Case Study_Nestle Ice Cream Excellence in Quality Control

-

Upload

qiqi-rizqi-awlya -

Category

Documents

-

view

119 -

download

6

Transcript of Case Study_Nestle Ice Cream Excellence in Quality Control

3Industrial Weighing and Measuring

Dairy & Cheese News

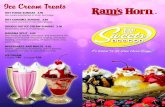

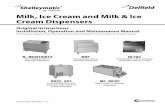

Excellence in Quality Controlin Nestlé’s Ice Cream Production

Comprehensive and efficient quality control is a must for the world leader

in the food industry. For almost 30 years, Nestlé in Guadalajara (Spain)

has been supported by METTLER TOLEDO weighing and Statistical Quality

Control (SQC) solutions.

TheNestléicecreamproductionplantinGuadalajaraproducesaround20millionliters per year. Products are distributedacrossEuropeaswellastooverseacoun-trieslikeChileandAustralia.Compliancewith Nestlé’s strict quality requirementsand net weight legislation demands anefficient quality control system. WithMETTLERTOLEDOFreeWeigh.Net®soft-wareMr.GerardoBermejoBarrera,Headof Quality Assurance, has an excellentnetworkedsysteminplacetomonitorandcontrolqualityparametersdirectlyattheproductionlines.

Networked Statistical Quality ControlAt six different test places, line opera-tors control quality parameters such ascolor, taste,weight or expiry date of the

semi-finished and finished ice creamproducts. Five test places, equippedwithaPC includingFreeWeigh.Net®softwareand BBA compact scales, are installedin the production area, number six islocatedinthecentrallaboratory.Thenet-worked topology – with FreeWeigh.Net®

software running at every test site anda centralized Microsoft SQL database–enablesoperators toexecute the samequality tests at every station. StatisticalQuality Control (SQC) provides qualityinformation based on random sampledata. FreeWeigh.Net® offers – amongothers–thefollowingcoredata:•Production(period)meanvalue•Number of violations of the legally

definedtolerancelimits•Mean standard deviation of the pro-

duction(period)

METTLER TOLEDO Dairy & Cheese News 32

PublisherMettler-Toledo AGIndustrialHeuwinkelstrasseCH-8606 NänikonSwitzerland

ProductionMarCom IndustrialCH-8606 NänikonSwitzerland

MTSI 44099116

Subject to technical changes© 06/2007 Mettler-Toledo AGPrinted in Switzerland

Mr. Gerardo Bermejo Barrera continues:“FreeWeigh.Net® lets us know imme-diately if overfill occurs. It helps us tosubstantiallyreduceunnecessaryoverfill-ingaswellascomplyingwithnetweightregulation. Due to FreeWeigh.Net® onlya click of a mouse is needed to retrievecurrent and historical production datawhichletsusregularlyaccountforover-fillingcosts.”

Quality parameters of semi-finished productsWith FreeWeigh.Net® Nestlé controlsand monitors three important productparameters at once: ice cream weight,chocolate weight and volume (density).Chocolate is the most expensive part of

the ice cream. With this method Nestlécan precisely account for the raw mate-rialandoptimizeproduction.Volumeordensitydetermination isnotonlyneces-sary tocontrolqualitybutalso to fulfilllegalregulations,whileatthesametimeminimizinggiveaway.

FreeWeigh.Net® test place with PC,BBA4-series compact scale for net content control, visual inspections and other attributive tests

Stat

istic

al Q

ualit

y Co

ntro

l

1.Determinationoficecreamweight(theweightofthecookieisknownandconsideredstable)

These parameters are required to ful-fill legal requirements e.g. in regard totheEuropeannetweight legislationand -marking.

METTLER TOLEDO Dairy & Cheese News 3 3

3. Volume (density) determination inwater:Themeasuredweightduringsub-mersionoftheicecreaminwaterisequiv-alenttothevolumeoftheicecream.

