

Helios UMG 50 Calibration Unit Pg 31

Granite Surface Plates and Stands Pg 32

Kordt Thread Measuring Intruments Pg 32

Gaugemakers Tolerance Chart Pg 33

Unified Thread GaugesThread Work Plugs - Part Numbers Chart

0-80 UNF 200-100 200-101 200-102 200-103 200-104

1-64 UNC 200-110 200-111 200-112 200-113 200-114

1-72 UNF 200-115 200-116 200-117 200-118 200-119

2-56 UNC 200-120 200-121 200-122 200-123 200-124

2-64 UNF 200-125 200-126 200-127 200-128 200-129

3-48 UNC 200-130 200-131 200-132 200-133 200-134

3-56 UNF 200-135 200-136 200-137 200-138 200-139

4-40 UNC 200-140 200-141 200-142 200-143 200-144

4-48 UNF 200-145 200-146 200-147 200-148 200-149

5-40 UNC 200-150 200-151 200-152 200-153 200-154

5-44 UNF 200-155 200-156 200-157 200-158 200-159

6-32 UNC 200-160 200-161 200-162 200-163 200-164

6-40 UNF 200-165 200-166 200-167 200-168 200-169

8-32 UNC 200-170 200-171 200-172 200-173 200-174

8-36 UNF 200-175 200-176 200-177 200-178 200-179

10-24 UNC 200-180 200-181 200-182 200-183 200-184

10-32 UNF 200-185 200-186 200-187 200-188 200-189

12-24 UNC 200-190 200-191 200-192 200-193 200-194

12-28 UNF 200-195 200-196 200-197 200-198 200-199

1/4-20 UNC 200-200 200-201 200-203 200-204 200-205

1/4-28 UNF 200-205 200-206 200-207 200-208 200-209

5/16-18 UNC 200-210 200-211 200-212 200-213 200-214

5/16-24 UNF 200-215 200-216 200-217 200-218 200-219

3/8-16 UNC 200-220 200-221 200-222 200-223 200-224

3/8-24 UNF 200-225 200-226 200-227 200-228 200-229

7/16-14 UNC 200-230 200-231 200-232 200-233 200-234

7/16-20 UNF 200-235 200-236 200-237 200-238 200-239

1/2-13 UNC 200-240 200-241 200-242 200-243 200-244

1/2-20 UNF 200-245 200-246 200-247 200-248 200-249

9/16-12 UNC 200-250 200-251 200-252 200-253 200-254

9/16-18 UNF 200-255 200-256 200-257 200-258 200-259

5/8-11 UNC 200-260 200-261 200-262 200-263 200-264

5/8-18 UNF 200-265 200-266 200-267 200-268 200-269

3/4-10 UNC 200-270 200-271 200-272 200-273 200-274

3/4-16 UNF 200-275 200-276 200-277 200-278 200-279

2

Nominal Complete 2B, 3B 2B MBR 3B MBR CompleteSize 2B Gauge GO MBR NOGO NOGO 3B Gauge

Thread Plugs from Gage Assembly are supplied in hardchrome at no additional cost.Thread Plugs can also be supplied in TiN coating orTungsten Carbide.

Unified Thread GaugesThread Work Plugs - Part Numbers Chart

3

7/8-9 UNC 200-280 200-281 200-282 200-283 200-284

7/8-14 UNF 200-285 200-286 200-287 200-283 200-289

1-8 UNC 200-290 200-291 200-292 200-293 200-294

1-12 UNF 200-295 200-296 200-297 200-298 200-299

1-14 UNS 200-300 200-301 200-302 200-303 200-304

1-1/8-7 UNC 200-305 200-306 200-307 200-308 200-309

1-1/8-12 UNF 200-310 200-311 200-312 200-313 200-314

1-1/4-7 UNC 200-315 200-316 200-317 200-318 200-319

1-1/4-12 UNF 200-320 200-321 200-322 200-323 200-324

1-3/8-6 UNC 200-325 200-326 200-327 200-328 200-329

1-3/8-12 UNF 200-330 200-331 200-332 200-333 200-334

1-1/2-6 UNC 200-335 200-336 200-337 200-338 200-339

1-1/2-12 UNF 200-340 200-341 200-342 200-343 200-344

12-32 UNEF 202-190 202-191 202-192 202-193 202-194

1/4-32 UNEF 202-200 202-201 202-202 202-203 202-204

5/16-32 UNEF 202-210 202-211 202-212 202-213 202-214

3/8-32 UNEF 202-220 202-221 202-222 202-223 202-224

7/16-28 UNEF 202-230 202-231 202-232 202-233 202-234

1/2-28 UNEF 202-240 202-241 202-242 202-243 202-244

9/16-24 UNEF 202-250 202-251 202-252 202-253 202-254

5/8-24 UNEF 202-260 202-261 202-262 202-263 202-264

11/16-24 UNEF 202-265 202-266 202-267 202-268 202-269

3/4-20 UNEF 202-270 202-271 202-272 202-273 202-274

13/16-20 UNEF 202-275 202-276 202-277 202-278 202-279

7/8-20 UNEF 202-280 202-281 202-282 202-283 202-284

15/16-20 UNEF 202-285 202-286 202-287 202-288 202-289

1-20 UNEF 202-290 202-291 202-292 202-293 202-294

1-1/16-18 UNEF 202-295 202-296 202-297 202-298 202-299

1-1/8-18 UNEF 202-305 202-306 202-307 202-308 202-309

1-3/16-18 UNEF 202-310 202-311 202-312 202-313 202-314

1-1/4-18 UNEF 202-315 202-316 202-317 202-318 202-319

1-5/16-18 UNEF 202-320 202-321 202-322 202-323 202-324

1-3/8-18 UNEF 202-325 202-226 202-227 202-228 202-229

1-7/16-18 UNEF 202-330 202-331 202-332 202-333 202-334

1-1/2-18 UNEF 202-335 202-336 202-337 202-338 202-339

Nominal Complete 2B, 3B 2B MBR 3B MBR CompleteSize 2B Gauge GO MBR NOGO NOGO 3B Gauge

Thread Plugs from Gage Assembly are supplied in hardchrome at no additional cost.Thread Plugs can also be supplied in TiN coating orTungsten Carbide.

Unified Thread GaugesThread Work Plugs - Pitch Diameter Chart

0-80 UNF .0519 .0542 .0536

1-64 UNC .0629 .0655 .0648

1-72 UNF .0640 .0665 .0659

2-56 UNC .0744 .0772 .0765

2-64 UNF .0759 .0786 .0779

3-48 UNC .0855 .0885 .0877

3-56 UNF .0874 .0902 .0895

4-40 UNC .0958 .0991 .0982

4-48 UNF .0985 .1016 .1008

5-40 UNC .1088 .1121 .1113

5-44 UNF .1102 .1134 .1126

6-32 UNC .1177 .1214 .1204

6-40 UNF .1218 .1252 .1243

8-32 UNC .1437 .1475 .1465

8-36 UNF .1460 .1496 .1487

10-24 UNC .1629 .1672 .1661

10-32 UNF .1697 .1736 .1726

12-24 UNC .1889 .1933 .1922

12-28 UNF .1928 .1970 .1959

12-32 UNEF .1957 .1998 .1988

1/4-20 UNC .2175 .2224 .2211

1/4-28 UNF .2268 .2311 .2300

1/4-32 UNEF .2297 .2339 .2328

5/16-18 UNC .2764 .2817 .2803

5/16-24 UNF .2854 .2902 .2890

5/16-32 UNEF .2922 .2964 .2953

3/8-16 UNC .3344 .3401 .3387

3/8-24 UNF .3479 .3528 .3516

3/8-32 UNEF .3547 .3591 .3580

7/16-14 UNC .3911 .3972 .3957

7/16-20 UNF .4050 .4104 .4091

7/16-28 UNEF .4143 .4189 .4178

1/2-13 UNC .4500 .4565 .4548

1/2-20 UNF .4675 .4731 .4717

1/2-28 UNEF .4678 .4816 .4804

9/16-12 UNC .5084 .5152 .5135

9/16-18 UNF .5264 .5323 .5308

9/16-24 UNEF .5354 .5405 .5392

5/8-11 UNC .5660 .5732 .5714

5/8-18 UNF .5889 .5949 .5934

5/8-24 UNEF .5979 .6031 .6018

11/16-24 UNEF .6604 .6656 .6643

3/4-10 UNC .6850 .6927 .6907

3/4-16 UNF .7094 .7159 .7143

3/4-20 UNEF .7175 .7232 .7218

13-16-20 UNEF .7800 .7857 .7843

7/8-9 UNC .8028 .8110 .8089

7/8-14 UNF .8286 .8356 .8339

7/8-20 UNEF .8425 .8482 .8468

15/16-20 UNEF .9050 .9109 .9094

1-8 UNC .9188 .9276 .9254

1-12 UNF .9459 .9535 .9516

1-14 UNS .9536 .9609 .9590

1-20 UNEF .9675 .9734 .9719

1-1/16-18 UNEF 1.0264 1.0326 1.0310

1-1/8-7 UNC 1.0322 1.0416 1.0393

1-1/8-12 UNF 1.0709 1.0787 1.0768

1-1/8-18 UNEF 1.0889 1.0951 1.0935

1-3/16-18 UNEF 1.1514 1.1577 1.1561

1-1/4-7 UNC 1.1572 1.1668 1.1644

1-1/4-12 UNF 1.1959 1.2039 1.2019

1-1/4-18 UNEF 1.2139 1.2202 1.2186

1-5/16-18 UNEF 1.2764 1.2827 1.2811

1-3/8-6 UNC 1.2667 1.2771 1.2745

1-3/8-12 UNF 1.3209 1.3291 1.3270

1-3/8-18 UNEF 1.3389 1.3452 1.3436

1-7/16-18 UNEF 1.4014 1.4079 1.4062

1-1/2-6 UNC 1.3917 1.4022 1.3996

1-1/2-12 UNF 1.4459 1.4542 1.4522

1-1/2-18 UNEF 1.4639 1.4704 1.4687

Nominal GO NOGO NOGOSize 2B,3B 2B 3B

Nominal GO NOGO NOGOSize 2B,3B 2B 3B

4

Larger sizes, PrePlate sizes and Specials can be quotedupon request.

Unified Thread GaugesThread Rings and Setting Plugs - Part Numbers Chart

0-80 UNF 210-100 210-101 210-102 210-103 211-100 211-101 211-102 211-103

1-64 UNC 210-110 210-111 210-112 210-113 211-110 211-111 211-112 211-113

1-72 UNF 210-115 210-116 210-117 210-118 211-115 211-116 211-117 211-118

2-56 UNC 210-120 210-121 210-122 210-123 211-120 211-121 211-122 211-123

2-64 UNF 210-125 210-126 210-127 210-128 211-125 211-126 211-127 211-128

3-48 UNC 210-130 210-131 210-132 210-133 211-130 211-131 211-132 211-133

3-56 UNF 210-135 210-136 210-137 210-138 211-135 211-136 211-137 211-138

4-40 UNC 210-140 210-141 210-142 210-143 211-140 211-141 211-142 211-143

4-48 UNF 210-145 210-146 210-147 210-148 211-145 211-146 211-147 211-148

5-40 UNC 210-150 210-151 210-152 210-153 211-150 211-151 211-152 211-153

5-44 UNF 210-155 211-156 211-157 211-158 211-155 211-156 211-157 211-158

6-32 UNC 210-160 210-161 210-162 210-163 211-160 211-161 211-162 211-163

6-40 UNF 210-165 210-166 210-167 210-168 211-165 211-166 211-167 211-168

8-32 UNC 210-170 210-171 210-172 210-173 211-170 211-171 211-172 211-173

8-36 UNF 210-175 210-176 210-177 210-178 211-175 211-176 211-177 211-178

10-24 UNC 210-180 210-181 210-182 210-183 211-180 211-181 211-182 211-183

10-32 UNF 210-185 210-186 210-187 210-188 211-185 211-186 211-187 211-188

12-24 UNC 210-190 210-191 210-192 210-193 211-190 211-191 211-192 211-193

12-28 UNF 210-195 210-196 210-197 210-198 211-195 211-196 211-197 211-198

1/4-20 UNC 210-200 210-201 210-202 210-203 211-200 211-201 211-202 211-203

1/4-28 UNF 210-205 210-206 210-207 210-208 211-205 211-206 211-207 211-208

5/16-18 UNC 210-210 210-211 210-212 210-213 211-210 211-211 211-212 211-213

5/16-24 UNF 210-215 210-216 210-217 210-218 211-215 211-216 211-217 211-218

3/8-16 UNC 210-220 210-221 210-222 210-223 211-220 211-221 211-222 211-223

3/8-24 UNF 210-225 210-226 210-227 210-228 211-225 211-226 211-227 211-228

7/16-14 UNC 210-230 210-231 210-232 210-233 211-230 211-231 211-232 211-233

7/16-20 UNF 210-235 210-236 210-237 210-238 211-235 211-236 211-237 211-238

1/2-13 UNC 210-240 210-241 210-242 210-243 211-240 211-241 211-242 211-243

1/2-20 UNF 210-245 210-246 210-247 210-248 211-245 211-246 211-247 211-248

9/16-12 UNC 210-250 210-251 210-252 210-253 211-250 211-251 211-252 211-253

9/16-18 UNF 210-255 210-256 210-257 210-258 211-255 211-256 211-257 211-258

5/8-11 UNC 210-260 210-261 210-262 210-263 211-260 211-261 211-262 211-263

5/8-18 UNF 210-265 210-266 210-267 210-268 211-265 211-266 211-267 211-268

3/4-10 UNC 210-270 210-271 210-272 210-273 211-270 211-271 211-272 211-273

3/4-16 UNF 210-275 210-276 210-277 210-278 211-275 211-276 211-277 211-278

Nominal Complete GO NOGO 2A set Complete GO NOGO 3A setSize 2A set 2A 2A Plug 3A set 3A 3A Plug

5

Thread Ring Gauges can be supplied as solid typefrom Europe.

Unified Thread GaugesThread Rings and Setting Plugs - Part Numbers Chart

6

7/8-9 UNC 210-280 210-281 210-282 210-283 211-280 211-281 211-282 211-283

7/8-14 UNF 210-285 210-286 210-287 210-288 211-285 211-286 211-287 211-288

1-8 UNC 210-290 210-291 210-292 210-293 211-290 211-291 211-292 211-293

1-12 UNF 210-295 210-296 210-297 210-298 211-295 211-296 211-297 211-298

1-14 UNS 210-300 210-301 210-302 210-303 211-300 211-301 211-302 211-303

1-1/8-7 UNC 210-305 210-306 210-307 210-308 211-305 211-306 211-307 211-308

1-1/8-12 UNF 210-310 210-311 210-312 210-313 211-310 211-311 211-312 211-313

1-1/4-7 UNC 210-315 210-316 210-317 210-318 211-315 211-316 211-317 211-318

1-1/4-12 UNF 210-320 210-321 210-322 210-323 211-320 211-321 211-322 211-323

1-3/8-6 UNC 210-325 210-326 210-327 210-328 211-325 211-326 211-327 211-328

1-3/8-12 UNF 210-330 210-331 210-332 210-333 211-330 211-331 211-332 211-333

1-1/2-6 UNC 210-335 210-336 210-337 210-338 211-335 211-336 311-337 211-338

1-1/2-12 UNF 210-340 210-341 210-342 210-343 211-340 211-341 211-342 211-343

12-32 UNEF 212-190 212-191 212-192 212-193 213-190 213-191 213-192 213-193

1/4-32 UNEF 212-200 212-201 212-202 212-203 213-200 213-201 213-202 213-203

5/16-32 UNEF 212-210 212-211 212-212 212-213 213-210 213-211 213-212 213-213

3/8-32 UNEF 212-220 212-221 212-222 212-223 213-220 213-221 213-222 213-223

7/16-28 UNEF 212-230 212-231 212-232 212-233 213-230 213-231 213-232 213-233

1/2-28 UNEF 212-240 212-241 212-242 212-243 213-240 213-241 213-242 213-243

9/16-24 UNEF 212-250 212-251 212-252 212-253 213-250 213-251 213-252 213-253

5/8-24 UNEF 212-260 212-261 212-262 212-263 213-260 213-261 213-262 213-263

11/16-24 UNEF 212-265 212-266 212-267 212-268 213-265 213-266 213-267 213-268

3/4-20 UNEF 212-270 212-271 212-272 212-273 213-270 213-271 213-272 213-273

13/16-20 UNEF 212-275 212-276 212-277 213-278 213-275 213-276 213-277 213-278

7/8-20 UNEF 212-280 212-281 212-282 212-283 213-280 213-281 213-282 213-283

15/16-20 UNEF 212-285 212-286 212-287 212-288 213-285 213-286 213-287 213-288

1-20 UNEF 212-290 212-291 212-292 212-293 213-290 213-291 213-292 213-293

1-1/16-18 UNEF 212-295 212-296 212-297 212-298 213-295 213-296 213-297 213-298

1-1/8-18 UNEF 212-305 212-306 212-307 212-308 213-305 213-306 213-307 213-308

1-3/16-18 UNEF 212-310 212-311 212-312 212-313 213-310 213-311 213-312 213-313

1-1/4-18 UNEF 212-315 212-316 212-317 212-318 213-315 213-316 213-317 213-318

1-5/16-18 UNEF 212-320 212-321 212-322 212-323 213-320 213-321 213-322 213-323

1-3/8-18 UNEF 212-325 212-326 212-327 212-328 213-325 213-326 213-327 213-328

1-7/16-18 UNEF 212-330 212-331 212-332 212-333 213-330 213-331 213-332 213-333

1-1/2-18 UNEF 212-335 212-336 212-337 212-338 213-335 213-336 213-337 213-338

Nominal Complete GO NOGO 2A set Complete GO NOGO 3A setSize 2A set 2A 2A Plug 3A set 3A 3A Plug