2. Determination of chocolate coatingweight: Gross weight of the finished icecream minus ice cream weight (deter-minedinstep1)

METTLER TOLEDO Dairy & Cheese News 34

Mr. Gerardo Bermejo Barrera concludes:“Duringourlong-lastingrelationshipwithMETTLERTOLEDO,wehavealwaysimple-mentedinnovativesolutionsfromacom-petent system specialist. FreeWeigh.Net®

Customizable test reports

Typical FreeWeigh.Net® monitoring screen showing ice cream weight, chocolate weight and volume (density)

gives us the flexibility we need in termsof quality control and documentation.The system with its intuitive setup iseasy-to-use after a short training periodandallowsustogeneratecustomizedtest

reports. Time-consuming manual datacollection is completely obsolete help-ing us to improve productivity, complywith regulations and avoid unnecessaryoverfilling.”

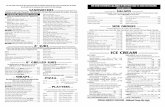

Quality parameters of finished productsEvery15–20minutes thenetcontentofasampleoffourfinishedicecreamprod-ucts is monitored. But FreeWeigh.Net®

allows Statistical Quality Control farbeyondweighing.Qualityattributessuchas correct product labels or barcodes,product expiry data and packagingare entered in preconfigured masks ofFreeWeigh.Net®, allowing subsequentgraphical representation with easy tounderstandbar-orparetocharts.

Product quality attributes are tested onanhourlybasis. Inaddition to thenet-,ice cream weight, chocolate-weight andvolume, Nestlé monitors the completeproductandpackagequalityparameters. Attributive tests: correct net weight, barcode, expiry date, box aspect and label control of finished products

Product quality parameters

• Ice cream weight• Chocolate coating weight• Volume (Density)• Taste • Color

Package quality parameters

• Net weight• Barcode • Expiry date • Label• Box aspect • Plastic wrap

Stat

istic

al Q

ualit

y Co

ntro

l

FreeWeigh.Net® Statistical Quality Control at Nestlé

METTLER TOLEDO Dairy & Cheese News 3 �

Parmalat Expandswith Safeline® Metal Detectors

Parmalat has chosen to work with leading metal detector producer, METTLER TOLEDO Safeline® to ensure it

achieves the highest possible levels of sensitivity to metal.

Parmalat Dairies UK Ltd has undergonea substantial expansion programme,requiring an upgrade of its produc-tion lines. The company manufacturesyoghurt,cottagecheeseanddairydessertproducts under its own label brands,Lakeland and Loseley, and also for themajor UK retailers. A top priority forParmalatisproductqualitycontrol.

Product effectsMETTLER TOLEDO Product InspectionSales & Service Manager, Mike Bradley,comments,“Wetdairyproductsareespe-cially challenging for metal detectionsystemsbecausetheyhavetheirownlevelof electrical conductivity. This contribu-tion by the product to the overall task

facedbythedetectorisknownas‚producteffect‘ and all metal detectors have todeal with it effectively to detect metalcontamination.“

Safeline’shighfrequencysignaturedetec-tion system is especially suited for suchdemandingproductsbecauseofitsabilityto screen out product effect and handledifferentproducttypesandsizeswiththeminimumofproductsettings.

Foil and film lidsParmalathasinstalledeightSafelinedetec-tion systems which are a combination ofstand-aloneSignaturemachinesanddouble-headsystemswhichcombinetheSignaturewithaferrous-in-foildetectorhead.

The double-headsystems offer completeflexibilityforParmalatwhichcanswitchfrom one detector head to the otherdepending on whether the pots beingmonitoredhavefilmorfoillids.

Parmalat Group Operations Director,ClarenceMcAteereexplains,“Thedoublehead systems are important because itmeans we can handle different prod-uct packaging on the same line. WedecidedtoworkwithSafelinebecauseoftheir quality reputation, the standard oftheir technology and because they werecompetitive.“

METTLER TOLEDO Dairy & Cheese News 36

High Accuracy Tank ScalePerfectly Rejecting Vibration

Thailand’s Minor Dairy Limited has recently put into operation a brand new

METTLER TOLEDO tank scale assuring reliability and high throughput.

Minor Dairy Limited is a subsidiary ofThe Minor Food Group a leader in theworld of food manufacturing, where inThailand it holds a market leader posi-tion for premium ice cream business,knownasSWENSEN’S.