Unified Thread GaugesThread Rings and Setting Plugs - Pitch Diameter Chart

Nominal GO NOGO GO NOGOSize 2A 2A 3A 3A

Nominal GO NOGO GO NOGOSize 2A 2A 3A 3A

7

0-80 UNF .0514 .0496 .0519 .0506

1-64 UNC .0623 .0603 .0629 .0614

1-72 UNF .0634 .0615 .0640 .0626

2-56 UNC .0738 .0717 .0744 .0728

2-64 UNF .0753 .0733 .0759 .0744

3-48 UNC .0848 .0825 .0855 .0838

3-56 UNF .0867 .0845 .0874 .0858

4-40 UNC .0950 .0925 .0958 .0939

4-48 UNF .0978 .0954 .0985 .0967

5-40 UNC .1080 .1054 .1088 .1069

5-44 UNF .1095 .1070 .1102 .1083

6-32 UNC .1169 .1141 .1177 .1156

6-40 UNF .1210 .1184 .1218 .1198

8-32 UNC .1428 .1399 .1437 .1415

8-36 UNF .1452 .1424 .1460 .1439

10-24 UNC .1619 .1586 .1629 .1604

10-32 UNF .1688 .1658 .1697 .1674

12-24 UNC .1879 .1845 .1889 .1863

12-28 UNF .1918 .1866 .1928 .1904

12-32 UNEF .1948 .1917 .1957 .1933

1/4-20 UNC .2164 .2127 .2175 .2147

1/4-28 UNF .2258 .2225 .2268 .2243

1/4-32 UNEF .2287 .2255 .2297 .2273

5/16-18 UNC .2752 .2712 .2764 .2734

5/16-24 UNF .2843 .2806 .2854 .2827

5/16-32 UNEF .2912 .2880 .2922 .2898

3/8-16 UNC .3331 .3287 .3344 .3311

3/8-24 UNF .3468 .3430 .3479 .3450

3/8-32 UNEF .3537 .3503 .3547 .3522

7/16-14 UNC .3897 .3850 .3911 .3876

7/16-20 UNF .4037 .3995 .4050 .4019

7/16-28 UNEF .4132 .4096 .4143 .4116

1/2-13 UNC .4485 .4435 .4500 .4463

1/2-20 UNF .4662 .4619 .4675 .4643

1/2-28 UNEF .4757 .4720 .4768 .4740

9/16-12 UNC .5068 .5016 .5084 .5054

9/16-18 UNF .5250 .5205 .5264 .5230

9/16-24 UNEF .5342 .5303 .5354 .5325

5/8-11 UNC .5644 .5589 .5660 .5619

5/8-18 UNF .5875 .5828 .5889 .5854

5/8-24 UNEF .5967 .5927 .5979 .5949

11/16-24 UNEF .6592 .6552 .6604 .6574

3/4-10 UNC .6832 .6773 .6850 .6806

3/4-16 UNF .7079 .7029 .7094 .7056

3/4-20 UNEF .7162 .7118 .7175 .7142

13/16-20 UNEF .7787 .7743 .7800 .7767

7/8-9 UNC .8009 .7946 .8028 .7981

7/8-14 UNF .8270 .8216 .8286 .8245

7/8-20 UNEF .8412 .8368 .8425 .8392

15/16-20 UNEF .9036 .8991 .9050 .9016

1-8 UNC .9168 .9100 .9188 .9137

1-12 UNF .9441 .9382 .9459 .9415

1-14 UNS .9519 .9463 .9536 .9494

1-20 UNEF .9661 .9616 .9675 .9641

1-1/16-12 UNF 1.0067 1.0010 1.0084 1.0042

1-1/16-18 UNEF 1.0250 1.0203 1.0264 1.0228

1-1/8-7 UNC 1.0300 1.0228 1.0322 1.0268

1-1/8-12 UNF 1.0691 1.0631 1.0709 1.0664

1-1/8-18 UNEF 1.0875 1.0828 1.0889 1.0853

1-3/16-12 UNF 1.1317 1.1259 1.1334 1.1291

1-3/16-18 UNEF 1.1499 1.1450 1.1514 1.1478

1-1/4 UNC 1.1550 1.1476 1.1572 1.1517

1-1/4-12 UNF 1.1941 1.1879 1.1959 1.1913

1-1/4-18 UNEF 1.2124 1.2075 1.2139 1.2103

1-5/16-12 UNF 1.2567 1.2509 1.2584 1.2541

1-5/16-18 UNEF 1.2749 1.2700 1.2764 1.2728

1-3/8-6 UNC 1.2643 1.2563 1.2667 1.2607

1-3/8-12 UNF 1.3190 1.3127 1.3209 1.3162

1-3/8-18 UNEF 1.3374 1.3325 1.3389 1.3353

1-7/16-12 UNF 1.3816 1.3757 1.3834 1.3790

1-7/16-18 UNEF 1.3999 1.3949 1.4014 1.3977

1-1/2-6 UNC 1.3893 1.3812 1.3917 1.3856

1-1/2-12 UNF 1.4440 1.4376 1.4459 1.4411

1-1/2-18 UNEF 1.4624 1.4574 1.4639 1.4602

Larger sizes, PrePlate sizes and Specials can be quotedupon request.

Metric Thread GaugesThread Work Plugs & Rings - Part Numbers Chart

Nominal Complete GO NOGO GO/NOGO GO Ring NOGO 6g setSize 6H Gauge MBR MBR Ring Set 6g Ring 6g Plug

8

M 1.6 x .35 300-140 300-141 300-142

M 1.6 x .20 300-145 300-146 300-147

M 1.8 x .35 300-150 300-151 300-152

M 1.8 x .20 300-155 300-156 300-157

M 2.0 x .40 300-160 300-161 300-162

M 2.0 x .25 300-165 300-166 300-167

M 2.2 x .45 300-170 300-171 300-172

M 2.2 x .25 300-175 300-176 300-177

M 2.5 x .45 300-180 300-181 300-182

M 2.5 x .25 300-185 300-186 300-187

M 3.0 x .50 300-190 300-191 300-192

M 3.0 x .35 300-195 300-196 300-197

M 3.5 x .60 300-200 300-201 300-202

M 3.5 x .35 300-205 300-206 300-207

M 4.0 x .70 300-210 300-211 300-212

M 4.0 x .50 300-215 300-216 300-217

M 4.5 x .75 300-220 300-221 300-222

M 4.5 x .50 300-225 300-226 300-227

M 5.0 x .80 300-230 300-231 300-232

M 5.0 x .50 300-235 300-236 300-237

M 6.0 x 1.0 300-240 300-241 300-242

M 6.0 x .75 300-245 300-246 300-247

M 7.0 x 1.0 300-250 300-251 300-252

M 7.0 x 0.75 300-255 300-256 300-257

M 8.0 x 1.25 300-260 300-261 300-262

M 8.0 x 1.0 300-265 300-266 300-267

M 10 x 0.75 300-270 300-271 300-272

M 10 x 1.0 300-275 300-276 300-277

M 10 x 1.50 300-280 300-281 300-282

M 10 x 1.25 300-285 300-286 300-287

M 12 x 1.50 300-290 300-291 300-292

M 12 x 1.0 300-295 300-296 300-297

M 12 x 1.75 300-300 300-301 300-302

M 12 x 1.25 300-305 300-306 300-307

310-140 310-141 310-142 310-143

310-145 310-146 310-147 310-148

310-150 310-151 310-152 310-153

310-155 310-156 310-157 310-158

310-160 310-161 310-162 310-163

310-165 310-166 310-167 310-168

310-170 310-171 310-172 310-173

310-175 310-176 310-177 310-178

310-180 310-181 310-182 310-183

310-185 310-186 310-187 310-188

310-190 310-191 310-192 310-193

310-195 310-196 310-197 310-198

310-200 310-201 310-202 310-203

310-205 310-206 310-207 310-208

310-210 310-211 310-212 310-213

310-215 310-216 310-217 310-218

310-220 310-221 310-222 310-223

310-225 310-226 310-227 310-228

310-230 310-231 310-232 310-233

310-235 310-236 310-237 310-238

310-240 310-241 310-242 310-243

310-245 310-246 310-247 310-248

310-250 310-251 310-252 310-253

310-255 310-256 310-257 310-258

310-260 310-261 310-262 310-263

310-265 310-266 310-267 310-268

310-270 310-271 310-272 310-273

310-275 310-276 310-277 310-278

310-280 310-281 310-282 310-283

310-285 310-286 310-287 310-288

310-290 310-291 310-292 310-293

310-295 310-296 310-297 310-298

310-300 310-301 310-302 310-303

310-305 310-306 310-307 310-308

Thread Work Plugs Thread Ring Gauges

Thread Plugs from Gage Assembly are supplied in hard chromeat no additional cost.Thread Plugs can also be supplied in TiN coating orTungsten Carbide.Thread Ring Gauges can be supplied as solid type from Europe.Metric Thread Gauges can be manufactured to ANS1 B1.16M, ISO,DIN 13 or JIS Standards.

Metric Thread GaugesThread Work Plugs & Rings - Part Numbers Chart

Nominal Complete GO NOGO GO/NOGO GO Ring NOGO 6g setSize 6H Gauge MBR MBR Ring Set 6g Ring 6g Plug

Thread Work Plugs Thread Ring Gauges

M 14 x 2.0 300-310 300-311 300-312

M 14 x 1.50 300-315 300-316 300-317

M 16 x 2.0 300-320 300-321 300-322

M 16 x 1.50 300-325 300-326 300-327

M 17 x 1.0 300-330 300-331 300-332

M 18 x 2.50 300-335 300-336 300-337

M 18 x 1.50 300-340 300-341 300-342

M 20 x 2.50 300-345 300-346 300-347

M 20 x 1.50 300-350 300-351 300-352

M 20 x 1.0 300-355 300-356 300-357

M 22 x 2.50 300-360 300-361 300-362

M 22 x 1.50 300-365 300-366 300-367

M 24 x 3.0 300-370 300-371 300-372

M 24 x 2.0 300-375 300-376 300-377

M 25 x 1.5 300-380 300-381 300-382

M 27 x 3.0 300-385 300-386 300-387

M 27 x 2.0 300-390 300-391 300-392

M 30 x 3.50 300-395 300-396 300-397

M 30 x 2.0 300-400 300-401 300-402

M 30 x 1.5 300-405 300-406 300-407

M 33 x 3.50 300-410 300-411 300-412

M 33 x 2.0 300-415 300-416 300-417

M 35 x 1.5 300-420 300-421 300-422

M 36 x 4.0 300-425 300-426 300-427

M 36 x 2.0 300-430 300-431 300-432

M 39 x 4.0 300-435 300-436 300-437

M 39 x 2.0 300-440 300-441 300-442

310-310 310-311 310-312 310-313

310-315 310-316 310-317 310-318

310-320 310-321 310-322 310-323

310-325 310-326 310-327 310-328

310-330 310-331 310-332 310-333

310-333 310-336 310-337 310-338

310-340 310-341 310-342 310-343

310-345 310-346 310-347 310-348

310-350 310-351 310-352 310-353

310-355 310-356 310-357 310-358

310-360 310-361 310-362 310-363

310-365 310-366 310-367 310-368

310-370 310-371 310-372 310-373

310-375 310-376 310-377 310-378

310-380 310-381 310-382 310-383

310-385 310-386 310-387 310-388

310-390 310-391 310-392 310-393

310-395 310-396 310-397 310-398

310-400 310-401 310-402 310-403

310-405 310-406 310-407 310-408

310-410 310-411 310-412 310-413

310-415 310-416 310-417 310-418

310-420 310-421 310-422 310-423

310-425 310-426 310-427 310-428

310-430 310-431 310-432 310-433

310-435 310-436 310-437 310-438

310-440 310-441 310-442 310-443

9

Thread Plugs from Gage Assembly are supplied in hard chromeat no additional cost.Thread Plugs can also be supplied in TiN coating orTungsten Carbide.Thread Ring Gauges can be supplied as solid type from Europe.Metric Thread Gauges can be manufactured to ANSI B1.16M, ISO,DIN 13 or JIS Standards.

Metric Thread GaugesThread Work Plugs - Pitch Diameter Chart

M 1.6 x .35 1.373 1.458

M 1.6 x .20 1.470 4H 1.512

M 1.8 x .35 1.573 1.658

M 1.8 x .20 1.670 4H 1.712

M 2.0 x .40 1.740 1.830

M 2.0 x .25 1.838 5H 1.898

M 2.2 x .45 1.908 2.003

M 2.2 x .25 2.038 5H 2.098

M 2.5 x .45 2.208 2.303

M 2.5 x .35 2.273 2.358

M 3.0 x .50 2.675 2.775

M 3.0 x .35 2.773 2.863

M 3.5 x .60 3.110 3.222

M 3.5 x .35 3.273 3.363

M 4.0 x .70 3.545 3.663

M 4.0 x .50 3.675 3.775

M 4.5 x .75 4.013 4.131

M 4.5 x .50 4.175 4.275

M 5.0 x .80 4.480 4.605

M 5.0 x .50 4.675 4.775

M 6.0 x 1.0 5.350 5.500

M 6.0 x .75 5.513 5.645

M 7.0 x 1.0 6.350 6.500

M 8.0 x 1.25 7.188 7.348

M 8.0 x 1.0 7.350 7.500

M 10 x .75 9.513 9.645

M 10 x 1.0 9.350 9.500

M 10 x 1.50 9.026 9.206

M 10 x 1.25 9.188 9.348

M 12 x 1.5 11.026 11.216

M 12 x 1.0 11.350 11.510

M 12 x 1.75 10.863 11.063

M 12 x 1.25 11.188 11.368

M 14 x 2.0 12.701 12.913

M 14 x 1.5 13.026 13.216

M 16 x 2.0 14.701 14.913

M 16 x 1.5 15.026 15.216

M 17 x 1.0 16.350 16.510

M 18 x 2.5 16.376 16.600

M 18 x 1.5 17.026 17.216

M 20 x 2.5 18.376 18.600

M 20 x 1.5 19.026 19.216

M 20 x 1.0 19.350 19.510

M 22 x 2.5 20.376 20.600

M 22 x 1.5 21.026 21.216

M 24 x 3.0 22.051 22.316

M 24 x 2.0 22.701 22.925

M 27 x 3.0 25.051 25.316

M 27 x 2.0 25.701 25.925

M 30 x 3.5 27.727 28.007

M 30 x 2.0 28.701 28.925

M 30 x 1.5 29.026 29.226

M 33 x 3.5 30.727 31.007

M 33 x 2.0 31.701 31.925

M 35 x 1.5 34.026 34.226

M 36 x 4.0 33.402 33.702

M 36 x 2.0 34.701 34.925

M 39 x 4.0 36.402 36.702

M 39 x 2.0 37.701 37.925

Nominal GO NOGOSize 6H 6H

Nominal GO NOGOSize 6H 6H

10

Larger sizes, PrePlate sizes and Specials can be quotedupon request.

Metric Thread GaugesThread Ring and Setting Plugs - Pitch Diameter Chart

M 1.6 x .35 1.354 1.291

M 1.6 x .20 1.453 1.403

M 1.8 x .35 1.554 1.491

M 1.8 x .20 1.653 1.603

M 2.0 x .40 1.721 1.654

M 2.0 x .25 1.820 1.764

M 2.2 x .45 1.888 1.817

M 2.2 x .25 2.020 1.964

M 2.5 x .45 2.188 2.117

M 2.5 x .35 2.254 2.191

M 3.0 x .50 2.655 2.580

M 3.0 x .35 2.754 2.687

M 3.5 x .60 3.089 3.004

M 3.5 x .35 3.254 3.187

M 4.0 x .70 3.523 3.433

M 4.0 x .50 3.655 3.580

M 4.5 x .75 3.991 3.901

M 4.5 x .50 4.155 4.080

M 5.0 x .80 4.456 4.361

M 5.0 x .50 4.655 4.580

M 6.0 x 1.0 5.324 5.212

M 6.0 x .75 5.491 5.391

M 7.0 x 1.0 6.324 6.212

M 8.0 x 1.25 7.160 7.042

M 8.0 x 1.0 7.324 7.212

M 10 x .75 9.491 9.391

M 10 x 1.0 9.324 9.212

M 10 x 1.50 8.994 8.862

M 10 x 1.25 9.160 9.042

M 12 x 1.5 10.994 10.854

M 12 x 1.0 11.324 11.206

M 12 x 1.75 10.829 10.679

M 12 x 1.25 11.160 11.028

M 14 x 2.0 12.663 12.503

M 14 x 1.5 12.994 12.854

M 16 x 2.0 14.663 14.503

M 16 x 1.5 14.994 14.854

M 17 x 1.0 16.234 16.206

M 18 x 2.5 16.334 16.164

M 18 x 1.5 16.994 16.854

M 20 x 2.5 18.334 18.164

M 20 x 1.5 18.994 18.854

M 20 x 1.0 19.324 19.206

M 22 x 2.5 20.334 20.164

M 22 x 1.5 20.994 20.854

M 24 x 3.0 22.003 21.803

M 24 x 2.0 22.663 22.493

M 27 x 3.0 25.003 24.803

M 27 x 2.0 25.663 25.493

M 30 x 3.5 27.674 27.462

M 30 x 2.0 28.663 28.493

M 30 x 1.5 28.994 28.844

M 33 x 3.5 30.674 30.462

M 33 x 2.0 31.663 31.493

M 35 x 1.5 33.994 33.844

M 36 x 4.0 33.342 33.118

M 36 x 2.0 34.663 34.493

M 39 x 4.0 36.342 36.118

M 39 x 2.0 37.663 37.493

Nominal GO NOGOSize 6g 6g

Nominal GO NOGOSize 6g 6g

11

Larger sizes, PrePlate sizes and Specials can be quotedupon request.

Pipe Thread GaugesPipe Thread Plugs & Rings - Part Numbers Chart

12

1/16-27 215-100 215-101 215-102 215-103

1/8-27 215-105 215-106 215-107 215-108

1/4-18 215-110 215-111 215-112 215-113

3/8-18 215-115 215-116 215-117 215-118

1/2-14 215-120 215-121 215-122 215-123

3/4-14 215-125 215-126 215-127 215-128

1-11.5 215-130 215-131 215-132 215-133

1-1/4-11.5 215-135 215-136 215-137 215-138

1-1/2-11.5 215-140 215-141 215-142 215-143

2-11.5 215-145 215-146 215-147 215-148

2-1/2-8 215-150 215-151 215-152 215-153

3-8 215-155 215-156 215-157 215-158

3-1/2-8 215-160 215-161 215-162 215-163

4-8 215-165 215-166 215-167 215-168

1/16-27 205-100 205-101 205-102 205-103

1/8-27 205-105 205-106 205-107 205-108

1/4-18 205-110 205-111 205-112 205-113

3/8-18 205-115 205-116 205-117 205-118

1/2-14 205-120 205-121 205-122 205-123

3/4-14 205-125 205-126 205-127 205-128

1-11.5 205-130 205-131 205-132 205-133

1-1/4-11.5 205-135 205-136 205-137 205-138

1-1/2-11.5 205-140 205-141 205-142 205-143

2-11.5 205-145 205-146 205-147 205-148

2-1/2-8 205-150 205-151 205-152 205-153

3-8 205-155 205-156 205-157 205-158

3-1/2-8 205-160 205-161 205-162 205-163

4-8 205-165 205-166 205-167 205-168

Nominal NPT L1 NPTF L1 NPTF L2 NPTF 6Size Ring Ring Ring Step Ring

Nominal NPT L1 NPTF L1 NPTF L3 NPTF 6Size Plug Plug Plug Step Plug

Straight Pipe Gauges in NPSM, NPSC, NPSL, NPSF, NPSI toleranceand larger sizes can be supplied upon request.

13

The roller thread gauge is used moreand more for testing the male thread. With

respect to the ring gauge it has the advantage thatfirstly gauging can be carried out considerably quicker, and secondlyright-handed and left-handed threads can be tested with one and thesame gauge. Beyond that, all grades of one nominal size areadjustable. The roller thread gauge is adjusted with the setting gaugeillustrated below. The corresponding socket-screw wrenches aredelivered with the gauge. The checking process is performed in thesame way as with go and nogo ring gauges. The go rollers must beable to be slide over the male thread; the nogo rollers must not passover the male thread.

Flexible Hole Location Plugs

Roller Thread GaugesThread Calipers

Flexible hole location gauge is slotted at 90° increments to ensurepositive location on the thread flank regardless of hole size. Othercommonly used location plugs must be inserted so that the shoulderis flush with a locating face, resulting in squareness deviationtransferred to centerline measurement.

0 - 801 64 722 56 643 48 564 40 485 40 446 32 408 32 3610 24 3212 24 281/4 20 285/16 18 243/8 16 247/16 14 201/2 13 209/16 12 185/8 11 183/4 10 167/8 9 141 8 12

Metric Measurements Unified / Inch Measurements

Size

M3 x 0.5

M4 x 0.7

M5 x 0.8

M6 x 1.0

M8 x 1.25

M10 x 1.5

M12 x 1.75

M12 x 1.25

M14 x 1.5

M14 x 2.0

M16 x 1.5

M16 x 2.0

Size UNC UNFThreads Per Inch

Made in the U.K., knife edge calipers are an easy way to check externalthreaded components. Available in sizes up to 12” or 300mm, thesecalipers can be set with a master plug or with gauge blocks. Parts still onthe machine can be checked with a go/nogo caliper as opposed to ringgauges which require moving the part from the machine. Frames andanvils are readily available from our gaugemaker and can be set andsealed to any pitch diameter and certified.