Due to the well-known good taste andgreatqualityofSWENSEN’Spremiumicecream, rawmaterial control isacriticalpoint inorder toassure consistencyandhigh throughput of production. MinorDairyLimitedproposed to install a tankscale system to accurately measure rawmaterialused in eachbatch.Theobjec-tives were to achieve a higher level ofaccuracy than the old system, eliminat-ing vibration caused from productionprocess agitator, and the need to com-

ply with international food regulationssuch as GMP and HACCP. Minor DairyLimited’s most important concern wasaftersalesservice.

The solution for a sensitive production processAfter demonstrating the benefits ofMETTLER TOLEDO tank scale compo-nents and services, Minor Dairy LimitedtookthefinaldecisiontoimplementtwosetsofIP68protectedFlexMount®weighmoduleswithan IND560processweigh-ing terminal and a Scoreboard (largedisplay module). Additionally, flexiblehoseswereinstalledintotheexistingpipesystem ensuring maximum tank scaleaccuracy – one of SWENSEN’S mainrequirements.

With its IP69k stainless steel housing,the IND560 weighing terminal is theperfect match for a tank scale processweighing application in the food indus-try. The extremely high A/D conversionrate of 366 readings per second is com-bined with proven TraxDSP™ filteringtomakesurethatthetankscaleconsist-ently provides fast and precise weigh-ing results even in difficult vibratingenvironments.Mr.SongwutReongkosum,FactoryEngineeringManager,concludes:“TheMETTLERTOLEDOsystemspecial-istsmadeabig effort tounderstandourrequirements and met them all to ourcomplete satisfaction. With the servicecontractwenowhavethesafetywerequiretorunourproductionsmoothly.”

METTLER TOLEDO Dairy & Cheese News 36

Tank

Sca

le

IND�60 process terminal

Scoreboardlarge display module

FlexMount® weigh module

Junction box

Dustproof and suitable for cleaning with high-pressure equipment

METTLER TOLEDO Dairy & Cheese News 3 7

TraxDSP™ is a patented filter design that practically eliminates environmental noise and vibration toprovide stable weights.

Fast facts: IND560 Process weighing terminal

• Display: Active VFD dot matrix, SmartTrac™ over/under display

• Alibi memory• Extremely high A/D conversion rate of 366

readings per second• TraxDSP™ supreme noise and vibration filtering• Panel-mount and harsh environment versions, IP69k• Digital I/0: 12 in/18 out• Interfaces: RS232, RS48�/422, Profibus® DP,

DeviceNet™, Allen-Bradley™ RIO, Ethernet, Digital I/O, 4-20mA and 0-10V analog output

Key Benefits for Minor Dairy Limited

• High accuracy tank scale• Accurate results even in difficult environments with vibration• Standard regulation compliance as GMP• Safety through service contract

Fast facts: FlexMount® weigh module

Hermetically sealed stainless steel IP68 load cell – the right choice for hygienic sensitive areas

• Capacity range 110kg – 20.4t• 3000e OIML, �000d NTEP• Top plate rigidly located for easy installation• Uplift protection• Large range of thermal expansion/contraction possible• Stainless steel mounting hardware• Global approvals standard on every load cell

Protected against submersion

www.mt.com/dairy-cheeseFor more information

Mettler-Toledo AGCH-8606 GreifenseeSwitzerlandTel. + 41 44 944 22 11Fax + 41 44 944 30 60

Your METTLER TOLEDO contact:

Prod

uct I

nspe

ctio

n

CheckweighingMetal DetectionX-ray InspectionService XXL

GARVENSCheckweighing

SAFELINEMetal Detection & X-ray Inspection

The food industryWe can provide solutions for all packaging and processing aspects of the food industry. Applications include the weighing and inspection of wet, dry, fresh and frozen food stuffs in all food sectors. We can also help your business to comply with legal requirements, industry guidelines and codes of practice including IFS and BRC standards.

The pharmaceutical IndustryOur solutions for the pharmaceutical industry include weighing and inspection technology for tablets, capsules, powders and insert documentation. We can also provide assistance in meeting the demands of GMP and our equipment is compatible with CFR 21 part 11 requirements.

Non-food and non-pharma industriesOur solutions can also be applied to a wide range of other applications including inspection in paper converting, textiles and component manufacture. We can also provide systems to determine piece count by weight, for example, nuts and bolts for D.I.Y markets and the weighing and rejection of out-of-tolerance coin blanks prior to embossing.