Threads Inc / Southern Gage

Piccadilly Precision Engineering Kolb & Baumann GmbH

Vermont Gage Pin Sets & Replacement Pins

.0060” to .0600” 55 11001 12001

.0065” to .0605” 55 13001 14001

.0110” to .0600” 50 11002 12002

.0115” to .0605” 50 13002 14002

.0110” to .2500” 240 11003 12003

.0115” to .2505” 240 13003 14003

.0610” to .2500” 190 11004 12004

.0615” to .2505” 190 13004 14004

.2510” to .5000” 250 11005 12005

.2515” to .5005” 250 13005 14005

.5010” to .6250” 125 11006 12006

.5015” to .6255” 125 13006 14006

.6260” to .7500” 125 11007 12007

.6265” to .7505” 125 13007 14007

.7510” to .8320” 82 11008 12008

.7510” to .8325” 82 13008 14008

.8330” to .9160” 84 11009 12009

.8335” to .9165” 84 13009 14009

.9170” to 1.0000” 84 11010 12010

.9175” to 1.0005” 84 13010 14010

Range No. of Order No. Order No.Gages (Plus) (Minus)

Inch Sets (.001 increments)

0.20mm to 1.28mm 55 21001 22001

0.21mm to 1.29mm 55 23001 24001

1.30mm to 4.98mm 185 21002 22002

1.31mm to 4.99mm 185 23002 24002

5.00mm to 9.98mm 250 21003 22003

5.01mm to 9.99mm 250 23003 24003

10.00mm to 13.98mm 200 21004 22004

10.01mm to 13.99mm 200 23004 24004

14.00mm to 16.48mm 125 21005 22005

14.01mm to 16.49mm 125 23005 24005

16.50mm to 18.98mm 125 21006 22006

16.51mm to 18.99mm 125 23006 24006

19.00mm to 20.98mm 100 21007 22007

19.01mm to 20.99mm 100 23007 24007

21.00mm to 22.48mm 75 21008 22008

21.01mm to 22.49mm 75 23008 24008

22.50mm to 23.98mm 75 21009 22009

22.51mm to 23.99mm 75 23009 24009

24.00mm to 25.48mm 75 21010 22010

24.01mm to 25.49mm 75 23010 24010

Range No. of Order No. Order No.Gages (Plus) (Minus)

Metric Sets (.02mm increments)

.0040” to .0105”

.0110” to .0605”

.0610” to .5005”

.5010” to .6255”

.6260” to .7505”

.7510” to .8325”

.8330” to .9165”

.9170” to 1.0005”

Range

Class ZZ Replacement Pins

Metric

0.20mm to 1.29mm

1.30mm to 4.99mm

5.00mm to 9.99mm

10.00mm to 13.99mm

14.00mm to 16.49mm

16.50mm to 18.99mm

19.00mm to 20.99mm

21.00mm to 22.49mm

22.50mm to 23.99mm

24.00mm to 25.49mm

Range

.0002” CL ZZ Tolerance .005mm CL ZZ Tolerance

Inch

14

All items are available in both a plus (+) tolerance or a minus (-) tolerance.

Custom Reversibles from .0040” to 1.0100”

.0040” to .0150”

.11mm to .38mm

.0151” to .0300”

.39mm to .76mm

.0301” to .0750”

.77mm to 1.91mm

.0751” to .1800”

1.92mm to 4.57mm

.1801” to .2810”

4.58mm to 7.14mm

.2811” to .4060mm

7.15mm to 10.31mm

.4061” to .5100”

10.32mm to 12.95mm

.5101” to .6350”

12.96mm to 16.13mm

.6351” to .7600”

16.14mm to 19.30mm

.7601” to 1.0100”

19.31mm to 25.65mm

• Class XX, X, Y, Z, or ZZ

• Go, NoGo, or Master tolerances

• NIST traceable

• Tool Steel; 60/62 Rc

(Cold Stabilized),

Chrome Plated tool steel; 70/72 Rc

or Tungsten Carbide; 90/92 Ra

• 2” long members

• Marking Gauge No’s or Part No’s-no extra charge

Range

15

Vermont Gage

Custom Taperlock,Trilock & Progressive Plug Gauges

16

Custom Taperlocks from .1050” to 1.5100”

• Class XX, X, Y, or Z

• Go, NoGo tolerances

• NIST traceable

• Tool Steel; 60/62 Rc

(Cold Stabilized),

Chrome Plated tool steel; 70/72 Rc

• Class XX, X, Y, or Z

• Go, NoGo tolerances

• NIST traceable

• Tool Steel; 60/62 Rc

(Cold Stabilized),

Chrome Plated tool steel; 70/72 Rc

• Class XX, X, Y, or Z

• Go, NoGo tolerances

• NIST traceable

• Tool Steel; 60/62 Rc

(Cold Stabilized),

Chrome Plated tool steel; 70/72 Rc

• Up to 1.510” Taperlock style

over 1.510” Trilock style

Custom Trilocks from .7600” to 8.010”

Custom Progressive Gauges from .1050” to 4.5100”

Also available in Tungsten Carbide

Dundick / Mid-Tech Gage

17

Available in custom diameters from .0150”to 16.010”.Ring gauges are custom made to your diameterspecifications in both Inch and Metric. Choosetolerance (Class XXX, XX, X, Y, Z) and material (Steel,Chrome Plated, Carbide). With a Go and NoGo Ring,an inspector can quickly pass/fail parts without takingtime consuming readings from an indicator. TheseRing gauges are also perfect for use as masters forsetting bore gauges and internal micrometers. Werecommend calibration certificates for all rings.

Available in custom diameters from .1500”to 15.010”.Master setting discs are custom made to your diameterspecifications in both Inch and Metric. Choosetolerance (Class XX, X, Y) and material (Steel, Chromeplated, Carbide). Use master setting discs to calibrateyour snap gauges, or measuring equipment. Designedto satisfy traceability requirements of your qualitycontrol system, these masters are a must for yourcalibration lab and inspection areas.

Master Ring Gauges

Master Setting Discs

Custom Ring Gauges, Setting Discs & Snap Gauges

Adjustable Snap GaugesType C available from 0 - 11 5/8” (0 - 295mm)Type U available from 0 - 11 1/4” (0 - 286mm)Type A available from 0 - 18” (0 - 457mm)

Miniature Adjustable Snap GaugesType C available from 0 - 0.760” (0 - 20mm)Type U available from 0 - 0.760” (0 - 20mm)

Adjustable Snap Gauges

Type C Type U

Kees / Mid-Tech Gage / Dundick / YPG Gages

18

Spline Ring Gauges and Indicators

Go and NoGo Spline ring gauges with Taper Masterplug gauges: for involute, helical and straight-sidedteeth, and serrations.

Spline Comparators measure the effective size againsta master of known size. A dial gauge reading showsthe variation in effective tooth thickness in 0.0001”(0.002mm) increments.

Simply by varying the component limits, tolerancechanges during production can be accommodated withthe same gauges.

Selective fits on assembly made easy.

Only one Spline Comparator is needed for each part,fulfilling functions of both Go and NoGo full formfixed gauges.

Made in internal or external versions, portable or asbench fixtures.

Min Ø 3/16” 5mm

Max Ø 20” 500mm

Min Pitch 180DP 0.15 Module

Max Pitch 3DP 8.0 Module

Max length 6” 150mm

Max helix 45°

Max taper 15°

Max number teeth 550

Standards materials Standard gauge steel

62/63C or Nitralloy if

below 1” Ø. (25mm)

Special Materials HSS, tungsten carbide

Specification Parameters

Spline Ring Gauges

Spline Indicators

19

Spline Plug Gauges

(Setting masters) and GO and NoGo alignment, taper and helical spline mandrels.

Min Ø 3/16” 5mm

Max Ø 20” 500mm

Min Pitch 220DP 0.1 Module

Max Pitch 1DP 25.4 Module

Max length 12” 300mm

Max helix 45°

Max taper 15°

Max number teeth 550

Standards materials Standard gauge steel

62/63C

Special Materials HSS, tungsten carbide

Specification Parameters

20

Dyer/Schwenk Indicating Plug Bore Gauges

FREEDOM TO CHOOSE

Any mechanical or electronic indicator can be used with these Bore Gauges. We recommend theMahr Mechanical Dial Comparators on page 28.

Special adapters are available to interface all manufacturers’ indicators with protective housingsto these Bore Gauges and the gauge handle accepts 3/8” or 8mm stem indicating units.

THE HIGHEST ACCURACY AND REPEATABILITY

For machine capability studies and SPC, the indicating plug gauge is North America’s leader inGAUGE R AND R performance.

All of these Bore Gauges, small and large, 0.079” thru 4.13” (2.0 - 105mm) are 10% capablewhen measuring high tolerance parts.

AUTOMATIC CENTERING AND NO OPERATOR ERROR

In achieving the highest accuracies, the centering sleeve is made approximately 0.001” or.025mm under the low limit of your minimum bore tolerance. The carbide ball contact pointshoused in the centering sleeve along with the free floating movement permit the highestmeasuring accuracy. The contact balls can be supplied in ruby, ceramic and teflon.

“The Measurement is locked in” and no operator error is possible. A special design at the baseof the centering sleeve creates a snow-plow effect clearing the way for a fast accuratemeasurement.

The spring loaded outward contact pressure along with automatic centering and non tippingmeans no operator error when measuring bores.

TWO POINT CONTACT MEASURING (AND YOU DON’T TIP THE GAGE)

Positive two point outward contact pressure and continuous on-line indication of the measuredvalue, in conjunction with a very small reversal error permit measurement of the following boreirregularities. Measuring deviations in a bore’s shape is accomplished by turning or sliding thegauge up and down in the hole.

Unlike three point contact bore gauges that average a bore’s diameter, the indicating plug’s twopoint contact system permits the measurement of out of round conditions. You will measurebores more precisely and with higher accuracies.

GAUGE R AND R

Because of differences in part measuring application, surface finish and factory temperatures,each customer should perform individual GAUGE R AND R studies with each gauge to determinethe GAUGE R AND R capability of a specific measuring application.

Hourglassor bell mouth

TaperBarrel shapeOvality

Linear < ± 0.000040”/< ± 0.001 mm

Repeatability < 0.000040” (< 0.001mm)

GAUGE R AND R capability* < 10% measuring0.0003” tolerance bores

Dyer/Schwenk indicating bore gauges areused for repetitive bore measurementapplications or dedicated high volumeproduction runs.

This rugged and dependable bore gauge wasdesigned with the operator in mind. Fast andeasy to use without operator error.

Available in dedicated sizes from 2.0 - 105mm(0.079 - 4.13”)

3 styles of plugs (measuring sleeve) areavailable; Blind, Super Blind, Thru Bore

Maximum Measuring Accuracy:

21

Subito Precision Bore Gauges

FEATURES

• Measurement of diameter, roundness and conicity of bores as well asdistances between flat parallel surfaces

• Measuring head consists of carbide-tipped moving anvil and aninterchangeable stationary anvil with hardened steel ball; carbide ballon request

• Transmission lever system transfers movement of the movable anvilto indicating instrument

• Extra wide bridge ensures automatic centering in the bore

• High wear-resistance due to carbide-tipped moving anvil

• Constant measuring force due to built-in spring thus eliminatinguser influence

• Highly versatile. Each gauge covers a large range. Within therespective limits, quickly and easily adjustable to any size and anytype of measuring application

Series SU Standard Version with Inspection Certificate

4.5 - 6 .18-.24” - - 100 00000 100 000016 - 8 .24-.31” - - 101 00000 101 000018 - 12 .31-.47” - - 102 00000 102 0000112 - 20 .47-.79” - - 103 00000 103 0000118 - 35 .71-1.38” 104 00000 104 00001 104 00002 104 0000335 - 60 1.38-2.36” 105 00000 105 00001 105 00002 105 0000350 -100 2.0-4.0” 106 00000 106 00001 106 00002 106 0000350 - 150 2.0-6.0” 107 00000 107 00001 107 00002 107 00003100 - 160 4.0-6.3” 108 00000 108 00001 108 00002 108 00003100 - 230 4.0-9.0” 109 00000 109 00001 109 00002 109 00003160 - 290 6.3-11.4” 110 00000 110 00001 110 00002 110 00003160 - 360 6.3-14.1” 111 00000 111 00001 111 00002 111 00003280 - 410 11.0-16.15” 112 00000 112 00001 112 00002 112 00003280 - 510 11.0-20.0” 113 00000 113 00001 113 00002 113 00003400 - 800 15.75-31.5” 114 00000 114 00001 114 00002 114 00003

Replacement parts and anvils can be supplied

Application Application Measuring pin steel Measuring pins tungsten carbiderange range Order No. Order No.(mm) (inch) SU SK SU SK

18 - 100 .71-4.0 115 00000 115 00002 115 00006 115 0000418 - 150 .71-6.0 116 00000 116 00002 116 00006 116 0000450 - 160 2.0-6.3 117 00000 117 00002 117 00006 117 0000450 - 230 2.0-9.0 118 00000 118 00002 118 00006 118 00004

Application Application Meas. pins Meas. pins Centr. plate Meas. pinsrange range steel carbide coated ruby(mm) (inch) Order No. Order No. Order No. Order No.

Series SK Same as Series SU but with short holder

Dyer 747 ID-OD Measuring Table

GENERAL DESCRIPTION OF THE 747-001, 747-002 AND 747-003ID-OD MEASURING TABLES

The ID-OD measuring table is an instrument for checking dimensions relative toa previously set distance. The dimension is obtained by reading the maximumpoint determined during the travel of the point between a fixed and mobileanvil. The accuracy is ±0.000040”, with a repeatability of < 0.000080”. Selecteither a mechanical or electronic indicating unit for either a direct orcomparative reading indication. With certain electronic indicating units, and oncertain applications, the capability of “Presetting in” an absolute value on theindicator is available.

The contact point retraction is 0.827” (21.0mm). The contact point reach is1.380” (35.0mm) as standard to 5.900” (150.0mm) is optional. The gaugecomes with spring loaded (adjustable pressure) contact points.

The 747-001 and 747-002 basic units are 5.91” (150.0mm) in diameter x2.36” (60.0mm) high and the weight is 7.72 pounds.

The 747-003 basic unit is 11.81” (300.0mm) in diameter x 3.54” (90.0mm)high and the weight is 43.0 pounds.

Use the 747 at each CNC machining or turning centre. Because it can do the jobof many different hand tools; it is ideal for use at your qualityassurance/inspection station.

The unit switches over from ID to OD and the measuring application possibilitiesare many.

Special contact measuring arms, tailored to fit unique gauging applications canbe made by Dyer. CAD drawings of the Top’s bolt pattern and anvils areavailable upon request.

ID-OD MEASURING STATION

A single 747 measuring station can do the job of many different types ofhand gauges.

IDEAL MEASURING APPLICATIONS

• Internal and external diameters• Internal and external grooves• Shallow counter bores and grooves• ID-OD diameters with boss or hub• Inside diameter of narrow counter bores• Concentricity between ID and OD• Cone ID-OD at specified depth• Wall thickness• Parallel surfaces, slots• Centre to centre distances• Position of bore relative to a face• Eccentricity of a hexagon relative to a bore• Gear tooth profiles• Length of a part

With over 2500 installations, the 747-SeriesID-OD Gauging Station has proven its valuetime and time again. This measuring station isdesigned for maximum versatility and themeasurement of parts where inspectionaccuracies and tolerances are critical. Also,contact pressure is easily adjusted by operator.This gage is excellent for inspecting thin wallparts or less rigid plastic parts.

The 747-Series is surprisingly affordable, andbecause of its capability will save you fromhaving to buy many gauges.

Maximum Measuring Accuracy:

Linear ± 0.000040”

Repeat < 0.000080”

GAUGE R AND R < 10% at high tolerances

22

23

Dyer 101 and 104 Series Calipers

Inch Specifications0.4-1.4” 1.0” 3.15” 0.170” 0.070” 0.040” 0.0005” 101-1001.0-2.0” 1.0” 3.15” 0.230” 0.098” 0.040” 0.0005” 101-1011.6-2.6” 1.0” 3.15” 0.230” 0.098” 0.040” 0.0005” 101-1022.2-3.2” 1.0” 3.15” 0.230” 0.098” 0.040” 0.0005” 101-1032.8-3.8” 1.0” 3.15” 0.230” 0.098” 0.040” 0.0005” 101-1043.2-4.2” 1.0” 3.15” 0.230” 0.098” 0.040” 0.0005” 101-114

Metric Specifications10-30mm 20mm 80mm 4.5mm 1.8mm 1.0mm 0.01mm 101-20020-40mm 20mm 80mm 6.0mm 2.5mm 1.0mm 0.01mm 101-20130-50mm 20mm 80mm 6.0mm 2.5mm 1.0mm 0.01mm 101-20240-60mm 20mm 80mm 6.0mm 2.5mm 1.0mm 0.01mm 101-20350-70mm 20mm 80mm 6.0mm 2.5mm 1.0mm 0.01mm 101-20460-80mm 20mm 80mm 6.0mm 2.5mm 1.0mm 0.01mm 101-20570-90mm 20mm 80mm 6.0mm 2.5mm 1.0mm 0.01mm 101-206

Max. Contact L Dim. A Dim. B Dim. Carbide Ball OrderRange Travel Reach of Max. Depth Min. Width Contacts Graduation Number

Arms of Groove Groove Standard

Inch Specifications0.1-0.3” 0.09-0.31” 1.07” 0.040” 0.022-0.040” 0.004” rad. tip 0.0002” 104-1000.2-0.4” 0.19-0.41” 1.07” 0.094” 0.022-0.040” 0.020” 0.0002” 104-1010.2-0.6” 0.19-0.61” 2.4” 0.094” 0.030-0.050” 0.006” rad. tip 0.0005” 104-1020.4-0.8” 0.39-0.81” 2.4” 0.200” 0.040” 0.040” 0.0005” 104-1030.8-1.2” 0.57-1.21” 2.4” 0.200” 0.040” 0.040” 0.0005” 104-1041.2-1.6” 0.96-1.61” 2.4” 0.200” 0.040” 0.040” 0.0005” 104-1051.6-2.0” 1.35-2.01” 2.4” 0.200” 0.040” 0.040” 0.0005” 104-106

Metric Specifications2.5-7.5mm 2.4-8.0mm 27mm 1.0mm 0.55-1.0mm 0.1 rad tip mm 0.005mm 104-2005.5-10mm 5.8-10.5mm 27mm 2.4mm 0.55-1.0mm 0.6mm 0.005mm 104-201

5-10mm 4.8-15.5mm 61mm 2.4mm 0.76-1.27mm 0.15 rad. tip mm 0.010mm 104-20210-20mm 9.5-20.5mm 61mm 5.4mm 1 1 0.010mm 104-20320-30mm 14.5-30.5mm 61mm 5.4mm 1 1 0.010mm 104-20430-40mm 24.5-40.5mm 61mm 5.4mm 1 1 0.010mm 104-20540-50mm 34.5-50.5mm 61mm 5.4mm 1 1 0.010mm 104-206

Calibrated Total L Dim. A Dim. B Dim. Carbide Ball OrderMeasuring Opening Reach of Max. Depth Min. Width Contact Graduation NumberRange Range Arms Groove Groove Standard

101

104

77MShallow Diameter Gauge. Large range7/16” to 9-5/16” - with 0-1” adjustablegauging depth. 2 models with fullrange of interchangeable contacts.