Prod

uct I

nspe

ctio

n So

lutio

ns Total Product Inspection Solutionsfor processing and packaging

Visit for more informationwww.mt.com/pi

Breadth of experience, depth of capabilityfor complete product inspection solutions

Fully Integrated Solutionstailored to suit your needs

Sys

tem

Inte

grat

ion

CheckweighingA part of the METTLER TOLEDO group since 1986, GARVENS is one of the world’s leading manufacturers of dynamic weighing systems. Our systems can ensure 100% quality control and give you total peace of mind.

Whatever your inspection needs, we can provide either stand-alone or fully integrated bespoke systems to address the challenge.

Market leading global brands

The Garvens and Safeline brands combine to give the most comprehensive product inspection range of equipment with solutions for checkweighing, metal contaminant detection and X-ray inspection.

Metal DetectionSafeline has long been the undisputed global market leader in metal detection technology. Since joining the METTLER TOLEDO group in 1996, Safeline have continued to dominate this important inspection market sector.

X-ray InspectionSince joining the METTLER TOLEDO group in 2002, Safeline X-ray Inspection has rapidly grown its range of innovative solutions using cutting edge X-ray technology. These systems provide the means to detect the broadest ranges of contaminants possible.

Focused on the key aspects of industrial product inspection, the METTLER TOLEDO PI division is the market leader in its field. We are a highly resourced business committed to innovation and new developments, dedicated to serving the needs of our customers by addressing their challenges of today and in the future. As part of a global business we are able to draw on a wealth of industry experience developed by working in true partnership with our customers worldwide.

Solutions for all markets

Experience gained over many years in the broadest range of industries and applications mean that we have an extensive array of solutions and technologies at our disposal. Our product range includes dynamic checkweighers, sophisticated metal contaminant detectors and cutting-edge X-ray based inspection technology.Whatever your processes or industrial sector, we have solutions to benefit your business and maintain your competitive edge.

The cosmetic and chemical industriesWe can provide solutions for the inspection, weighing and sorting of products from bulk liquid, powder and granular chemicals through to small consumer packs such as healthcare products, toothpastes, lotions and detergents.

GARVENS SAFELINE SAFELINECheckweighing Metal Detection X-ray Inspection

The full range of METTLER TOLEDO PI products can be further integrated using state of the art communications software packages facilitating greater control and traceability in all of your processes. Equipment is compatible with METTLER TOLEDO’s innovative FreeWeigh.net package, Safeline Explorer and the GARVENS ReAcT systems. In addition, all equipment can be linked to a wide range of other market leading data acquisition or factory management/SCADA systems such as InTouch, RSView, Intellution and Matrikon.

Unrivalled connectivity options...

Mettler-Toledo Garvens GmbH Kampstraße 7D-31180 GiesenGermanyTel: +49 (0)5121 9330Fax:+49 (0)5121 933 456 Email: [email protected]

Mettler-Toledo Safeline Ltd Montford StreetSalford, M50 2XDUKTel: +44 (0)161 848 8636Fax:+44 (0)161 848 8595 Email: [email protected]

Mettler-Toledo Safeline X-ray Ltd Greenfield, Royston Business Park Royston, Herts SG8 5HNUKTel: +44 (0)1763 25 7900Fax:+44 (0)1763 25 7909 Email: [email protected]

Subject to technical changes © Mettler-Toledo PI Printed in UKMTPI-UKPO-PICBE-0506-1M

1.PUA579Drive-throughfloorscale2.BBA449over/undercheckscalewithcoloredbacklight3.GarvensS3SHARKCombiweigher4.In-lineturbidity,pHandconductivitysensors

A Wide Range of Solutionsto Improve Processes

1.StatisticalQualityControl/StatisticalProcessControl2.Processweighing3.IndustrialCatalog4.ProductInspectionsolutions

Share our KnowledgeLearn from our specialists – our knowledge and experience are at your

disposal in print or online.

Learnmoreaboutallofoursolutionsforthedairyandcheeseindustryonourweb-site.Youcanfindinformationonawiderangeoftopicstoimproveyourprocesses,

including case studies, application sto-ries, return-on investment calculators,plusalltheproductinformationyouneedtomakeaninformeddecision.

1 2 3 4

1

colorWeight®2

EHEDG

3

4