1900Groove diameter gauge. Checks ID’sand OD’s. ID range 3/16” to 6-7/8”.Complete range of interchangeablemeasuring tips available.

179Groove Diameter Gauge - parallel ballbushing movement. Large ID rangefrom .290” to 7.9” with measuring tipsto 4-1/2” inreach - full 1” retraction.

590Reference Masters. Available for all560 models. Verifies gauge settings.Model 590 shown with 560 gauge.

1750Deep inreach groove diameter gauge.4 models offer 8” to 20” inreach. 5/8”retraction. 1.4” to 6.4” standard IDrange.

711Groove Location Gauge. Fullyadjustable to check groove togroove or C’bore to groove dimensions.2 Models - 6” to 12”

900Small Diameter Groove Gauges. 6models offer 5/32” to 1-1/8” range.Inreach up to 4” with the largest model.Specials available.

560Shallow Diameter Gauges. 5 modelsoffer 4-1/2” to 60” diameter range with0 to 1” adjustable depth range. Largersizes available.

2900Large Shallow Diameter/GrooveGauge. 3/4” retraction with ballbushing movement. 6-1/2” to 60”diameter range with 5 models. 0 to 3”adjustable gauging depth Largerdiameter range available.

1550Shallow Diameter/Groove Gauge.Checks ID’s, OD’s and groovediameters. Ball bushing movement.Full 1” retraction for deep grooves. 1”to 7-3/4” ID range with 1/16” to 3”adjustable depth range. Many contactstyles available.

700Double action Groove Location andDepth Gauge. Will check groovelocation and width in one setting. 0 to12” adjustable depth range. 2 models.

179-200Outside version of model 179. Parallelball bushing movement. Specialmeasuring tips available.

2000Shallow Diameter Gauge. .8” to 8.5”diameter range with 1/32” to 5/16”adjustable depth range. 2 models.Several contact point styles available.

1400Pitch Diameter Gauge for gears andsplines. Carbide ball tips available from.050” to .505” diameter in .0001”increments. This is our #1900 serieswhen used with groove checking tips.

70MSmaller version of the 77 series - whenspace is a consideration. 7/16” to 3-1/4” adjustable diameter range with 0to 1” adjustable gauging depth and fullrange of contact styles.

3125Reference Masters. Available for all2900 models. Verifies gauge settings.Model 3125 shown with 2910 gauge.

24

Mueller Precision Gauges

25

Mueller Shallow Diameter Gauges

SERIES 77LIGHTWEIGHT ADJUSTABLE SHALLOW DIAMETER GAUGES

• Fast and dependable 2 point measurement directly across diameter• Frictionless Reed Transfer Mechanism provides precise repeatability• 0 to 1” adjustable gauging depth• Hardened steel gauge rest surface• Fast acting Rack and Pinion fine adjustment for rapid setting• Positive mechanism instantly changes gauging direction and preloads indicator. • May be set with gauge blocks, master or qualified part• Several contact types available from stock.• Gauging contacts may be rotated as they wear, greatly extending their useful life

SERIES 560LIGHTWEIGHT ADJUSTABLE SHALLOW DIAMETER GAUGES

• Checks diameters by comparing part dimensions to gauging blocks. Actual partdimension shown on dial indicator

• Gauge may be used with any AGD Group 2 style (2-1/4” diameter) Electronicdigital indicator with SPC output.

• Gauge rests on face of part for fast and dependable 2 point measurement directlyacross diameter

• Lightweight - Alloy Steel Airframe tubing gauge body• 4-1/2” to 60” Diameter Range - 6 Models - Larger sizes available• Frictionless Reed Transfer Mechanism provides precise repeatability• Fast acting Rack and Pinion fine adjustment for rapid setting• Positive mechanism instantly changes gauging direction and preloads indicator• Easily set with gauge blocks, master or qualified part• 0 to 1” adjustable gauging depth• Carbide gauging contacts and gauge rest surface• Gauging contacts may be rotated as they wear, greatly extending their useful life• Hardwood storage cases available for all models

For quick and easy checking of shallow insideand outside diameters, centre distances ofholes, pitch diameters of gears and relateddimensions.

70M .0001” .025” 7/16” - 3 1/4” 1/32” - 3” 0” -1” 4 1/2”

71M .0005” .025” 7/16” - 3 1/4” 1/32” - 3” 0” -1” 4 1/2”

75M .0005” .050” 7/16” - 5 1/2” 1/32” - 5 3/16” 0” -1” 7 1/2”

76M .0005” .050” 7/16” - 9 5/16” 1/32” - 9” 0” -1” 11 3/8”

77M .0001” .050” 7/16” - 5 1/2” 1/32” - 5 3/16” 0” -1” 7 1/2”

78M .0001” .050” 7/16” - 9 5/16” 1/32” - 9” 0” -1” 11 3/8”

Model Indicator Indicator Inside Outside Adjustable Length

No. Travel Range Range Gauging Depth

560 4.5” to 12” 18” 2lb.561 12” to 18” 24” 2lb. 2oz.562 18” to 24” 30” 2lb. 4oz.563 24” to 36” 41.5” 3lb.564 36” to 48” 53.5” 4lb.565 48” to 60” 65.5” 4lb 8oz

Specifications for #560 GaugesModel # I.D.-O.D. Range Length Wgt.Approx.

For use at machine or inspection area forchecking inside and outside diameters, shallowbores, counter bores, pitch diameters of gearsand many other dimensions.

26

Mahr Self-Centering Dial Bore Gauges

FEATURES

• Measurement of diameter, roundness and conicity of bores

• Spring-loaded halfs of measuring probe are split via expanding pinwith precision-lapped taper. This movement is transferred toindicating instrument

• Maximum wear-resistance due to hard chromium-plated measuringfaces, 4 mm and above carbide-tipped measuring faces on request

• Constant measuring force as a result of built-in spring thus eliminatinguser influence

• Highly versatile. Each gauge covers a large range. Within the respectivelimits, quickly and easily adjustable to any size and any type ofmeasuring application

• Measuring probe, holder, angle attachments and depth extensions,right-angle attachments and depth stops are part of an extensivemodular system

ACCURACY

Deviation of linearity≤2% measuring ranges 0.47-1.55 mm

≤1% measuring ranges 1.5-18.6 mm

Repeatability1um manual measurement

≤0,5 um measurement with Stand 844 Kst and Floating Holder 844Ksts

INDICATING INSTRUMENTS (see page 28)

Any indicator featuring an 8 mm mounting shank may be used.Recommendations:

Zentimess 1010 0.01mm .0005”

Compramess 1004 5 um .0001”

Millimess 1003 1 um .00005”

Supramess 1002 0.5 um .00002”

Indicating Metric InchInstruments Readings Readings

CHROME OR CARBIDE PROBES

844K Measuring heads hard chromium-plated,expanding pin made of stainless steel

844 KH Measuring heads carbide-tipped on both sides, carbide expanding pin

884 K 0.47 - 0.97 (.018 - .038”) 6 44700000.95 - 1.55 (.037 - .060”) 5 44700011.5 - 4.2 (.060 - .160”) 10 44700023.7 - 7.3 (.145 - .29”) 7 44700036.7 - 10.3 (.26 - .40”) 7 44700049.4 - 18.6 (.37 - .73”) 9 4470005

884 KH 3.7 - 7.3 (.145 - .29”) 7 4471003 carbide

6.7 - 10.3 (.26 - .40”) 7 4471004 carbide

9.4 - 18.6 (.37 - .73”) 9 4471005 carbide

Catalog no. Measuring range No, of measuring Order no.*mm (inch) probes

*Includes holder, measuring probe, expanding pin and wooden case, but not indicating instrument.

844 Series Split Probe

Mahr Indicating Snap Gauges

FEATURES

• For cylindrical parts such as shafts, bolts and spindles, for thickness andlength measurements

• Rugged, forged steel frame with heat insulators

• Measuring spindle mounted in long guideway, lever-controlled retraction

• Anvil spindle easily adjustable

• Measuring spindle and anvil spindle made of hardened stainless steel,carbide-tipped or ceramic (840 FC) measuring faces

• Adjustable centre stop for automatic alignment

• Maximum wear resistance due to non-contact positioning in conjunctionwith carbide-tipped measuring faces

• Constant measuring force as a result of built-in spring, thus eliminatinguser influence

• Highly versatile. Each gauge covers a large range. Within the respectivelimits, quickly and easily adjustable to any size and any type of measuringapplication

• Increased tool life due to ceramic measuring faces (840 FC)

840 F 0 - 25 (0 - 1”) 7.5 2 8 ≤0.2 ≤1 4450000 4450010

25 - 60 (1 -2-3/8”) 7.5 2 9 ≤0.2 ≤2 4450001 4450011

50- 100 (2 - 4”) 7.5 2.5 10 ≤0.2 ≤2 4450002 4450012

100- 150 (4 - 6”) 7.5 2.5 12 ≤0.2 ≤2 4450003 4450013

150- 200 (6 - 8”) 7.5 2.5 12 ≤0.2 ≤2 4450004 4450014

840 FC 0 - 25 (0 - 1”) 7.5 2 8 ≤0.2 ≤1 4450100 4450010

25 - 60 (1 - 2-3/8”) 7.5 2 9 ≤0.2 ≤2 4450101 4450011

Measuring Range Measuring** Travel of Moving 0 Measuring face parallelism Order No.* Order No.mm (inch) force N Spindle mm mm Flatness um um wooden case

*Without indicators - see page 28 for mechanical dial comparators**Other measuring forces on request

27

840F Series Marameter

28

Mahr Mechanical Dial Comparators

Metric1002 Supramess ± 25 um 0,5 um

1003 Millimess ± 50 um 1 um

1004 Compramess ± 0.13 mm 5 um

1010 Zentimess ± 0.25 mm 0.01mm

1050 Dezimes ± 1.5 mm 0.05 mm

Inch1002 Z Supramess ± .0010” .00002”

1003 Z Millimess ± .0020” .00005”

1004 Z Compramess ± .0050” .0001”

1010 Z Zentimess ± .0100” .0005”

Catalog no. Measuring Readingsrange

29

Barcor Chamfer Gages

The BARCOR CHAMFER GAGE is a precision instrument designed specifically to measurethe top (major) diameter of a chamfer, countersink, centre drill, or tapered hole. Merelypress the spring loaded, conically ground, precision 3-blade Gauging Plunger into thechamfer or countersink and instantly read the dial in the .001” or .01mm/.02mm diameterincrements.

The CHAMFER GAGE is a direct reading gauge. No Setting Master (Standard) or look-upchart is required. To “Zero” the gauge or check the setting, press the base of the gaugeagainst any flat ground surface and adjust the dial to read the “Set To” number stamped onthe back.

The CHAMFER GAGE is available in two angular ranges: 0°-90° for angles of 90° or less,and 90°-127° for angles greater than 90° but less than 127°. Models for angles largerthan 127° upon request. The standard BARCOR CHAMFER GAGE is furnished with ahardened Tool Steel Gauging Plunger. Optional Solid Carbide Gauging Plungers with aLIFETIME wear guarantee are also offered. Other options include .0001” reading SuperCHAMFER GAGE, External Models, Micrometer Models, HALF-SIZE© Models, Electronic Modelswith SPC capabilities, NIST (formerly NBS) traceable Setting Masters and Letters ofCertification.

• Chamfer/Countersinks • Valve Seats

• Hydraulic Fittings • Rivet Seats

• Screw Machine Parts • Tube Flares

• Aircraft Components • Piston Rings

• Production Machining • Shaft Centers

• Automotive Assembly • Instruments

• Quality Control/Gauge Room • Stampings

• Model Shop and Prototype • Castings

• Receiving Inspection • Bushings

Modifications or Specials upon request

Barcor also manufactures Countersink Gages, Hole Gages, Bevel Gages, Center Gages and RivetGages. Details can be provided upon request.

IDEAL APPLICATOINS

Instantly Measure Top Diameter of Tapered Holes

30

Opus MetrologyTungsten Carbide Gauge Blocks

ADVANTAGES OF OPUS TUNGSTEN CARBIDE GAUGE BLOCKS• Dense homogenous material allows high quality finishing of gauge surfaces

• Micro-lapped finish of less than 0.01um Ra gives maximum bearing area andimproves gauge life

• High quality surface finish and flatness gives the best wringing characteristics - farbetter than steel

• Hardness of about 1350 VPN gives long life

• Low coefficient of thermal expansion (4.23 x 10-6 per °C)

• Good thermal conductivity means gauges normalize to ambient conditions quickly

• Wear life of 5-10 times that of steel gauge blocks

• Every gauge individually serialized and traceable

• Manufactured to meet the accuracy requirements of all major National &International Standards

• Available in Federal Gr.1 (Laboratory) Gr.2 (Inspection) Gr. 3 (Toolroom)

Inch Sets: 81pc, 49pc, 41pc, 35pc, 28pc, 27pc, 9pc, and Mic-Check sets 8pc, 10pc, 11pc, 13pc

Metric Sets: M122, M112, M105, M103, M88, M87, M76, M47,M46, M41, M32, M25, M9, M88/2, M46/2, M33/2, and Mic-Check sets M8, M10, M11, M13

Opus also manufactures most sets in Ceramic and Steel and can supplyindividual blocks in standard and non-standard sizes.

31

Helios

This measuring system offers extremely high accuracy and is therefore capable of coveringtwo fields of application. The measuring system is a 2” built-in glass scale mounted on themeasuring axis.

INTERNAL AND EXTERNAL MEASUREMENTS ON WORKPIECES UP TO 4”.

The system covers an external measuring range of 4” and thus replaces 4 externalmicrometers, facilitates handling and offers a considerably higher accuracy. This is alsotrue for internal measurements where the UMG 50 replaces several sets of bore gaugesand internal micrometers. By shifting the internal measuring probes the measuring rangefor internal measurements can be displaced at any time. Then e.g. only 2” are calibratedon a setting ring, so a measuring range from e.g. 0.6” to 2.5” is available.

Switching from external to internal measurement is possible at any time without the needto recalibrate the system.

INSPECTION OF MASTERS AND THREAD GAUGES

Measurement of plug gauges from 0 to 4” and ring gauges or setting rings from 0.6” to 4”is possible (on request also from 0.25”). External threads up to 4” can be measured bymeans of the three wire method and 40 oz. measuring force.

UNITRON 2 CHA DIGITAL DISPLAY

2 column display, 10 digit; 13mm heightIncrements: .0001 / .001 / .005mmor .000005” / .000010” / .00005”16 digit dialogue display with password protection

HELIOS-UMG 50 AND UNITRON 2 CHA.

Universal single axis length measuring instrument with 2channel measuring valve display

2-channel measuring valvedisplay UNITRON 2 CHA (standavailable as option)

HELIOS-UMG 50

THE MOST IMPORTANT FEATURES

• Dampened measuring probe with 2preselectable measuring forces

• Constant measuring force over the wholemeasuring range

• Integrated measuring system according to theAbbe principle

• Infinitely adjustable support table for exactpositioning in case of internal measurements

• Combined external and internal measurementwithout the need to recalibrate

• Easily exchangeable measuring inserts whichcan be perfectly adapted to the individual task

• Sturdy cast body to prevent any stresses anderrors due to distortion

• Display unit UNITRON with interface RS 232for easy transmission of measuring values toa PC

• With the transmission software Optoface(available as option) transmission ofmeasuring values to all Windows programs(e.g. Microsoft Excel) is possible

32

Granite Surface PlatesAvailable in crystal pink granite (Starrett) or imported black granite

Internal and external thread measuring instruments

CORDITESTINTERNAL THREAD GAUGE

Segment-shaped gauge anvils, Type 5090, for full form or pitchdiameter can be set by a plain ring, are used for the threadmeasurement. Master thread setting rings are not required.

• Quick insertion, no screwing in

• Setting without a thread setting ring

• Segmentally-divided thread measuring anvils having a dirtscraper edge

• Adjustable measuring force

• Movement of slide free from play

• Available with Stand, Type 5753

• High Quality

• Ease of Use

• Robust Construction Suitable for the Workshop

• Ensuring Great Measuring Certainty

Type 5090anvils

Kordt

12x12 .0001” .0002”

12x18 .0001 .0002

18x18 .0001 .0002

18x24 .00013 .00026

24x24 .00014 .00028

24x36 .00017 .00034

36x36 .0002 .0004

36x48 .0003 .0005

36x60 .0004 .0007

48x48 .0004 .0008

48x72 .0006 .0012

Sizes Overall Accuracy Overall AccuracyGrade A Grade B Custom heavy duty stands with 3 point suspension and leveling screws

Delivery included in K-W, Cambridge, Guelph and Area

Customer must specify working weight

18x24”

24x24

24x36

36x36

36x48

36x60

48x48

48x72

Type 5075Size A3-20mm

Type 5200Type 5620

Gaugemakers Tolerance Chart

HOW TO ORDER CYLINDRICAL PLUG AND RING GAUGES

1. Quantity and Whether Go or No Go Member

2. Exact Diameter of Member

3. Z, Y, X, XX Tolerance

4. Type Material Required - Steel - Hard Chrome - Carbide

5. Type of Gauge: Reversible - Taperlock - Trilock - Progressive

6. Whether Handles are required if Plug

7. Marking Instructions

DIRECTION OF TOLERANCE:

The following will apply to all gauges unless otherwise specified:

GO Cylindrical Plug gauges - Plus tolerance (+)

NO GO Cylindrical Plug gauges - Minus tolerance (-)

Master Cylindrical Plug gauges - Bilateral tolerance (±)

GO Cylindrical Ring gauges - Minus tolerance (-)

NO GO Cylindrical Ring gauges - Plus tolerance (+)

Master Cylindrical Ring gauges - Bilateral tolerance (±)

A rule of thumb regarding tolerances on gauges is to use 10% of the totalmanufacturing tolerance of piece part for gauges, with 1/2 of the 10% tobe applied against the GO and 1/2 of 10% to be applied on NO GO.

Example #1 Part Size =.250 + .002/_.000

GO = .250 NO GO = .252

Total Manufacturing Tolerance = .002

10% of .002 = .0002

1/2 of .0002 = .0001

Class Z Recommended

Example #2 Part Size =.250 + .0005/ - .0000

GO = .250 NO GO = .2505

Total Manufacturing Tolerance = .0005

10% of .0005 = .00005

1/2 of .00005 = .000025

Class XX Recommended

.029- .825 .00002 .00004 .00007 .00010

.740 mm 20.96 mm .00051 mm .00102 mm .00178mm .00254 mm

.825- 1.510 .00003 .00006 .00009 .0001220.96 mm 38.35 mm .00076 mm .00152 mm .00229 mm .00305 mm1.510- 2.510 .00004 .0008 .00012 .0001638.35 mm 63.75 mm .00102 mm .00203 mm .00305 mm .00406 mm2.510- 4.510 .00005 .00010 .00015 .0002063.75 mm 114.55 mm .00127 mm .00245 mm .00381 mm .00508 mm4.510- 6.510 .000065 .00013 .00019 .00025114.55 mm 165.35 mm .00165 .00330 mm .00483 mm .00635 mm6.510- 9.010 .00008 .00016 .00024 .00032165.35 mm 228.85 mm .00203 mm .00406 mm .00610 mm .00813 mm9.010- 12.010 .00010 .00020 .00030 .00040228.85 mm 305.05 mm .00254 mm .00508 mm .00762 mm .01016 mm

Above To and Including XX X Y ZNominal Size Tolerances

33

2288 Dumfries Rd. RR#2Cambridge, ON, N1R 5S3Tel: 519-620-2044Fax: 519-620-1723Toll Free Fax: 1-800-210-6846Email: [email protected]: www.fishermet.com

Authorized Dealer: